Solar heat collector panel

A technology of solar heat collection and heat collection panels, which is applied in the directions of solar thermal energy, solar thermal power generation, solar collectors, etc., and can solve the problems of setting shape and setting place restrictions, weak mechanical strength, easy damage, etc.

Inactive Publication Date: 2007-01-03

DAINATSUKUSU

View PDF4 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0010] The above-mentioned Japanese Patent Laying-Open No. 9-217961 and Japanese Patent Laid-Open No. 2002-130835 disclose that the existing solar heat collecting panels usually have a surface area of several m 2 The flat shape, so the setting shape and setting place are limited

[0011] In addition, as in the heat collector described in Japanese Patent Laid-Open No. 9-217961, for the structure in which the heat collecting plate is cove

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

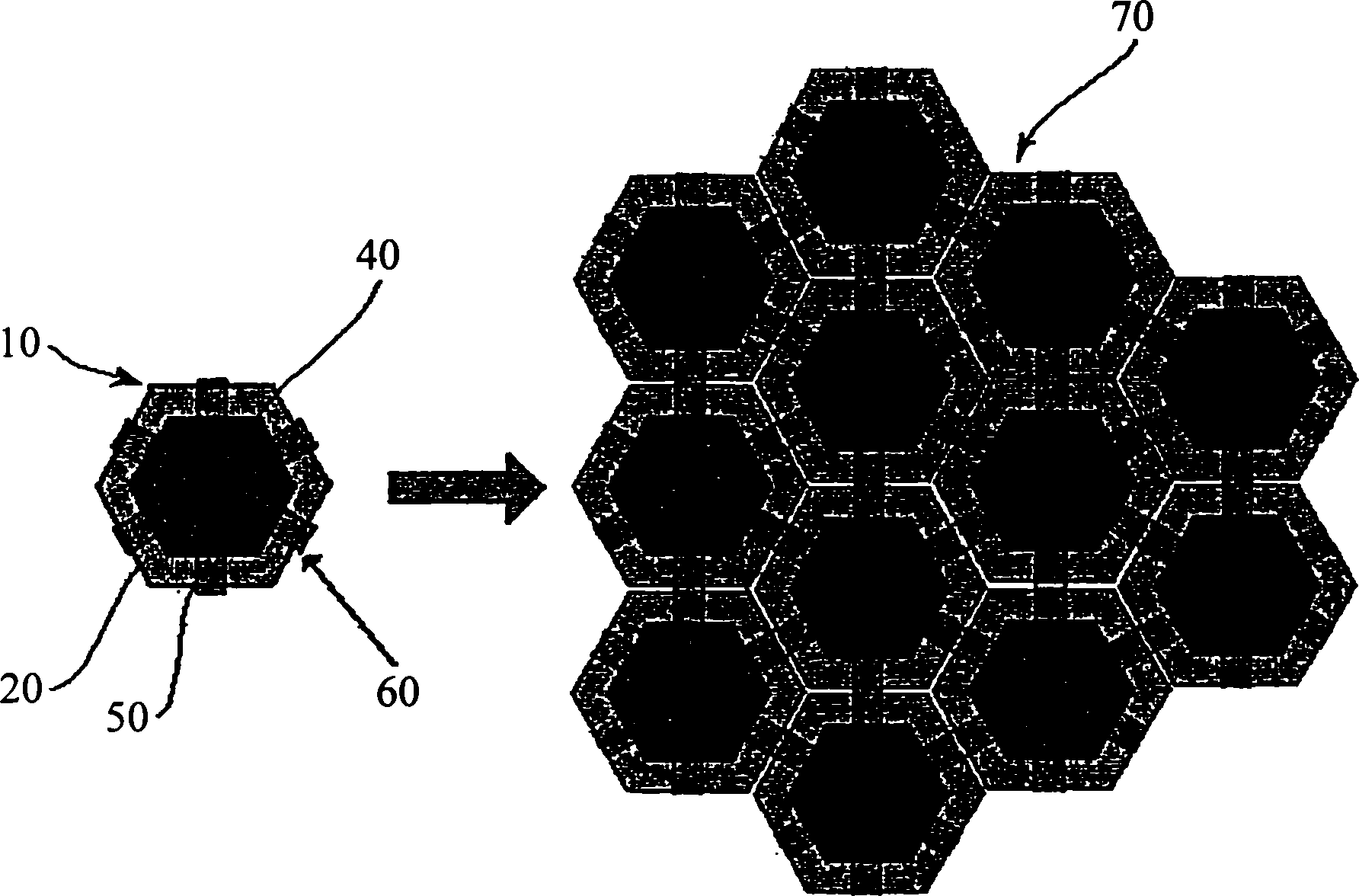

[0057] The heat medium ethylene glycol was circulated for 1 hour by the solar heat collection system using the panel 70 of this invention. The outside air temperature is 9.5 degrees and the insolation is 852J / S (average). The temperature of ethylene glycol was measured at outlet 90 and found to be 154°C.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more PUM

