Patents

Literature

39results about How to "Characteristics unchanged" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Improved mesenchyme stem cell protection solution and application thereof

ActiveCN101919380ACharacteristics unchangedMeet application needsDead animal preservationMesenchymeCell activity

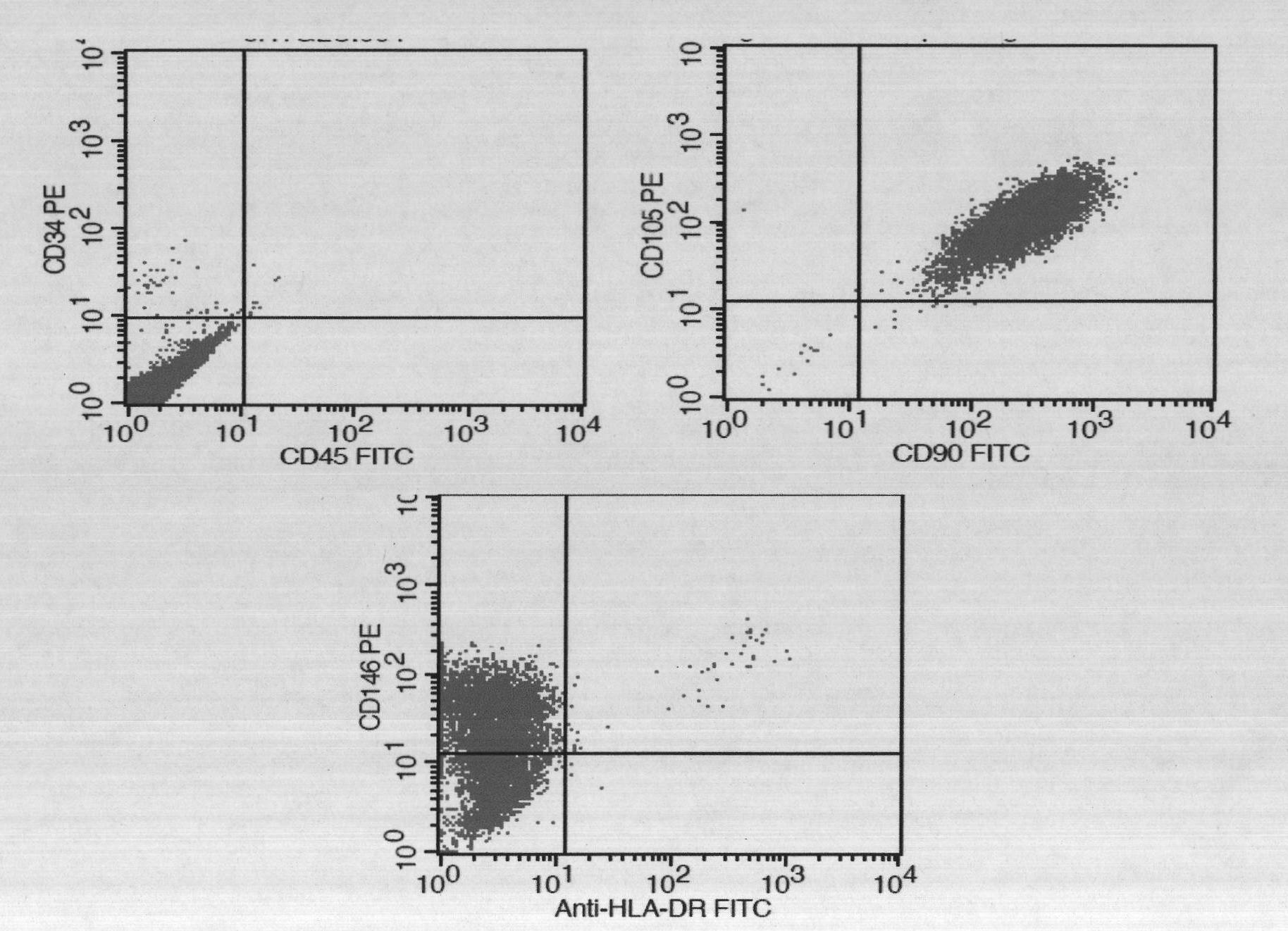

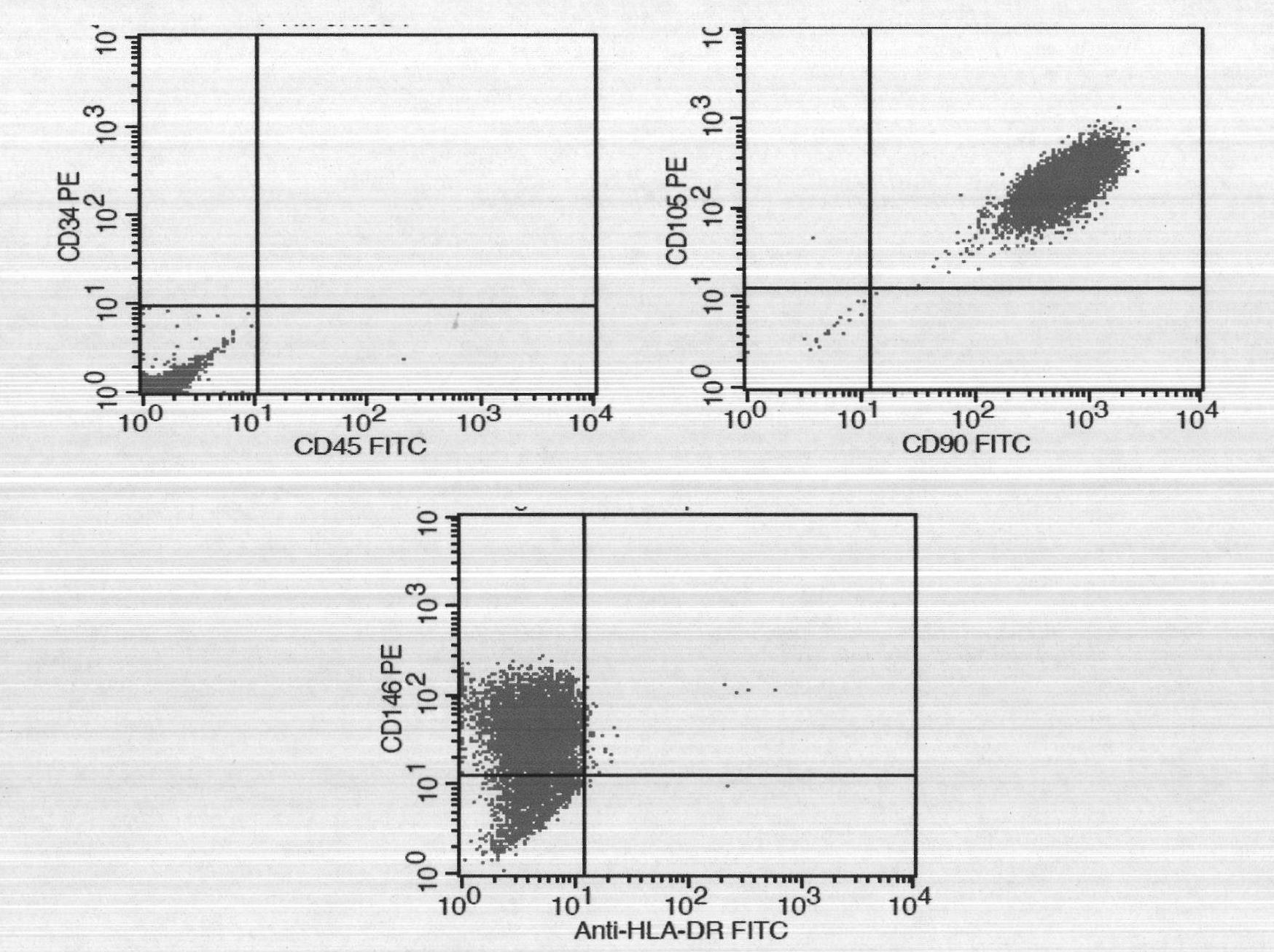

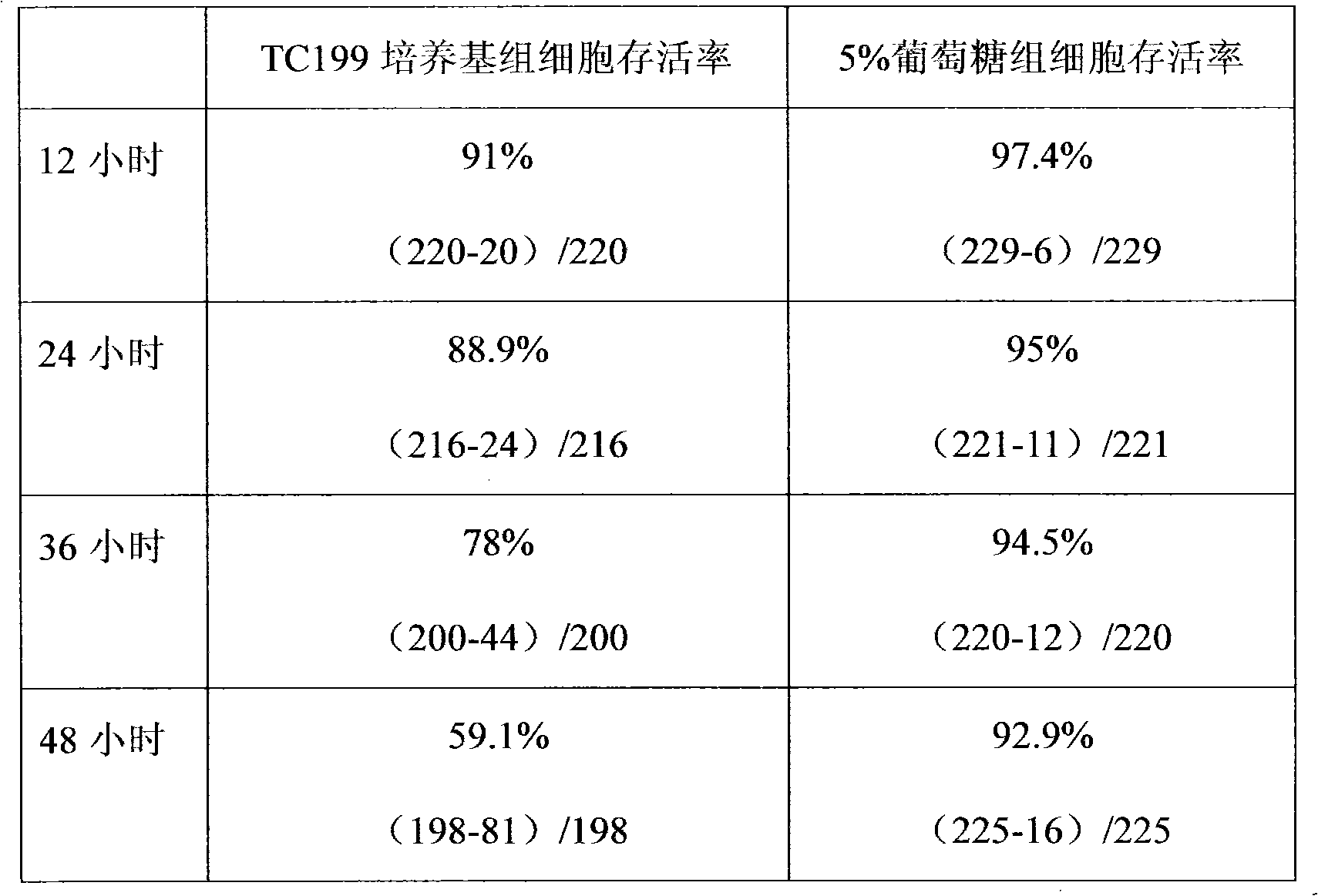

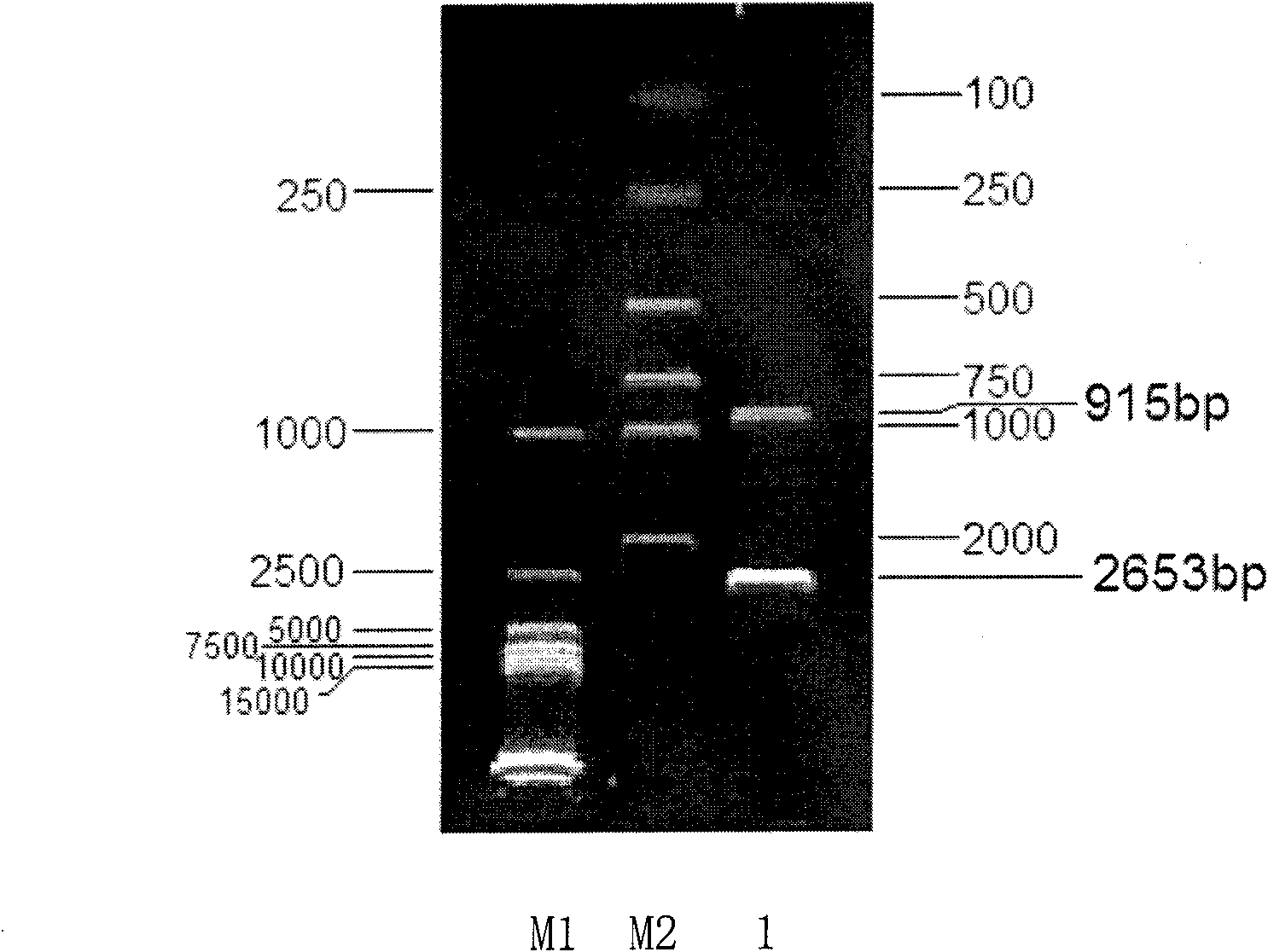

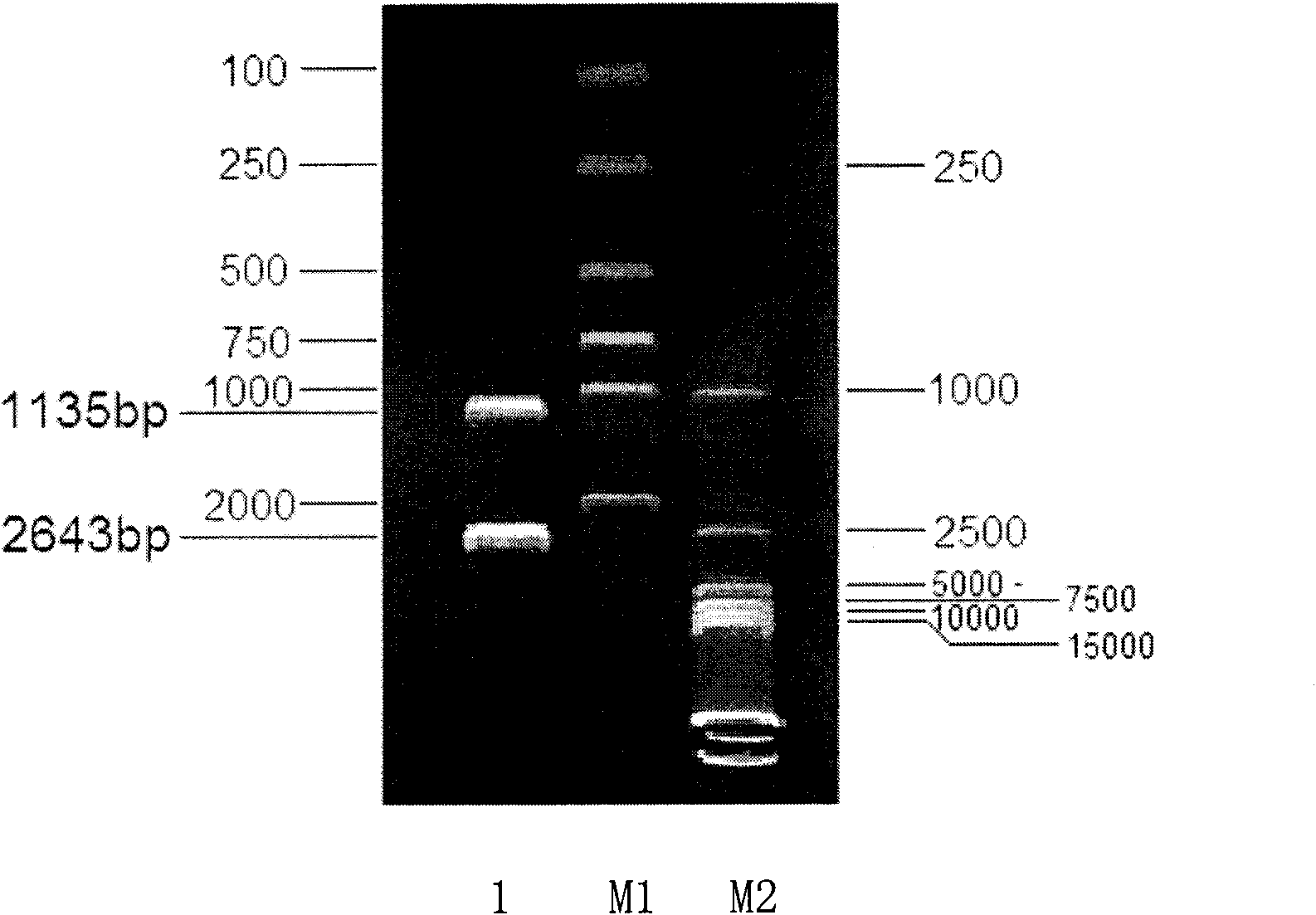

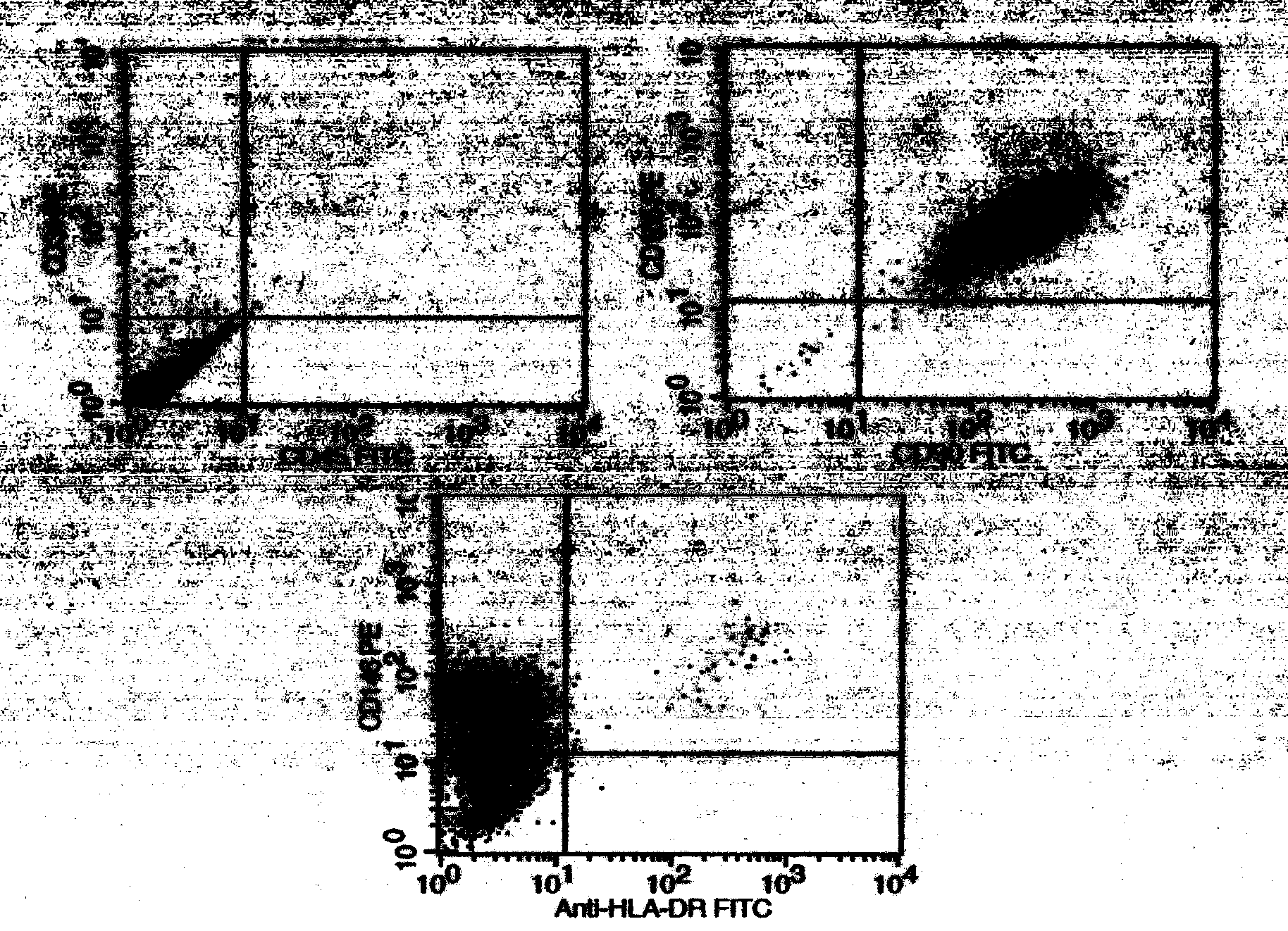

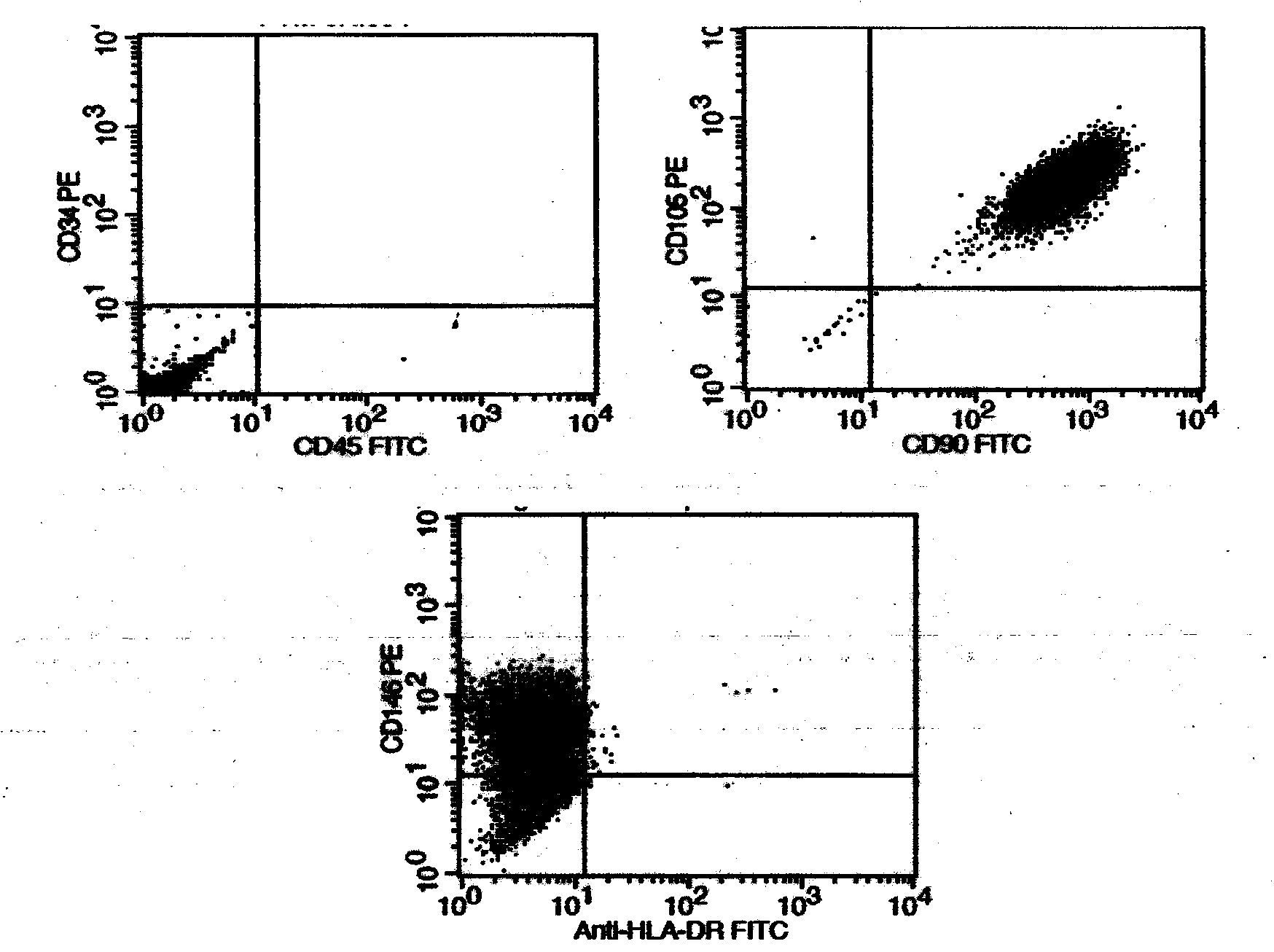

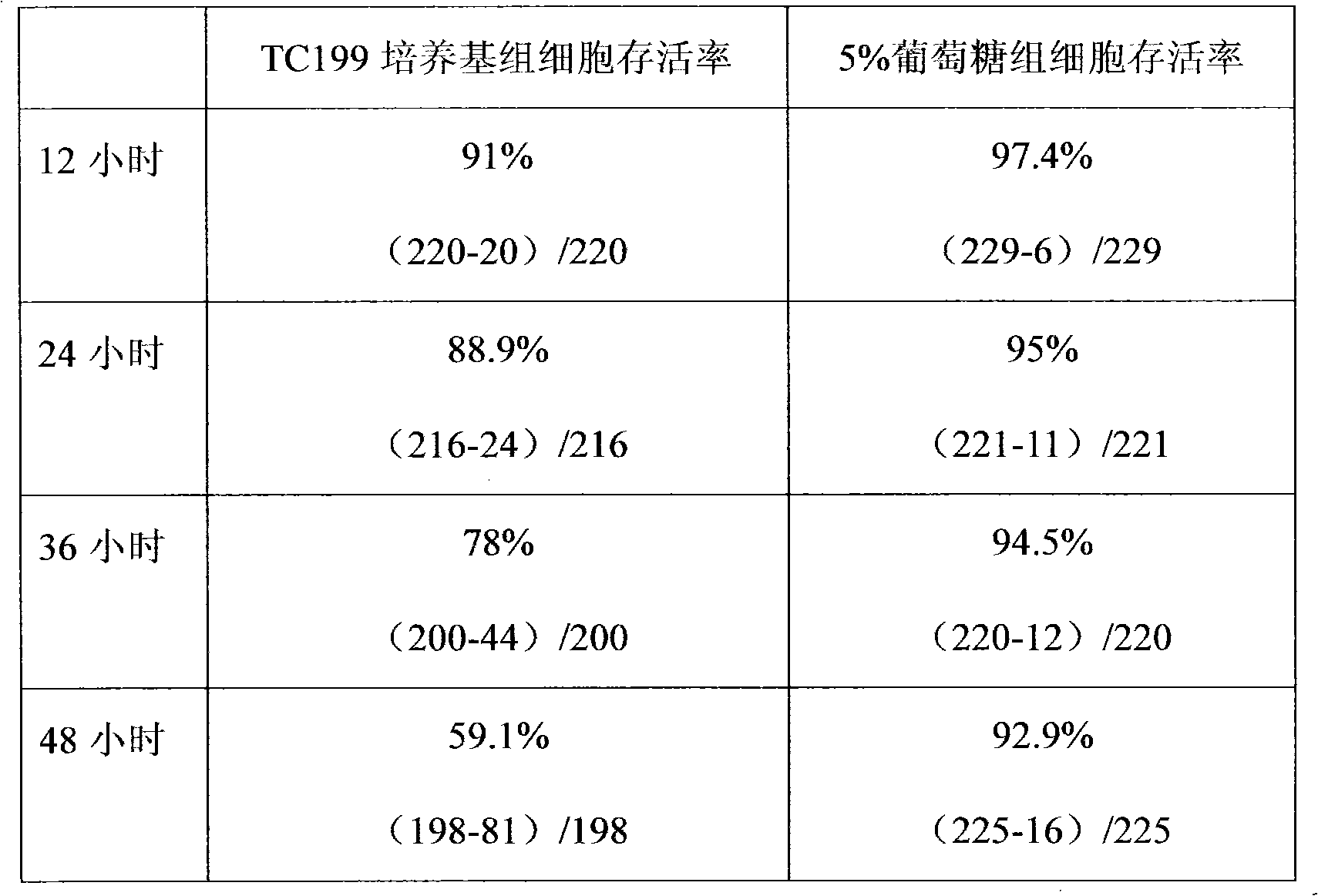

The invention relates to an improved mesenchyme stem cell protection solution as well as application and a preparation method thereof. The protection solution can effectively prolong the activity remaining time of mesenchyme stem cells, reduces preparation cost, and has the advantages of wide raw material source, simple preparation, safe and reliable direct clinical application; and after the mesenchyme stem cells are preserved for 48 hours in the protection solution, the cell activity is still above 90 percent, the cell morphology is normal, and the multiplication capacity and mesenchyme stem cell phenotype characteristics are not influenced.

