Prism three-beam-splitting system

A three-splitting, total reflection prism technology, applied in the field of three-splitting optical systems, can solve the problems of asynchrony, increased influence, complicated equipment structure, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

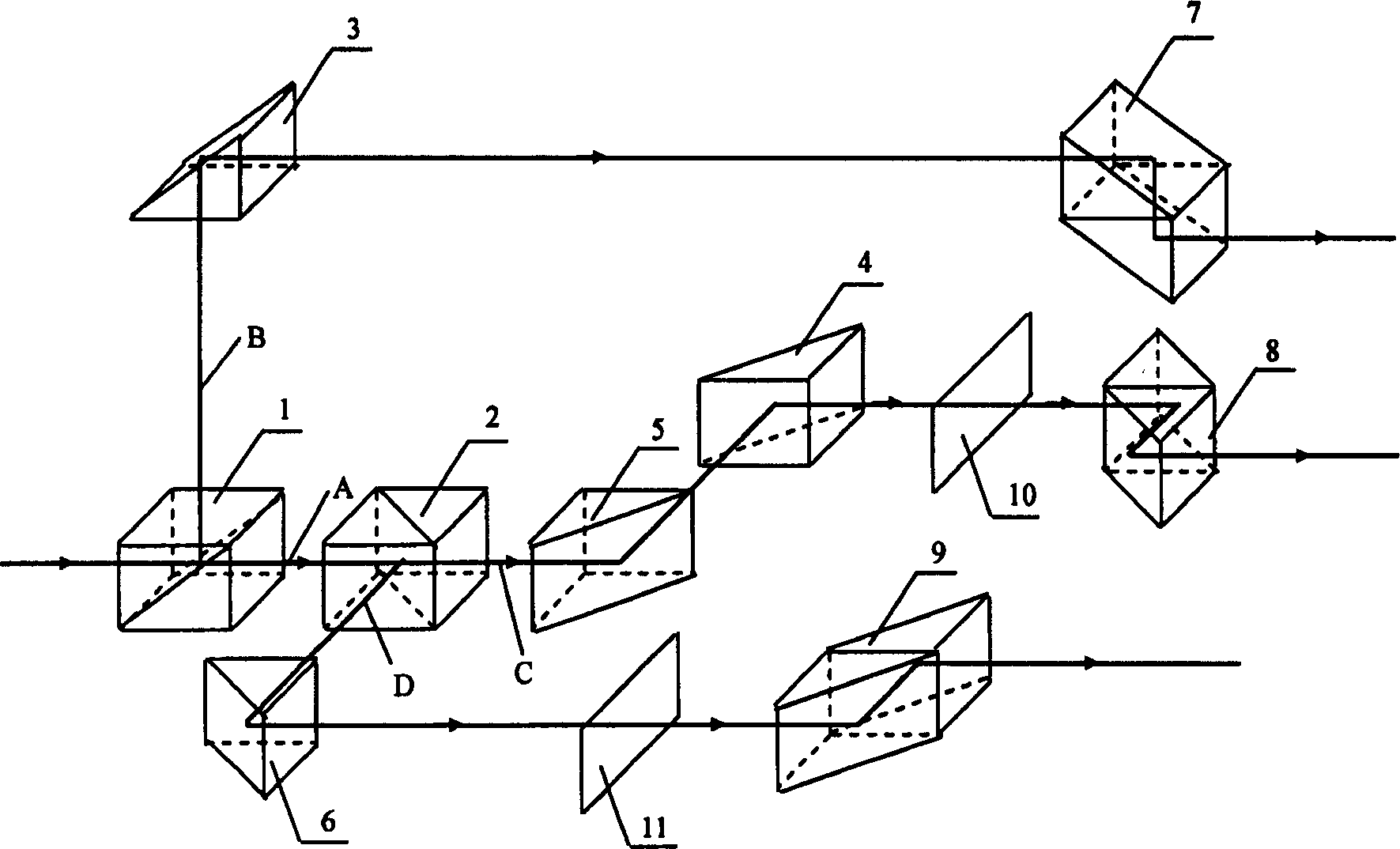

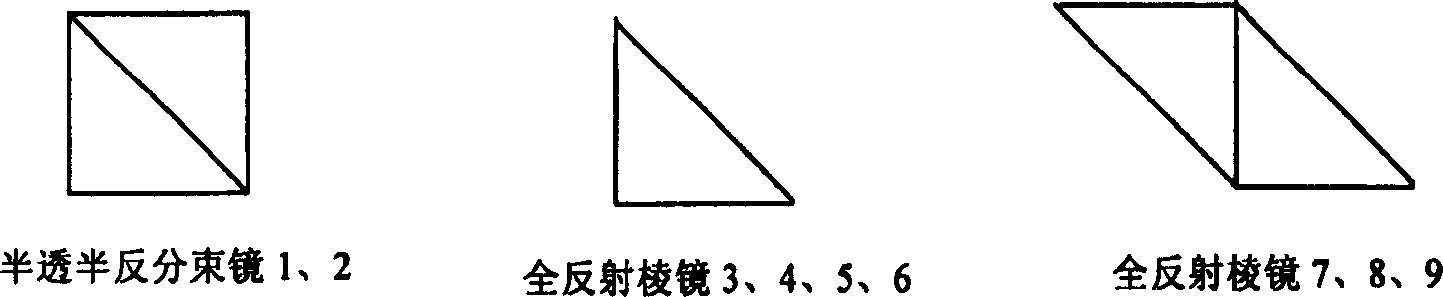

[0025] A prism three-splitting system comprising:

[0026] ——Non-polarizing beam-splitting semi-transparent beam splitter, two non-polarizing beam-splitting semi-transparent beam splitters can split an incident beam into three beams; ——Total reflection prism, seven total reflection prisms are in the optical path Arranged according to requirements, through the adjustment of the position of the total reflection prism, the optical path of the two beams of light filtered by the filter can be equal; - the optical filter, the optical filter can be placed in the optical path to obtain the light beam of the required wavelength.

[0027] The light splitting process of the present invention is: the light beam emitted by the target is divided into three beams after passing through two semi-transparent and semi-reflective beam splitters, and the three beams are arranged in two layers; After reflecting the prism, it is projected onto the imaging target surface according to the required dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com