Login to view more

Login to view more Abstract

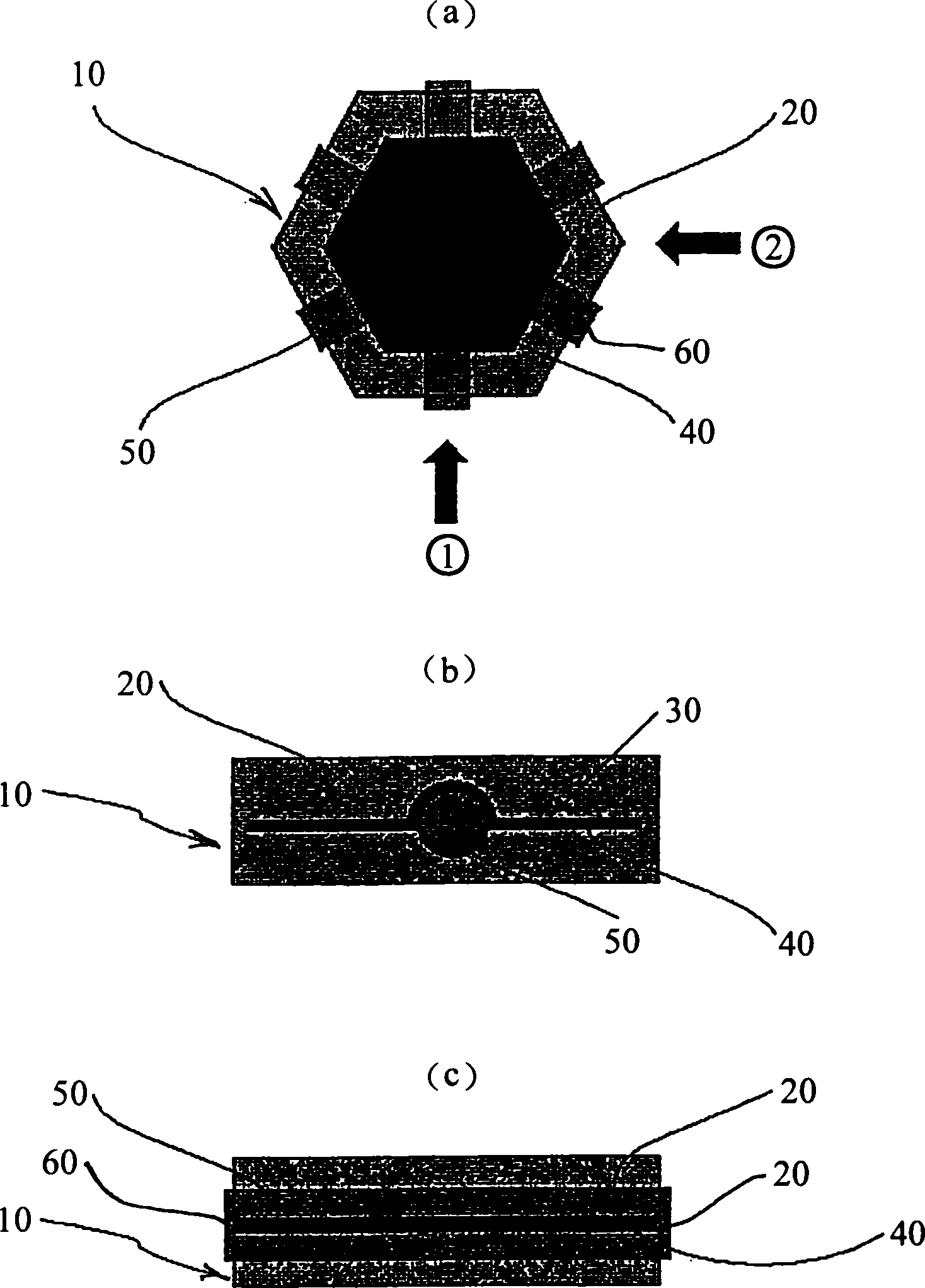

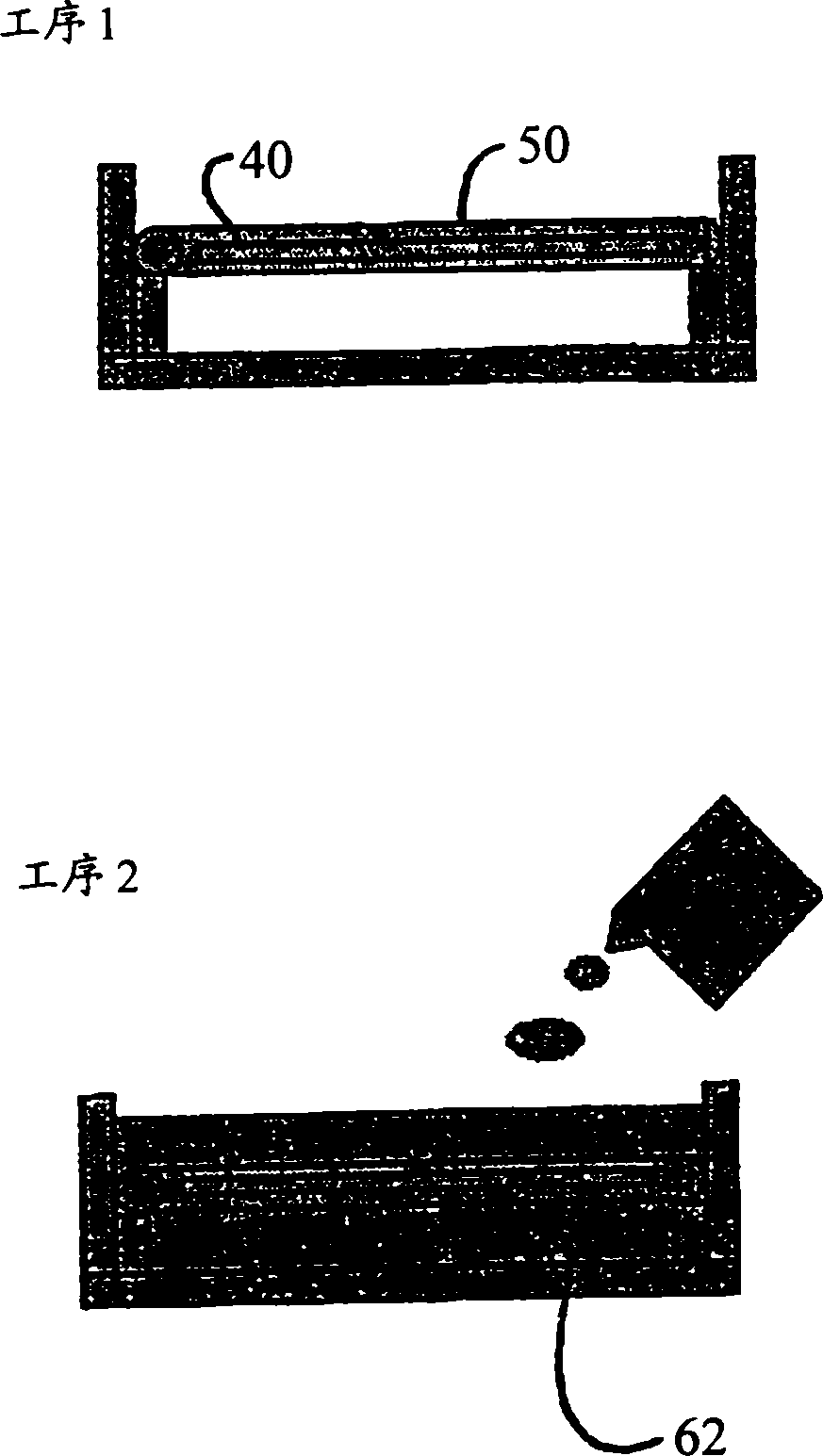

A solar heat collector panel unit, comprising a heat collecting plate, a heat medium pipe, and a transparent insulator which are formed integrally with each other. The heat collecting plate is coated with an MOxNy (Ti or Al is substituted for M) selective absorbing film. The transparent insulator is a silica aero-gel. Since the heat collecting plate is buried in the transparent insulator, the strength of the transparent insulator is increased. Accordingly, the transparent insulator such as the silica aero- gel can be used as the insulator of the solar heat collector panel unit, and the selective absorbing film, the heat collecting plate, and the heat medium pipe can be sealed without clearance. As a result, the convection of air does not occur, excellent insulation performance can be provided, and the panel can be reduced in weight and simplified in structure. Also, since the solar heat collector panel unit comprises a connector and is connected to an adjacent unit through the connector, the unit can be formed in a specified shape and/or size. The projected shape thereof is a regular polygon. When the units are connected to each other, the shape and/or size thereof can be set freely, and the units can be formed not only in a plan shape but also in a three-dimensional curved shape by improving the material and shape of the connector.

Description

technical field [0001] The invention relates to a solar heat collecting plate (flat solar heat collecting device). Background technique [0002] With increasing concerns over environmental issues and energy issues, the demand for solar thermal panels is increasing. [0003] The known solar heat collecting panels are mainly flat plate type and vacuum tube type, and the flat plate type which is simple in structure and easy to reduce cost is developing into the mainstream of solar heat collecting plate. [0004] The flat plate type requires high-performance heat insulation compared with the vacuum tube type because the heat loss due to convection and conduction is large. As a conventional flat-type heat insulation method, double glass is used for the lighting part, but this structure is heavy and requires a high-strength cabinet. [0005] Various studies have been made to improve the heat collection efficiency of flat-plate solar heat collecting panels, and are disclosed in J...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more IPC IPC(8): F24J2/20F24J2/04F24J2/46F24J2/48F24J2/50F24J2/51F24S10/50F24S10/70F24S10/75

CPCF24J2002/0038Y02E10/44F24J2/0488F24J2/4647F24J2/515F24J2/26F24S10/75F24S70/60F24S80/30F24S80/65F24S2020/10

Inventor 会泽守后藤裕介和泉博明

Owner DAINATSUKUSU

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap