Filter cleaning system for a vacuum cleaner

A technology for vacuum cleaners and filters, applied in the direction of suction filters, devices for cleaning filters, etc., which can solve the problem of no instructions on how to clean auxiliary filters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

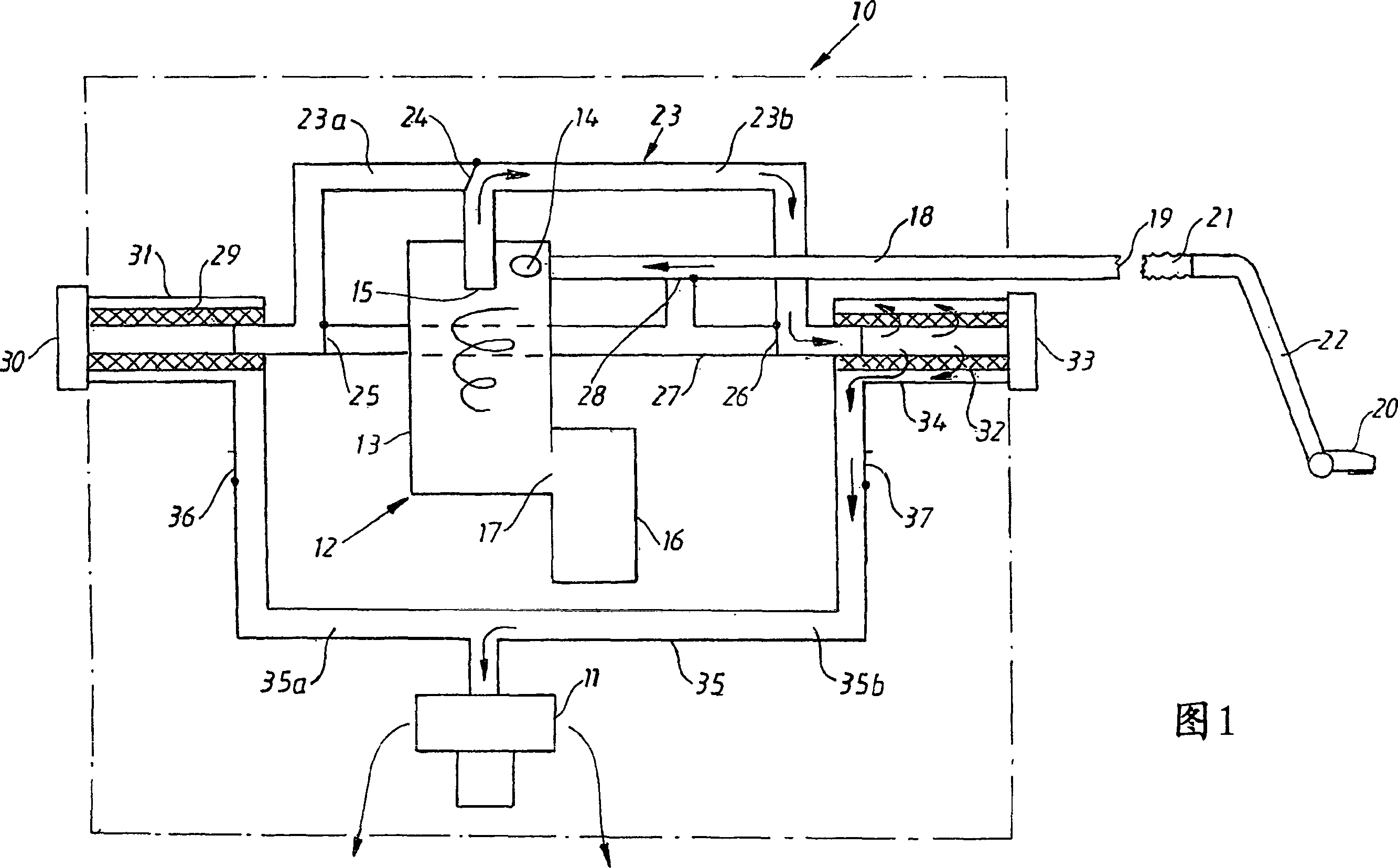

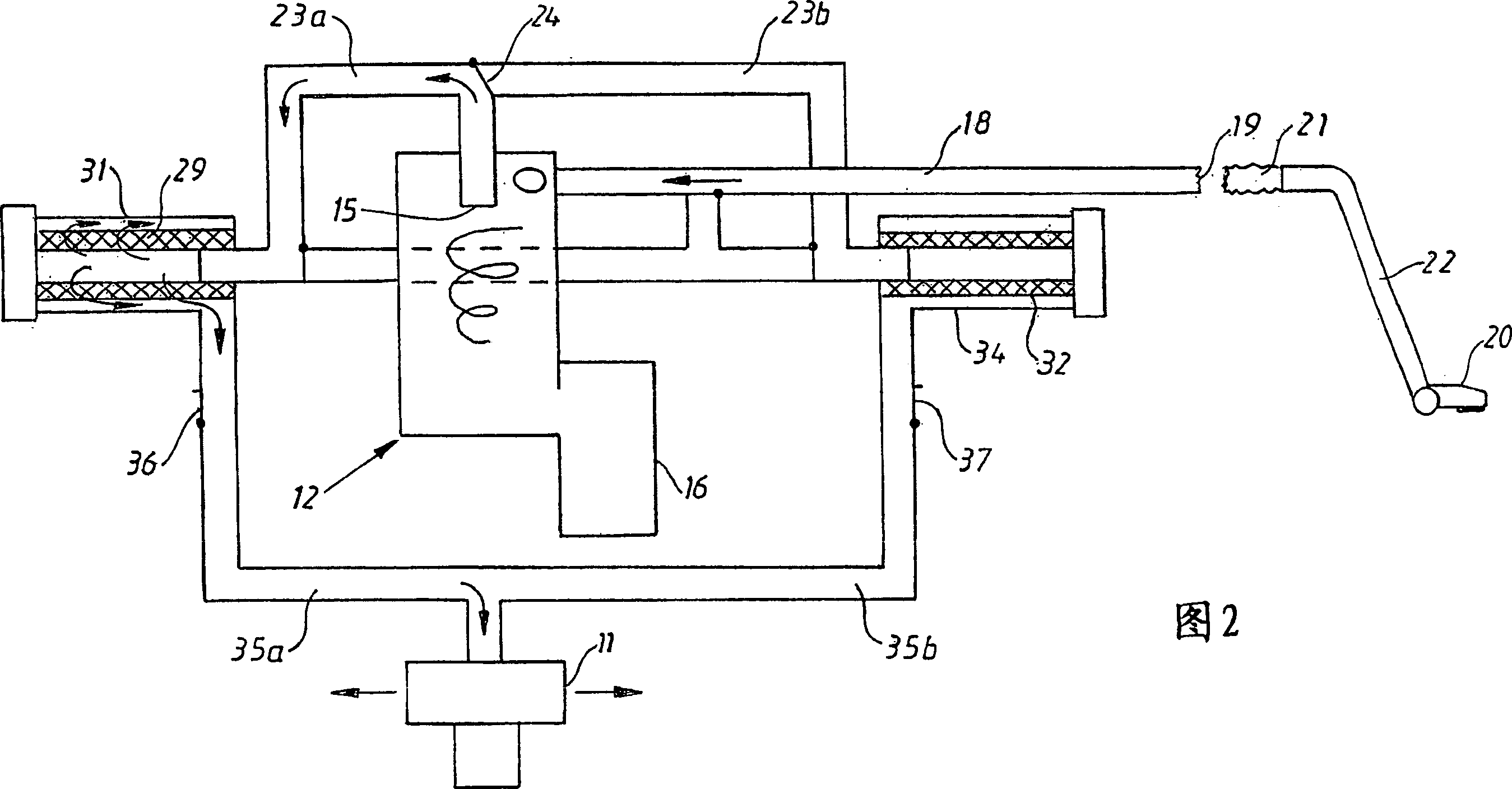

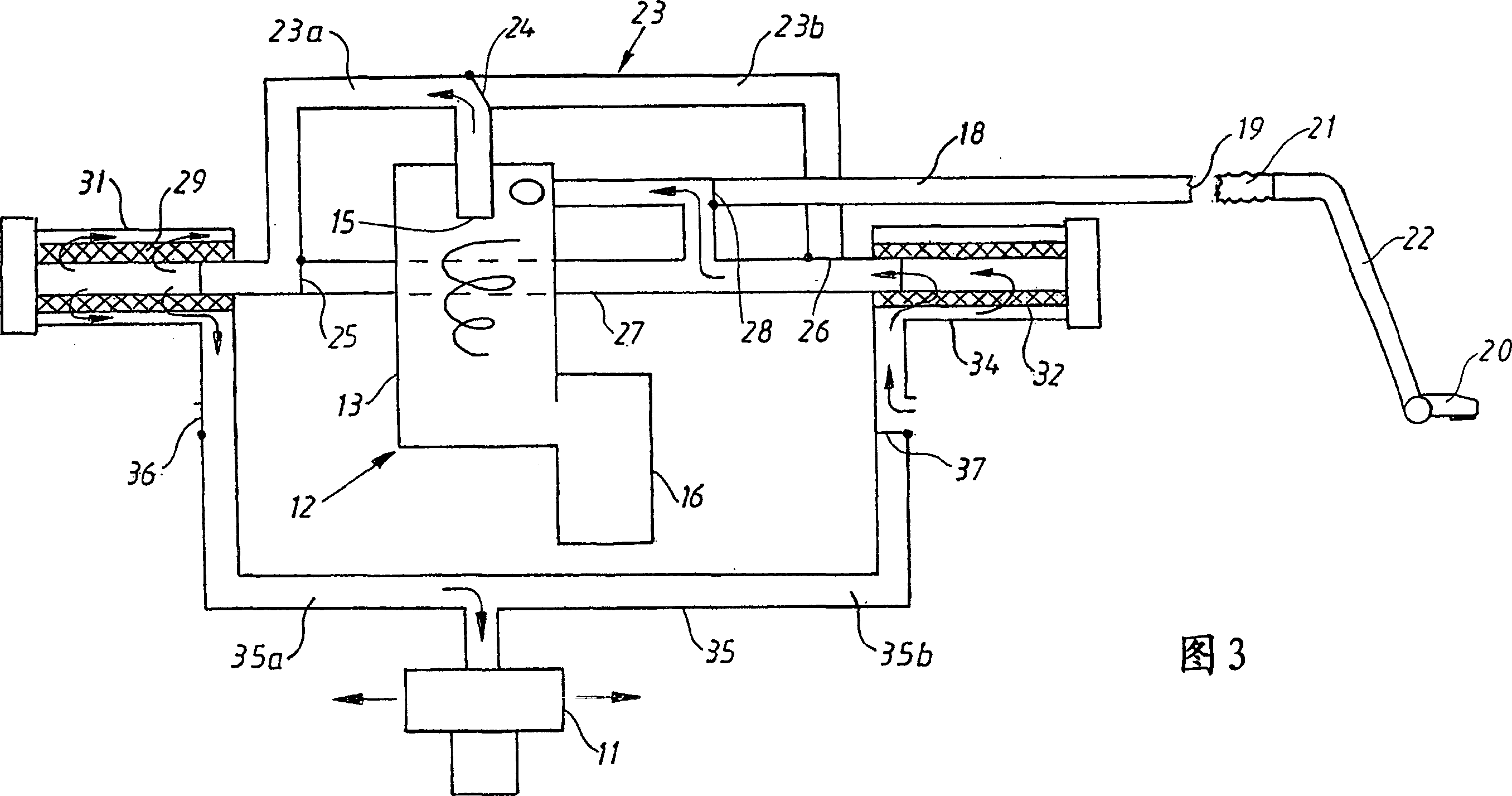

[0010] FIG. 1 schematically shows a vacuum cleaner body 10 enclosing a single vacuum source, such as a fan unit 11 , and a dust separation unit 12 . The dust separation unit 12 is of the so called cyclone type and comprises a circular chamber 13 provided with a tangential inlet 14 for dusty air and a central outlet 15 for clean air. Owing to the air flow, a vortex is generated in the chamber 13 and the dust particles are separated from the air flow by the action of the centrifugal force and enter the dust collection container 16 via the opening 17 .

[0011] The inlet 14 is connected via a channel 18 to an opening 19 in the vacuum cleaner body which is connectable to the vacuum cleaner mouth 20 via a hose 21 and a tube shaft 22 in a conventional manner. The central cyclone outlet 15 is connected to the channel 23 via a valve 24 so that the gas flow can be directed to either the first part 23a or the second part 23b of the channel 23 . Said portions 23a and 23b are connected v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com