Over-voltage monitoring sensor for AD electricity system

A technology for monitoring sensors and power systems. It is applied in the direction of measuring current/voltage, instruments, and measuring devices. It can solve the problems of inability to collect overvoltage signals of the power system, high cost of sensors, and inability to use the power grid to achieve safe and reliable operation. The effect of high measurement accuracy and fast response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

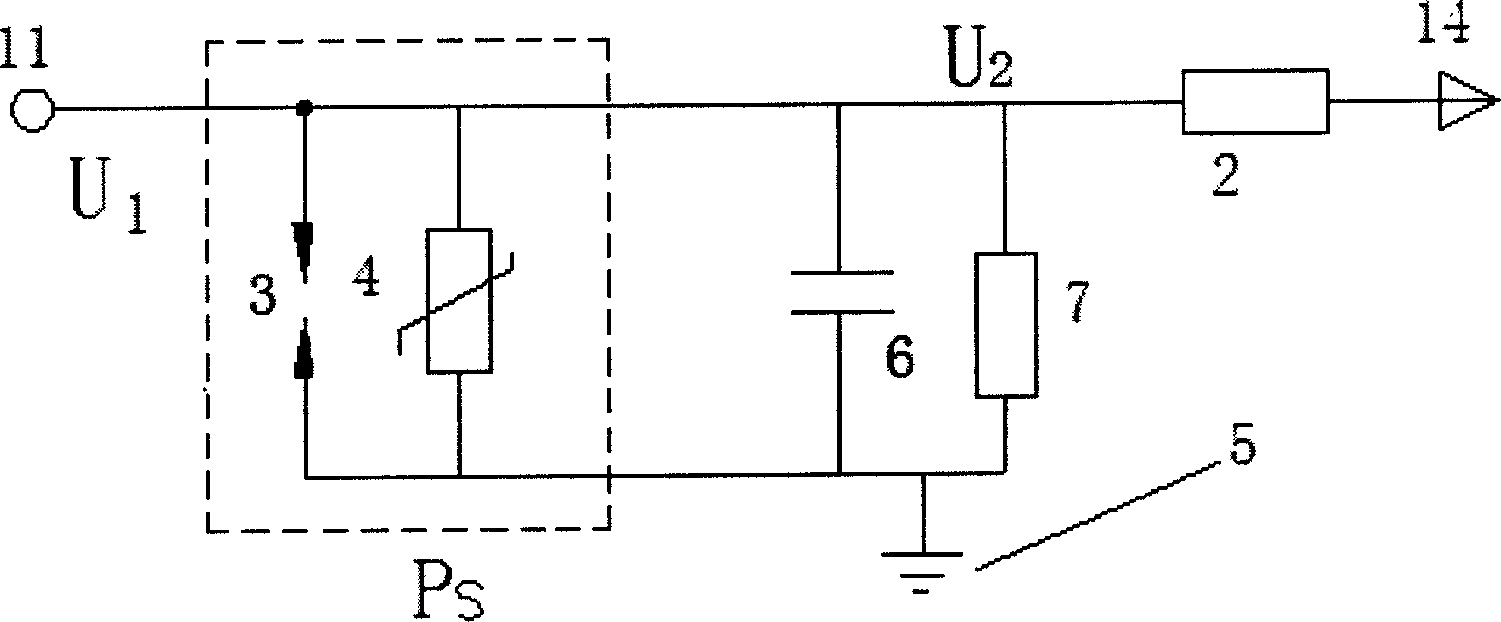

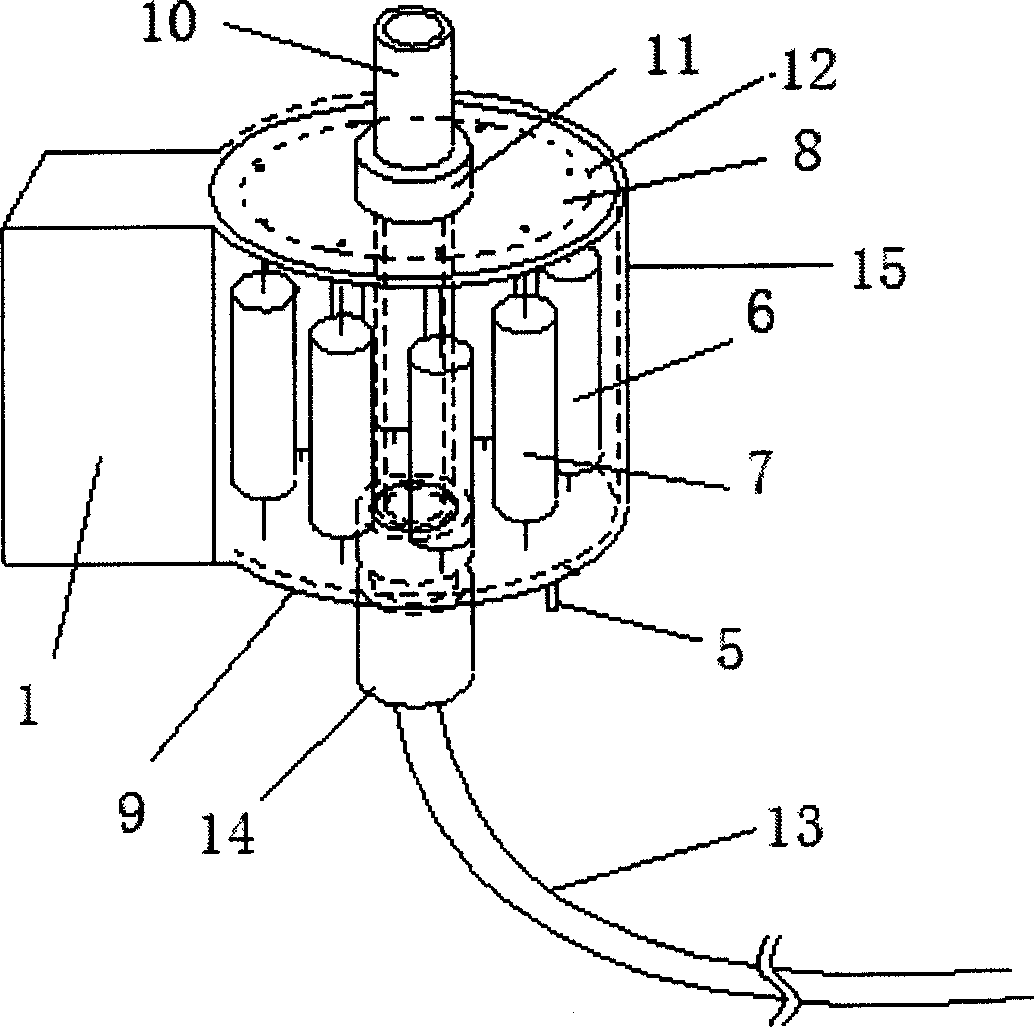

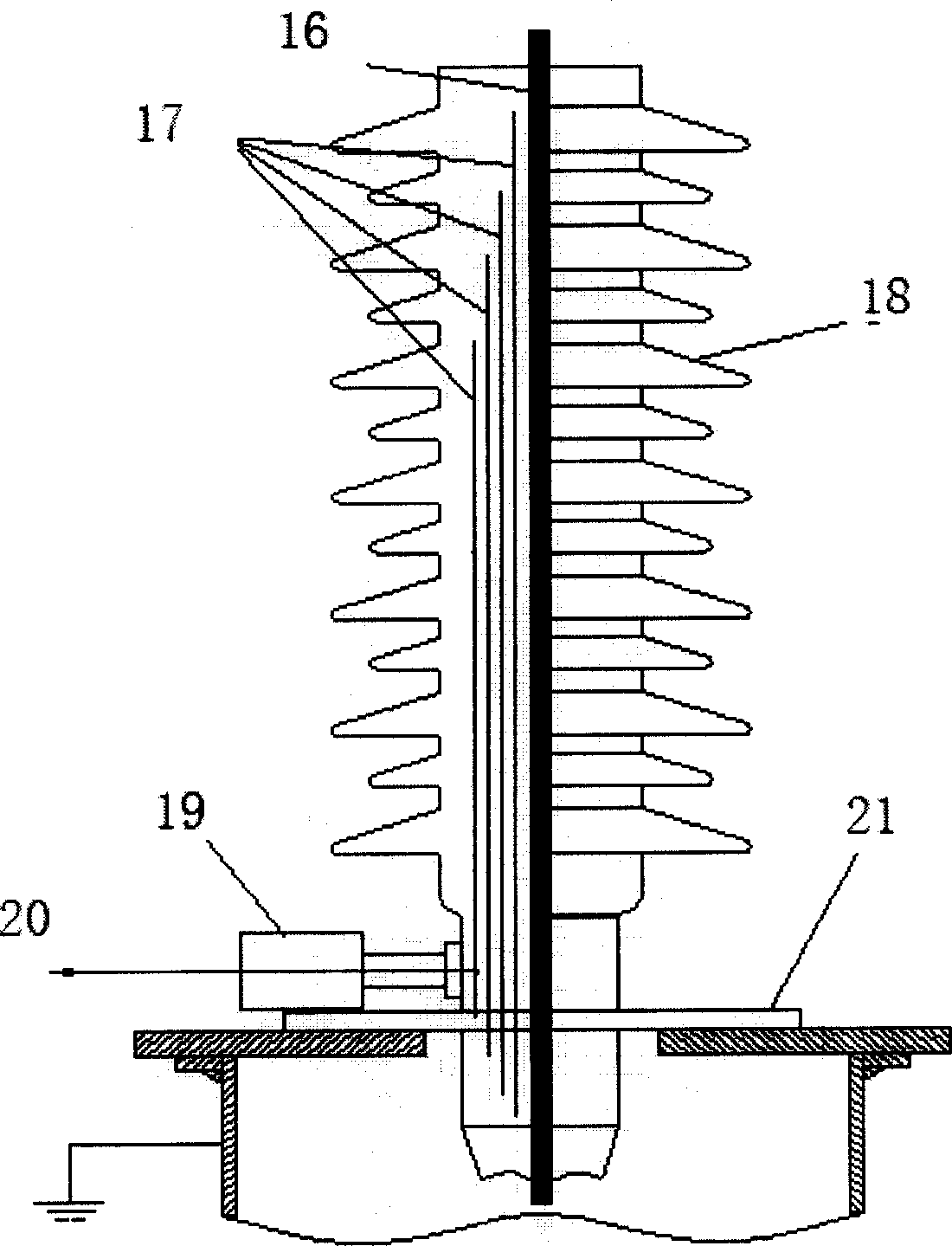

[0019] like Figures 1 to 3 As shown, a transformer bushing end screen AC power system overvoltage monitoring sensor mainly includes: a casing 15, two copper discs 8, 9, a voltage dividing capacitor 6, a voltage dividing resistor 7, a matching resistor 2, and a protection unit 1. Coaxial cable 13, etc. The shell 15 is a stainless steel cylindrical shell, and the thickness of the shell 15 is 10mm. Two copper discs 8, 9 are respectively arranged on the two ends of the stainless steel shell 15. And be fixedly connected with shell 15 by the internal screw thread of shell 15, a through hole is respectively set at the center of two disks 8,9, a nut 11 is affixed by screw rod at the center through hole of disk 8, and in this circle The inner side of the disk 8 is fixedly connected with an insulating bracket 12 by a screw; the cable plug 14 is threaded through the central through hole of the disk 9, and the double-shielded coaxial cable 13 for transmitting voltage signals is inserte...

Embodiment 2

[0021] like Figures 1 to 2As shown, a capacitive current transformer AC power system overvoltage monitoring sensor mainly includes: a casing 15, two copper discs 8, 9, a voltage dividing capacitor 6, a voltage dividing resistor 7, a matching resistor 2, and a protection unit 1. Coaxial cable 13, etc. The shell 15 is a stainless steel cylindrical shell, and the thickness of the shell 15 is 3mm. Two copper discs 8, 9 are respectively arranged on the two ends of the stainless steel shell 15. And be fixedly connected with shell 15 by the internal screw thread of shell 15, a through hole is respectively set at the center of two disks 8,9, a nut 11 is affixed by screw rod at the center through hole of disk 8, and in this circle The inner side of the disk 8 is fixedly connected with an insulating bracket 12 by a screw; the cable plug 14 is threaded through the central through hole of the disk 9, and the double-shielded coaxial cable 13 for transmitting voltage signals is inserted ...

Embodiment 3

[0023] like Figures 1 to 2 As shown, a capacitive voltage transformer AC power system overvoltage monitoring sensor mainly includes: a casing 15, two copper discs 8, 9, a voltage dividing capacitor 6, a voltage dividing resistor 7, a matching resistor 2, and a protection unit 1. Coaxial cable 13, etc. The shell 15 is a tempered glass cylindrical shell, and the thickness of the shell 15 is 5mm. Two copper discs 8, 9 are respectively arranged on the two ends of the stainless steel shell 15. And be fixedly connected with shell 15 by the internal screw thread of shell 15, a through hole is respectively set at the center of two disks 8,9, a nut 11 is affixed by screw rod at the center through hole of disk 8, and in this circle The inner side of the disk 8 is fixedly connected with an insulating bracket 12 by a screw; the cable plug 14 is threaded through the central through hole of the disk 9, and the double-shielded coaxial cable 13 for transmitting voltage signals is inserted ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com