Electronic ballast with transformer interface

A technology of electronic ballasts and transformers, applied in the direction of electric light sources, electrical components, lamp circuit layout, etc., can solve the problems of expensive optocouplers, increased manufacturing and retail costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

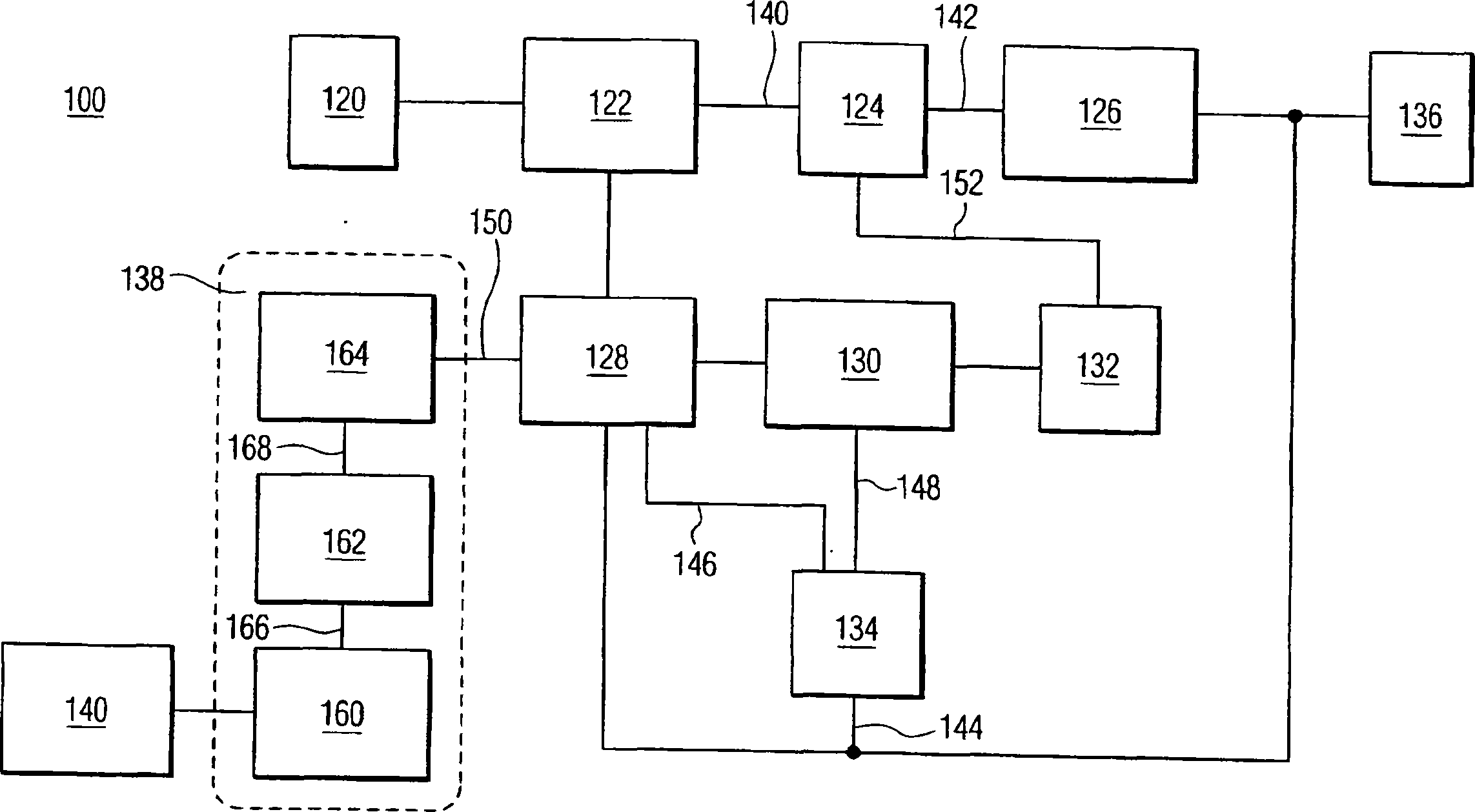

[0017] figure 1 It is a block diagram of an electronic ballast with a transformer interface manufactured according to the present invention. Electronic ballast 100 includes AC / DC converter 122, half bridge 124, resonant tank 126, microprocessor 128, regulating pulse width modulator (PWM) 130, high voltage (HV) driver 132, error circuit 134 and filament current sense Test circuit 138. AC / DC converter 122 receives mains voltage 120 and resonant tank 126 supplies power to lamp 136 . The external signal 140 is sent and received between the communication interface circuit 138 and an external control system (not shown).

[0018] The main voltage 120 is the AC line voltage provided to the electronic ballast 100 , such as 120 volts, 127 volts, 220 volts, 230 volts or 277 volts. AC / DC converter 122 receives mains voltage 120 . The AC / DC converter 122 converts the AC main voltage 120 into a DC voltage 140 and provides it to the half bridge 124 . AC / DC converter 122 typically includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com