Owner:青岛奥克生物开发有限公司

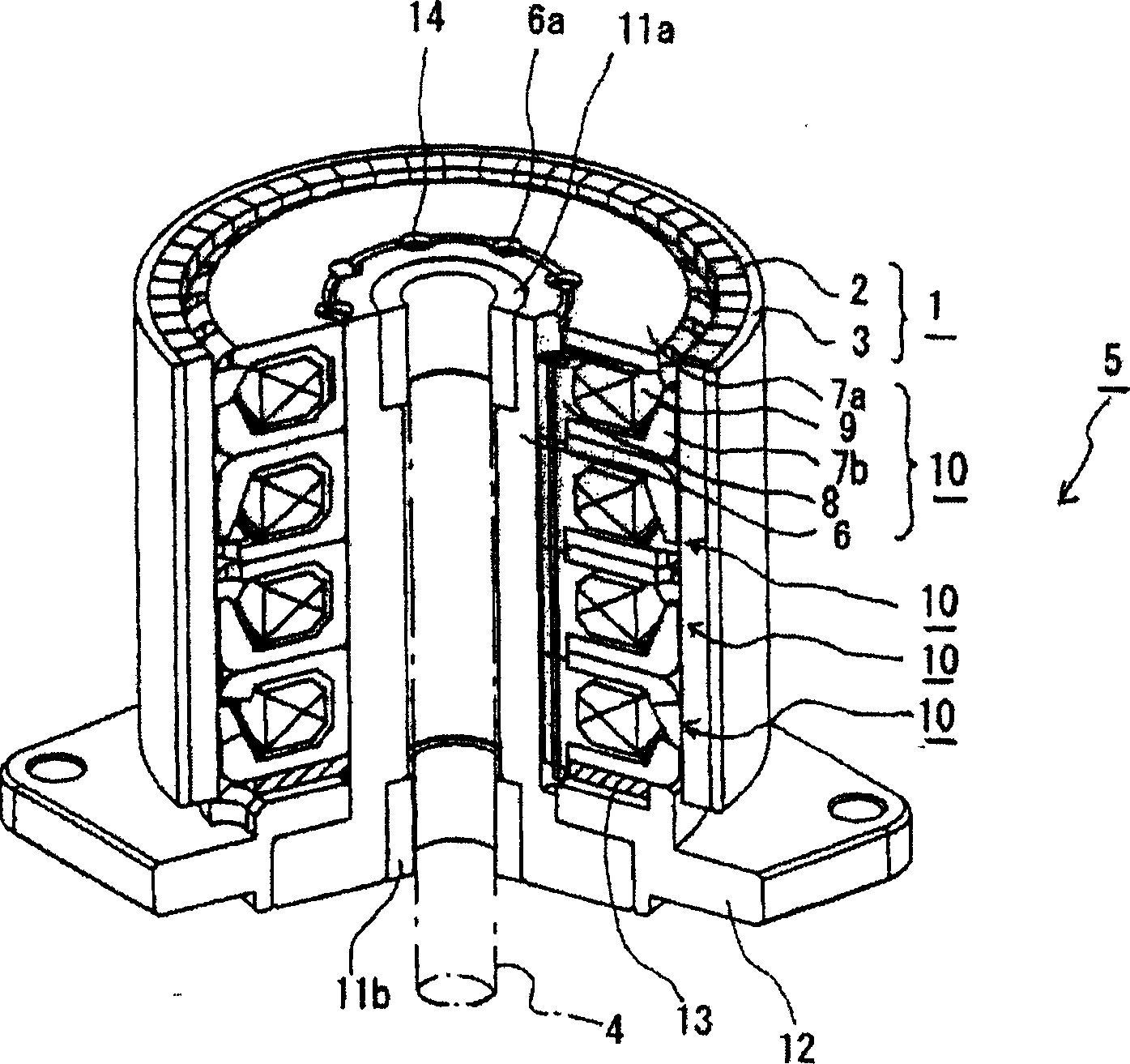

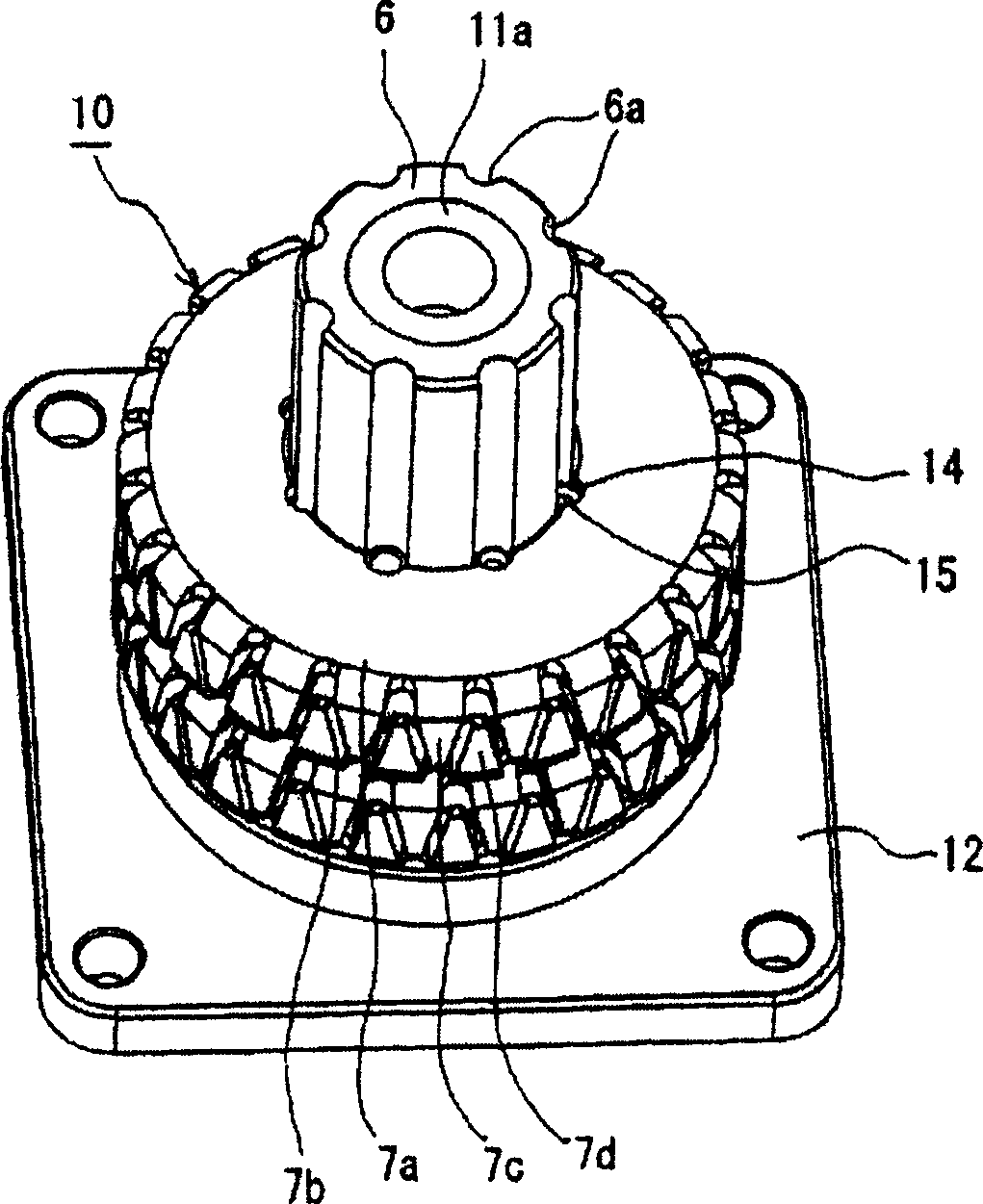

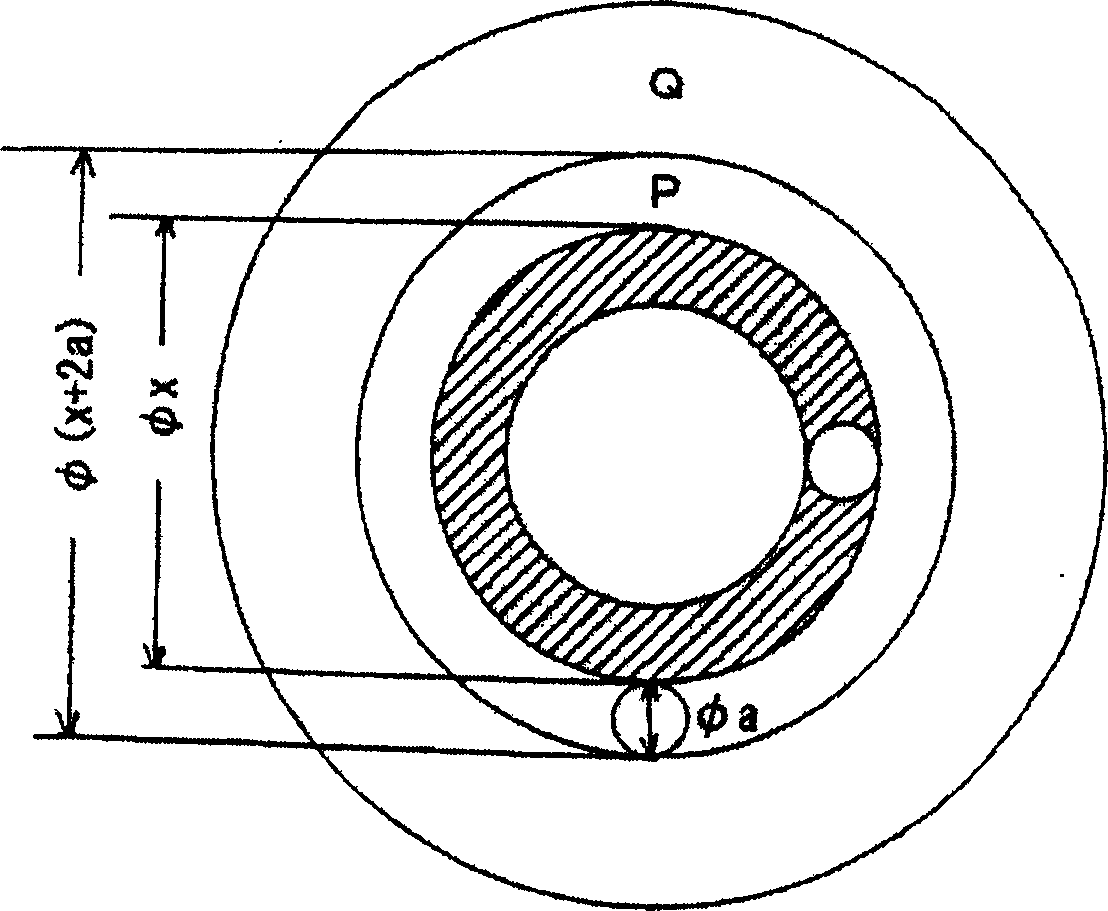

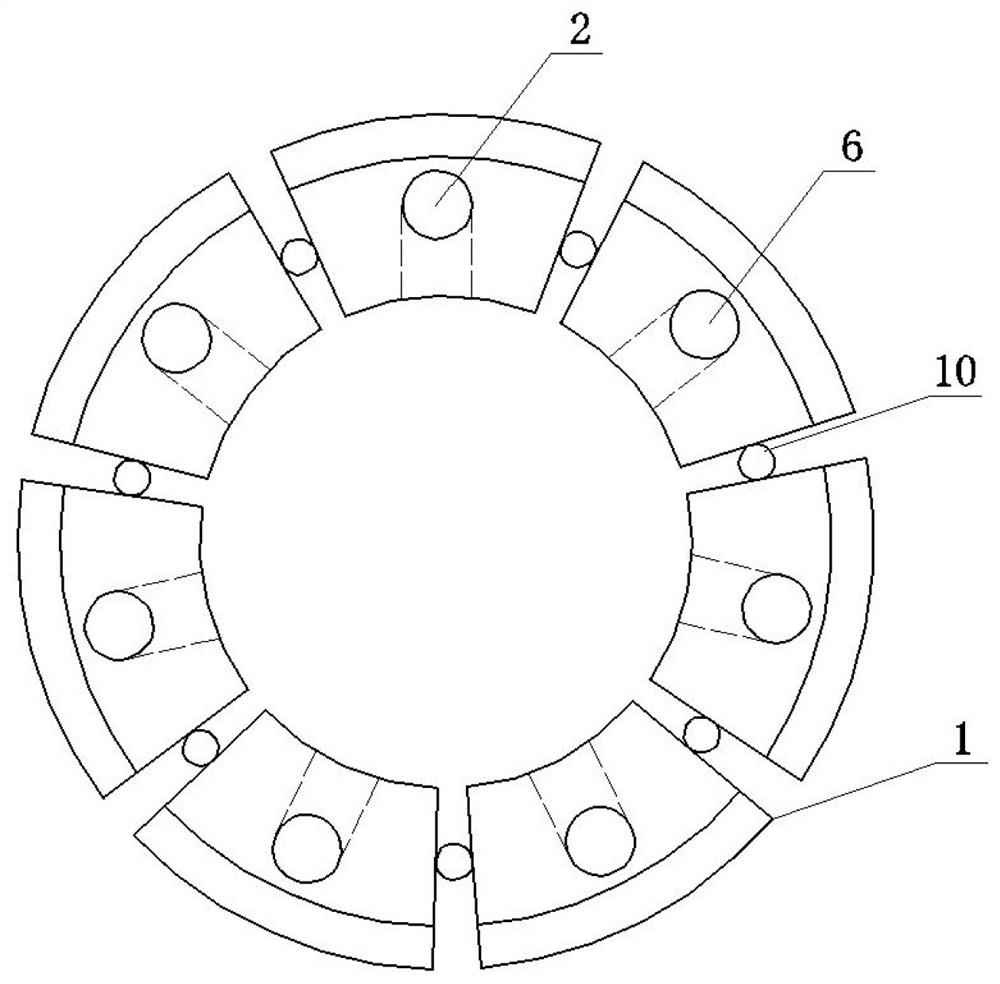

