Pipeline ring hollow cleaning assembly

A technology for cleaning components and annulus, which is applied in the direction of cleaning hollow objects, cleaning methods and tools, chemical instruments and methods, etc. It can solve the problems of no sealing function, lack of annulus cleaning equipment, and inconvenient maintenance of pipelines, etc., so as to achieve simple operation , Simple structure, easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to have a clearer and more comprehensive understanding of the characteristics, effects and technical objectives of the annulus cleaning assembly of the present invention, the specific embodiments of the present invention will now be described with reference to the accompanying drawings.

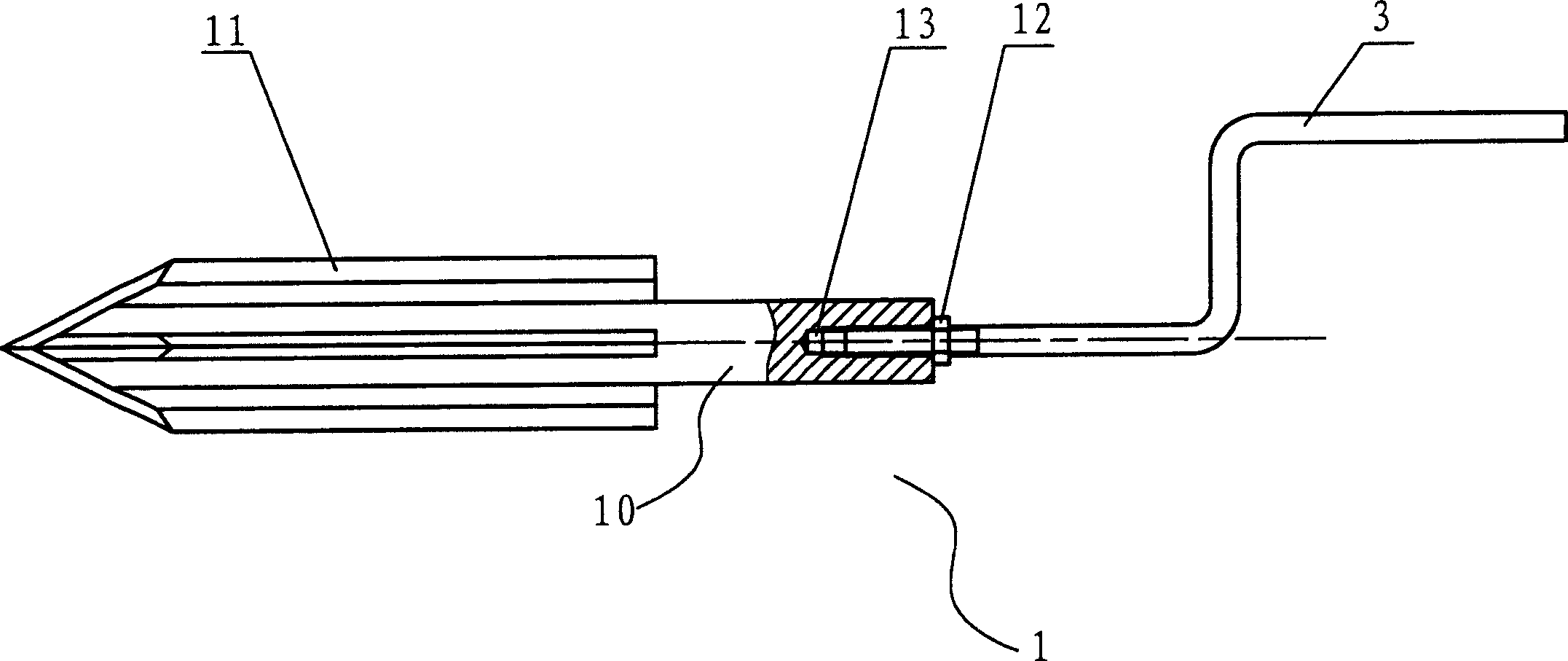

