Molten steel covering agent and its preparation method

A covering agent and molten steel technology, applied in the direction of improving process efficiency, etc., can solve problems such as deterioration of steel quality and inability to realize metallurgical functions, and achieve the effect of eliminating the danger of deterioration of steel quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

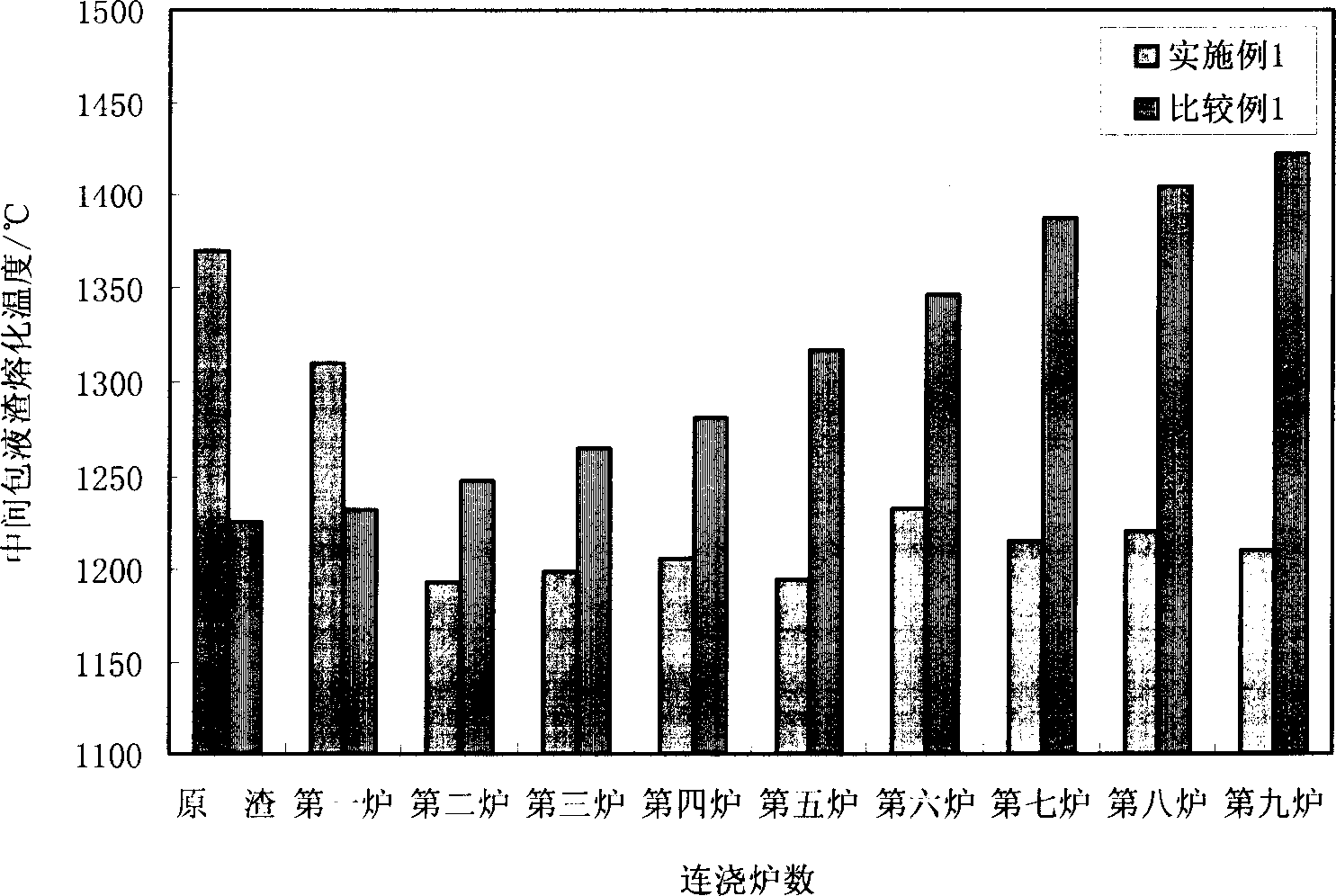

Embodiment 1

[0042] The molten steel covering agent of the present invention was compared with Comparative Example 1 and Comparative Example 2 in a tundish with a capacity of 30 tons. Casting ultra-low carbon steel with carbon content less than or equal to 50ppm, the tundish lining is made of MgO paint, and the stopper rod is made of MgO-Cr 2 o 3 The chemical composition and performance of each covering agent are shown in Table 1. The preparation process of each covering agent is:

[0043] Embodiment 1 The preparation process of the covering agent is: the preparation process of the carbon-free alkaline foamed steel molten steel covering agent of the present invention, that is: weighing ingredients→preparing mother liquor→pulping→forming→drying→crushing→sieving→inspecting packaging and use.