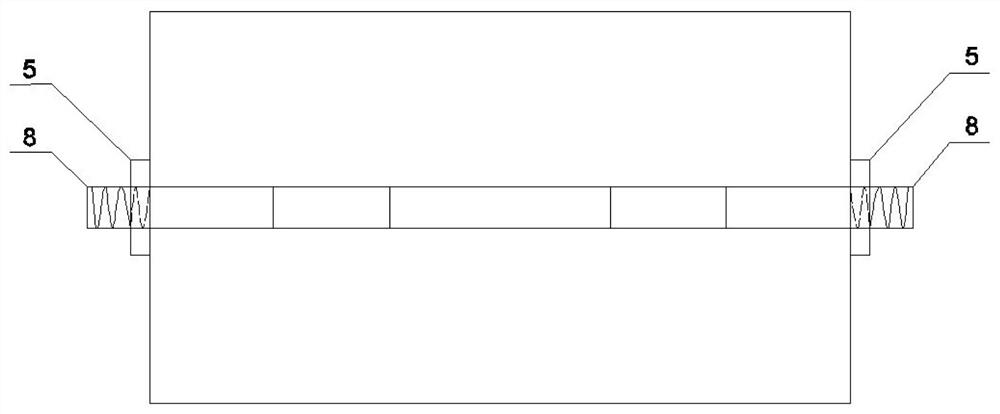

Outside-rotor motor

InactiveCN1913303ACharacteristics unchangedCharacteristics will not dropMagnetic circuitBobbinEngineering

Owner:SHINANO KENSHI

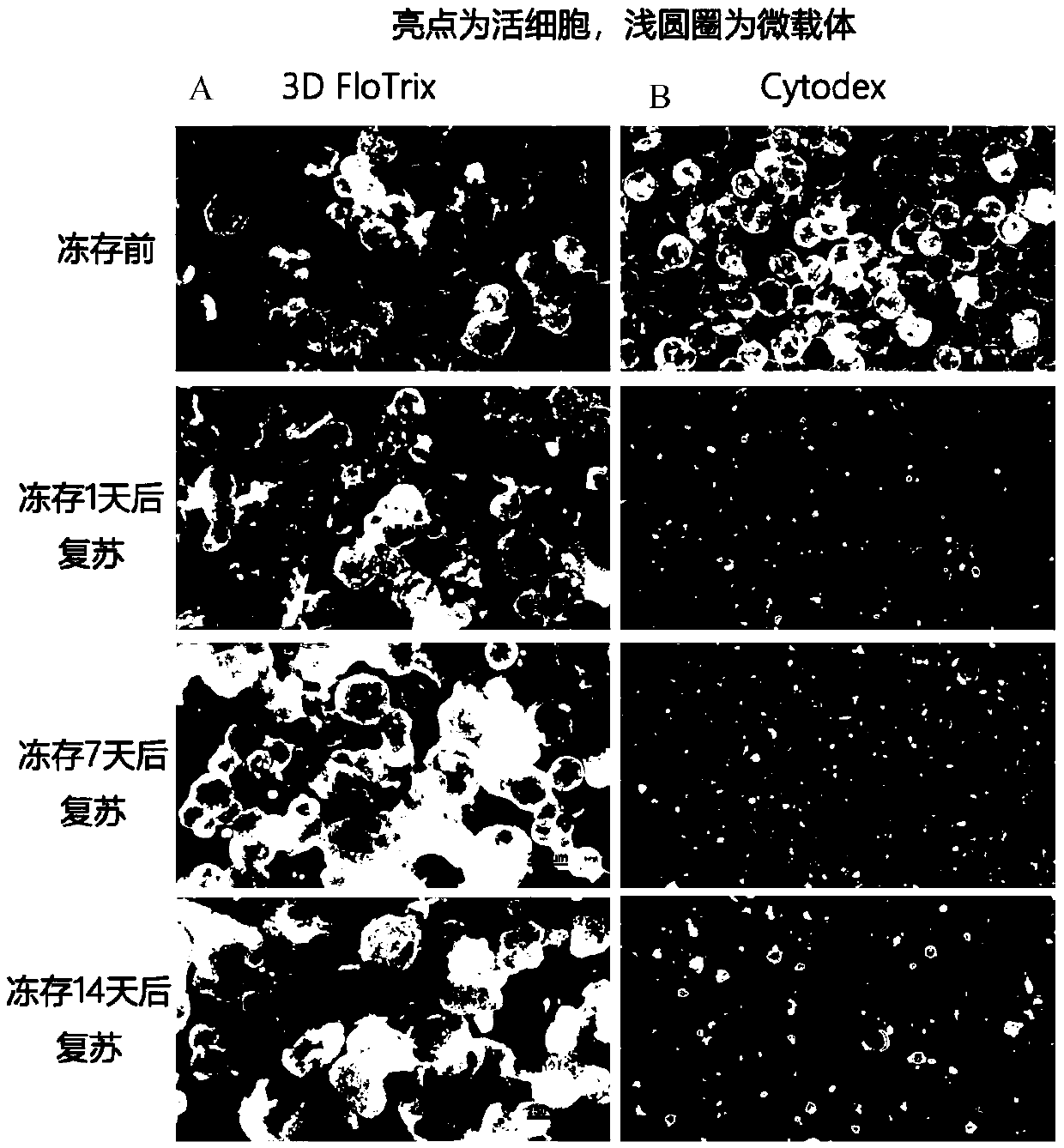

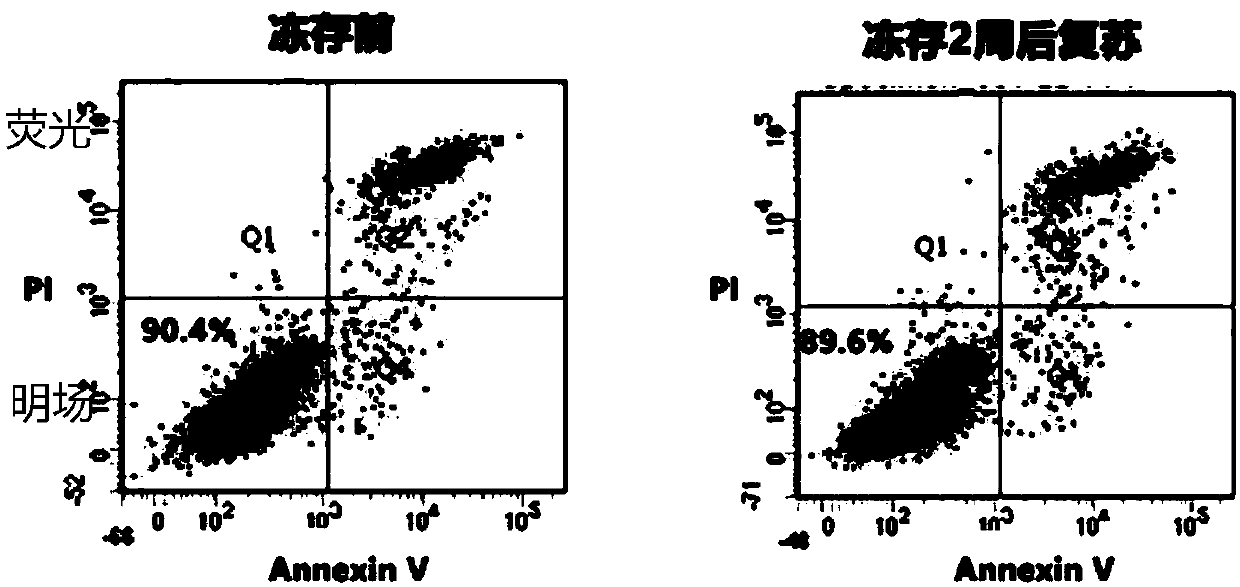

