Cryogenic distillation method and installation for air separation

An air separation and air technology, applied in lighting and heating equipment, cold treatment separation, refrigeration and liquefaction, etc., can solve the problem of low thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

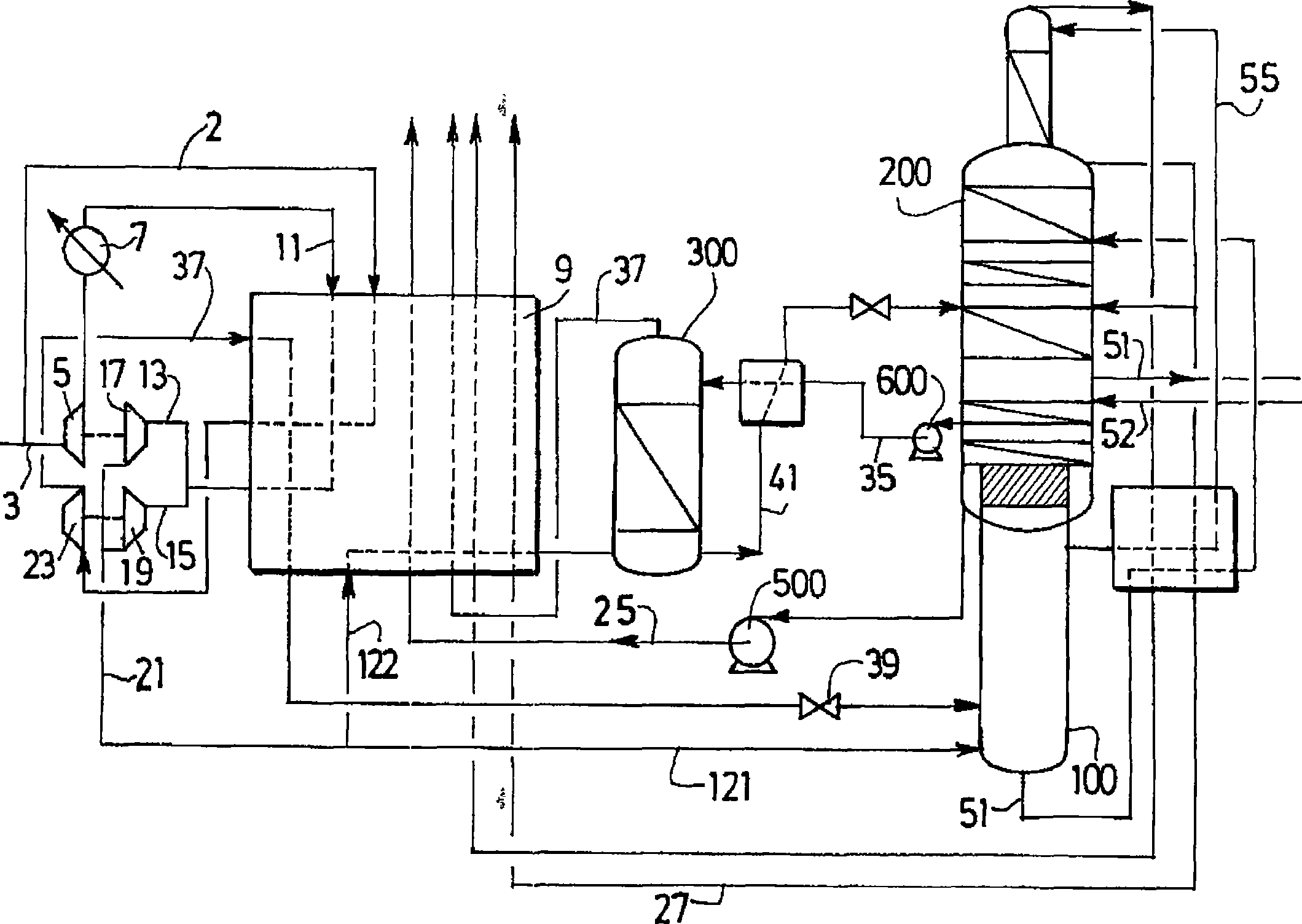

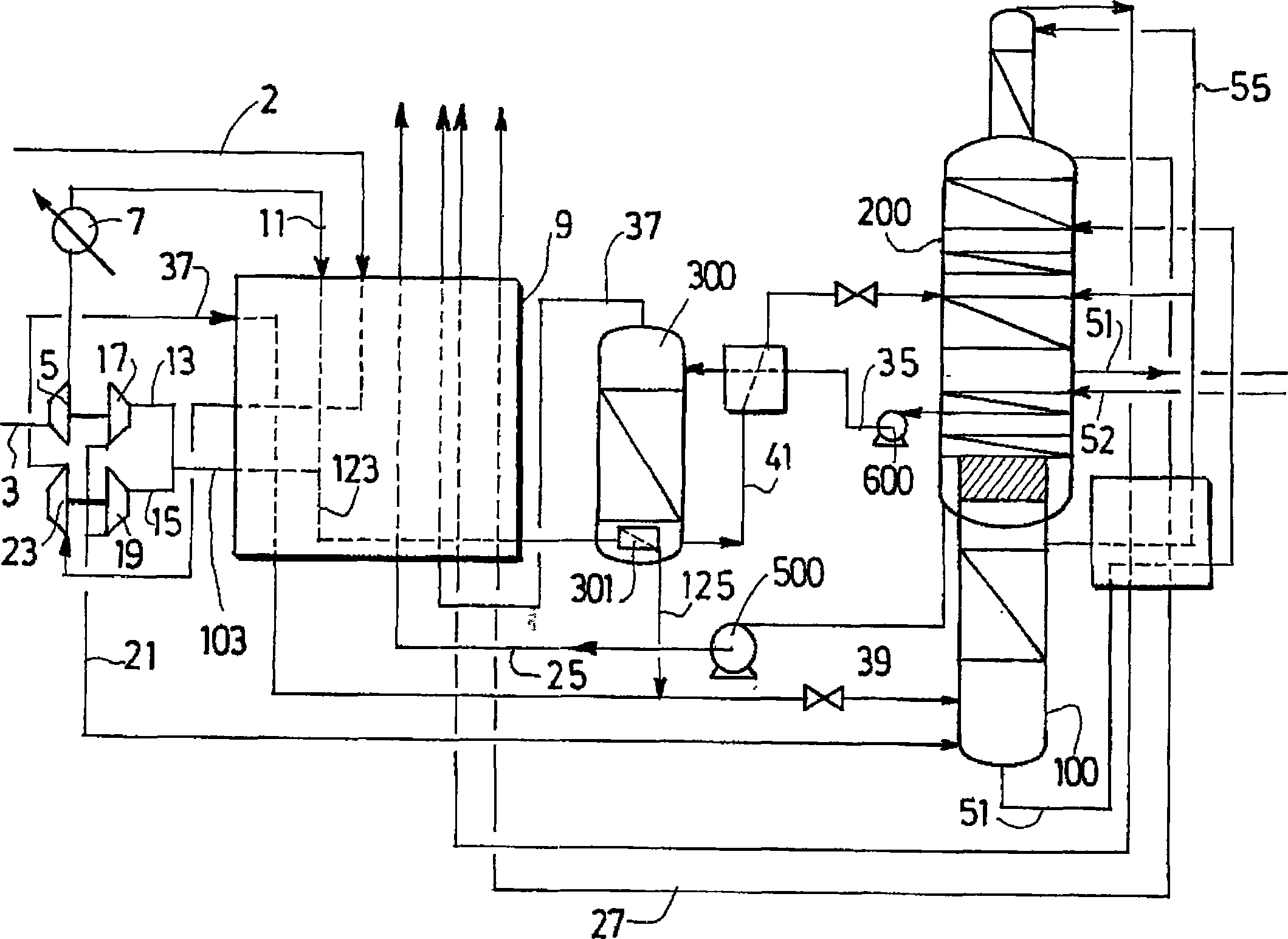

[0049] exist figure 1 , the air flow at atmospheric pressure is compressed to about 15 bar in a main compressor (not shown). The air is then optionally cooled before being purified (not shown) to remove impurities. Divide the purified air into two parts. A portion 3 of the air is sent to the booster 5 where it is compressed to a pressure between 17 and 20 bar, then the boosted air is sent to the warm end of the main exchange line 9 of the air separation plant Cooled by water cooler 7 before. The charge air 11 is cooled to an intermediate temperature before leaving the exchange line and being divided into two parts. Of course, a portion of stream 11 may continue to be cooled until it reaches the cold end of exchange line 9 from which it is liquefied and discharged. One portion 13 is sent to turbine 17 and the remaining portion 15 is sent to turbine 19. The two turbines have the same intake air temperature and pressure and the same exhaust temperature and pressure, but of c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com