Method and device for causing a ship to dive by using additional buoyancy

A technology with additional buoyancy and buoyancy, applied in the direction of buoyancy, transportation and packaging, slipway, etc., can solve problems such as low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The preferred specific implementation manners of the present invention will be described in detail below with reference to the accompanying drawings.

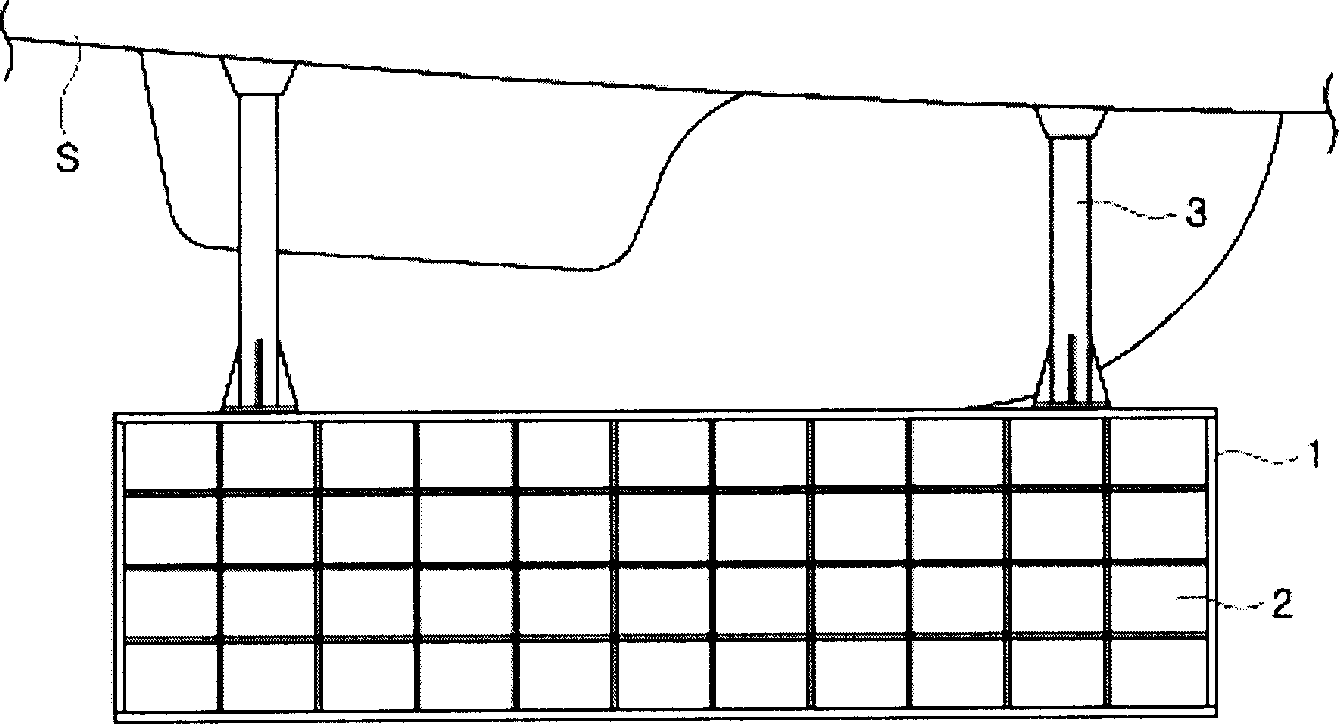

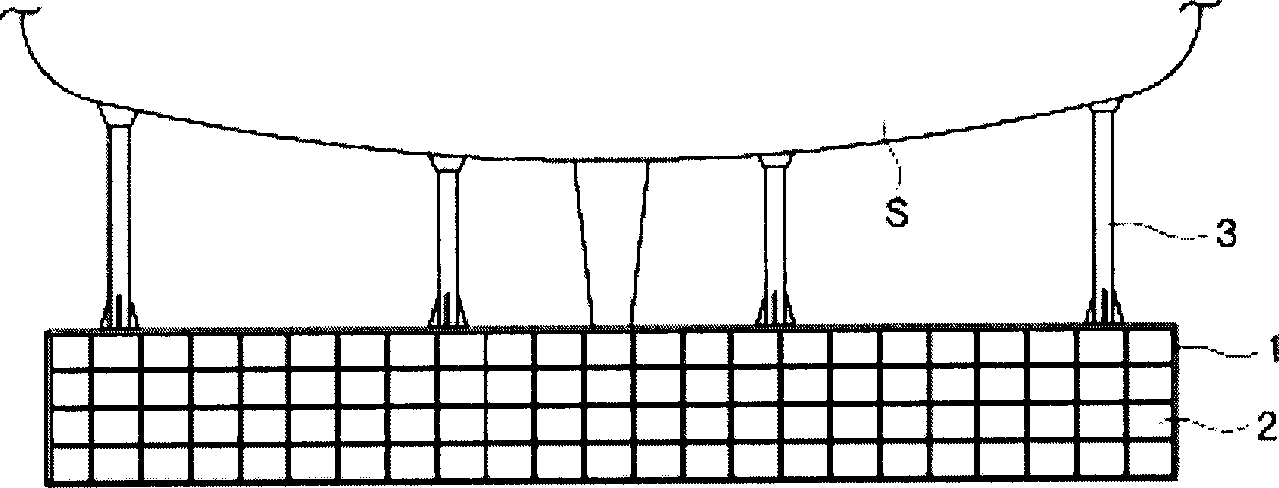

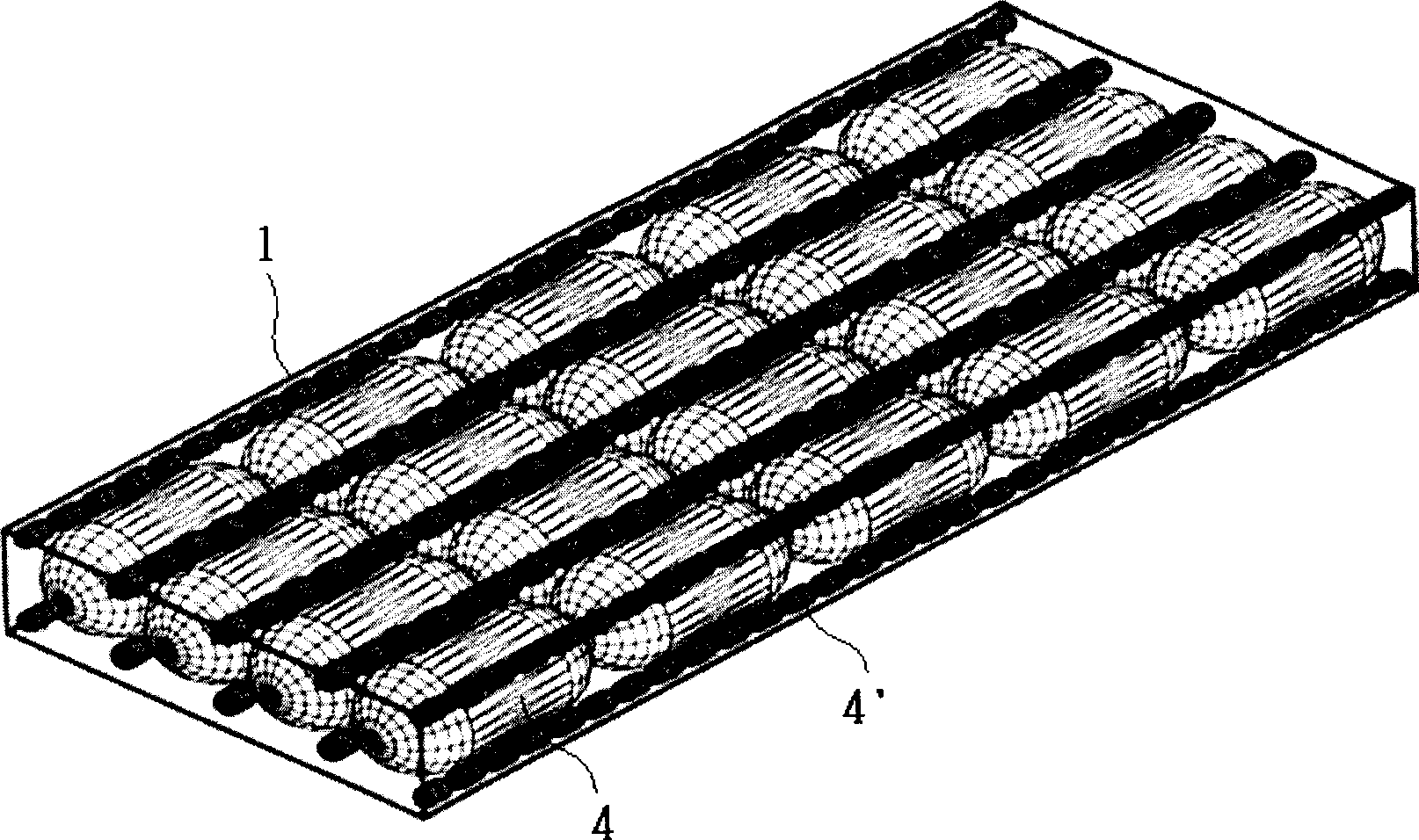

[0026] figure 1 and figure 2 are respectively a front view and a side view of a device for launching a ship using additional buoyancy according to an embodiment of the present invention in an installed state, and image 3 yes figure 1 and figure 2 Perspective view of the buoyancy cabinet of the shown device. refer to Figure 1 to Figure 3 , the device according to one embodiment of the present invention includes a buoyancy cabinet 1 for placing a buoyancy body therein, a buoyancy body 2 placed in the buoyancy cabinet 1 to generate buoyancy; The buoyancy cabinet 1 is installed on the bottom surface of the hull, and the buoyancy cabinet 1 is connected to the hull by welding, so that the additional buoyancy generated can act on the hull evenly.

[0027] The buoyancy cabinet 1 is manufactured to have a lattice shape....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com