Efficient corrosion resisting dust-collecting energy-saving chimney

A chimney and slope ratio technology, which is applied in the treatment of combustion products, combustion methods, exhaust gas devices, etc., can solve the problem of high cost of the inner sleeve, and achieve the effects of good environmental protection, reduced power consumption, and high structural stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

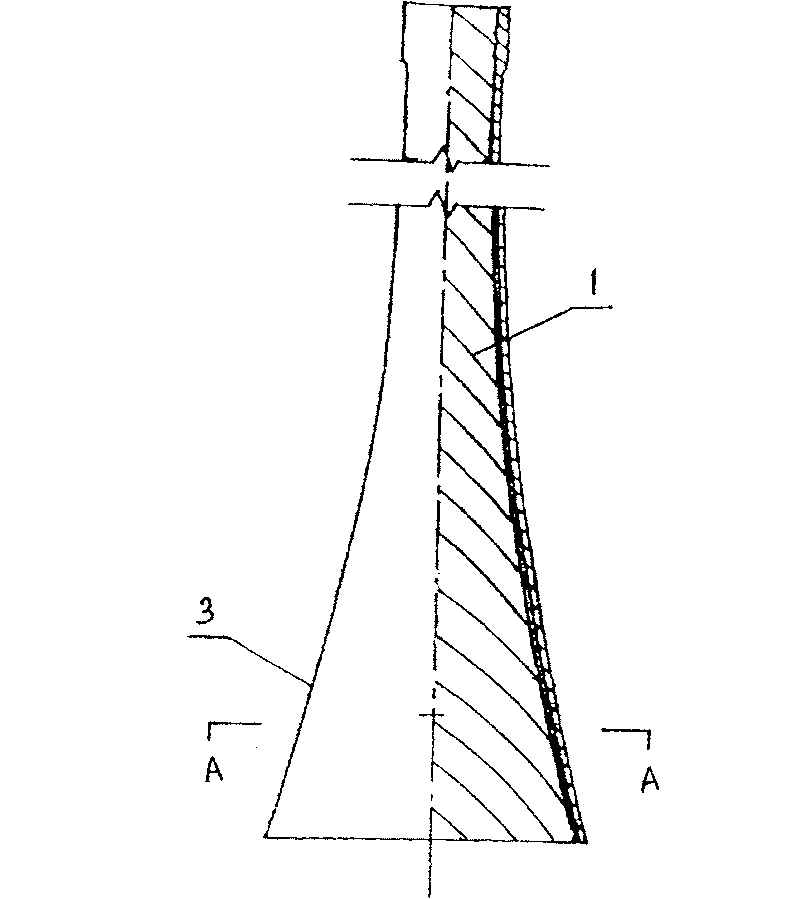

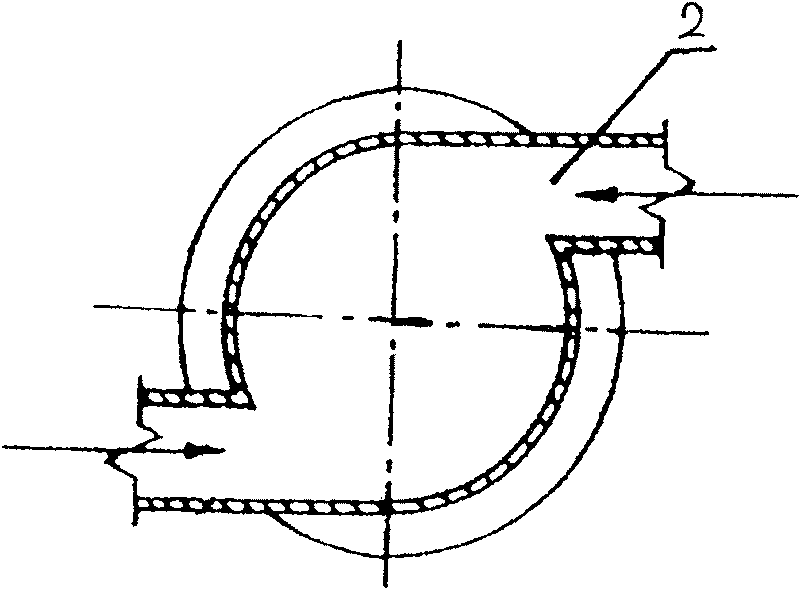

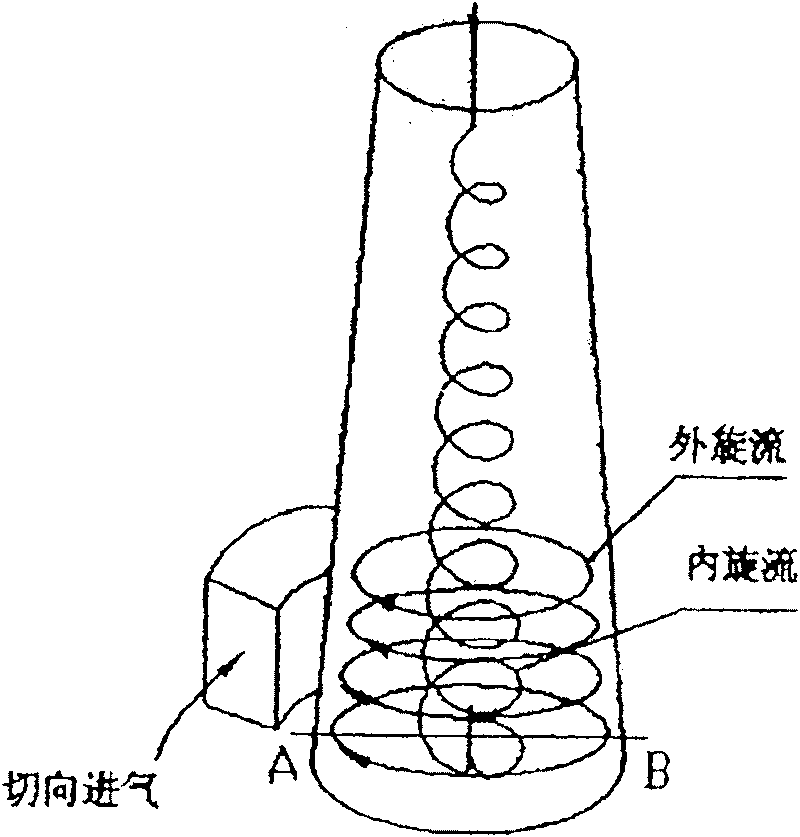

[0013] according to Figure 1 to Figure 3 And the embodiment of the anticorrosion dust collecting energy-saving chimney of the present invention of above-mentioned structure, chimney body 3 is made of lining brick masonry, and chimney bottom diameter is ¢9 meters, and height is 100 meters. The chimney shell 3 has 5 different slope ratios from bottom to top, which are as follows: slope ratio i (1) =0.06~0.08, slope ratio i (2) =0.04~0.06, slope ratio i (3) =0.02~0.04, slope ratio i (4) =0.01~0.02, slope ratio i (5) =0.00, where the height of each section is the percentage of the total height of the chimney: the above slope ratio i (1) Accounting for 20% to 30% of the total height of the chimney, slope ratio i (2) Accounting for 25% to 30% of the total height of the chimney, slope ratio i (3) Accounting for 20% to 25% of the total height of the chimney, slope ratio i (4) Accounting for 20% to 25% of the total height of the chimney, slope ratio i (5) It accounts for 15% t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com