Warning device and electric dust collector employing same

A vacuum cleaner and reporting technology, which is applied to vacuum cleaners, cleaning equipment, household appliances, etc., can solve the problems of proper reporting, obstruction of dust detection, and difficulty in correcting dust and pulse numbers to achieve high-efficiency cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0047] First, use Figure 1 to Figure 5 A first embodiment of the present invention will be described.

[0048] Hereinafter, the same reference numerals are attached to components having the same configuration as conventional ones, and description thereof will be omitted.

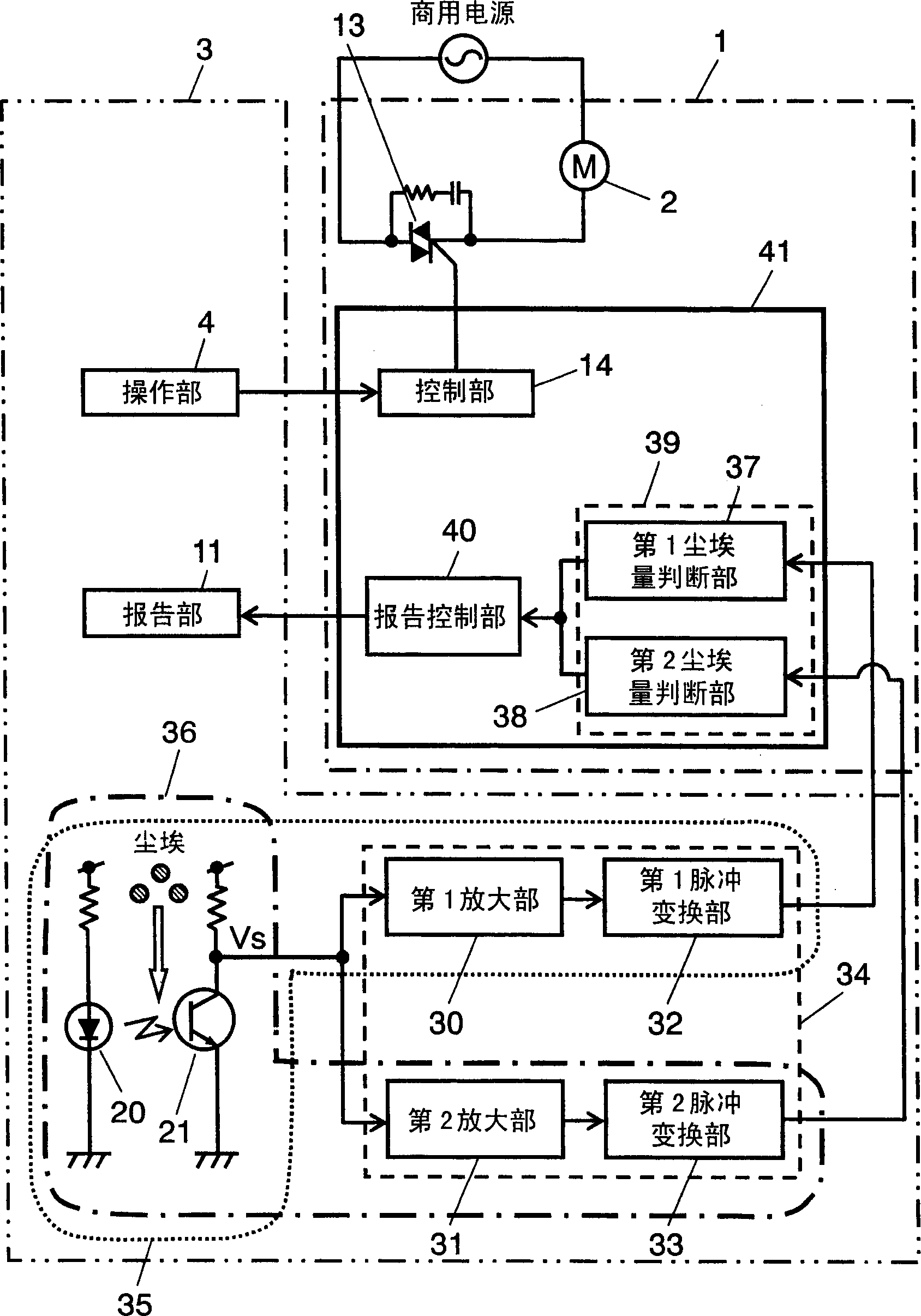

[0049] figure 1 It is a control block diagram of the electric vacuum cleaner reporting device in Embodiment 1 of the present invention.

