Expanding clamping device

A technology of expansion and contraction and fixture, which is applied in the direction of chuck, sleeve/socket connection, pipe/pipe joint/pipe fitting, etc., and can solve problems such as complex sealing measures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

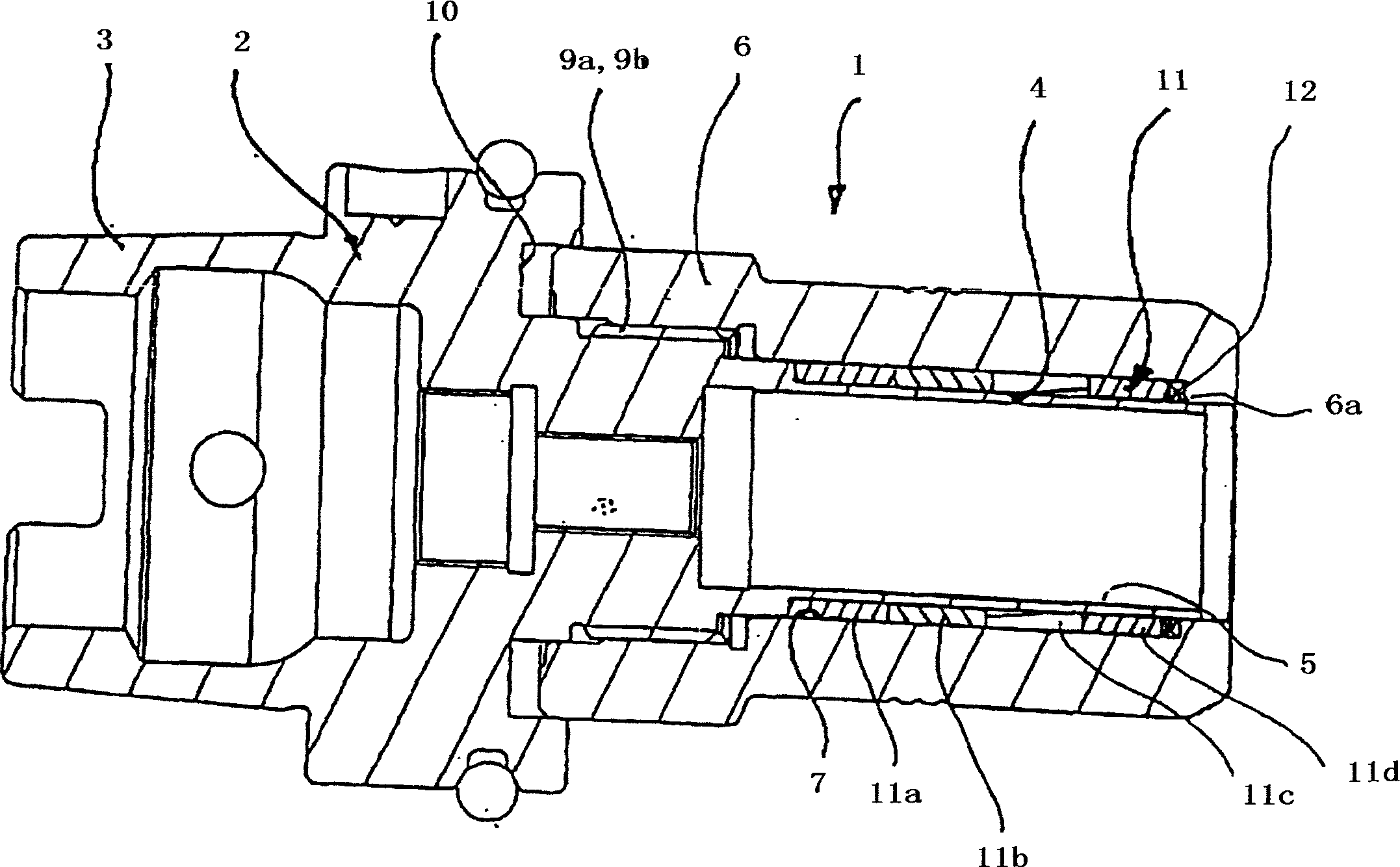

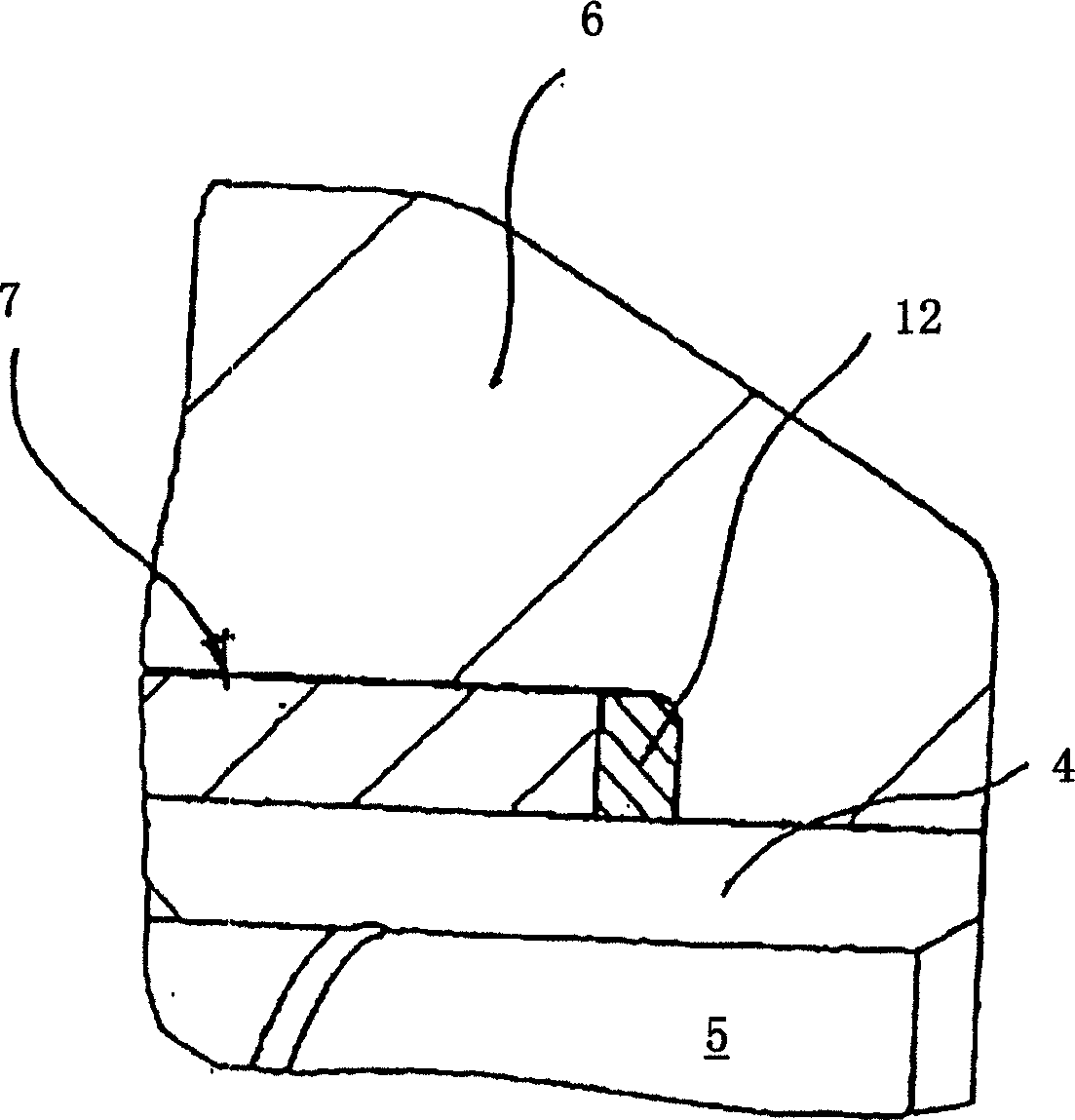

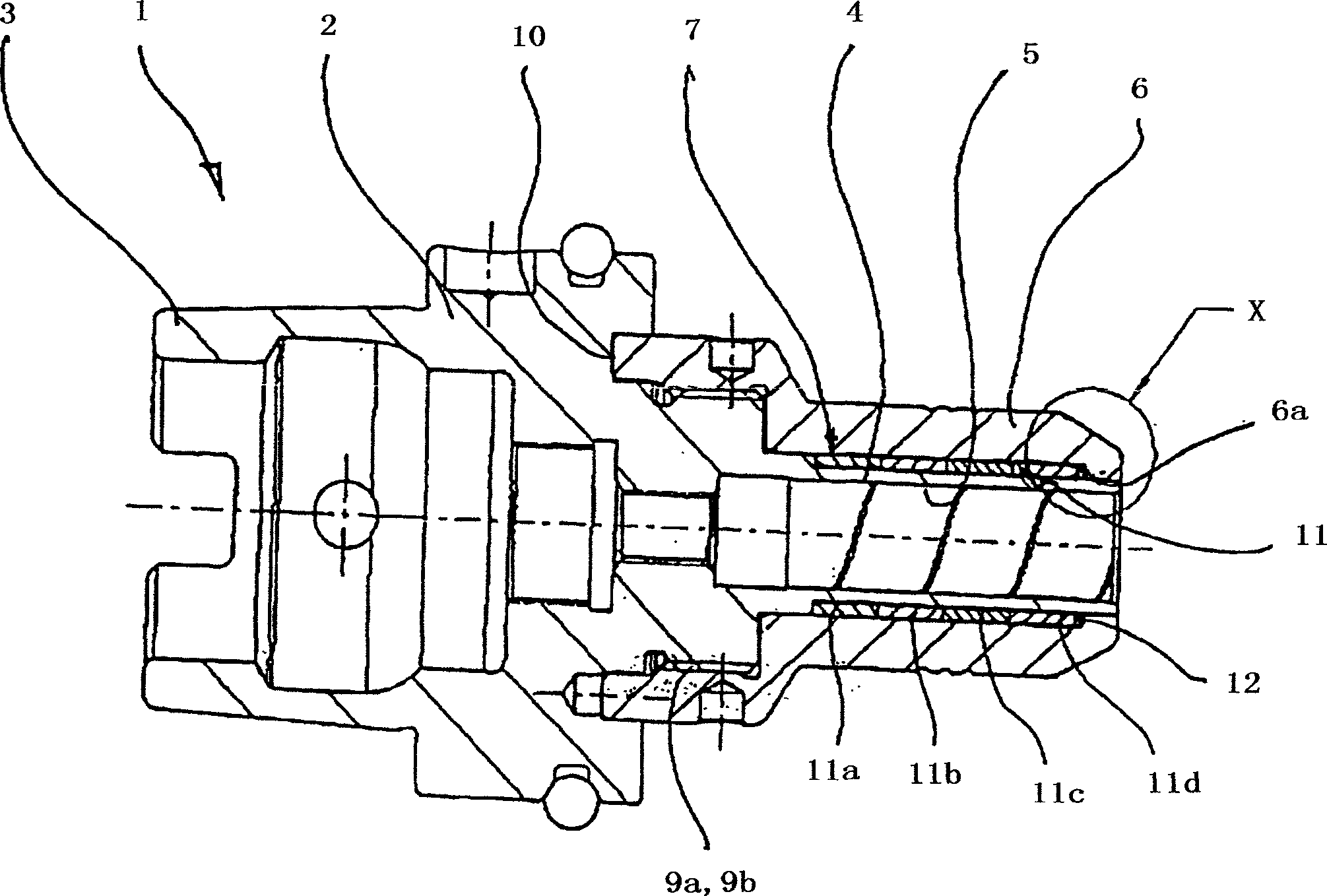

[0015] figure 1 A longitudinal sectional view of an embodiment of an expandable chuck 1 in the form of a high-angle conical toolholder according to the invention is shown. The expandable chuck 1 comprises a base body 2 made of rigid material which, on the left side in the figure, has at its end a connection cone 3 in a known manner for clamping to a rotationally driven on the working spindle. On the other axial end of the base body 2, a thin-walled expansion sleeve 4 is provided, which is here integrally formed with the base body 2, but alternatively, the expansion sleeve The cartridge 4 can also be a separate component, which is connected to said base body 2 in a firm manner. The expansion sleeve 4 forms a central socket 5 into which a cylindrical shaft of a tool such as a drill bit or a cutter to be clamped can be inserted.

[0016] The expansion sleeve 4 is surrounded by a tensioning ring 6 in the form of a stop nut, which is screwed onto the base body 2 on its axial end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com