Self-adhering and environmental-protective flock cloth and its production

A production method and self-adhesive technology, which is applied in the fields of shockproof, thermal insulation materials, and self-adhesive sound insulation, can solve problems such as inconvenience to the human body or the environment, and adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

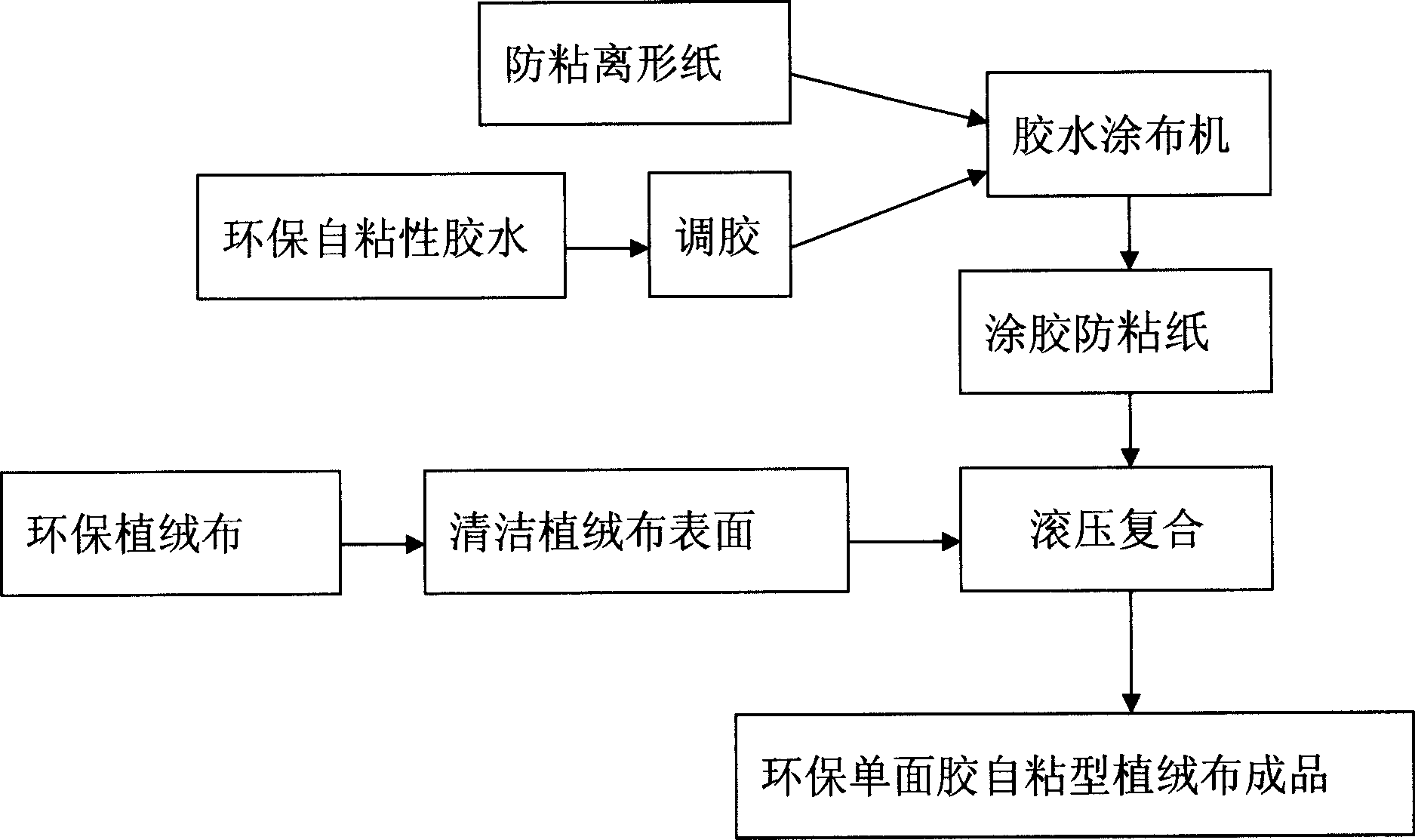

[0010] Embodiment 1: Method for making self-adhesive flocking cloth with single-sided adhesive

[0011] to combine figure 1 . Clean the surface of the raw material of the environmentally friendly flocking cloth, and use a detergent to clean it for later use. Put a kind of anti-adhesive functional paper coated with anti-adhesive silicone oil on one side - kraft anti-adhesive release paper on the paper holder at the end of the oil glue coating machine (QLD-1092 type), and use the guide cloth and anti-adhesive release paper After bonding, start the conveyor belt so that it enters between the rollers of the coating machine. Then adjust the width of the glue tank according to the width of the material, and use a feeler gauge to adjust the gap between the knife edge of the coating machine and the roller, so that the thickness of the glue coating can meet the specified requirements. The thickness of the commonly used glue coating is between 0.01mm-0.2mm. Pour the environmentally ...

