Roller ironing machine for articles of clothing

A technology of ironing machine and roller type, applied in the field of roller ironing machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

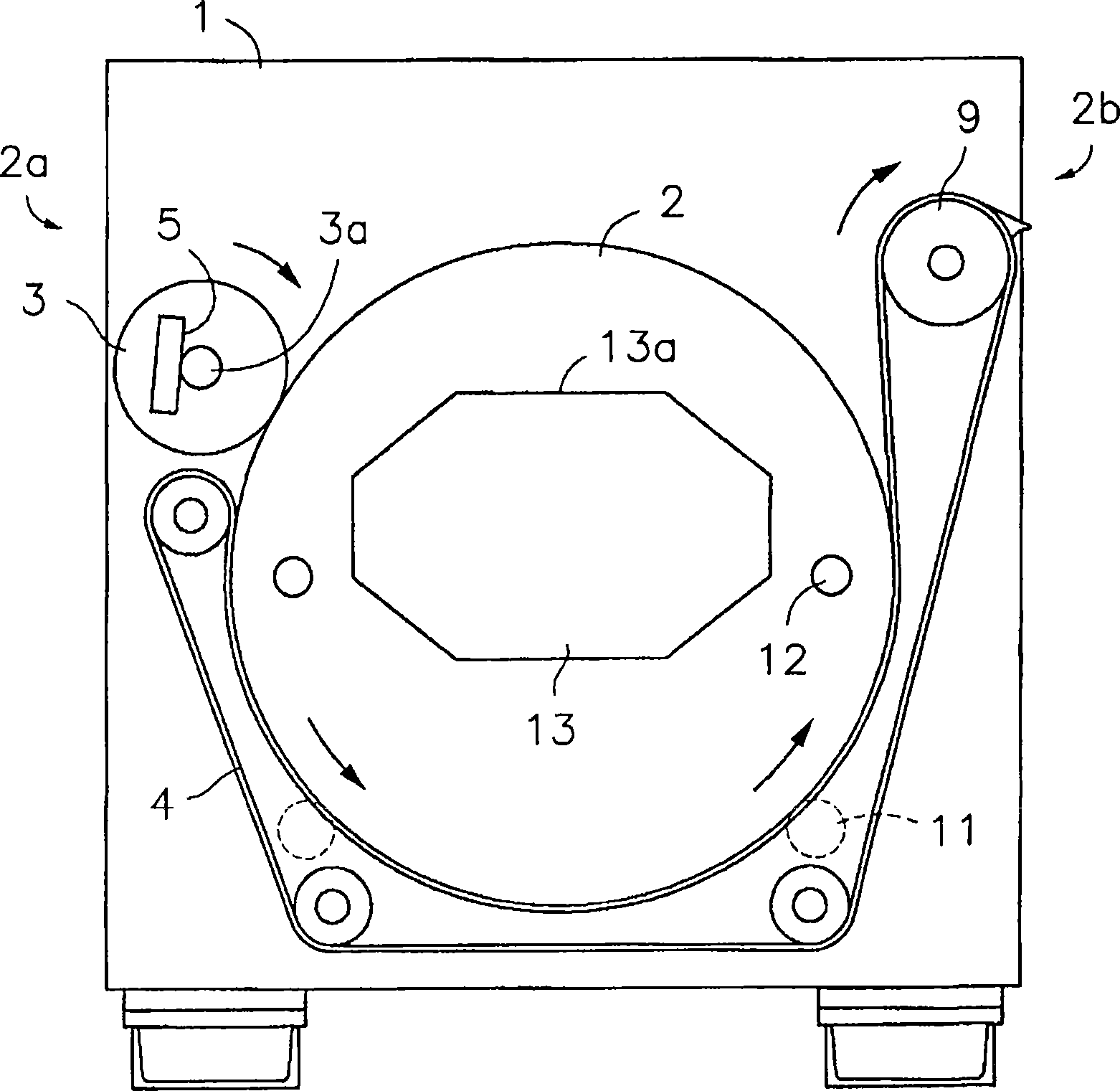

[0017] first refer to attached figure 1 , which shows an exemplary embodiment of the roller ironing machine for clothes according to the invention, comprising an ironing unit comprising a frame 1 supported in rotation and guided on the frame 1 The ironing roller 2. Then, for example, two pairs of wheels 11 are mounted such that they can rotate freely on the frame 1 and the ironing roller 2 is supported by its ends on said two pairs of wheels 11 . Other known means for supporting and guiding the ironing roller 2 can likewise be applied in a rotational manner.

[0018] A heating device is provided inside the ironing roller 2 to heat the surface thereof. Since the screed roll rotates at a constant speed, it is simpler to heat its outer surface uniformly from the inside, using, for example, one of several rows of gas nozzles 12 located in a fixed position, and a gas extractor comprising an axial In place there is provided a duct 13 inside the screed roll 2, the duct 13 having a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com