Gun drill driven type gun of squeezing glue

A glue gun and pistol drill technology, applied in the field of extrusion guns, can solve the problems of time-consuming and laborious glue production, uneven costs, etc., and achieve the effect of saving time and effort in glue production and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

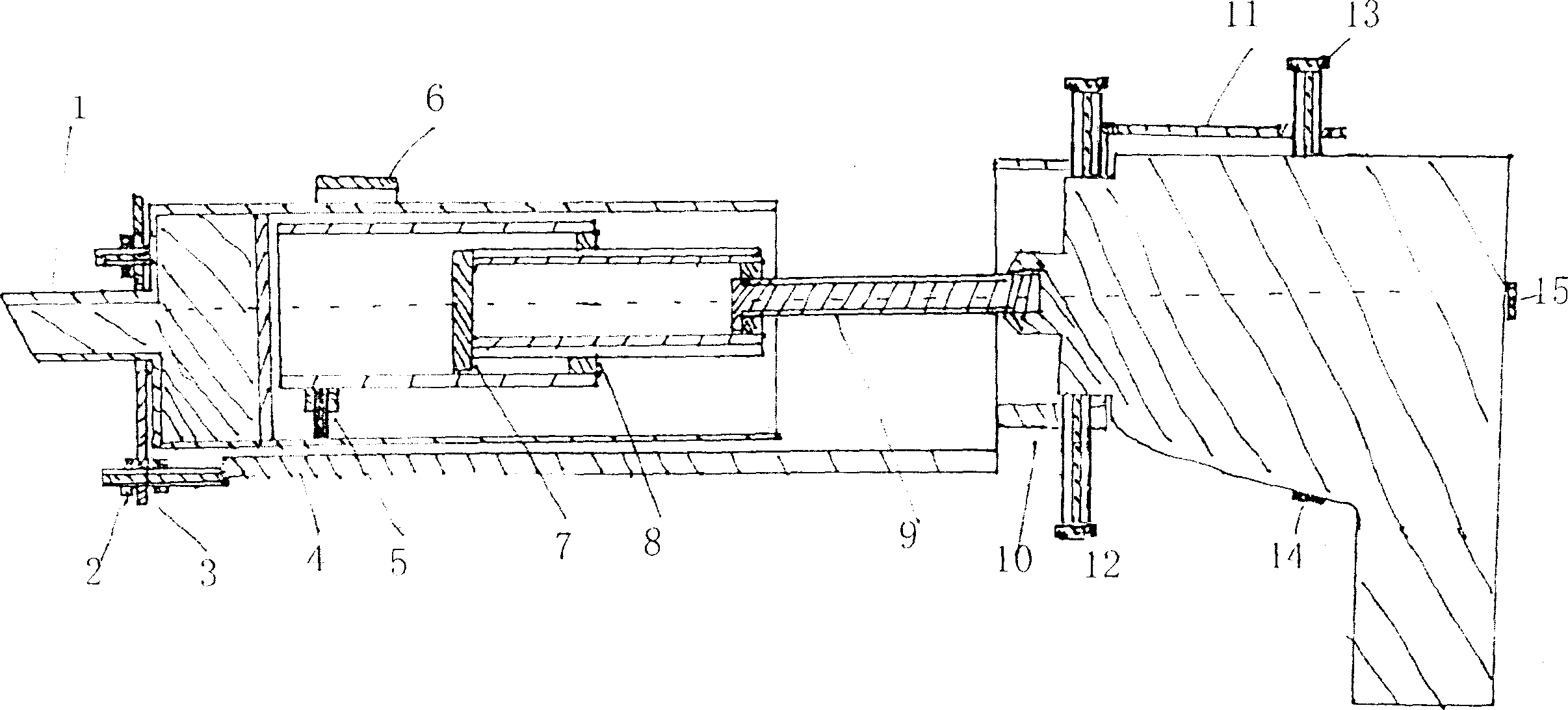

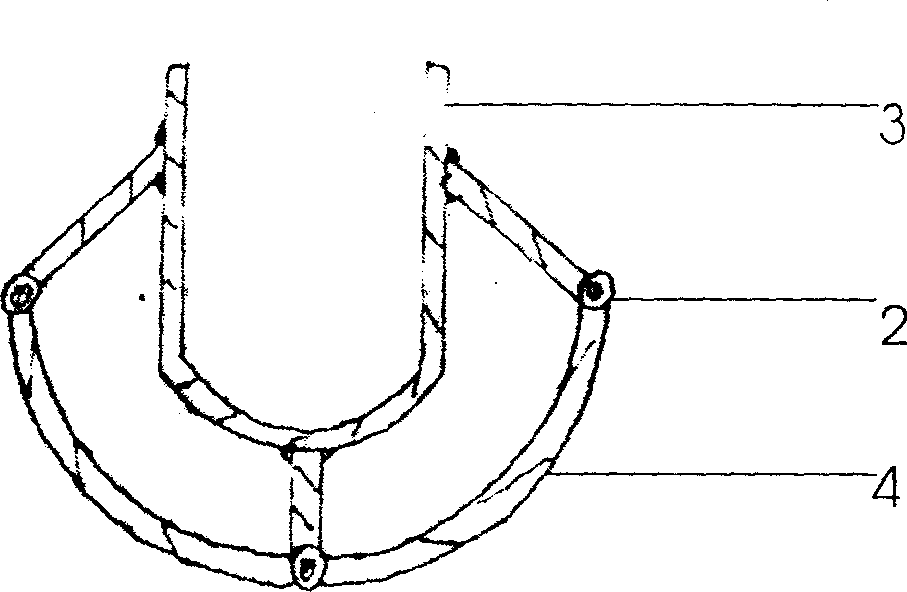

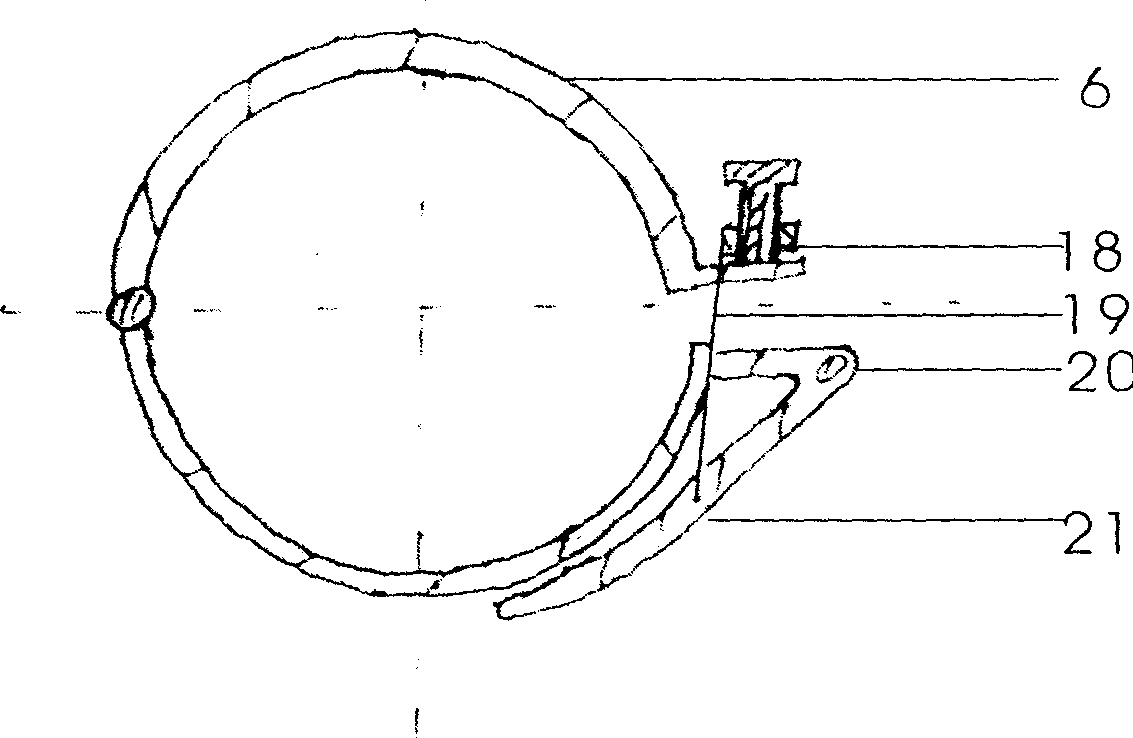

[0014] exist figure 1 In the implementation diagram, the glue cartridge (1) is placed in the glue gun frame (4), the glue nozzle passes through the U-shaped rubber baffle (3) and the glue body is blocked in the glue gun frame (4), and the tail of the push rod (9) Clamp the pistol drill neck belt (15) to block the glue gun holder (4) back tightly, the anti-swing card (11) is held by the belt (15) downwards on the pistol drill, and press the screw to hold it tightly on the pistol drill superior. The rotation of the gun drill makes the third section and the second section of the push rod (9) rotate. The push rod and the rubber tube are not on the same axis, so the third section will not rotate, so that the push rod is pushed forward to extrude the glue in the rubber tube. And baffle plate (7) (8) can not make every joint of push rod come off or squeeze tightly mutually.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com