Notching machine of sealing strip

A technology of cutting machine and seal, applied in metal processing and other directions, can solve the problems of poor structural firmness, affect the appearance, and time-consuming, and achieve the effect of saving man-hours, reducing consumables, and high structural firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

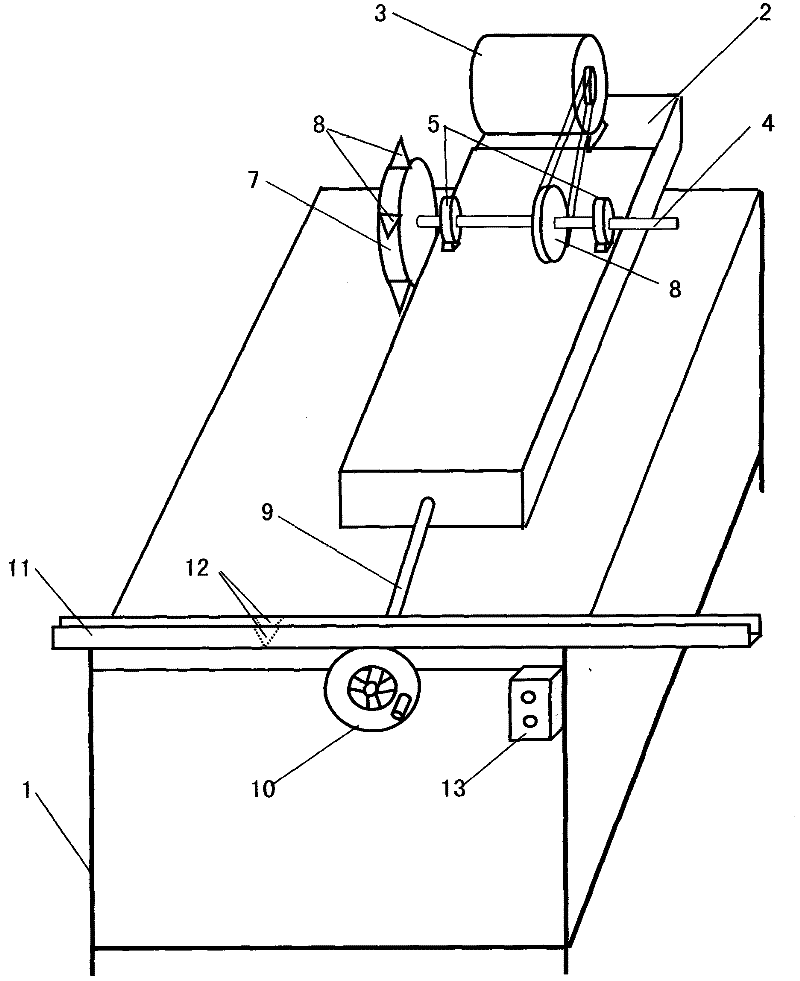

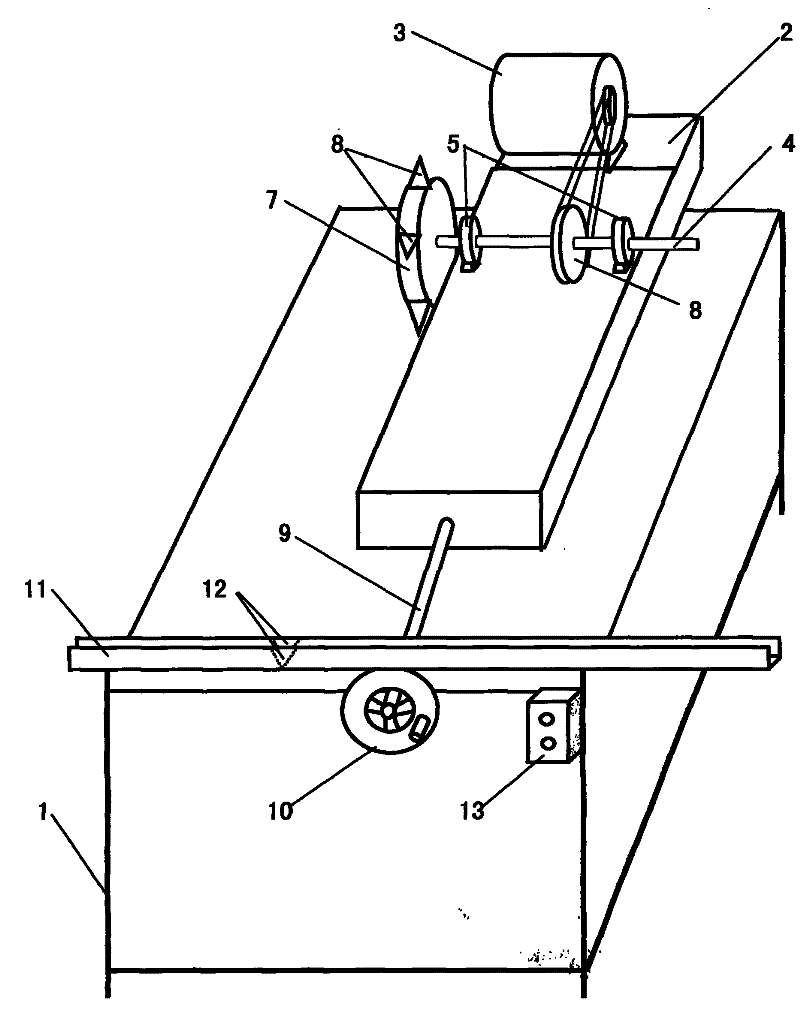

[0016] Below in conjunction with accompanying drawing the implementation details of the present invention are described as follows:

[0017] Such as figure 1 Shown, a kind of seal notching machine is characterized in that by frame 1, the carriage 2 that is movably installed on the frame above, the motor 3 that is fixed on one end of carriage, the 2 that is installed near the position of motor on carriage surface A bearing assembly 4, the main shaft 5 that passes through the two bearing assemblies movably, the power wheel 6 fixedly sleeved on the main shaft at the center, the cutter wheel 7 fixed at the top of the main shaft at the center, and the cutter head group fixed at the outer periphery of the cutter wheel 8. It consists of a screw 9 connected to the bottom of the carriage in the form of nuts and screws, a handle wheel 10 fixed on the top of the screw, and a motor switch 11 for controlling the motor to run or stop.

[0018] Such as figure 1 As shown, the main shaft 5 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com