Improved coating method for preparing membrane of oxide ceramics

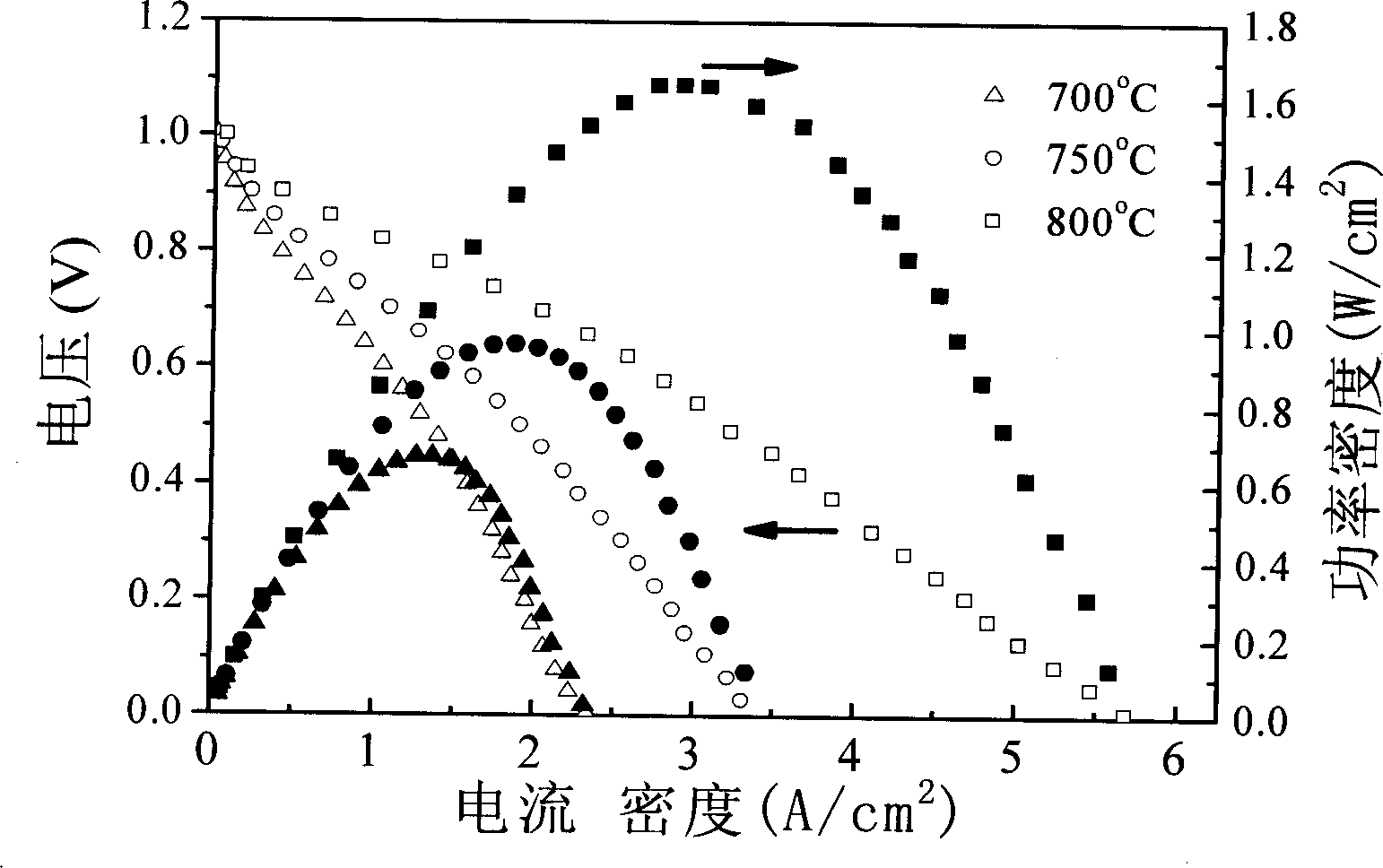

A technology of oxide ceramics and oxides, which is applied in the field of oxide ceramic film preparation, can solve the problems of difficult control of film thickness uniformity, too thick slurry concentration, poor slurry fluidity, etc., and achieve high output power density , High raw material utilization rate, stable performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0015] Specific implementation mode 1: This implementation mode adopts the following technical scheme to prepare oxide ceramic membranes:

[0016] 1. Preparation of the support body: the support body is composed of a mixture of various oxides. The support body used for the oxide electrolyte film of the solid oxide fuel cell is a powder of a transition metal oxide micron or submicron particle size and another A mixture of oxide solid solution solid electrolyte powder and organic pore-forming agent. Transition metal oxide refers to a mixture of one or two of nickel oxide, cobalt oxide, copper oxide, and iron oxide; oxide solid solution electrolyte refers to elements doped with yttrium, scandium, calcium, or magnesium (accounting for 3 to 15 mol%) Miscellaneous zirconia with cubic or tetragonal structure, or rare earth (one or more of Y, Sm, La, Pr, Nd, Gd, etc.) or alkaline earth (Ca and / or Sr) doped cerium oxide; The pore agent is flour, starch, activated carbon or graphite po...

specific Embodiment approach 2

[0023] Specific Embodiment 2: In this embodiment, the fabrication of a support for an oxide electrolyte membrane used in a solid oxide fuel cell is taken as an example. The raw materials are nickel oxide (NiO) nanopowder synthesized by glycine-nitrate method, yttria stabilized zirconia (YSZ) electrolyte ceramic powder, and flour for pore forming agent. The mass ratio of these three raw materials is 5:5:1.7 After the ingredients are fully mixed and ground, they are placed in a mold and pressed at 150-200MPa to form a disc with a thickness of 0.6mm, and then placed in a high-temperature electric furnace, and the temperature is raised to 1000°C at a heating rate of 2°C / min-10°C / min , and sintered for 2 hours to obtain a NiO-YSZ anode support body for solid oxide fuel cell electrolyte membrane preparation.

specific Embodiment approach 3

[0024] Specific Embodiment Three: This embodiment takes the fabrication of a support for an oxide electrolyte membrane used in a solid oxide fuel cell as an example. The raw materials are nickel oxide nano-powder synthesized by precipitation method, samarium oxide-doped cerium oxide (SDC) electrolyte ceramic powder, and flour for pore-forming agent. These three raw materials are mixed and ground in a mass ratio of 5:5:2. Finally, put it in a mold and press it into a disc with a thickness of 0.5mm at 150-200MPa, then place it in a high-temperature electric furnace, raise the temperature to 1000°C at a rate of 2°C / min-10°C / min, and sinter for 2 hours. That is, the NiO-SDC anode support body used for the preparation of solid oxide fuel cell electrolyte membrane is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Graininess | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com