Flat-type cold cathode fluorescent lamp

A cold-cathode fluorescent lamp, flat type technology, applied in the direction of discharge lamps, gas discharge lamps, parts of gas discharge lamps, etc., can solve the problems of uneven brightness of the light-emitting surface, reduced luminous flux, etc., to suppress uneven brightness and improve luminous flux Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

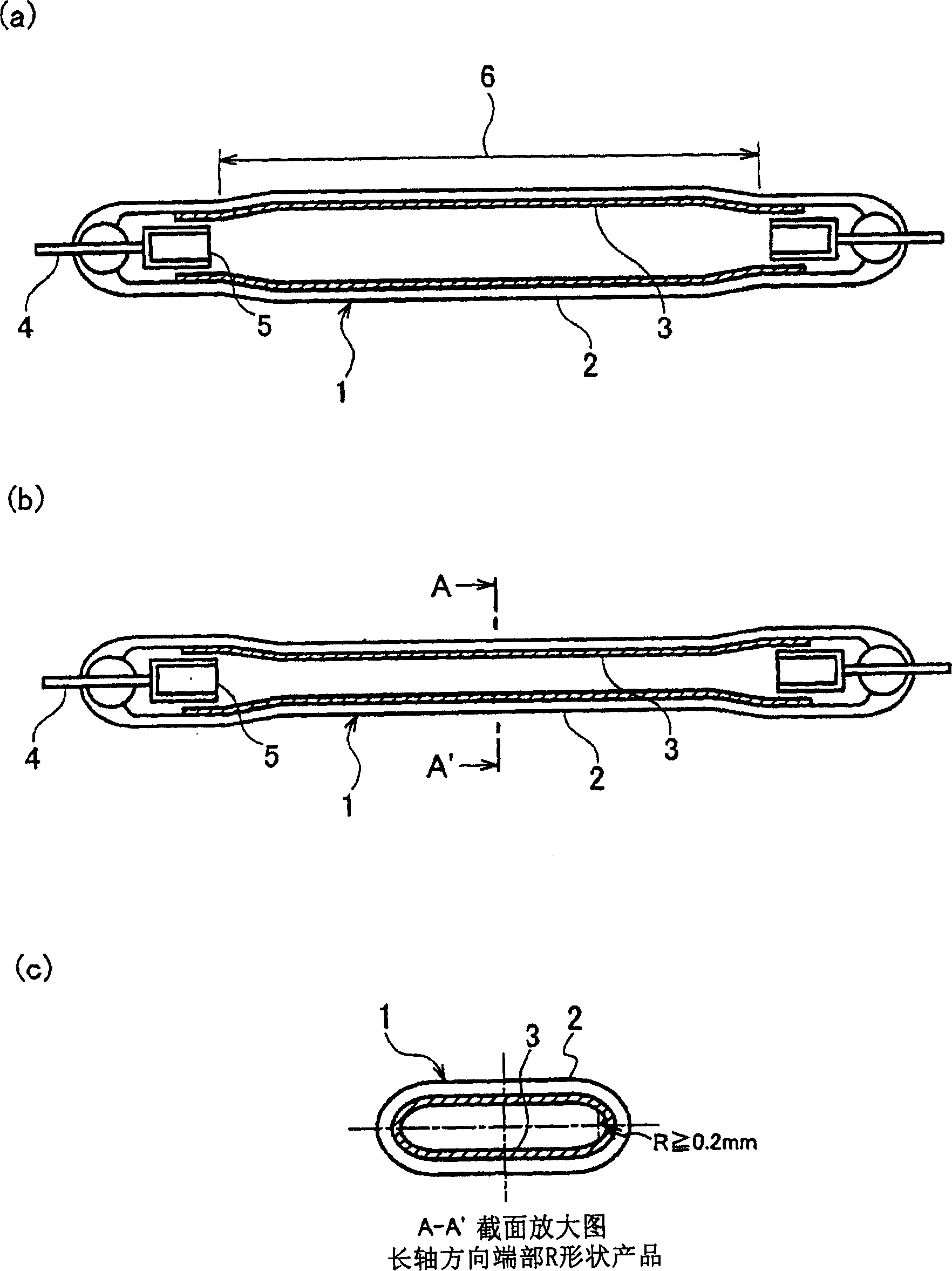

[0042] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

[0043] (first embodiment)