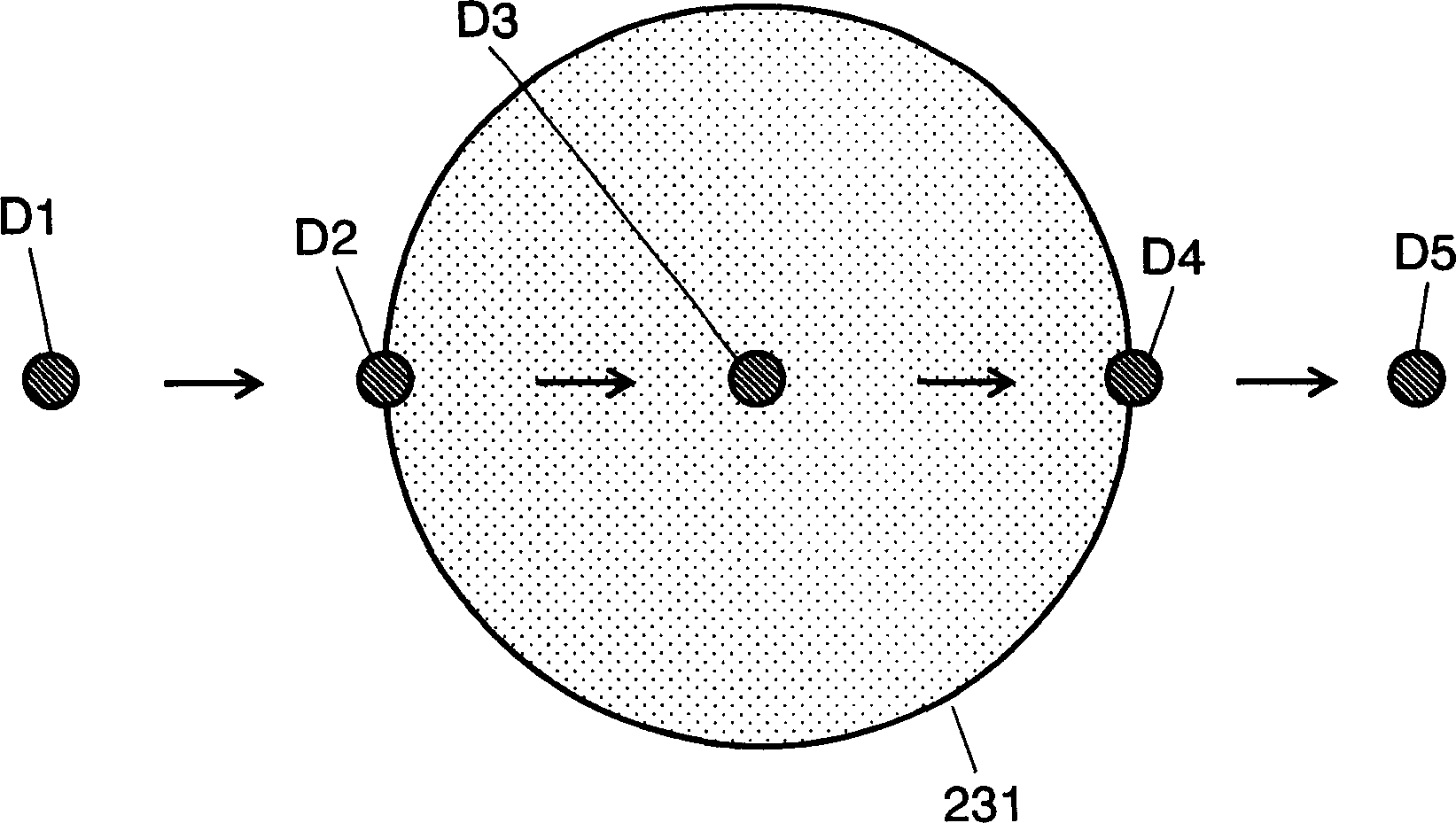

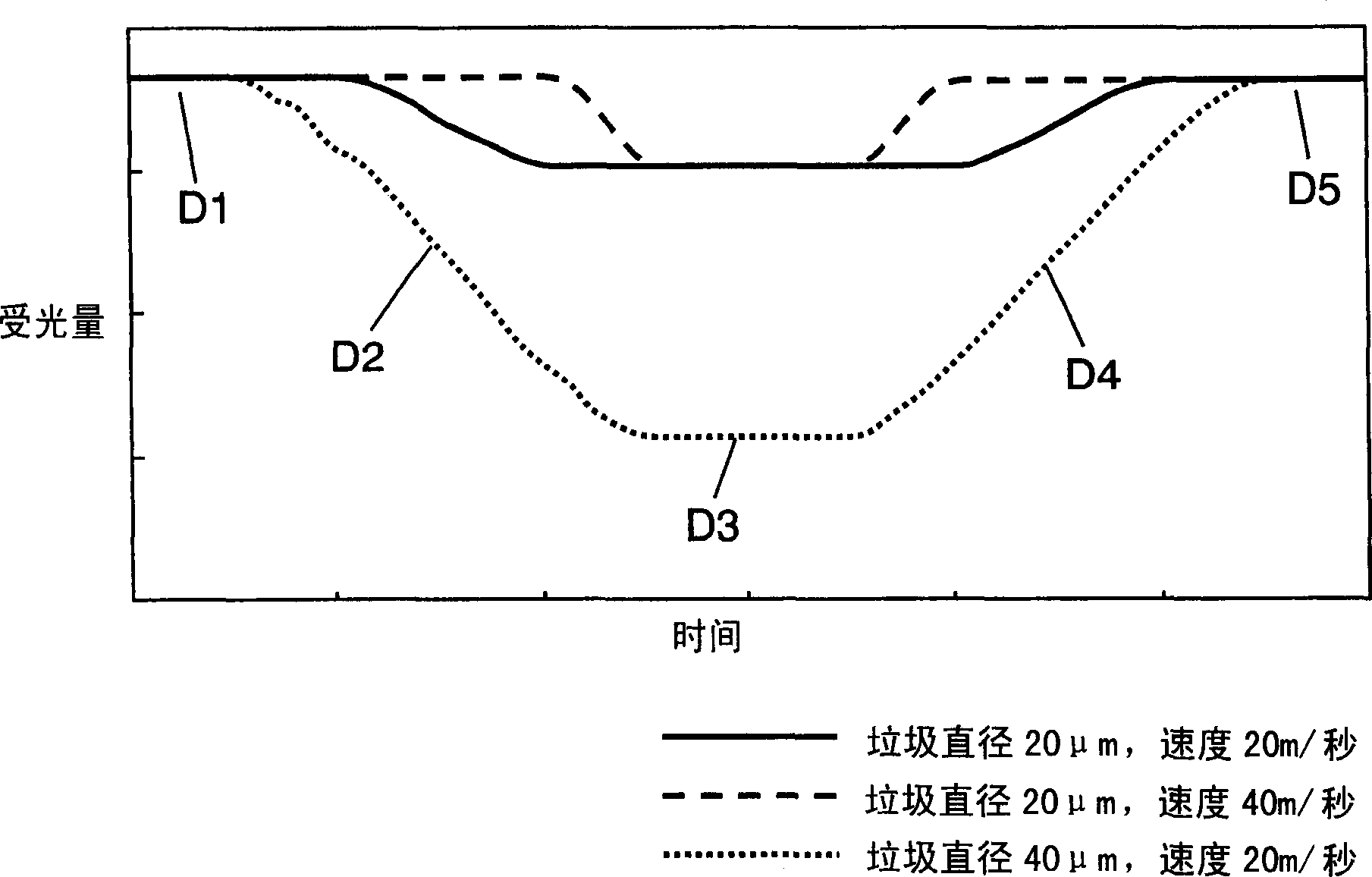

[0050] exist figure 1 Among them, the light emitting unit 20 is composed of an infrared light emitting diode or the like. The light receiving unit 521 is composed of a phototransistor and the like. According to the dust passing between the two, a signal Vs corresponding to the dust is output.

[0051] The first amplification unit 30 is composed of an operational amplifier and the like, and amplifies the detection unit with a predetermined first amplification factor (refer to Figure 10 ) 22 output signal Vs. The first amplifying unit 30 has an amplifying function...

Embodiment approach 2

[0082] Below, use Figure 6 and Figure 7 A second embodiment of the present invention will be described. In addition, components having the same configuration as conventional components are given the same reference numerals, and their descriptions are omitted.

[0083] Figure 6 It is a control block diagram of the notification device of the electric vacuum cleaner in Embodiment 2. The difference from Embodiment 1 is that, based on the dirt levels judged by the first dust amount judging unit 37 and the second dust amount judging unit 38, the composition of the dust passing through the suction flow path is shown in Table 2, and it is judged Dust determined from five types of dust type 1 to dust type 5 constitutes the determination unit 50 . In addition, in the notification control part 40, the notification by the notification part 11 can be controlled according to the structure judged by the dust composition judgment part 50. in addition, Figure 7 shows the configuratio...

Embodiment approach 3

[0094] Below, use Figure 8 A third embodiment of the present invention will be described.

[0095] In addition, the same code|symbol is attached|subjected to the component of the same structure as conventional, and description is abbreviate|omitted.

[0096] Figure 8 It is a figure which shows the structure of the reporting part 11 in Embodiment 3 of this invention, The structure other than that is the same as Embodiment 1.

[0097] exist Figure 8 Among them, the symbol 71 is displayed by the dirt level judged by the first dust amount judging part 37 or the second dust amount judging part 38, is composed of LEDs, and is a dirt level 1 display showing dirt level 1. Likewise, the soil level 2 display 72 shows the soil level 2, the soil level 3 display 73 shows the soil level 3, and the soil level 4 display 74 shows the soil level 4.

[0098] If the report control section 40 has a dirt level of 0, all of the displays will be extinguished. For the dirt levels judged by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com