Combined dynamic load sensing torque amplifying and converting device

A technology of dynamic load and conversion device, which can be used in fluid pressure actuation devices, servo motor components, mechanical equipment, etc., and can solve problems such as energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

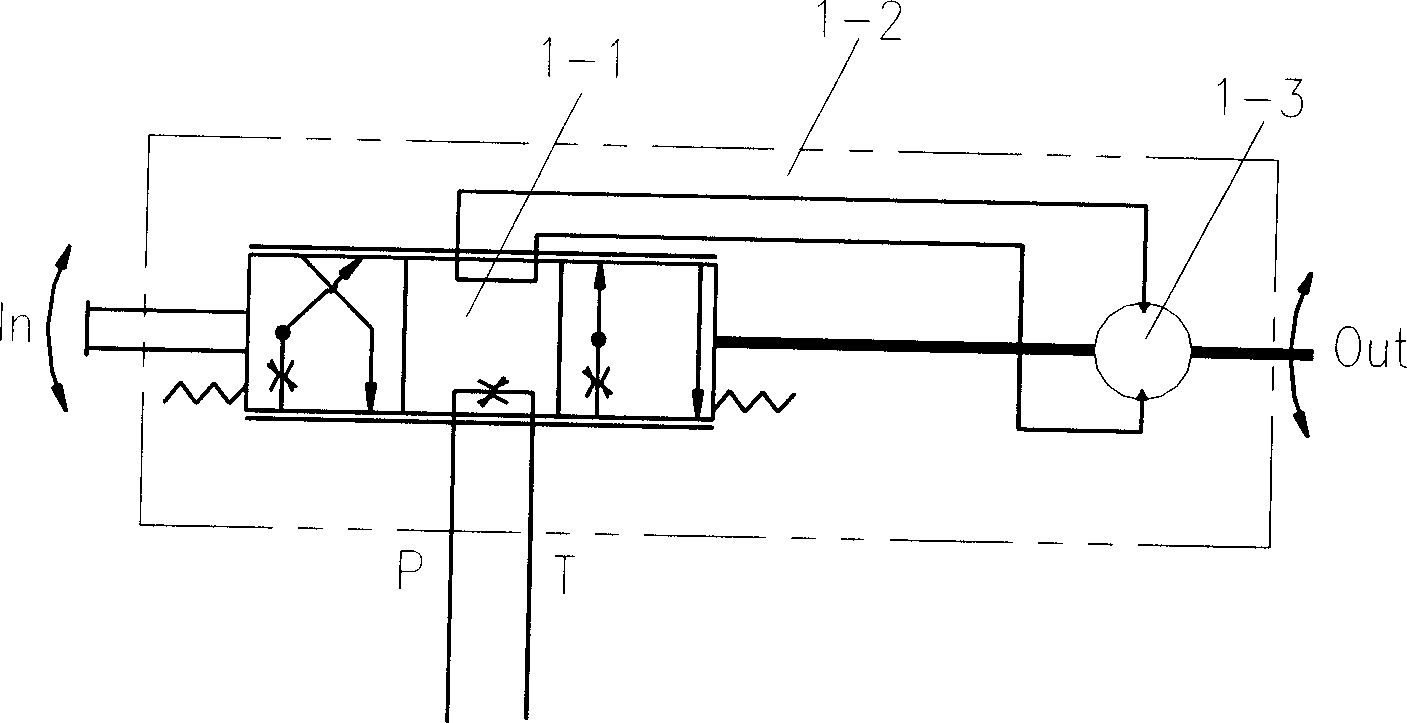

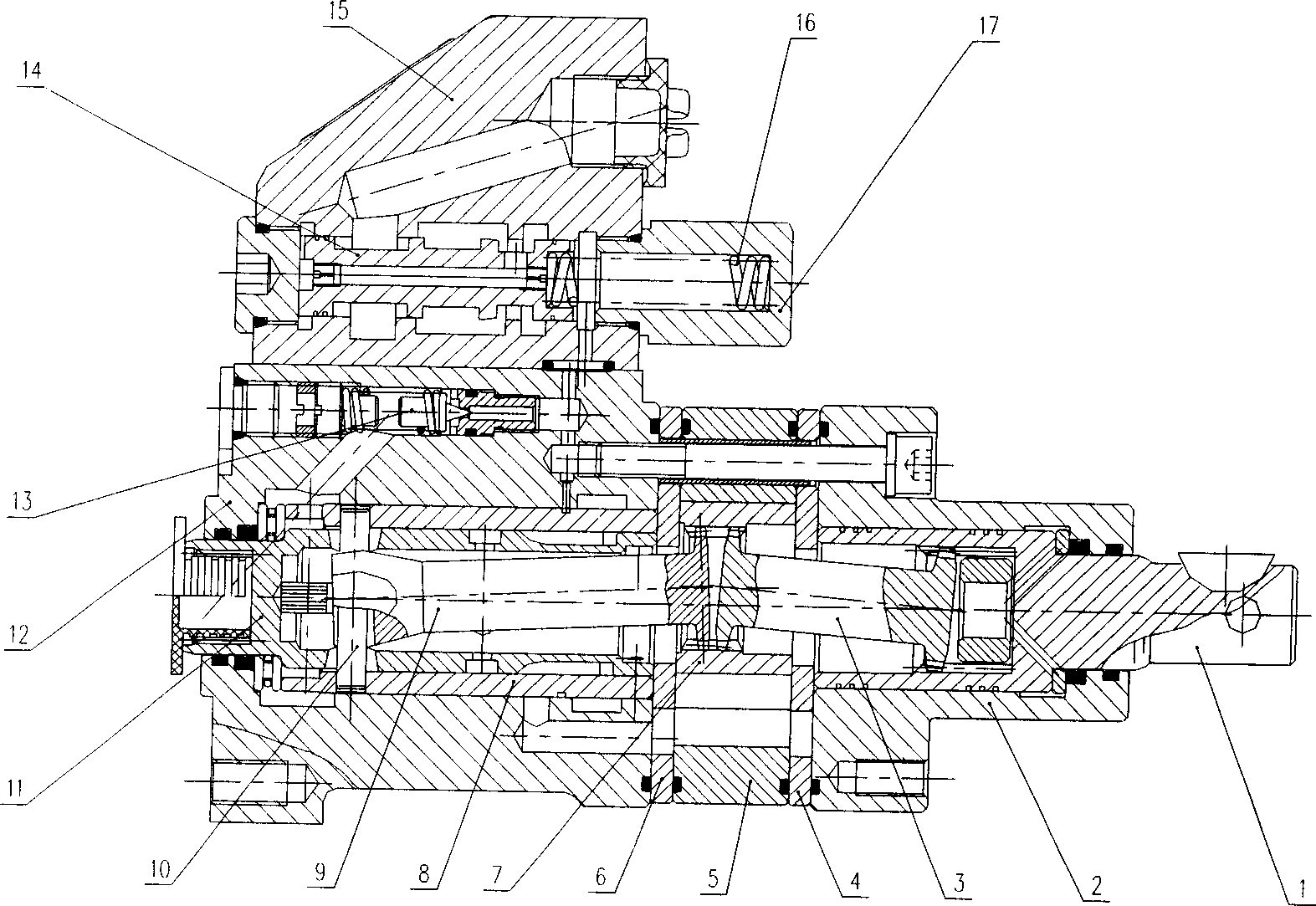

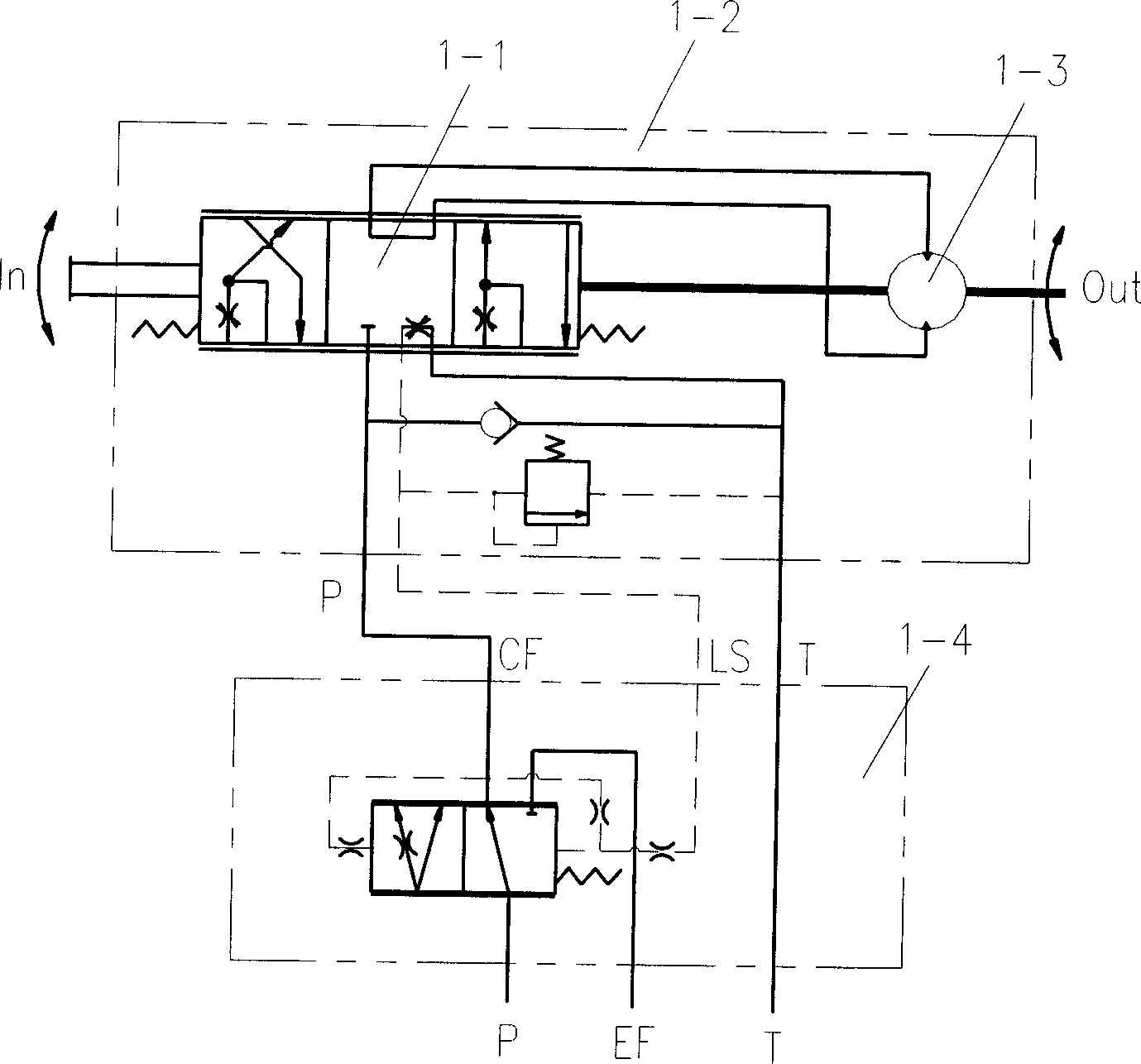

Embodiment 1

[0014] The combined dynamic load sensing torque amplification conversion device of this embodiment is as follows: figure 2 As shown, it is composed of two parts: torque amplifier (abbreviated as amplifier) and dynamic priority valve. The torque amplifier wherein consists of a fixedly connected valve body 12, a first partition 6, a stator 5, a second partition 4, and an end cover 2 to form a housing member that forms a chamber inside, and the stator 5 is located between the first partition 6 and the second partition. Between the spacers 4, this is more conducive to the formation of an airtight cavity. The shell member is formed with the liquid inlet and the liquid return port and the flow channels communicated therewith. The valve core 4, linkage shaft 9, valve sleeve 8, rotor 7, transmission shaft 3 and output shaft 1 are housed in the chamber. One end of the valve body 12 supports the spool 14 extending to the outside. The inner end of the spool 14 is connected with one e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com