Direct current power supply and lead-acid storage battery parallel power supply method and its device

A lead-acid battery and DC power supply technology, applied in battery circuit devices, circuit devices, battery load switching, etc., can solve problems such as charging safety cannot be guaranteed, DC power supply is complicated, and output voltage is pulled down to achieve enhanced stability and robustness performance, easy maintenance, and the effect of improving the range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below with reference to the accompanying drawings and in conjunction with specific embodiments.

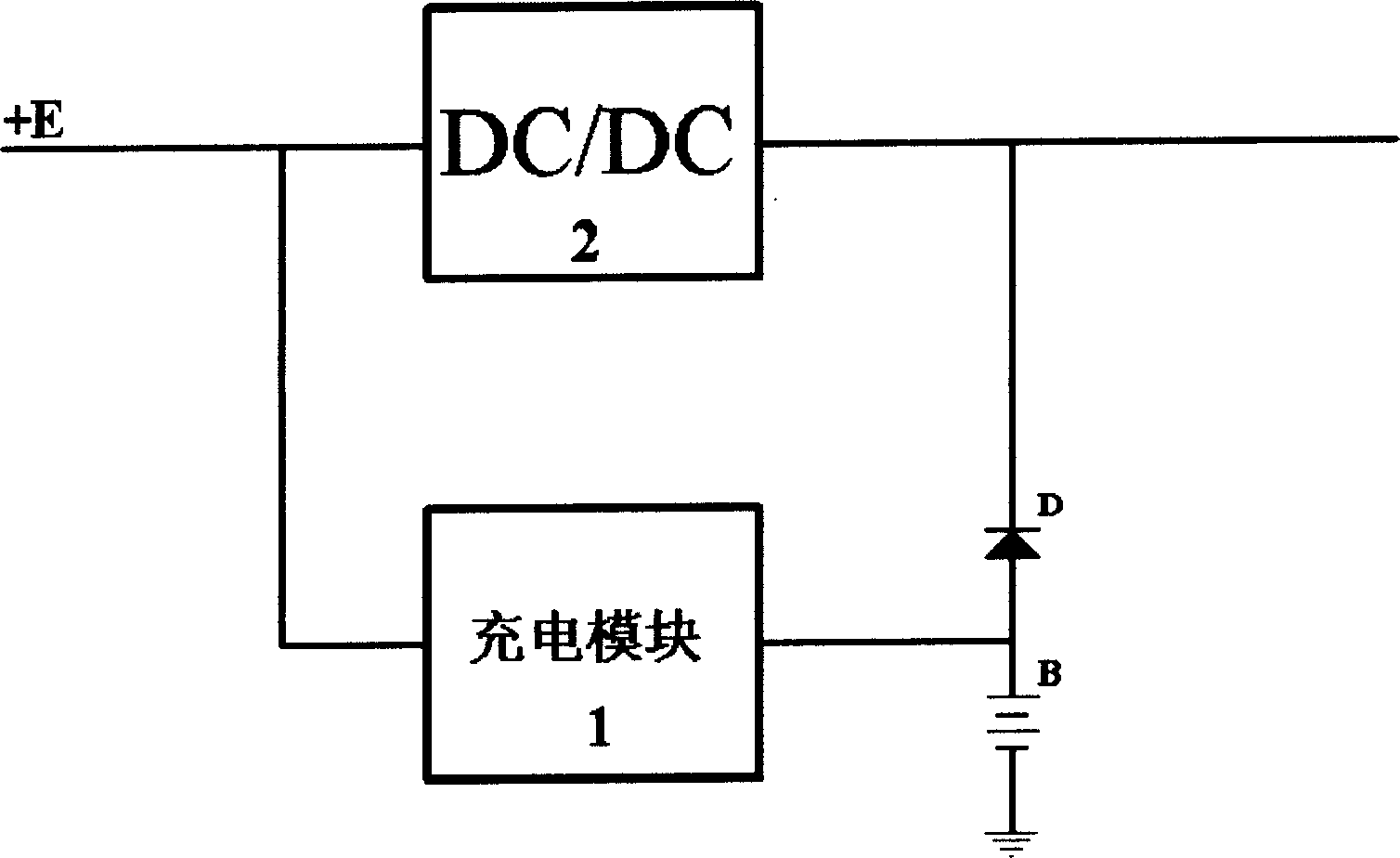

[0032] A DC power supply and lead-acid battery parallel power supply device, including a power supply branch composed of a lead-acid battery B and a charging module 1 that provides charging current to the lead-acid battery B in series, one end of the charging module 1 is connected to the DC power supply Positive pole + E, the other end of the charging module 1 is connected to the positive pole of the lead-acid battery B, and also includes a main power supply branch circuit composed of a DC-DC module 2, and the input terminal of the DC-DC module 2 is also connected to the DC The positive pole +E of the power supply, the output end of the DC-DC module 2 is connected to the load.

[0033] The DC-DC module 2 of the main power supply branch is a high-power DC-DC system composed of six single-ended flyback DC-DC modules;

[0034] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com