Automatic lifting platform with split base and its using method

A technology of self-elevating platform and bottoming, which is applied in water conservancy projects, artificial islands, underwater structures, etc., can solve the problems of rising cost of self-elevating platforms, reduce pile fixation load, exert material efficiency, and improve platform safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

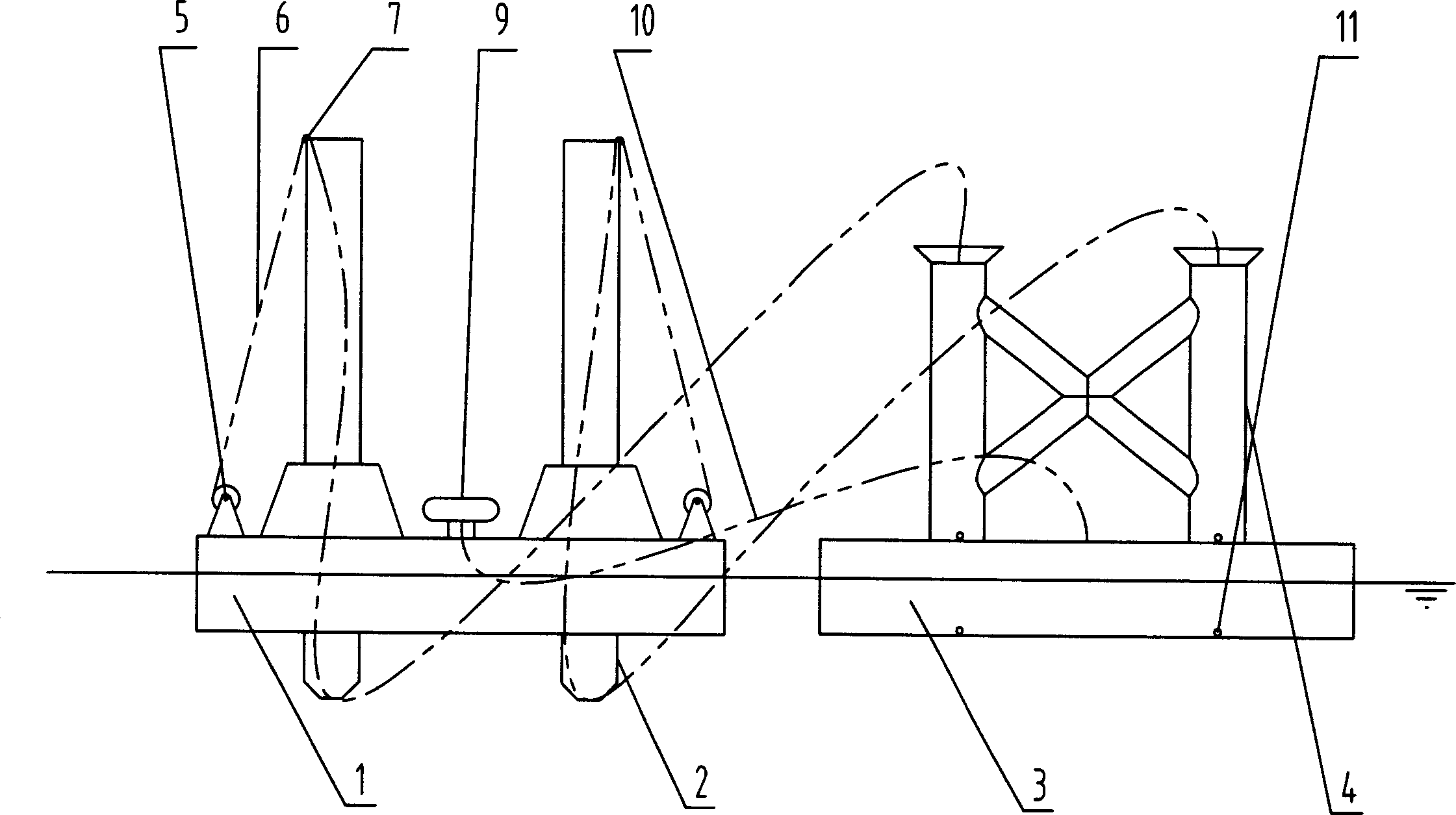

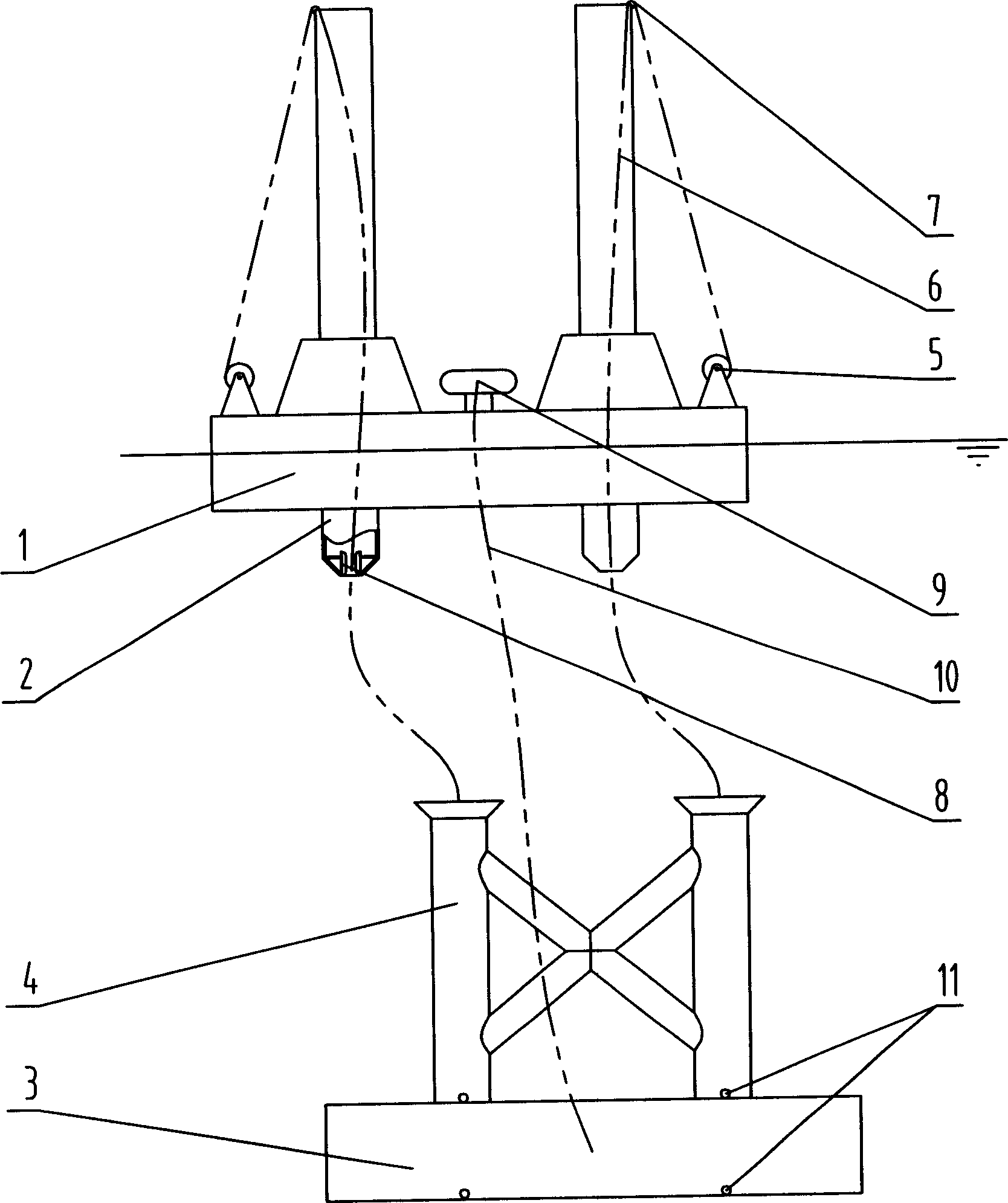

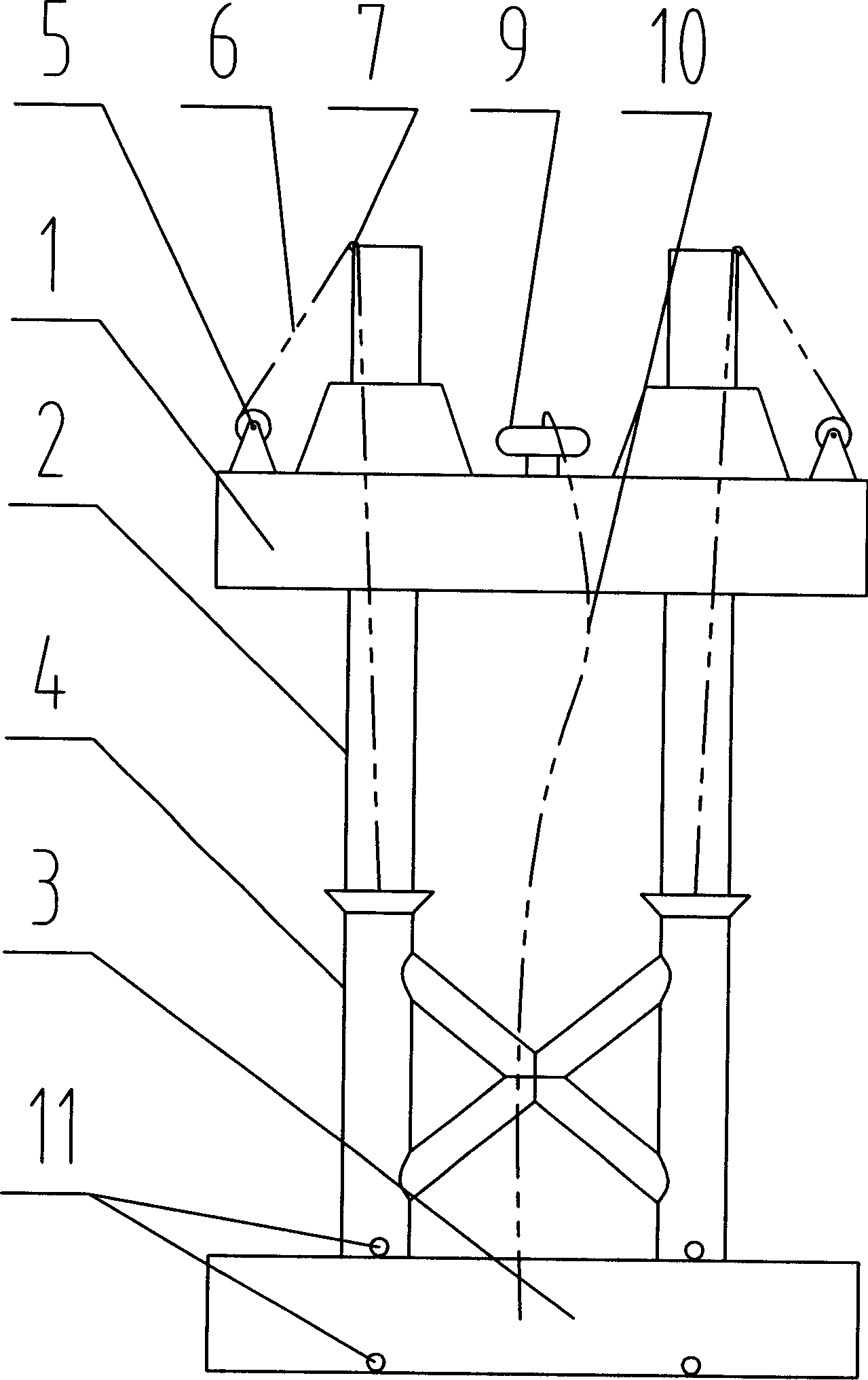

[0020] Now combined with the manual figure 1 , 2 , 3, the present invention is further described:

[0021] The split sitting bottom jack-up platform is mainly composed of jack-up main platform, bottom supporting structure, docking guide device and ballast system. The self-elevating main platform includes platform upper box body 1, lifting pile legs 2, solid piles and lifting machinery, drilling and repairing operation facilities, and the bottom support structure includes platform lower box body 3, fixed pile legs 4 and other connecting and fixing rods, docking The guiding device includes winch 5 , associated guide rope 6 , guide wheel 7 , and guide sleeve 8 , and the ballast system includes air compressor unit 9 , associated ballast control air circuit 10 , and sea port 11 . Considering various performances of the platform such as towage, docking, positioning, and dismantling, the platform is divided into two parts with floating performance, which can be docked up and down o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com