Seal moving device for remote network seal machine

A remote network and mobile device technology, applied in the field of seal mobile devices, can solve problems such as time delay, troublesome seal identification, economic loss, etc., and achieve the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

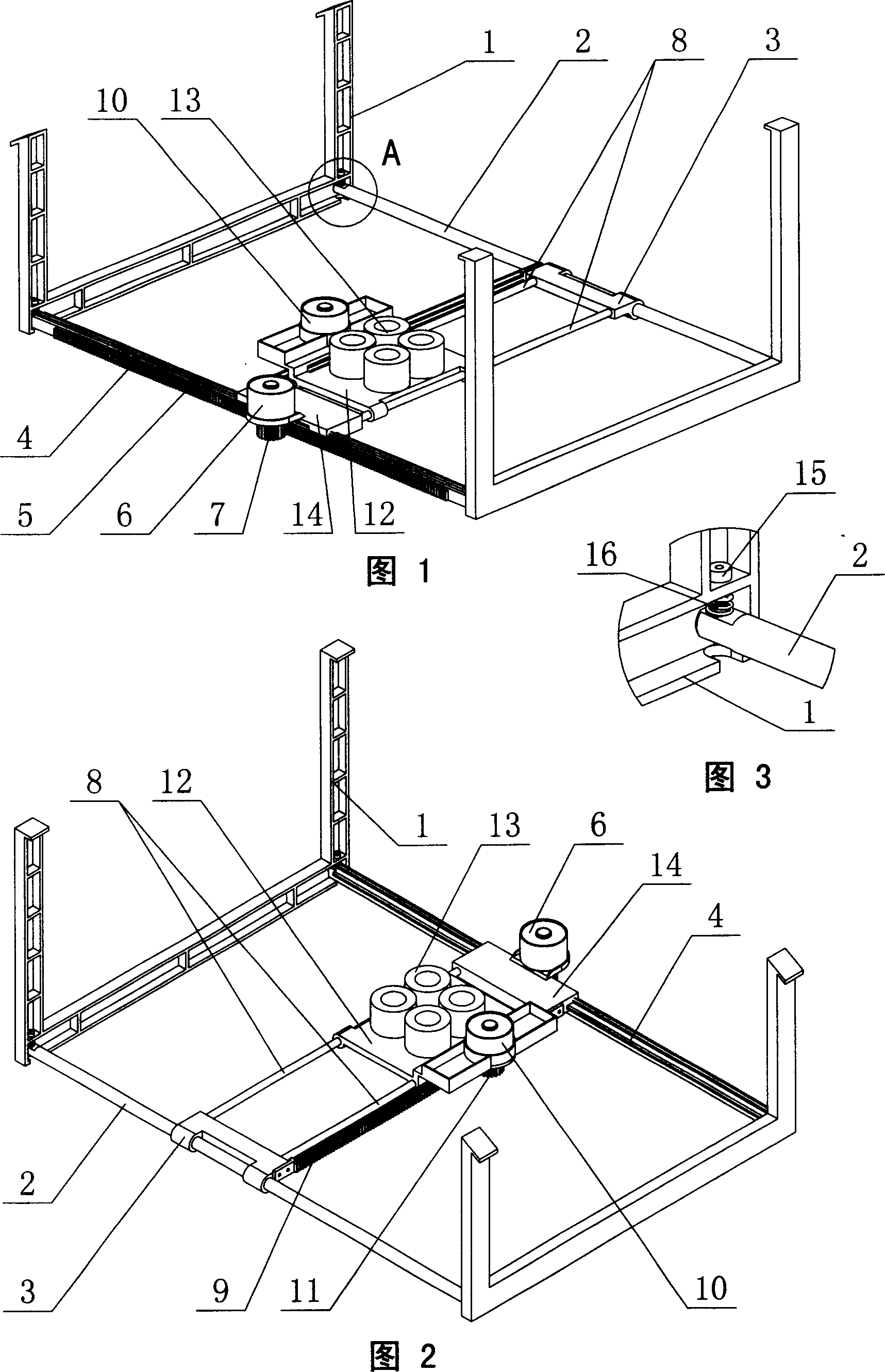

[0025] As shown in Fig. 1, Fig. 2, Fig. 3, the present invention comprises fixed support 1, longitudinal driving mechanism, transverse driving mechanism, mobile support 12, and stamp holding device 13 is fixed on the described mobile support 12, and described longitudinal driving mechanism Connected with the fixed bracket 1, the longitudinal drive mechanism includes a longitudinal motor 6, an I longitudinal guide rail 2, and an II longitudinal guide rail 4, and the I longitudinal guide rail 2 and the II longitudinal guide rail 4 are parallel to each other and are connected to the fixed bracket 1 is connected, the output shaft of the longitudinal motor 6 is fixedly connected to the I gear 7, the I longitudinal guide rail 2 is smooth and cylindrical, and the II longitudinal guide rail 4 is provided with a guide rail groove and an I rack 5.