Embodiment 2

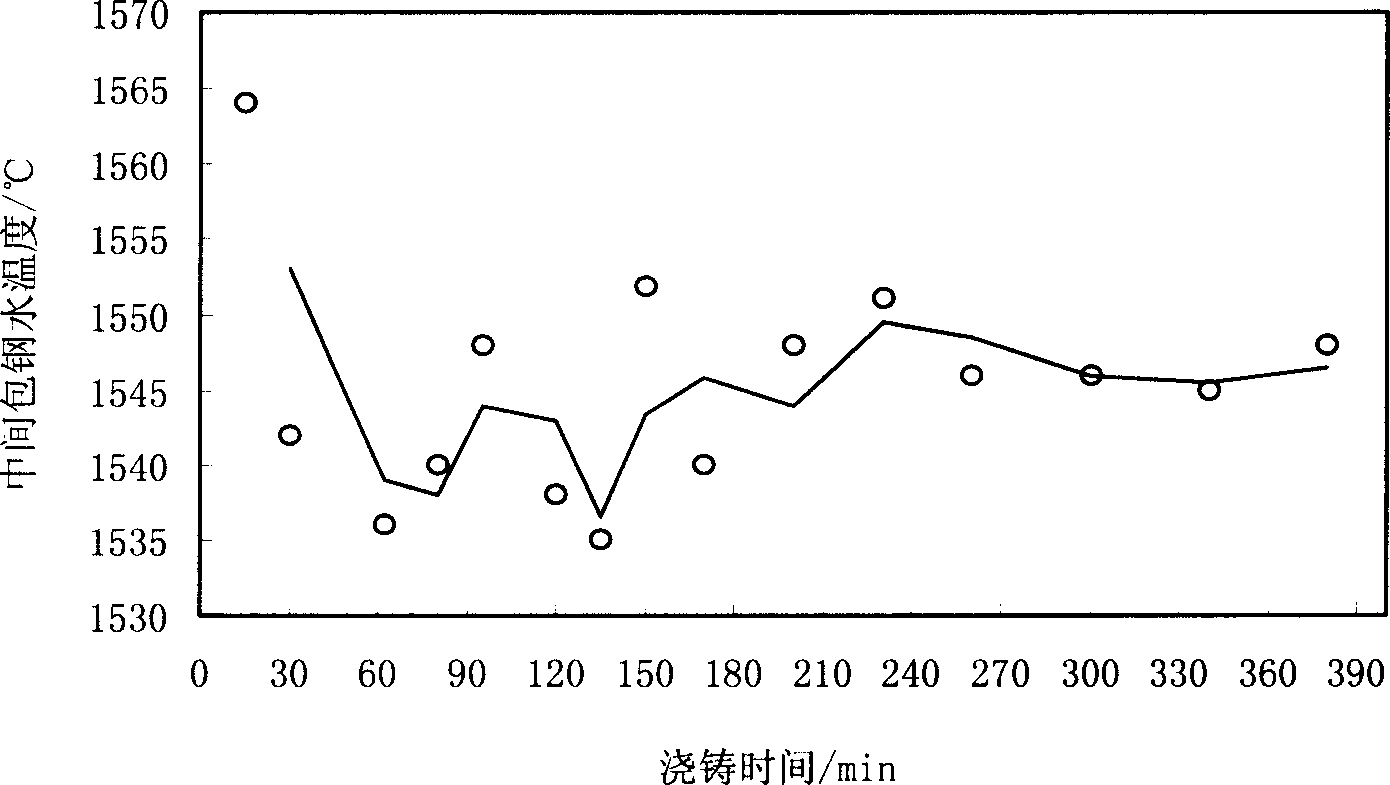

[0050] In a steel ladle with a capacity of 50 tons, the molten steel covering agent of the present invention and Comparative Example 3 were compared and verified (see Table 1 for components and properties).

[0051] The carbon content of molten steel is (weight%) 0.02-0.06. The preparation process of the covering agent of Example 2 is the same as that of the covering agent of Example 1, and the preparation process of the covering agent of Comparative Example 3 is the same as that of the covering agent of Comparative Example 2. The dosage of each covering agent is 0.15Kg / T steel, and after the molten steel is refined, they are added to the ladle steel surface at one time. There is no carburization phenomenon when using the covering agent of Example 2, and the carbon content of molten steel using the covering agent of Comparative Example 3 increases (% by weight) by 0.015.

[0052] Example 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com