Retractable rolling device for dividing filament bundle into parallel monofilament and method therefor

A technology of unwinding equipment and monofilament, which is used in filament/line forming, conveying filamentous materials, textiles and papermaking, etc. It can solve the problems that split filaments cannot meet the requirements of stiffness and special-shaped cross-section filaments, and achieve cost Low, meet the production requirements of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

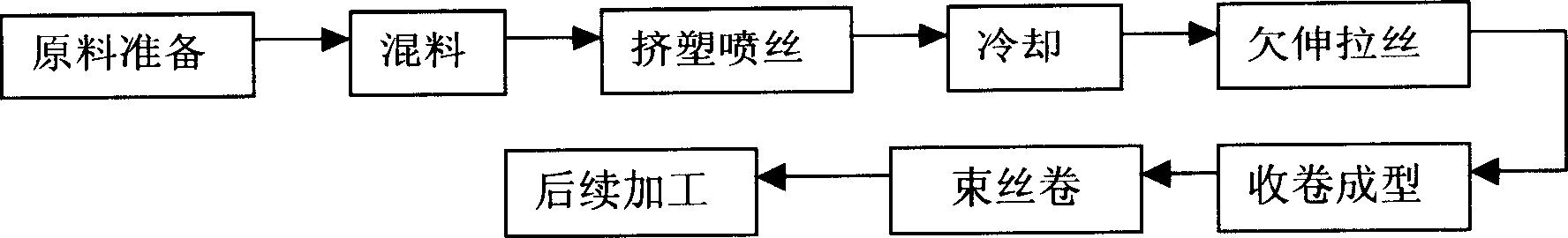

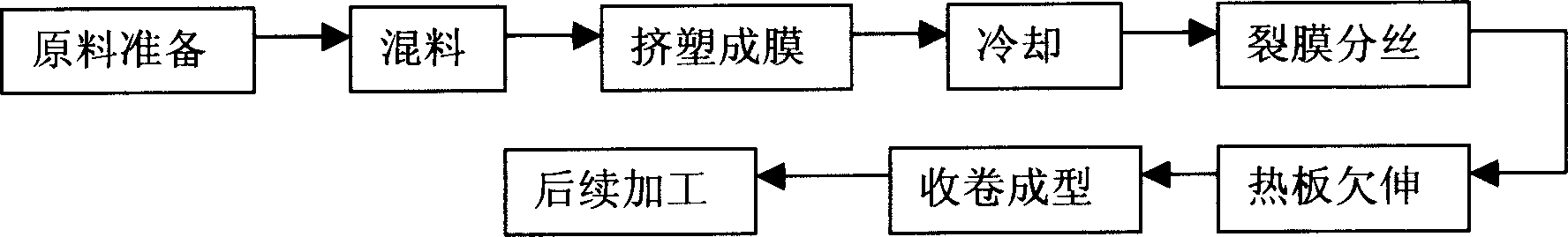

Method used

Image

Examples

Embodiment 1

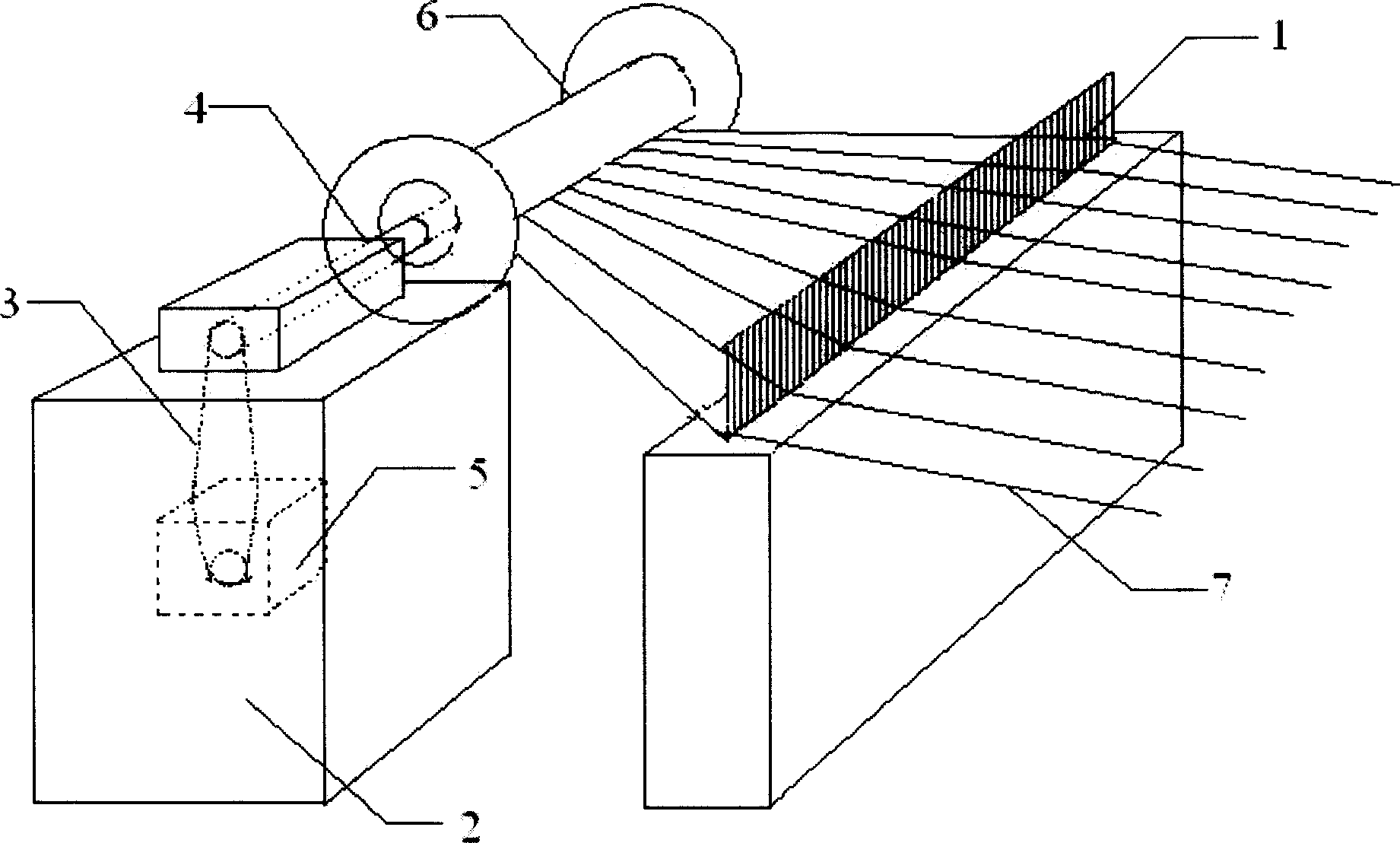

[0026] A rewinding / unwinding device for decomposing a bundle of filaments into parallel monofilaments, comprising a reed divider and a tension control device, the reed divider includes a divided reed 1, and the tension control device includes a reed / unwind frame 2 1. Creel 4, tension controller 5 and chain belt 3 arranged on the take-up / unwind frame, the rotating shaft of the creel 4 is connected with the rotating shaft of the tension controller 5 through the chain belt 3. The creel 4 is arranged in parallel with the dividing reed 1 .

Embodiment 2

[0028] A winding / unwinding method for decomposing bundles into parallel monofilaments, using the winding / unwinding device for decomposing bundles into parallel monofilaments in Embodiment 1, the method includes two processes of winding and unwinding. Specifically include the following steps:

[0029] 1) Adopt the front part of the production process of the cable wire, change the winding and forming step, and install the wire dividing reed 1 to decompose the bundle wire 7 into parallel monofilaments, and wind them in parallel on the special package bobbin 6;

[0030] 2) The tension is controlled by the tension control device, and the formed parallel monofilament on the special package bobbin 6 is unwound in parallel through the dividing reed 1,

[0031] 3) Using the winder in the production process of the split film yarn, the constant tension is used to wind and form monofilament; provide it to subsequent factories to process various monofilament fabrics.

[0032] The special ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com