Embodiment 2

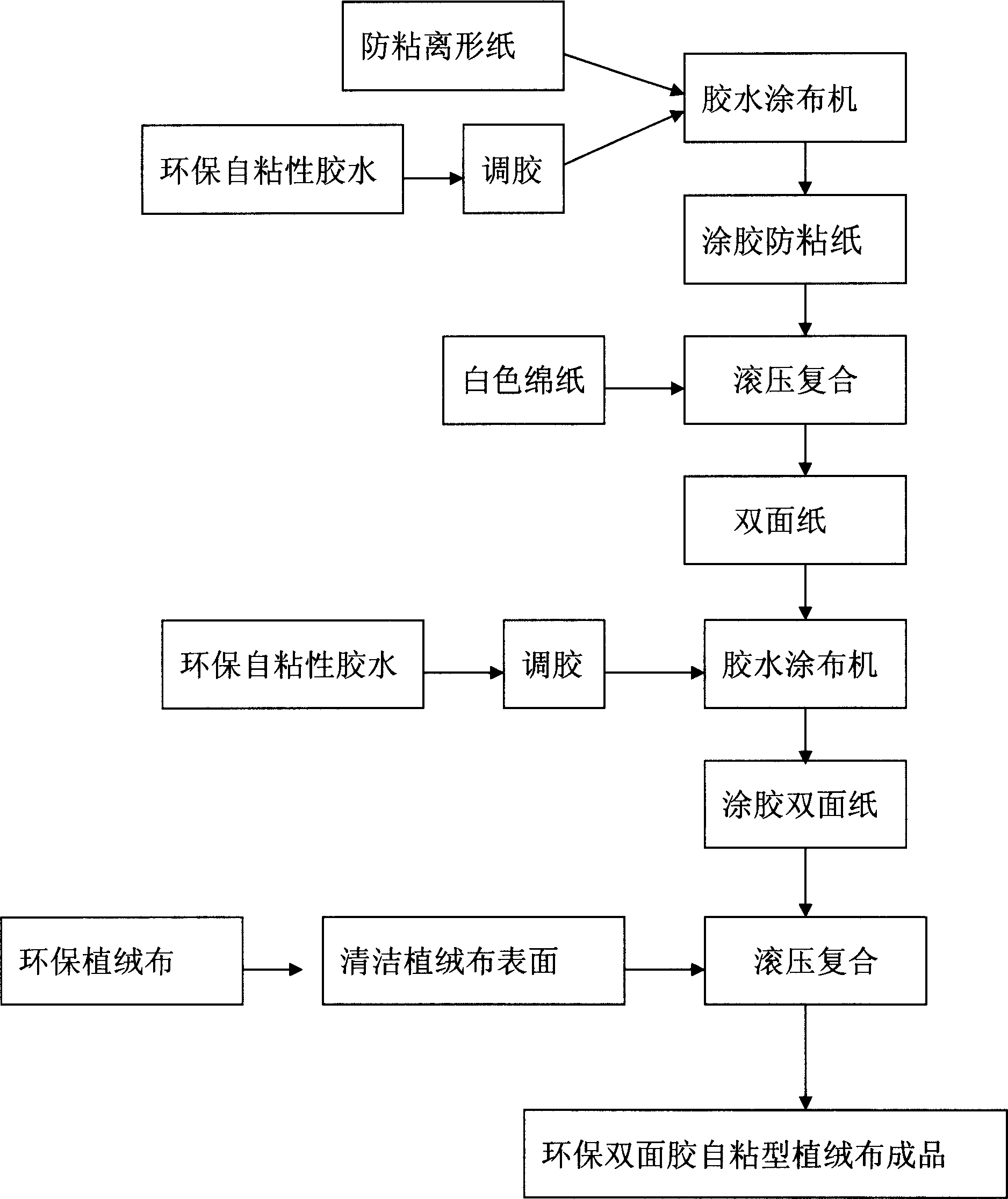

[0012] Embodiment two: double-sided adhesive self-adhesive type flocking cloth production method

[0013] The first process: anti-adhesive functional paper and reinforced functional paper are glued and compounded (referred to as double-sided paper).

[0014] will combine figure 2 . Put a kind of reinforced functional paper - white tissue paper on the paper holder at the end of the coating machine, adjust the distance to wait for processing. Put the anti-adhesive functional paper--kraft anti-adhesive release paper on the paper frame at the end of the oil glue coating machine (QLD-1092 type), bond it with the anti-adhesive release paper with the guide cloth, and start the conveyor belt to make it enter between the nip rolls of the coater. Then adjust the width of the glue tank according to the width of the material, and use a feeler gauge to adjust the gap between the knife edge of the coating machine and the roller, so that the thickness of the glue coating can meet the spe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap