Method and apparatus for carrying a plate-shaped part

A technology for handling devices and objects, which is applied in the direction of transportation and packaging, conveyor objects, chucks, etc. It can solve the problems of difficult position control, large-scale handling devices, and large handling loads, and achieve the effect of less contact and less deflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

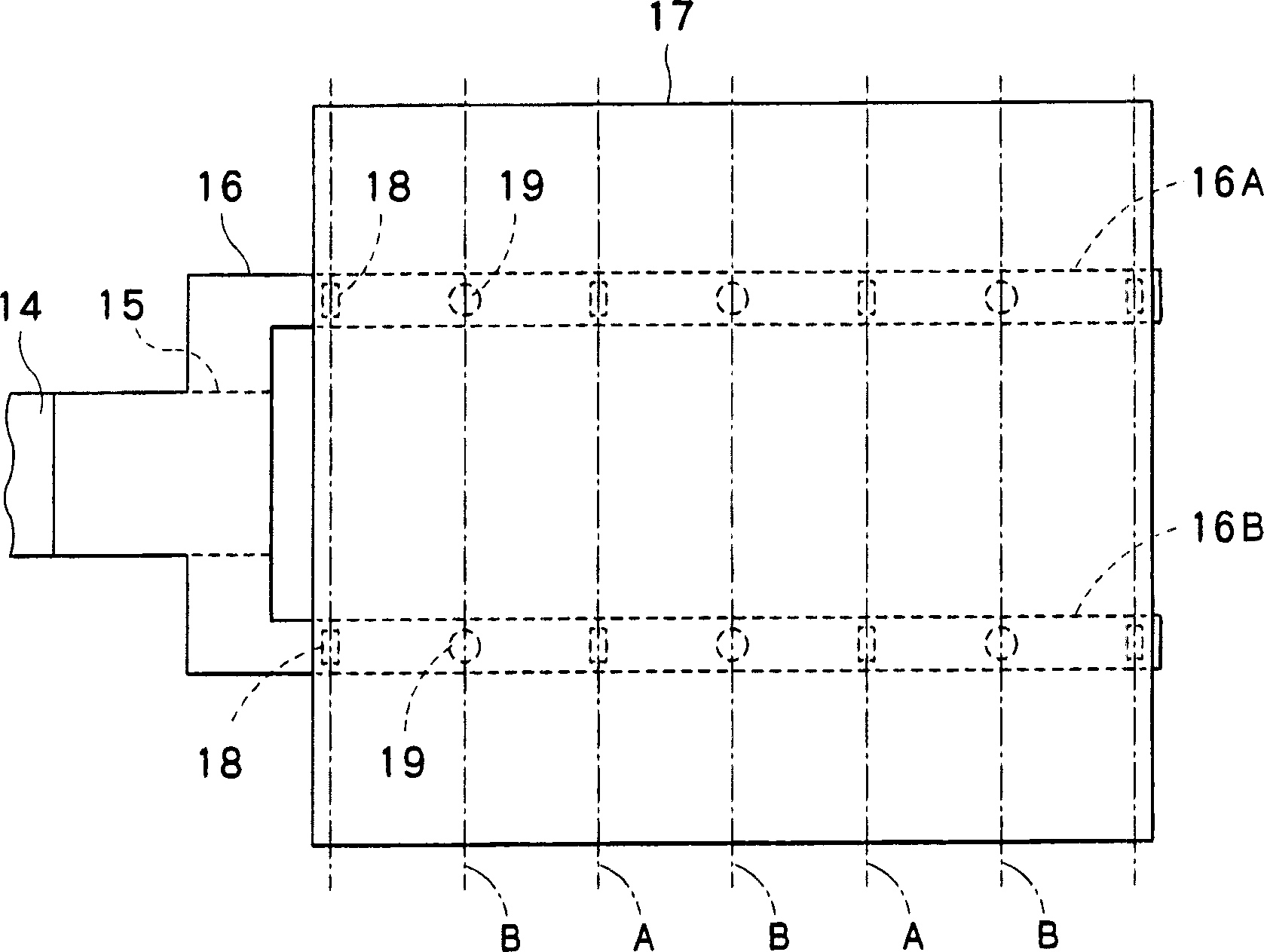

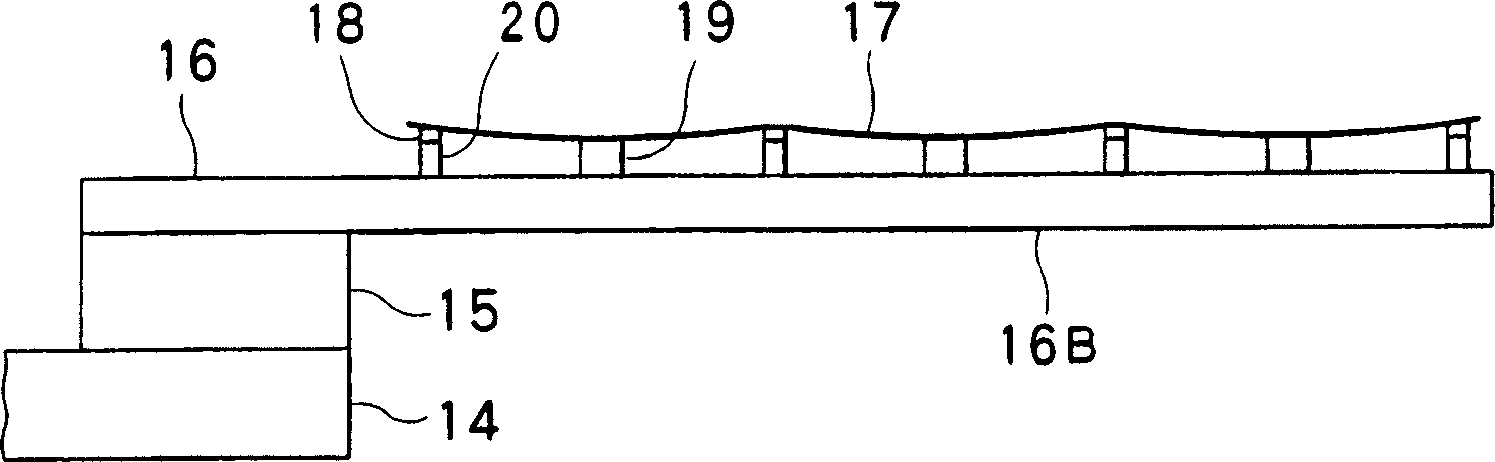

[0053] use Figure 2 to Figure 3 As shown in the figure, the illustrated fork 16 holds a glass plate-shaped carrier 17 of the following size and thickness. among them,

[0054] The size of the flat conveying object 17: length×width×thickness=1500mm×1000mm×1mm

[0055] Interval between fingers 16A and 16B = 600mm

[0056] The distance between the gasket 18 and the suction part 19 = 240mm

[0057] The height difference between the pad 18 and the suction part 19 during suction = 2mm

[0058] At this time, the amount of deflection in the width direction of the flat conveyed object 17 = 8 mm.

[0059] In contrast, as Comparative Example 1, when the suction portion 19 is replaced with a pad 18, that is, all the pads 18 are the same height, and the other conditions are the same as in the above-mentioned Example 1, the amount of deflection in the width direction is It is 9mm.

[0060] use Figure 4 to Figure 5 As shown in the figure, the illustrated fork 26 holds a glass plate-shaped carri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com