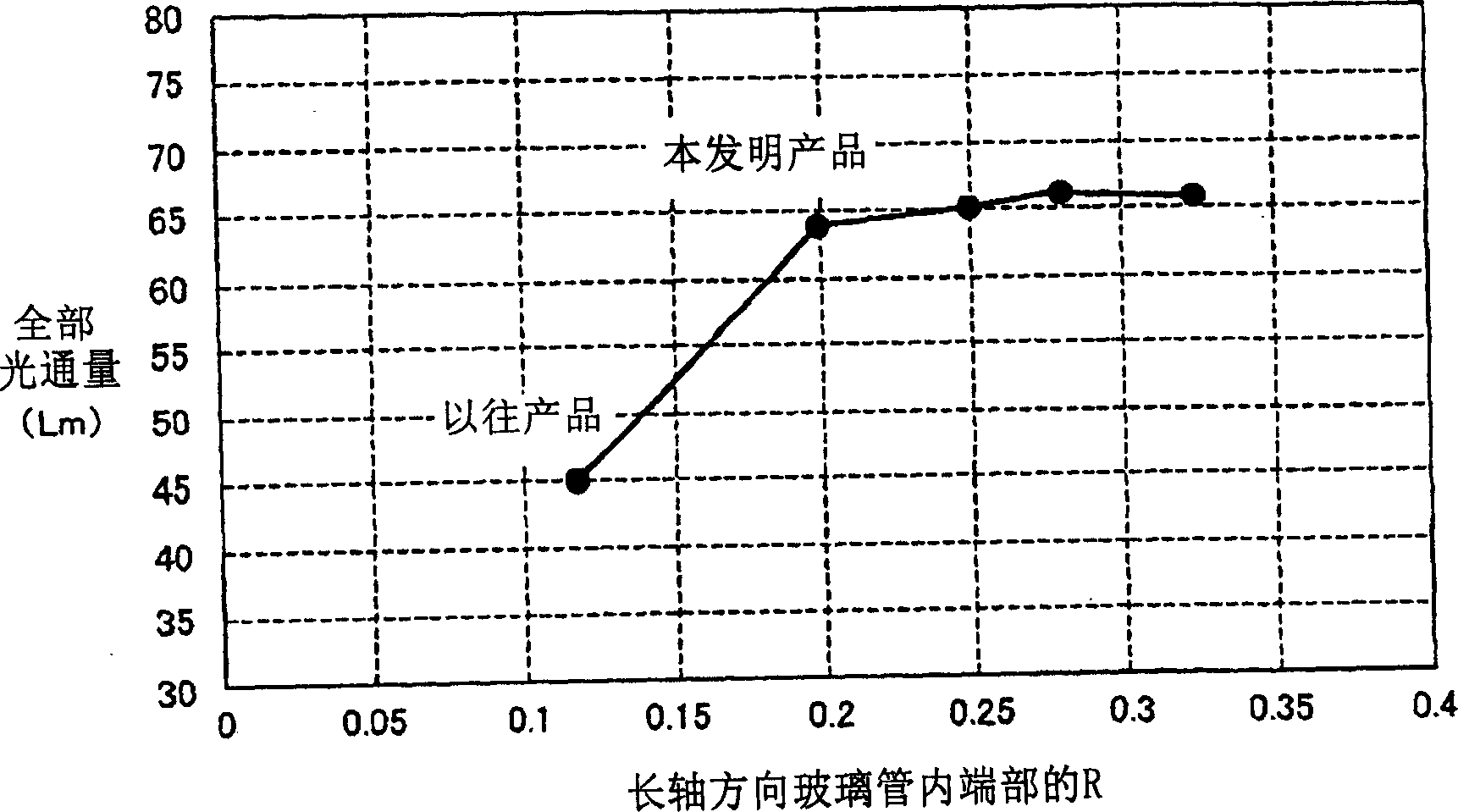

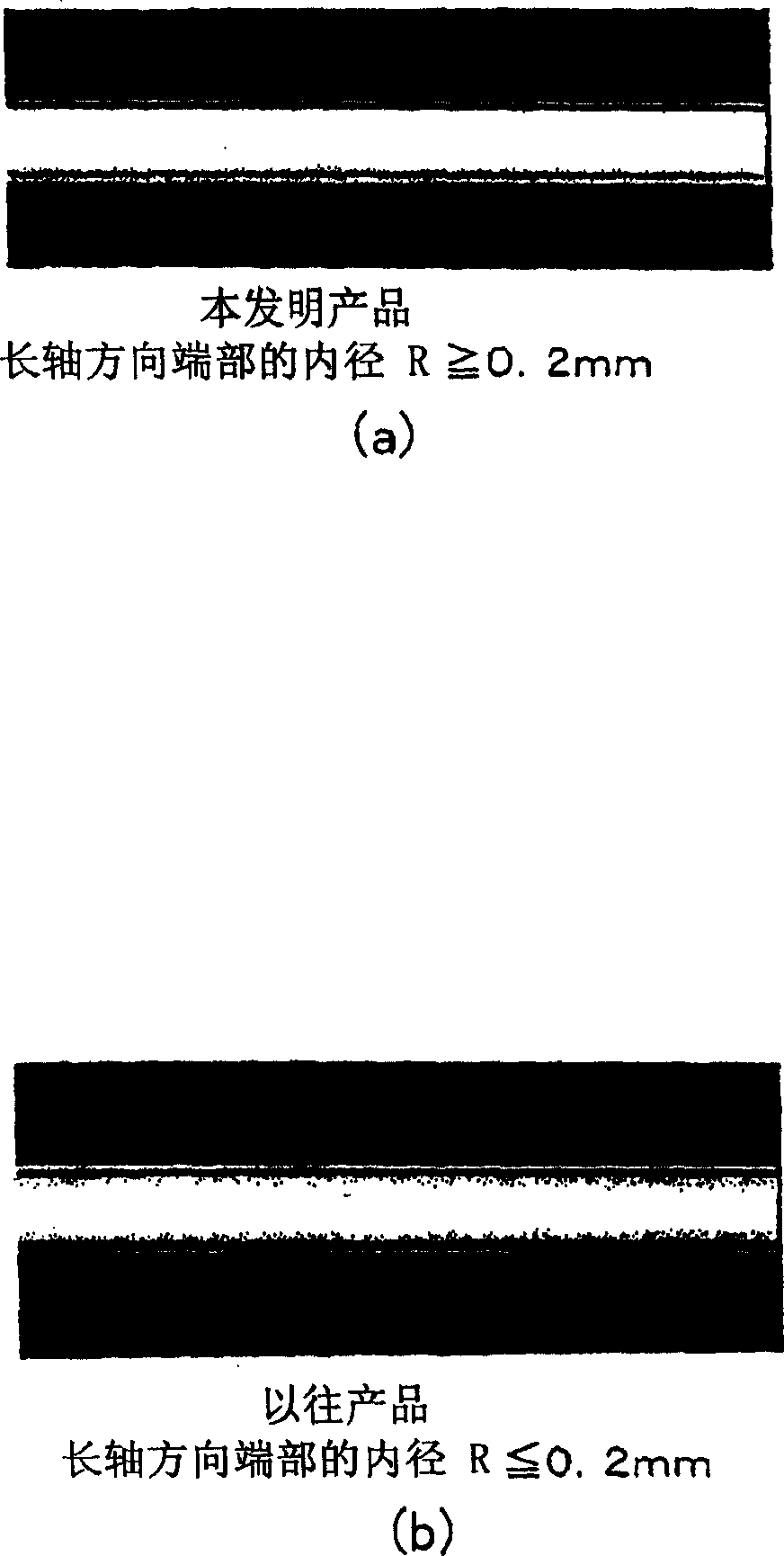

[0044] In a first embodiment of the present invention, in the flat cold cathode fluorescent lamp, the inner diameter of the longitudinal end in the discharge space is R≧0.2 mm.

[0045] figure 1 The short axis direction of the flat processed part of the flat cold cathode fluorescent lamp is constant, and the inner diameter (radius) R of the R part at the end of the long axis direction in the discharge space is changed, and it is confirmed that the brightness unevenness of the light emitting surface and the entire lamp Limit value for luminous flux reduction. If the inner diameter of the longitudinal end in the discharge space is R≦0.2 mm as in the conventional case, it is found that the anode beam is difficult to spread to the longitudinal end, and the total luminous flux of the lamp is significantly reduced.

[0046] figure 2...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap