Hemi-membrane substrate integrated waveguide

A technology of half-mode substrate integration and integrated waveguide, which is applied in the direction of waveguide, waveguide-type devices, circuits, etc., can solve the problems of large circuit board area, increased final product size, large size, etc., and achieves strong anti-interference ability and easy Mass production, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

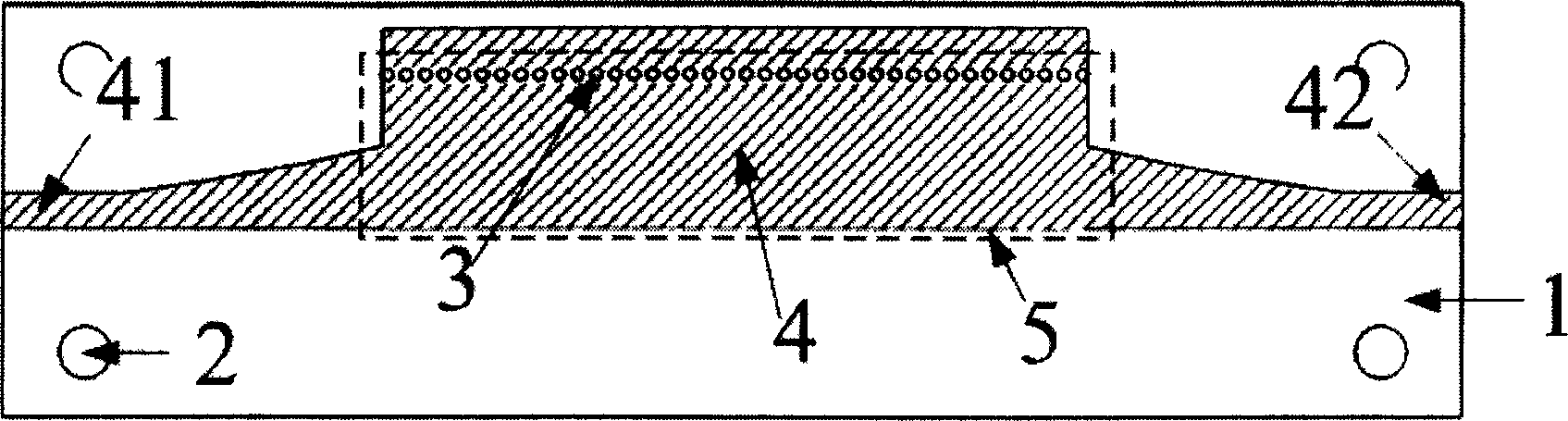

[0012] The half-mode substrate integrated waveguide of the present invention relates to a half-mode substrate integrated waveguide (HMSIW) waveguide structure of millimeter wave and microwave devices, including a dielectric substrate 1 provided with a metal patch, and a row of Periodically arranged metallized holes 3 for connection, the diameter of the metallized through hole is 0.5 mm, and the distance between the centers of adjacent metallized through holes is 0.8 mm; The distance between the edges 5 is 6.5 mm. The input port 41 and the output port 42 are input and output ports, respectively. The above-mentioned metallized through hole is to open a through hole on the dielectric substrate, set a metal sleeve on the inner wall of the through hole and connect the metal sleeve with the metal patches covering both sides of the dielectric substrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com