Membraneless fuel cell catalyst slurry and methods for preparing catalyst slurry and electrode

A catalyst slurry and fuel cell technology, which is applied to battery electrodes, circuits, electrical components, etc., can solve the problems of high platinum consumption and poor conductivity, and achieve the effects of simple preparation process, avoiding agglomeration, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

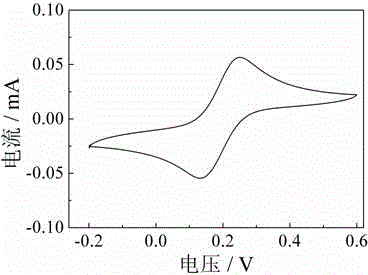

[0031] Preparation of Pt / graphene solid catalyst

[0032] The Pt / graphene solid catalyst used in the present invention can be prepared according to the method disclosed in the literature, such as the document "Co-reduction preparation and characterization of platinum / graphene oxygen reduction electrocatalyst" (Acta Physicochemical Sinica, 2012, 28( 12)). The preparation method of the solid catalyst used in the present invention is as follows, 0.5g graphene is dissolved in 20mL of high-purity water, then add concentration is 100mL of the chloroplatinic acid solution of 30mmol / L, stir and dissolve evenly. Add 0.2 mmol / L NaBH dropwise under high-speed stirring 4 150 mL of the solution was stirred continuously for 60 minutes, and after centrifugal separation, a Pt / graphene solid catalyst was obtained.

Embodiment 1

[0034] Take 10mL of ethanol, 15g of methylcellulose, and 20g of soluble polyaniline into the flask, and stir continuously for 1 hour to obtain a paste slurry; then add 0.15g of Pt / graphene catalyst to the paste slurry under high-speed stirring conditions , and continued to stir for 4 hours to obtain a catalyst slurry of the present invention.

[0035] Cut the carbon paper into a 5cm×10cm rectangle as the substrate, wash the surface 3 times with absolute ethanol, then wash 4 times with deionized water, then dry, and print the catalyst slurry obtained above on the treated substrate 10 times , after every printing 5 times, put it at 50° C. and dry it for 20 minutes, and after printing, put it at 80° C. and dry it for 90 minutes to obtain an electrode assembly of the present invention.

Embodiment 2

[0037] Take 10mL of ethylene glycol and 25g of soluble polythiophene into the flask and mix evenly, then add 20g of ethyl cellulose to the mixture under stirring conditions, and continue stirring for 2 hours to obtain a paste slurry; then under high-speed stirring conditions Add 0.10 g of Pt / graphene catalyst into the pasty slurry, and keep stirring for 6 hours to obtain a catalyst slurry of the present invention.

[0038] Cut the nickel foam into a 5cm×10cm rectangle as the substrate, wash the surface 3 times with absolute ethanol, then wash 4 times with deionized water, then dry, and print the catalyst slurry obtained above on the treated substrate 10 times , after every printing 5 times, put it at 80°C to dry for 5 minutes, and after printing, put it at 120°C to dry for 40 minutes to obtain an electrode assembly of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com