Outside-rotor motor

A technology of external rotor motor and stator yoke, which is applied in the direction of electrical components, electromechanical devices, electric components, etc., and can solve the problems of motor characteristic degradation and poor reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

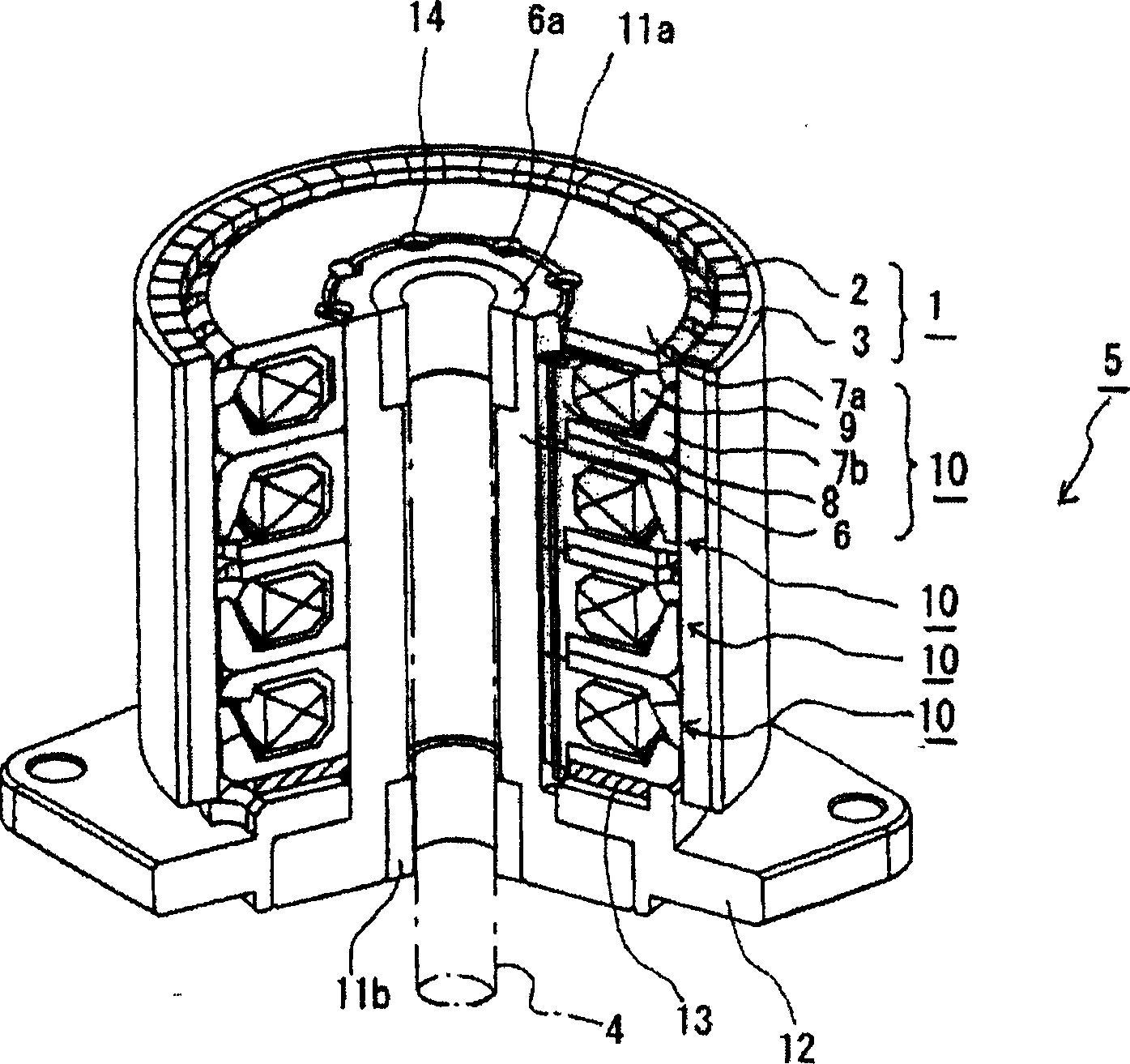

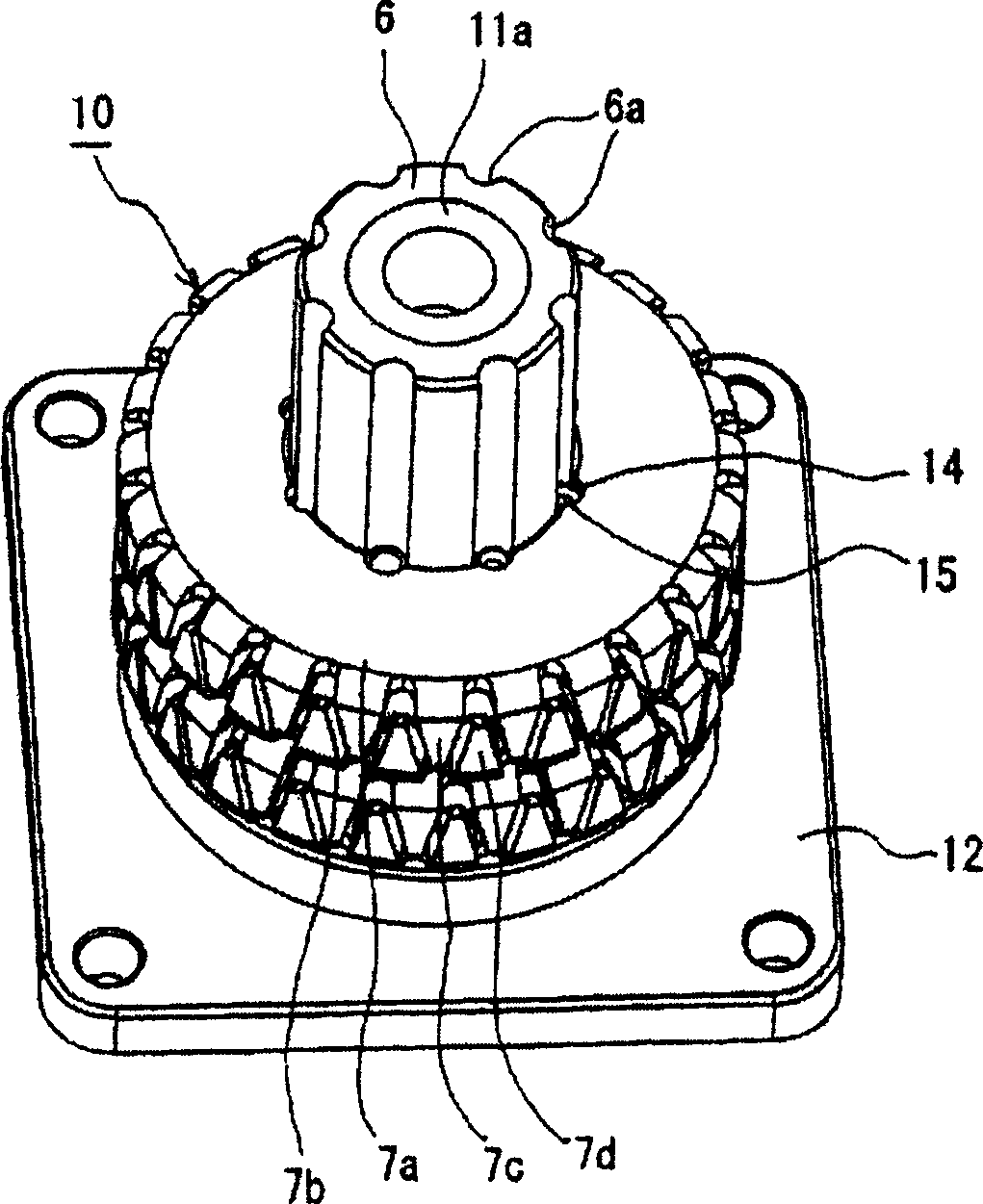

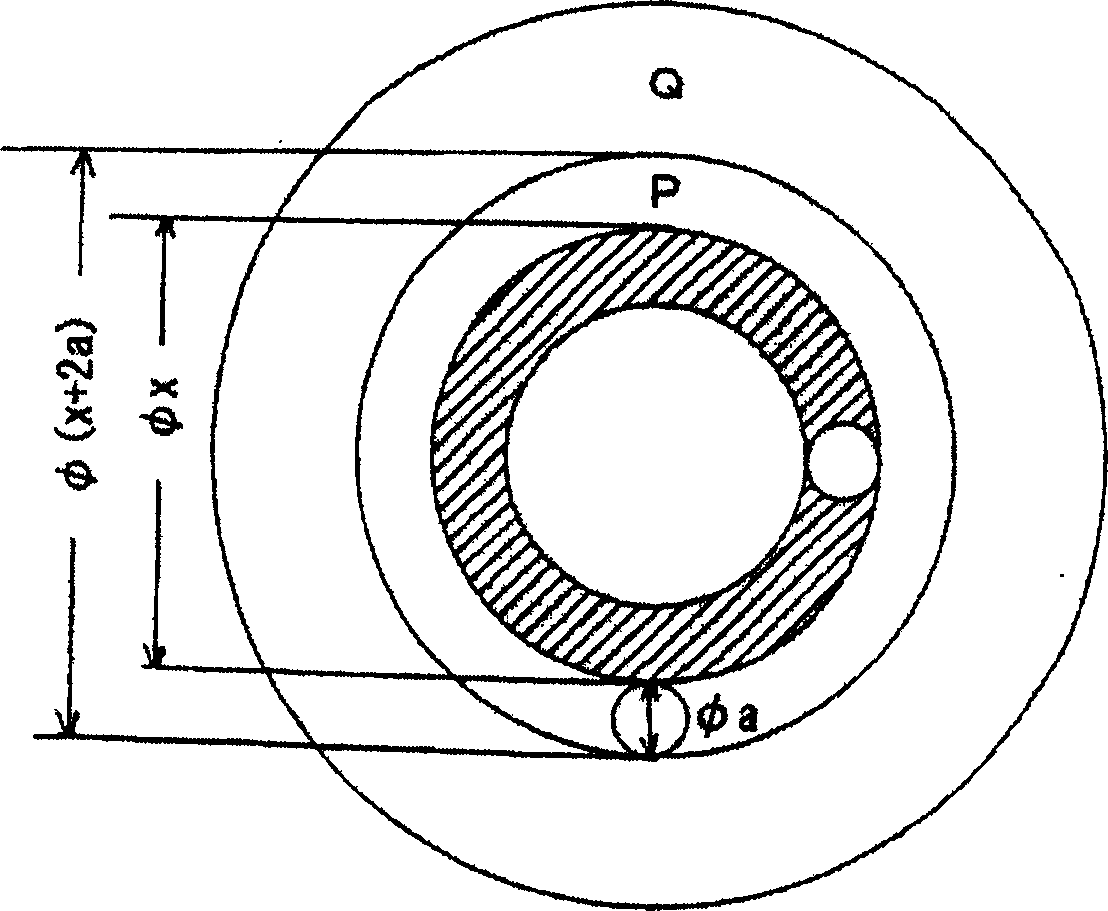

[0039] Preferred embodiments of an outer rotor motor according to the present invention will now be described with reference to the accompanying drawings. The outer rotor motor according to the present invention is a claw pole type motor in which a plurality of stator units are coaxially stacked inside the stator, each stator unit is formed such that a coil is sandwiched by a stator yoke, and claw poles are engaged with each other.

[0040] An outer rotor motor will now be described using a two-phase stepping motor used in OA appliances, computer peripherals, automobiles, transmission equipment related to FA (factory automation), and the like.

[0041] will now refer to figure 1 Describe the overall structure of a two-phase stepper motor. exist figure 1 In this, the rotor 1 is constructed such that a permanent magnet 2 is provided on the inner peripheral surface of a rotor yoke 3 in a cylindrical form, the permanent magnet 2 having been magnetized with alternating N and S po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com