Guiding magnet system and magnetic levitation vehicle equipped therewith

A magnetic levitation, magnet technology, applied in railway vehicles, vehicle components, transportation and packaging, etc., to achieve the effect of weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

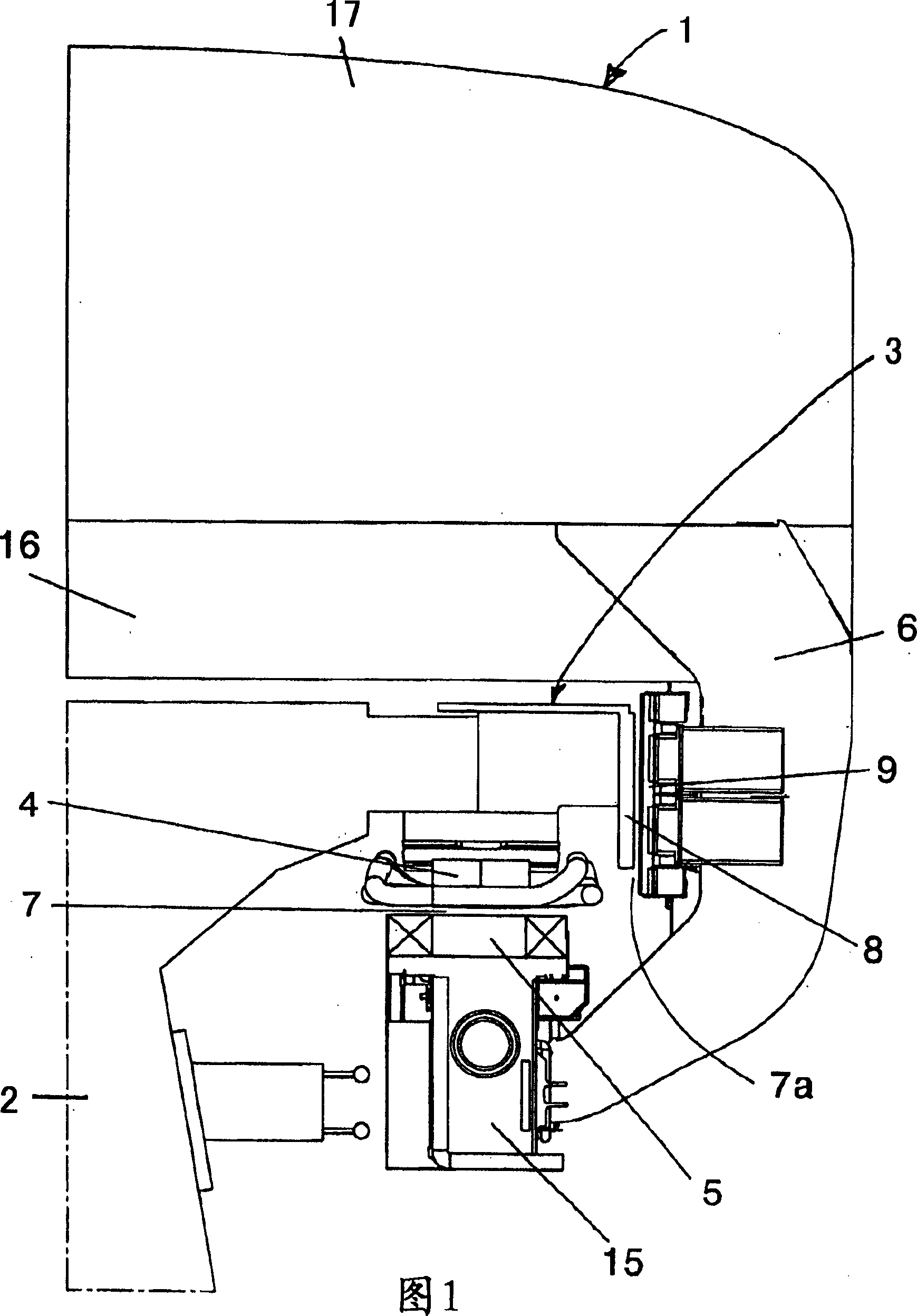

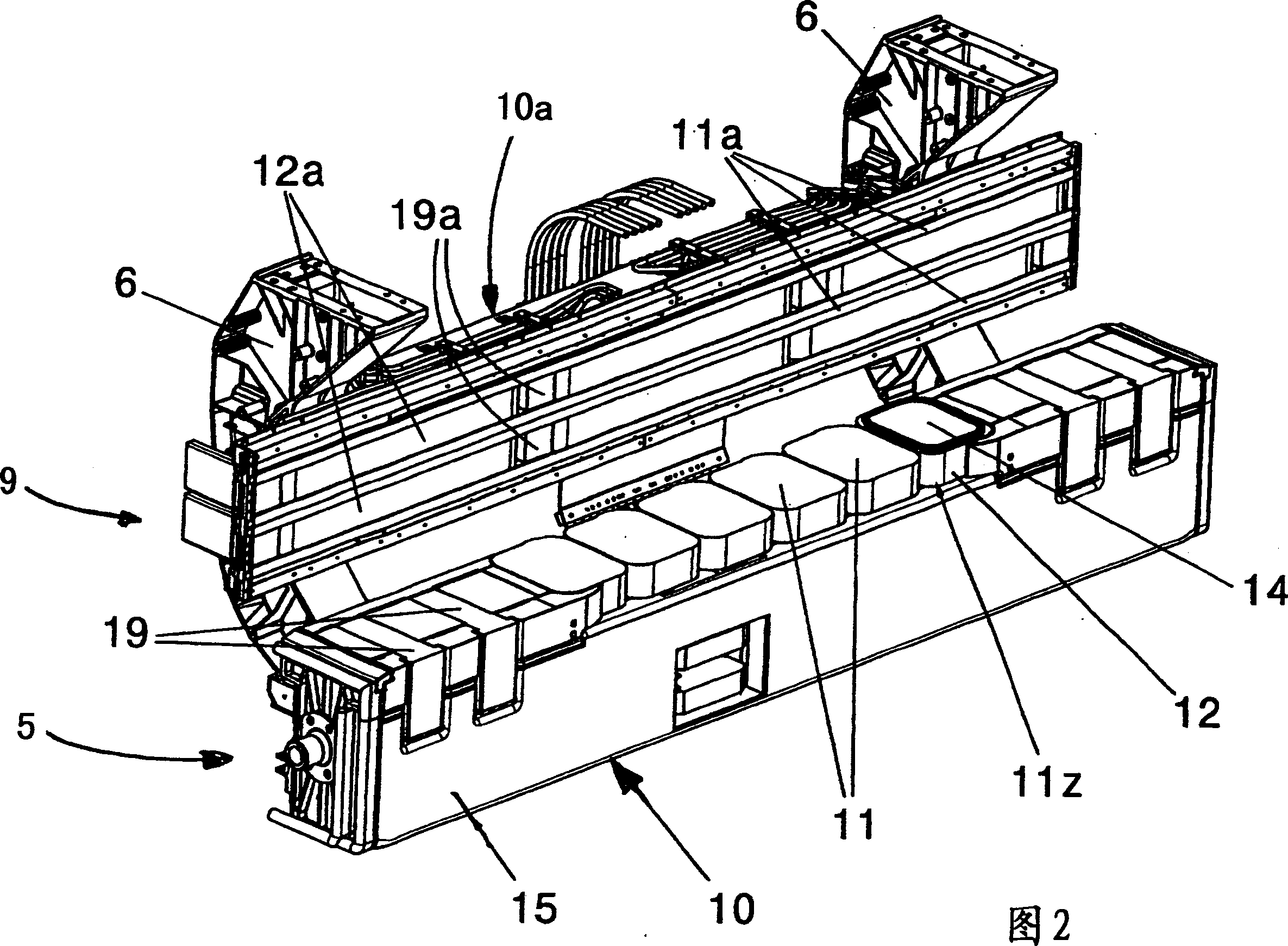

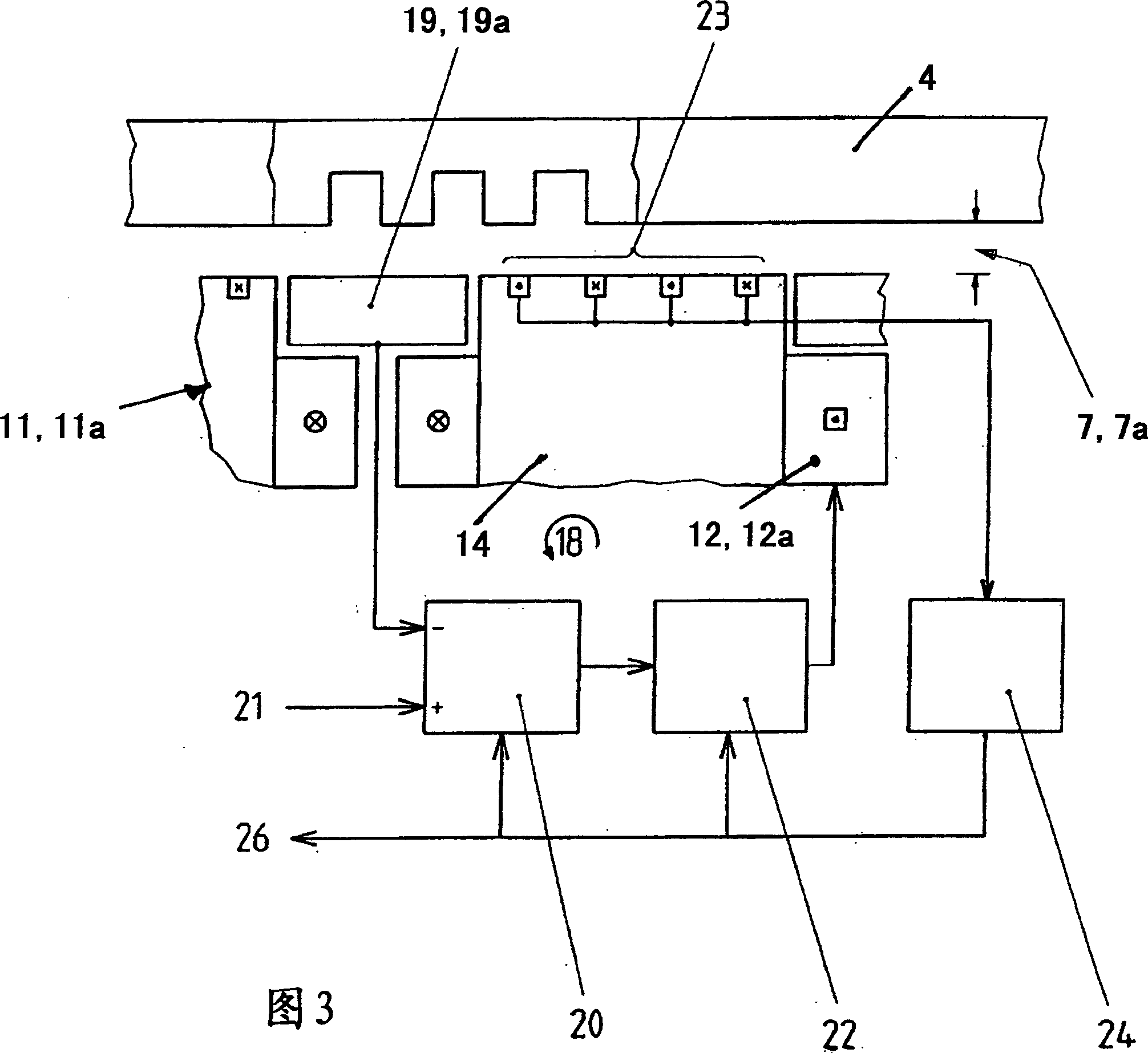

[0019] Figure 1 schematically represents a cross-section through a magnetically levitated vehicle 1 conventionally movably mounted on guide rails extending in the longitudinal direction of the route, said guide rails comprising beams made of steel and / or concrete (support) 2 and the guide rail plate 3 installed on it. The thrust of the magnetically levitated vehicle 1 is achieved by a long stator motor comprising stator laminations 4 attached below the rail plate 3 and arranged one behind the other in its longitudinal direction. The stator laminations 4 comprise an alternating succession of teeth and slots, shown only in FIG. 3 , into which windings supplied with three-phase currents of variable amplitude and frequency are inserted. The actual excitation field of the long stator motor is generated by at least one first magnet arrangement which plays the role of carrying (supporting) the magnet 5 attached to the magnetic levitation vehicle 1 by at least one lateral support brac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com