Evaporation system

A technology of evaporation equipment and evaporator, which is applied in the directions of evaporation, total evaporation, multi-effect evaporation, etc., and can solve the problem of the limitation of the number of evaporator stages in series.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

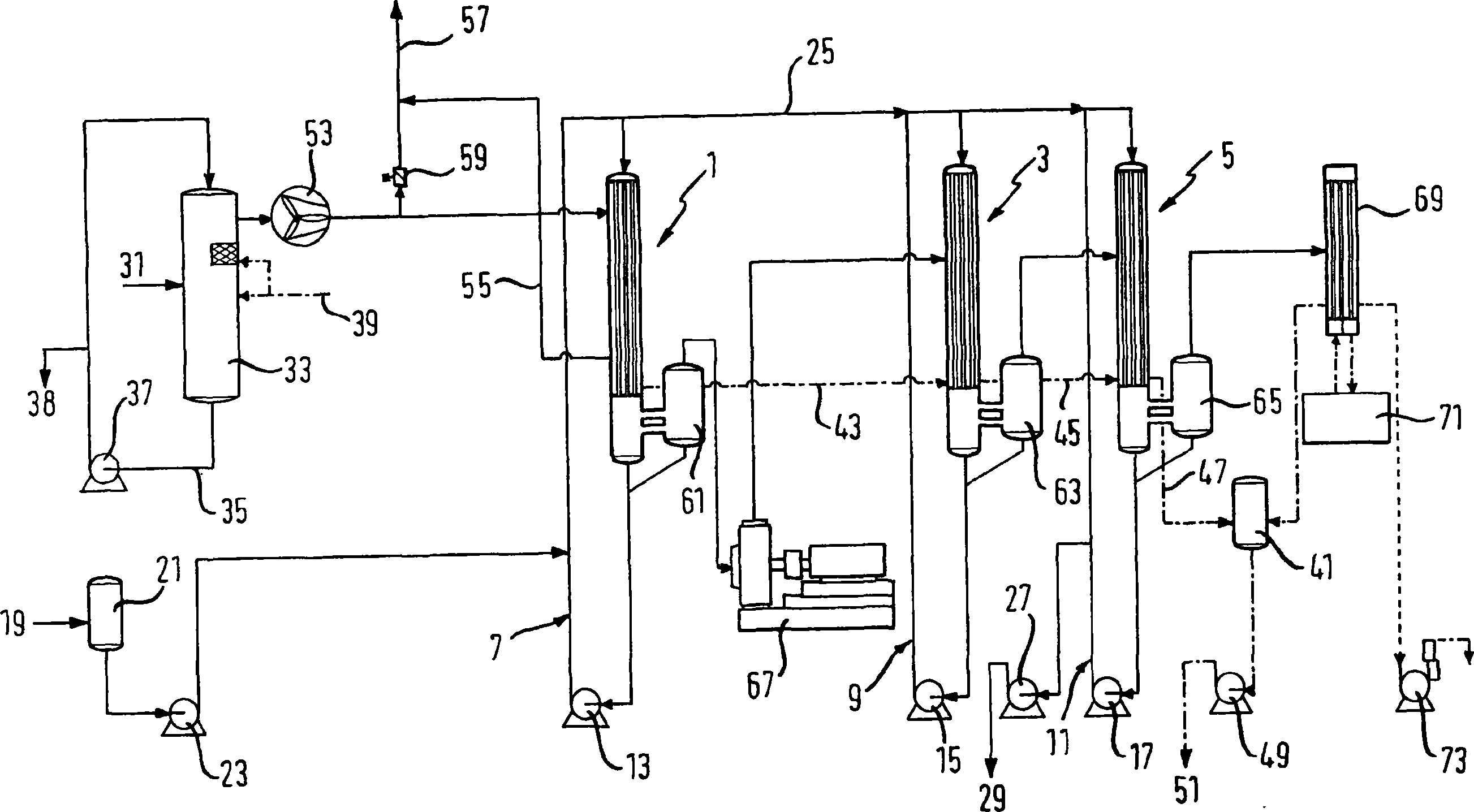

[0010] The evaporation plant comprises three evaporator stages 1 , 3 , 5 each formed as a down-flow evaporator, each evaporator stage comprising a product circulation circuit 7 , 9 or 11 with a circulation pump 13 , 15 or 17 . The product to be evaporated, supplied at 19 via a buffer container 21 and a delivery pump 21, is fed into the circulation circuit 7 of the first evaporator stage 1 and is usually supplied via this circulation circuit 7 to the evaporator chamber of the evaporator stage 1 in the upper area. In the same way, the product to be evaporated also reaches the circulation loop 9 , 11 of the evaporator stages 3 , 5 via the line 25 . The evaporated concentrate is discharged at outlet 29 by means of delivery pump 27 .

[0011] The heating energy required to heat the evaporator stages 1, 3 and 5 uses the superheated steam-air-mixture from a dryer stage not shown in detail, which mixture is fed at 31 to a spray-wet-scrub column 33, This washing column removes dust e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com