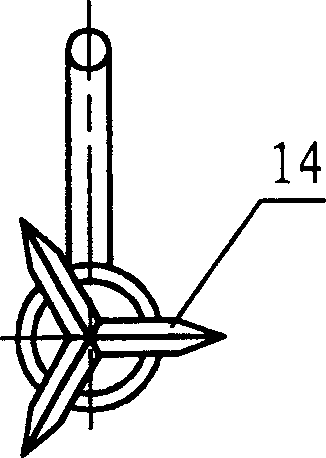

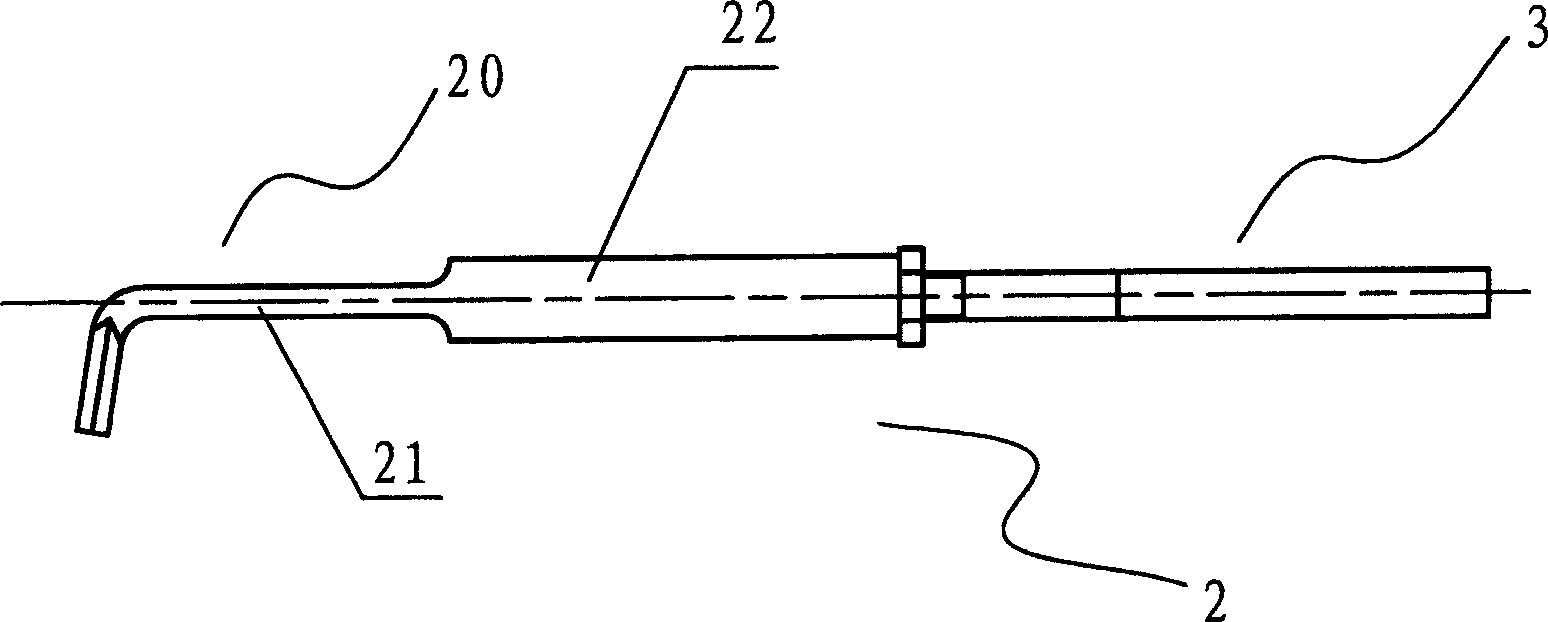

[0024] See figure 1 with 3 , which are respectively schematic diagrams of embodiments of the crushing tool and the clearing tool in the pipeline annulus cleaning assembly of the present invention. The pipeline annulus cleaning assembly of the present invention includes a crushing tool 1 and a cleaning tool 2. The crushing tool 1 is used to initially crush the filling, and the cleaning tool 2 is used to plan out the filling and further clean out the pipe wall. filling on top.

[0025] See figure 1 with 2 The crushing tool 1 in the pipeline annulus cleaning assembly of the present invention includes a multi-edged cutter head 11 with a tapered front end and a handle 3, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com