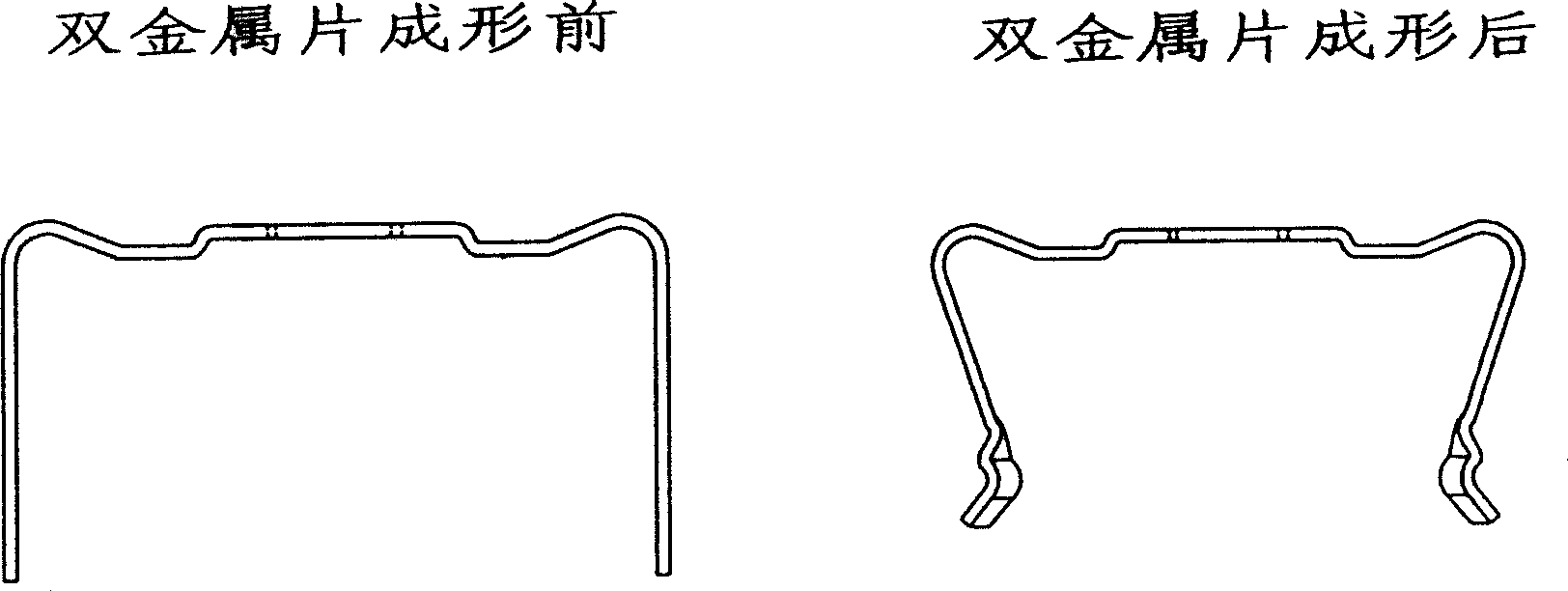

Full-automatic bimetal element forming machine

A bimetal sheet and forming machine technology, applied in metal processing equipment, forming tools, safety equipment, etc., can solve the problems of increased product cost, backward manufacturing method, low work efficiency, etc., and achieve the reduction of enterprise product cost, reasonable structure design, The effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

