A kind of molten iron slag collecting agent and preparation method thereof

A technology of slag collecting agent and molten iron, which is applied in the field of slag collecting agent, can solve the problems of troublesome storage and use, defects of slag inclusion, high cost, and achieve the effects of improving fluidity and dispersibility, bonding residues firmly, and enhancing fluidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] (1) Preparation of expanded perlite samples: collect and select massive perlite ores of 5-8 cm in size, crush them into granules by a crusher, sieve and select the crushed particles to 0.9-1.7 mm, and then add additives to the sieved particles. Soak in the solvent solution for 10-15 seconds, do pre-expansion treatment, drain the water and put it in a 750°C oven to dry for 2-3 minutes to remove the water adsorbed on the surface of the particles to obtain a perlite sample with a micro-porous structure, and then heat the oven to Preheating at 850-1100 °C makes the pores in the micro-cavities expand, and obtains expanded perlite samples with micro-cavities;

[0029] (2) Preparation of slag collecting agent slurry, according to the proportion of covering agent, weigh adhesive, heat preservation agent, and deoxidizer into the stirring tank, add water and stir to obtain liquid, and use mechanical stirring to mix the liquid with expanded perlite Stir the samples together evenly...

Embodiment 1

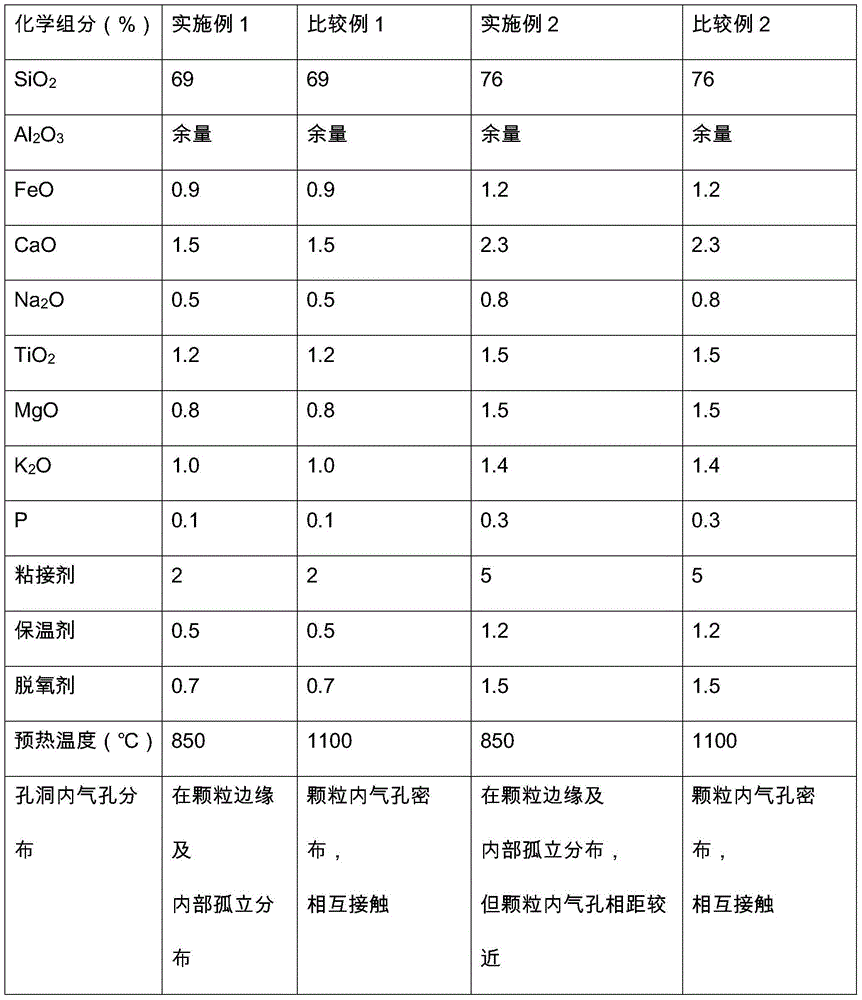

[0032] The molten iron slagging agent of the present invention was compared with Comparative Example 1 in a tundish with a capacity of 1.5 tons. The chemical components and performance of the slag collecting agent are shown in Table 1.

[0033] The preparation process of embodiment 1 slag collecting agent is: (1) collect and select the massive perlite ore of 5~8cm, break it into granules through the crusher, sieve and select the crushed particles to 0.9~1.7mm, and then to the sieved Add co-solvent solution to the granules and soak for 10-15s, do pre-expansion treatment, drain the water and put it in a 750°C oven to dry for 2-3 minutes to remove the water adsorbed on the surface of the granules to obtain a perlite sample with a micro-porous structure. The oven is then heated to 850°C to preheat to expand the pores in the micro-cavity, and obtain the expanded perlite sample with micro-cavity structure;

[0034] (2) Preparation of slag collecting agent slurry, according to the pr...

Embodiment 2

[0039] In a tundish with a capacity of 1.5 tons, the molten iron slagging agent of the present invention is compared and verified with Comparative Example 2. The chemical components and performance of the slag collecting agent are shown in Table 1, and the difference with Example 1 is only: collecting slag The proportion of each chemical component of the agent is not the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com