Spinning spindle assembly with damping device

A spindle and component technology, applied in the field of spindle components, can solve problems such as damping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

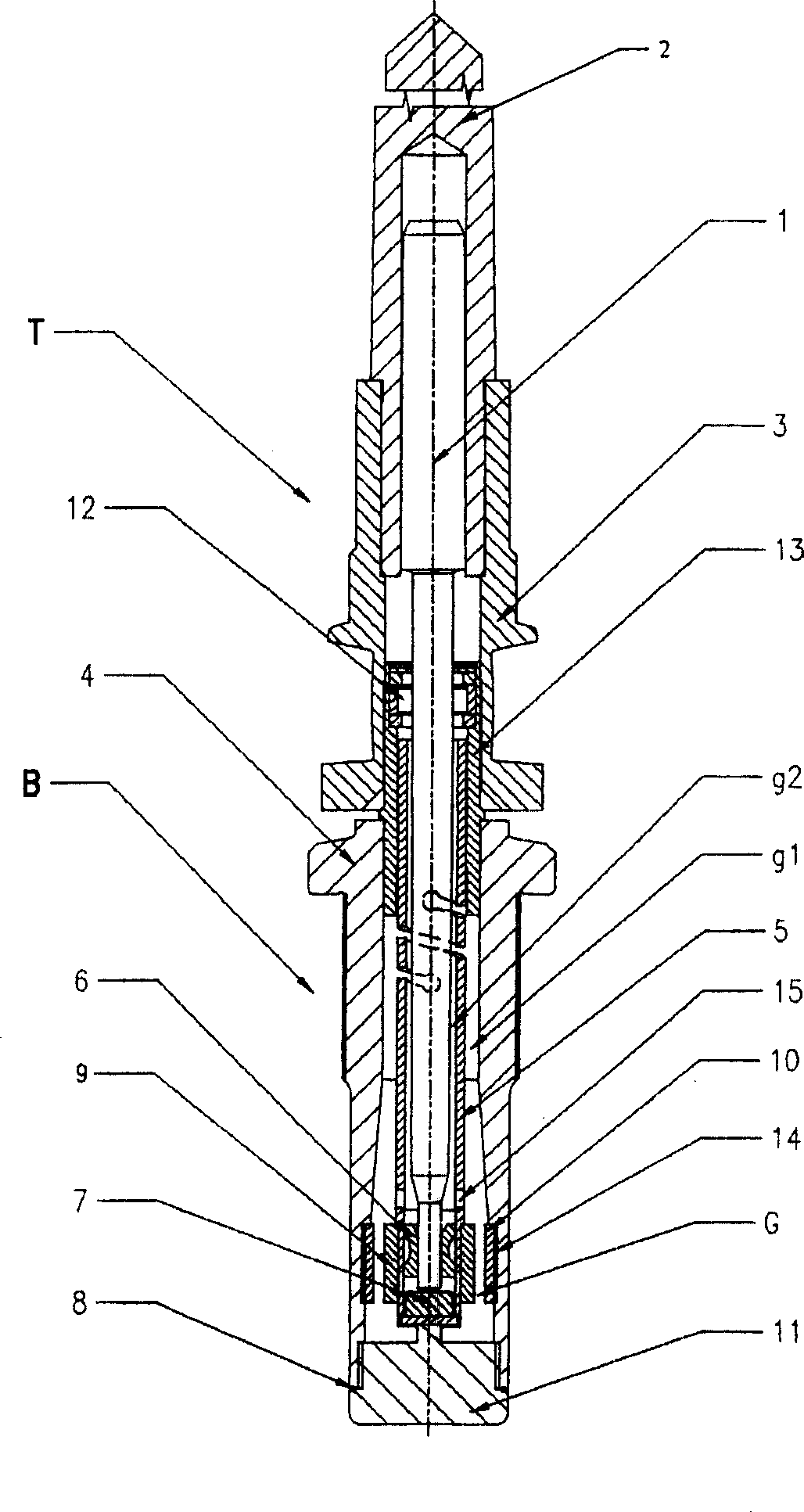

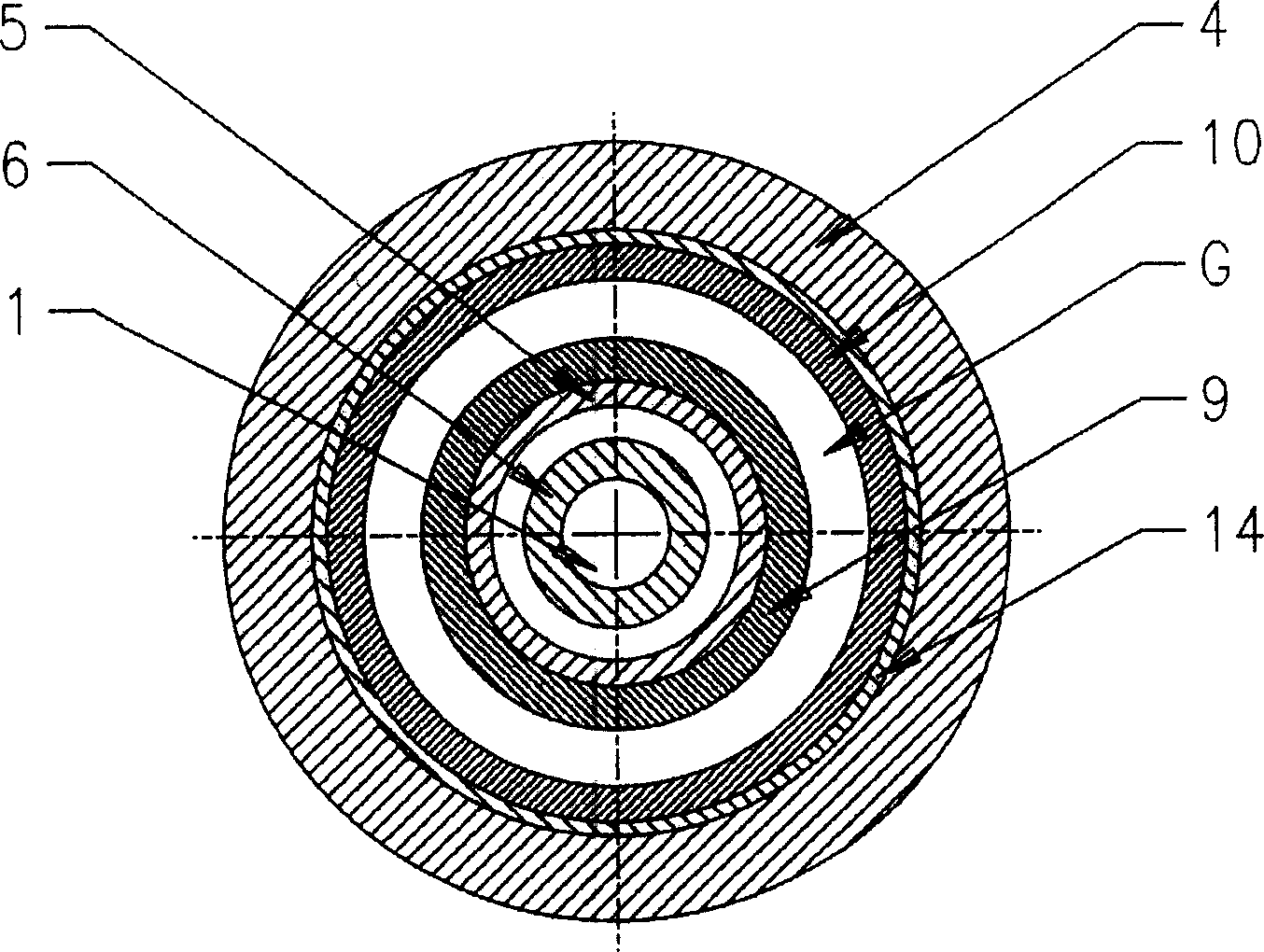

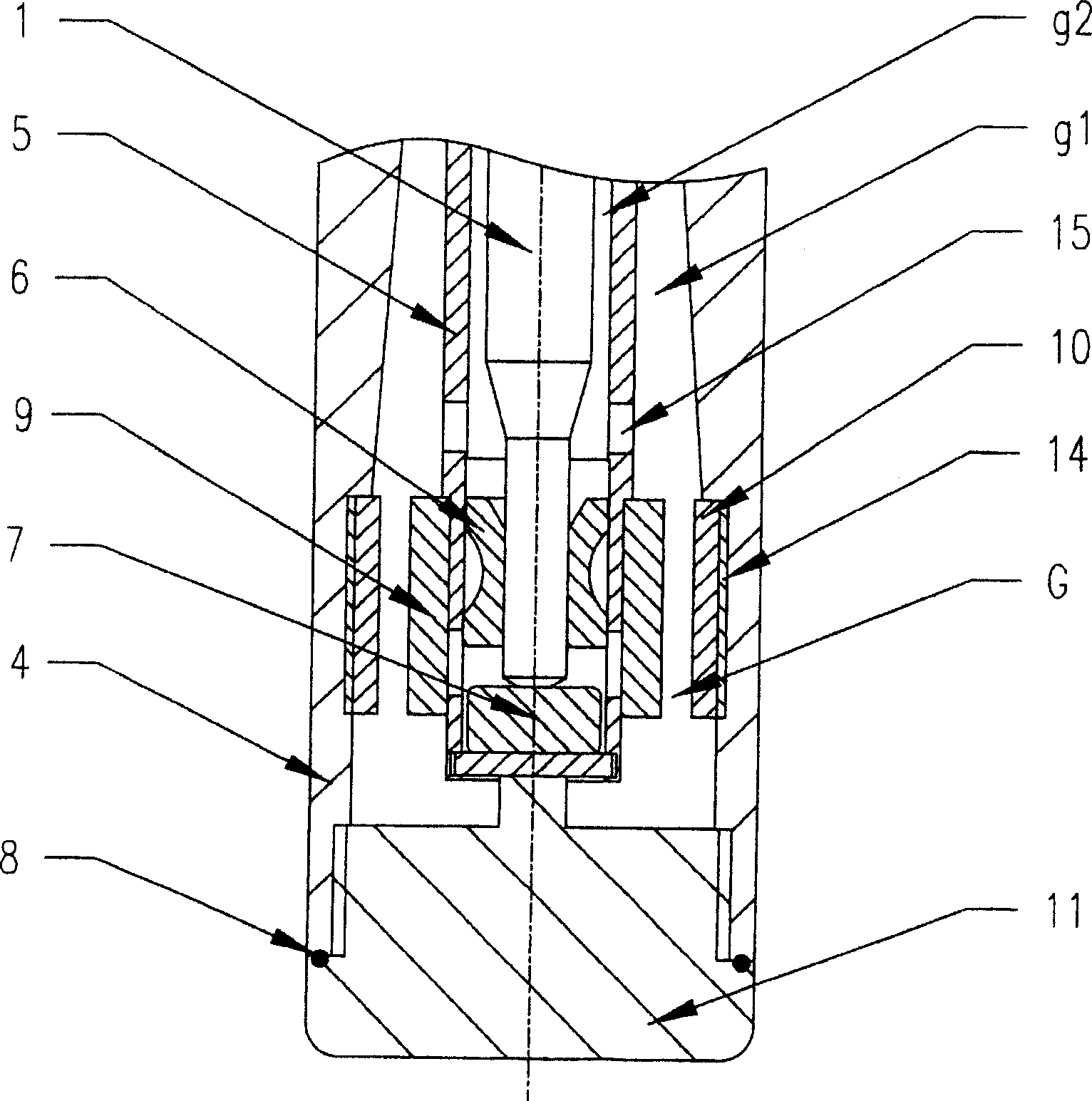

[0020] Accordingly, the present invention provides a spindle assembly, the detailed description of which is initially incorporated by reference to figure 1 &3 explain. The spindle assembly consists of a top part T and a bottom part B. The top part comprises a spindle bar 1 and a conical part 2 made of a lightweight material such as aluminium, which is rigidly fitted to the spindle bar 1 . The bottom part of the conical part is further fitted with the spindle part 3 for radially coupling the cylindrical member of the drive belt to couple the rotational movement to the top part T of the spindle.

[0021] The bottom part B comprises a spindle foot 4 which houses a spindle insertion assembly 13 . The spindle insert assembly 13 is press fit to the spindle foot 4 as a supporting element. The spindle insert assembly 13 includes an intermediate bearing 12 fitted on top of it and a centering sleeve 5 fitted next to the intermediate bearing 12 . The bottom of the centering sleeve 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com