[0026] Described transverse driving mechanism comprises transverse motor 10, two smooth cylindrical transverse guide rails 8 parallel to eac...

Embodiment 2

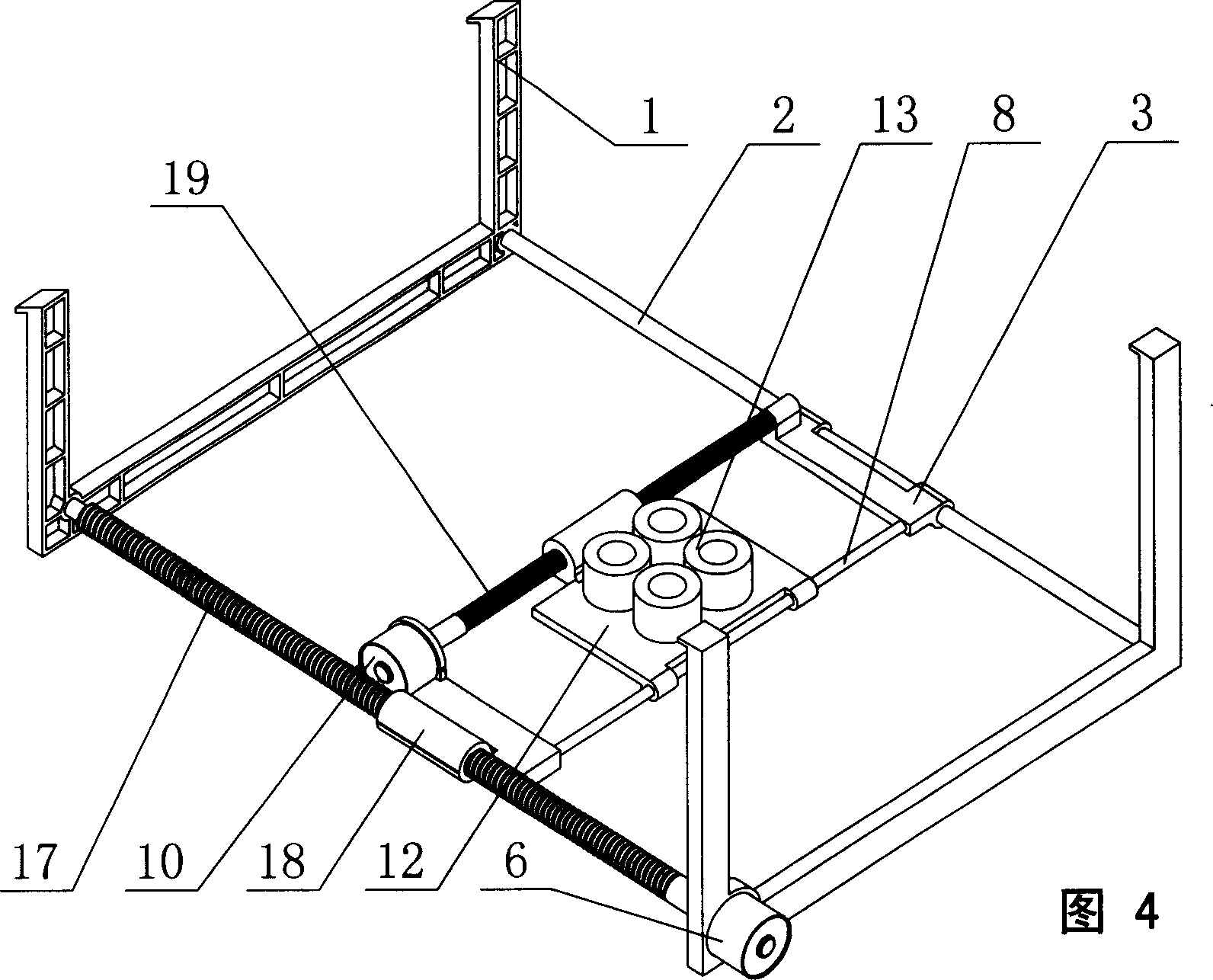

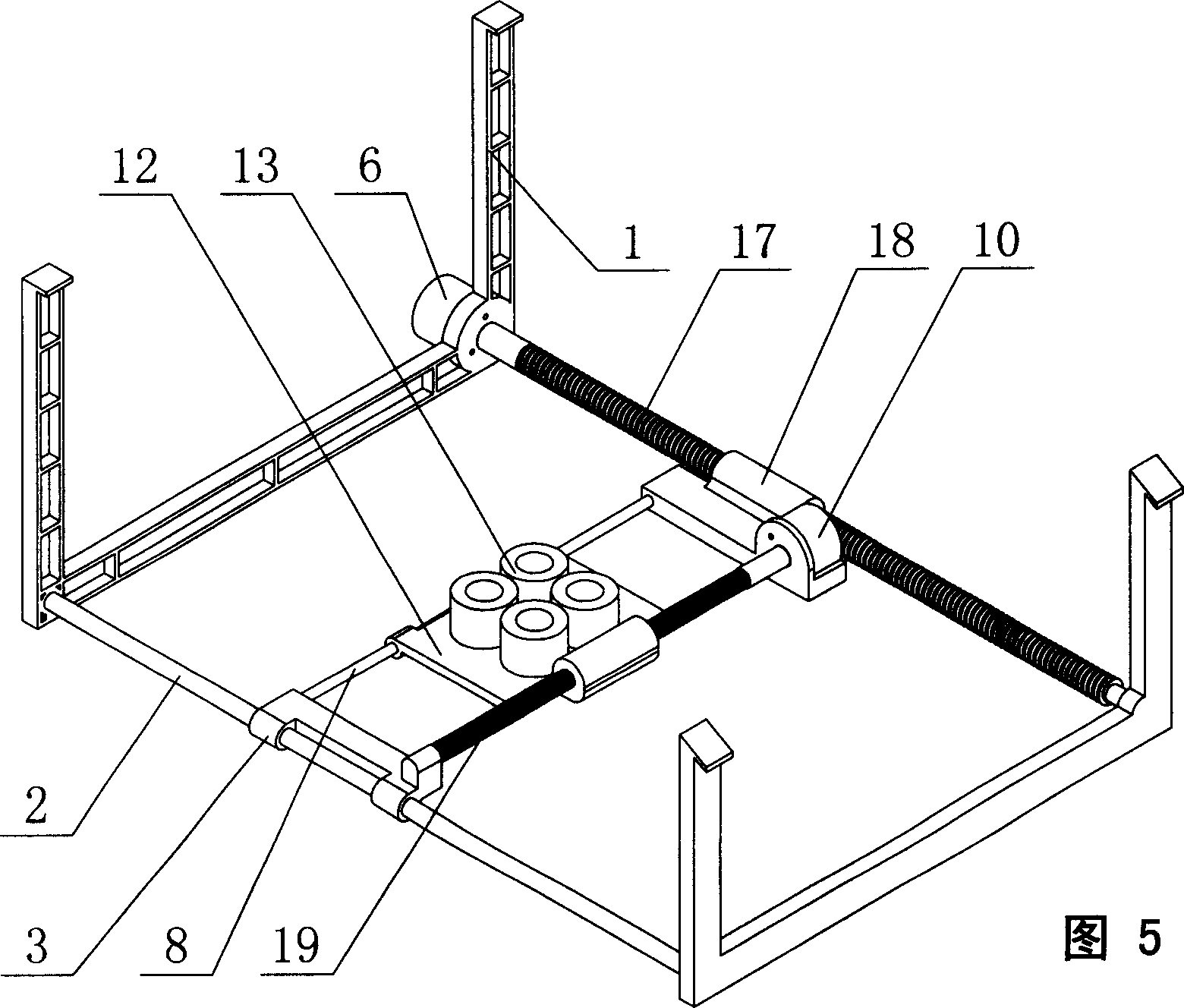

[0030] As shown in Fig. 4 and Fig. 5, the present embodiment includes a fixed support 1, a longitudinal drive mechanism, a lateral drive mechanism, and a movable support 12, and a stamp clamping device 13 is fixed on the movable support 12, and the longitudinal drive mechanism is connected to the movable support 12. Described fixed bracket 1 is connected, and described longitudinal driving mechanism comprises longitudinal motor 6, I longitudinal guide rail 2, longitudinal lead screw 17, and described I longitudinal guide rail 2, described longitudinal lead screw 17 are parallel to each other and with described fixed support 1 connected, the longitudinal motor 6 is fixedly connected to the fixed bracket 1 , and the output shaft of the longitudinal motor 6 is fixedly connected to the longitudinal lead screw 17 .

[0031]Described transverse driving mechanism comprises transverse motor 10, transverse guide rail 8, transverse leading screw 19, and described 1 longitudinal guide rai...

Embodiment 3

[0034] Such as Figure 6 , Figure 7 , Figure 8 As shown, the present embodiment includes a fixed bracket 1, a longitudinal drive mechanism, a lateral drive mechanism, and a movable bracket 12, and a seal holding device 13 is fixed on the movable bracket 12, and the longitudinal drive mechanism is connected with the fixed bracket 1 , the fixed bracket 1 includes two longitudinal beams 20, two cross beams 21, the longitudinal drive mechanism includes a longitudinal motor 6, two endless gear belts 23 parallel to the longitudinal beams 20, four III gears 22, two One main shaft 25, four auxiliary shafts 26, the rotating shaft of the III gear 22 is fixed on the two ends of the beam 21, the longitudinal motor 6 is fixedly connected to the fixed bracket 1, and the output shaft of the longitudinal motor 6 is connected to a The III gear 22 is fixedly connected, and the two main shafts 25 are arranged in parallel. Each of the two ends of the main shaft 25 has a notch, and the notch is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com