Method and apparatus for detecting heat conducting pipe performance

A detection method and detection equipment technology, applied in the field of heat dissipation, can solve problems such as the inability to actually input heat into the heat pipe and detect the temperature difference at both ends, and achieve the effect of short test time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

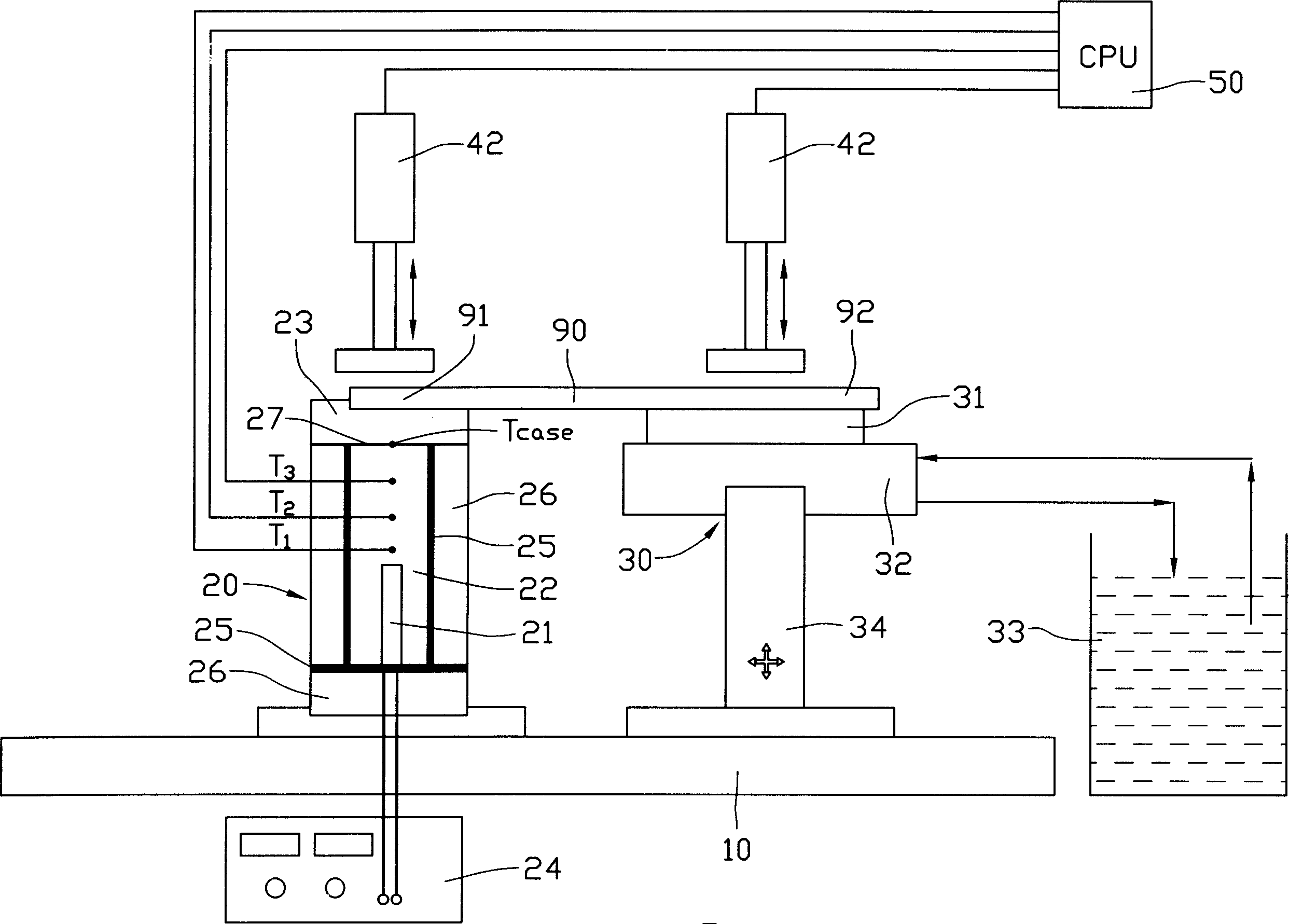

[0012] figure 2 Shown is a schematic diagram of the test principle of the performance test of the heat pipe according to the present invention, which mainly includes a bracket 10 and a test main part arranged on the bracket 10 . The main part of the test includes a heating device 20 and a cooling device 30 for simulating heating and cooling of the heat pipe 90, respectively, and a temperature measuring device (see below) for measuring temperature.

[0013] The heating device 20 includes an electric heating rod 21 , a heat conducting copper block 22 and a heating copper block 23 . The heat-conducting copper block 22 is a vertical column structure. The electric heating rod 21 is used as a heating source to heat the heat pipe 90. It is vertically placed in the same direction as the heat conduction copper block 22 and embedded in the middle of the lower half of the heat conduction copper block 22, and can be connected from a DC power supply. The heat is obtained at 24 and trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com