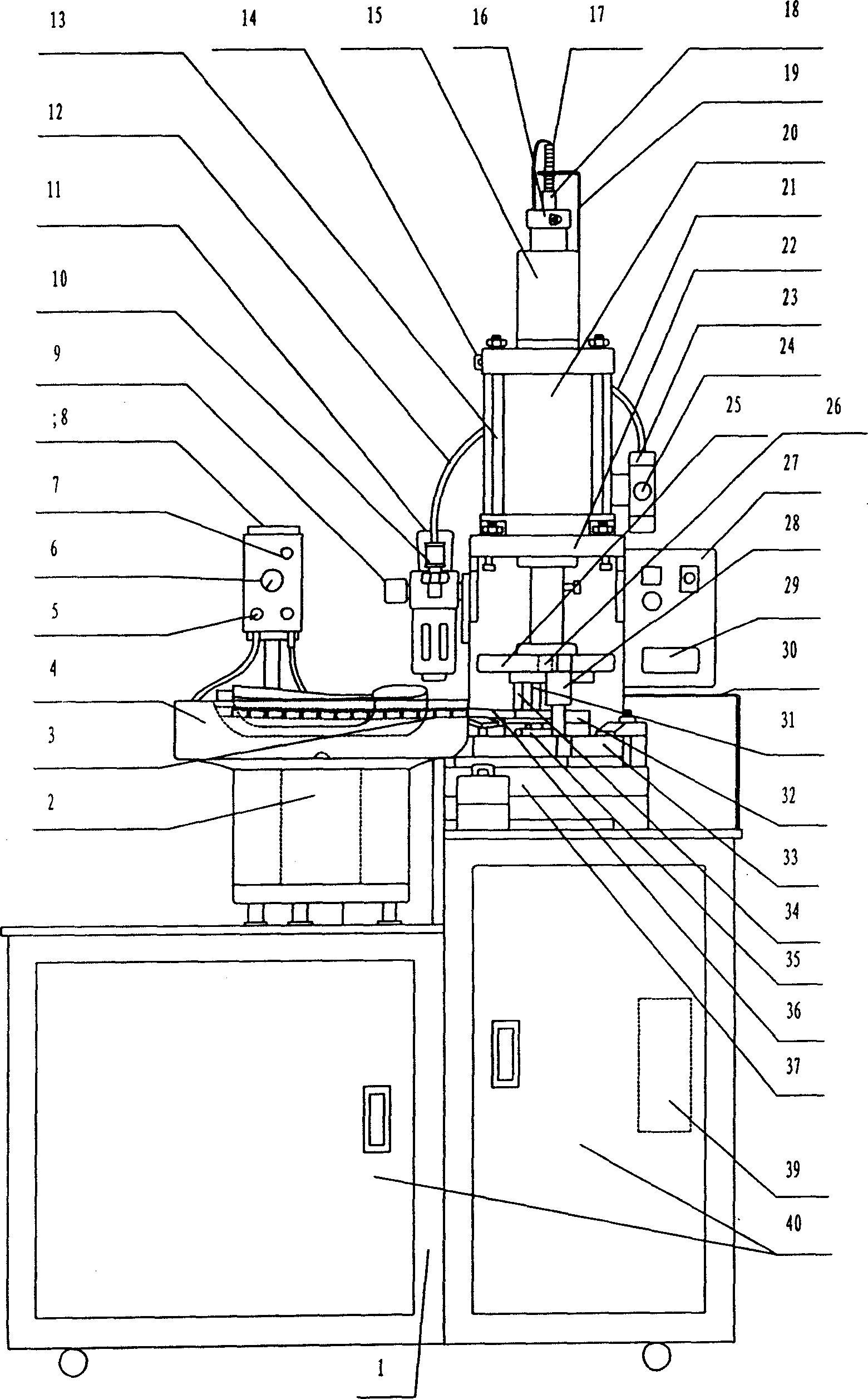

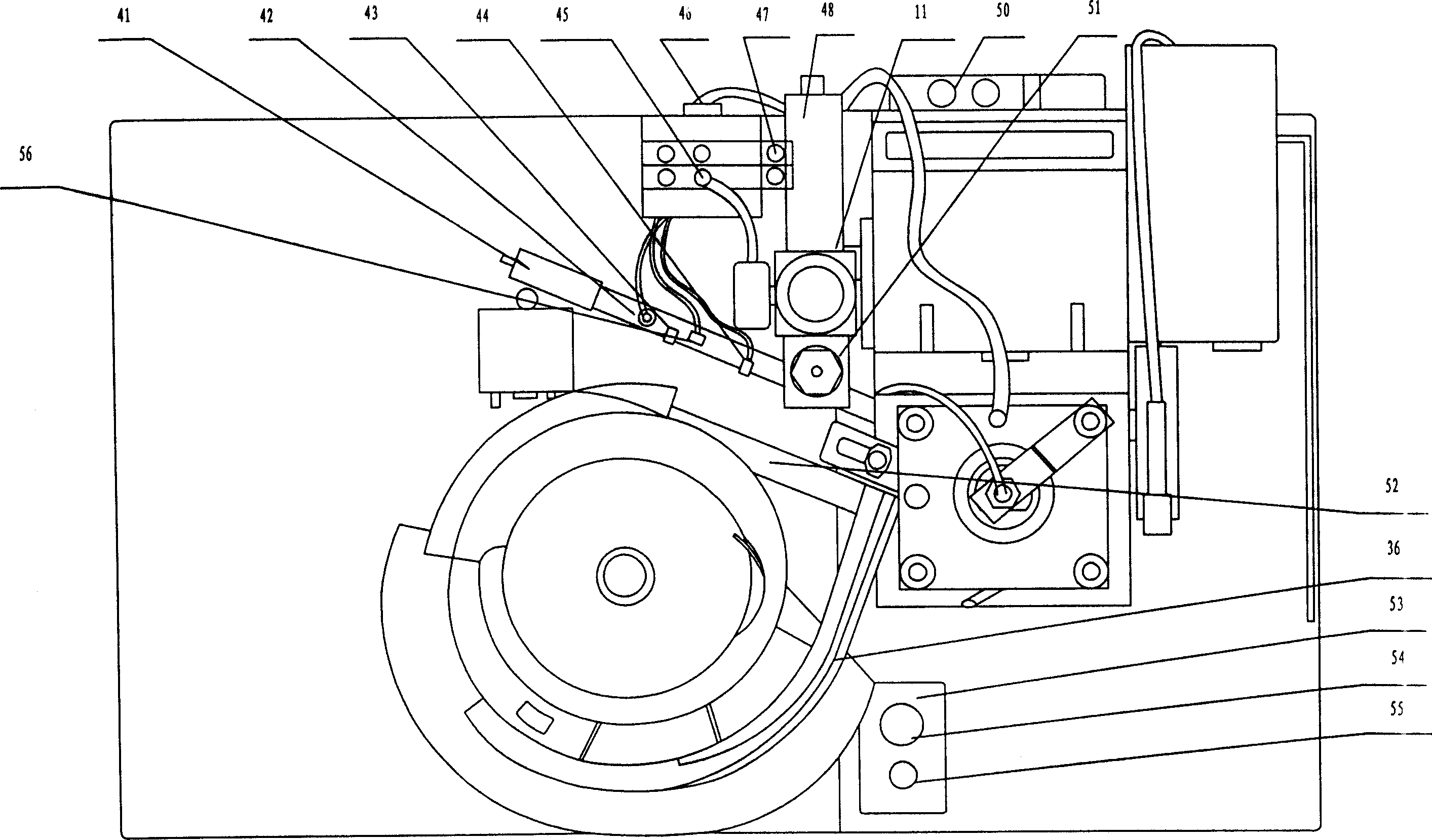

[0016] see figure 1 , figure 2 and Figure 4 , the bimetal sheet automatic forming machine of the embodiment of the present invention is provided with controller, sorting and feeding mechanism, stamping and forming mechanism, air blowing device and workbench support 1, controller and sorting and feeding mechanism, stamping and forming mechanism, blowing device Connected separately, the controller, the sorting and feeding mechanism, the stamping and forming mechanism, and the air blowing device are all installed on the workbench support 1 .

[0017] The sorting and feeding mechanism is equipped with a vibrating plate 4, a vibrating table 2, a feeding guide rail 36, a feeding cylinder 41, a feeding cylinder regulating valve 42, a valve seat 46, a vibration switch control box 8, a guide rail support frame 52, a vibrating table 2, and a vibration switch control Box 8, feeding cylinder 41, valve seat 46, and guide rail support frame 52 are installed on the workbench bracket 1, a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap