Contact holding structure of connector

A technology for maintaining structures and connectors, applied in the direction of connection, components of connection devices, fixed/insulated contact components, etc., can solve problems such as falling off, and achieve the effect of simple structure, no increase in the number of devices, and easy assembly and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

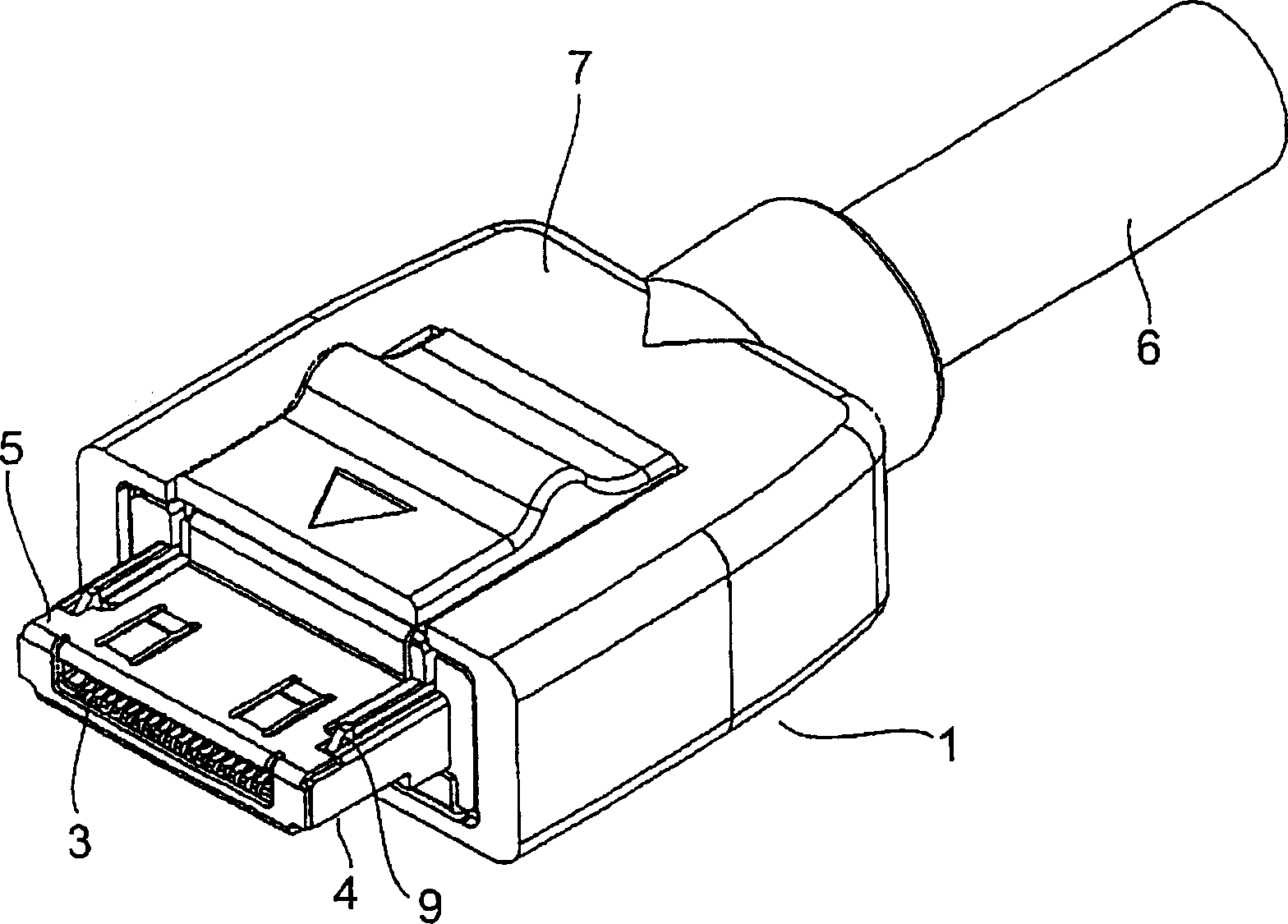

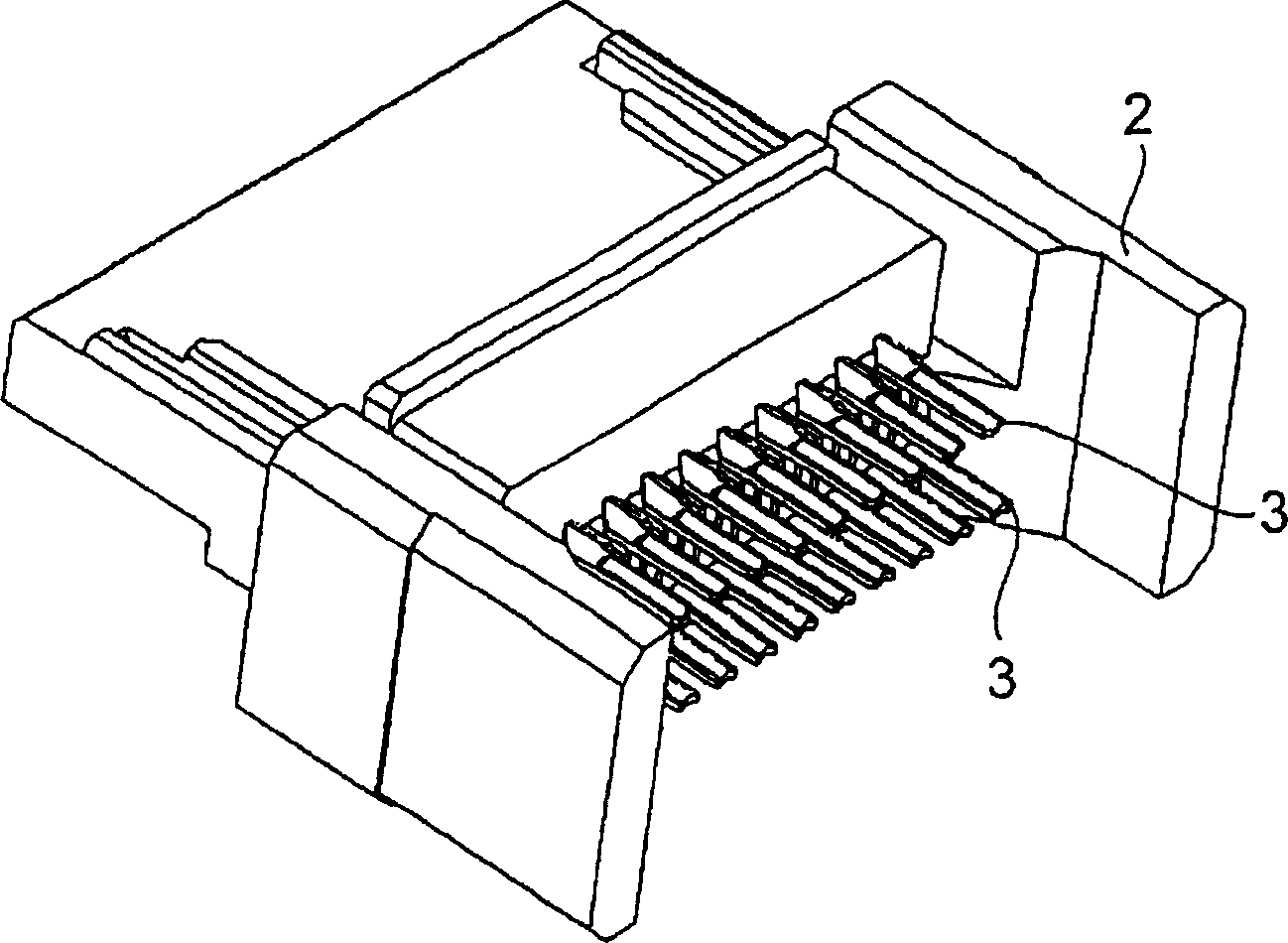

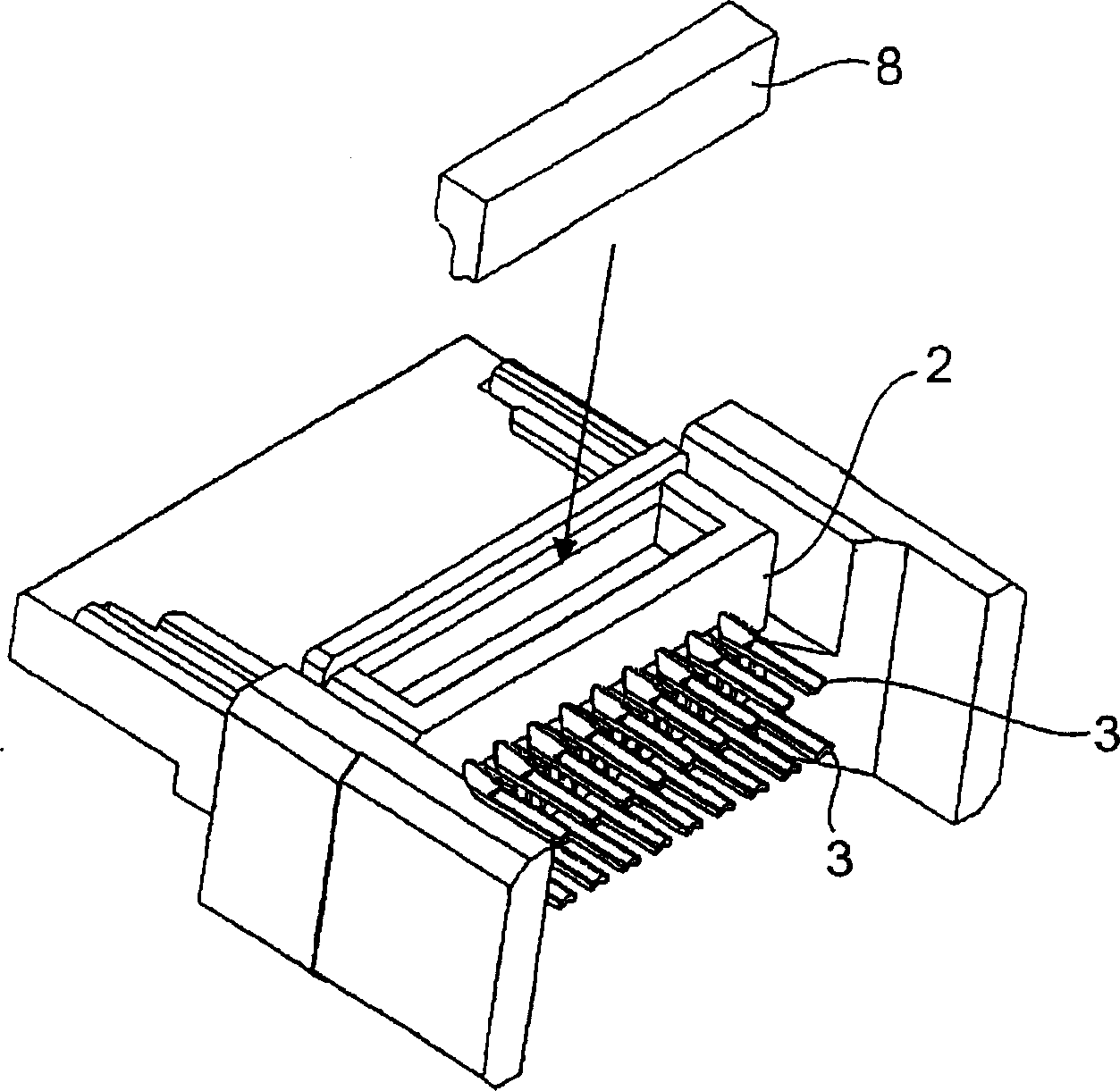

[0041] refer to Figure 1 to Figure 6 , to illustrate the plug connector of Embodiment 1 of the present invention. figure 1 is a perspective view viewed from the front side of the plug connector, figure 2 It is a perspective view viewed from the rear side of the plug connector before attaching a hood, etc., image 3 It is a perspective view viewed from the back side of the plug connector before the retainer (the member that fixes the contacts in the insulator) is installed in the insulator, Figure 4 is a perspective view viewed from the rear side of the plug connector with the retainer installed in the insulator, Figure 5 is a sectional view showing the state before the contact is installed in the insulator, Figure 6 The upper side of shows the cross-sectional view when the contact is installed deeply in the insulator, Figure 6 The lower side of the shows a cross-sectional view of the contact installed shallowly in the insulator.

[0042] First, refer to Figure 1 ...

Embodiment 2

[0051] refer to Figure 7 , to illustrate the second embodiment of the present invention. In the first embodiment, the contacts 3 are arranged in one row. On the other hand, in the second embodiment, the contacts 3 are arranged so as to face each other in two rows of upper and lower layers, and the holders 8 are inserted into the insulator 2 from the upper and lower directions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com