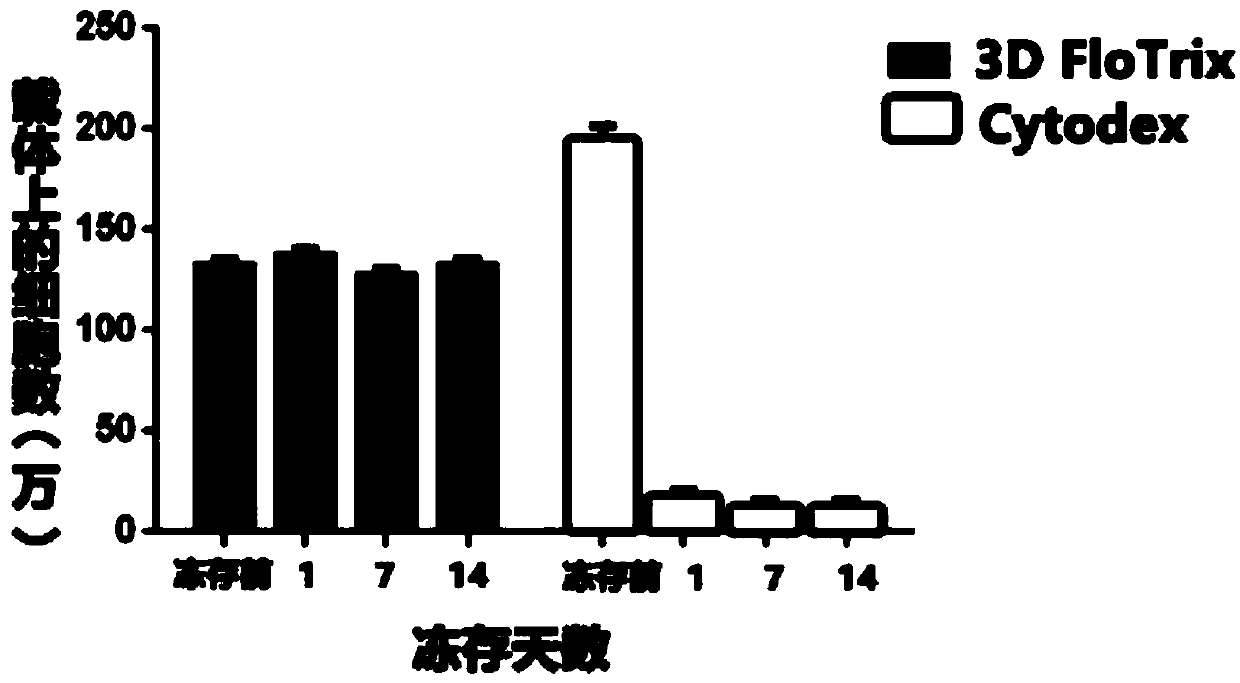

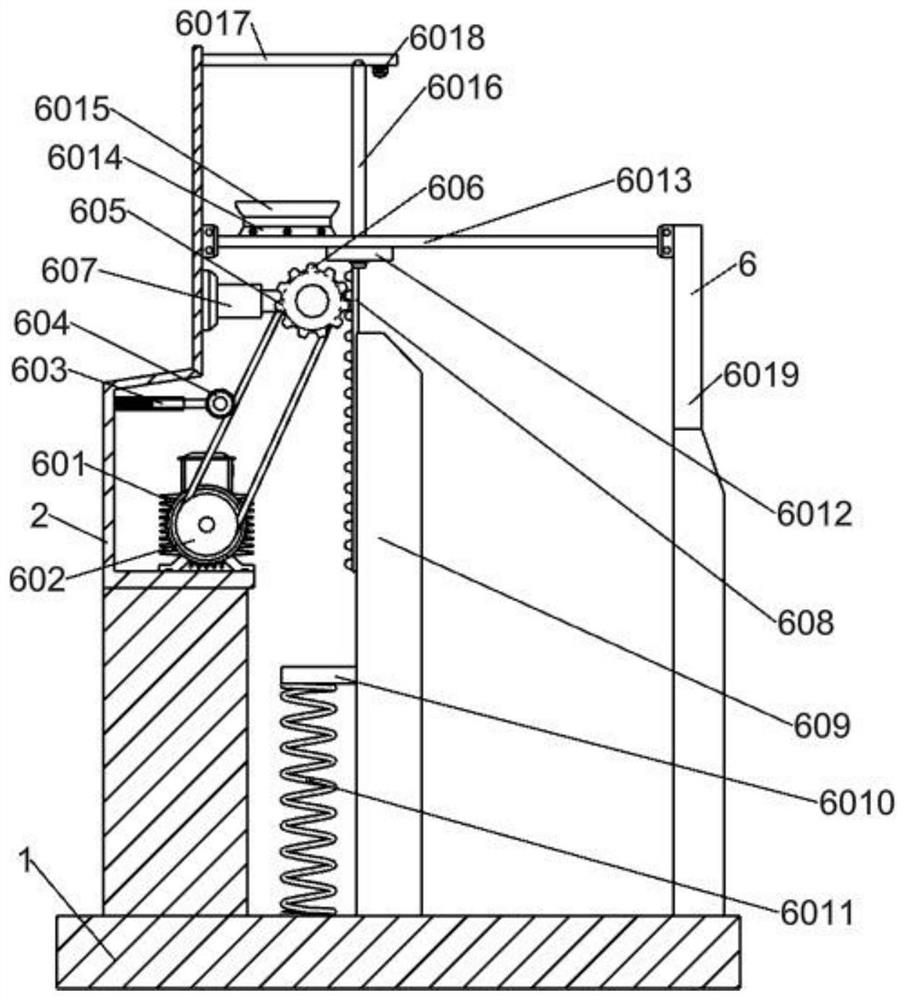

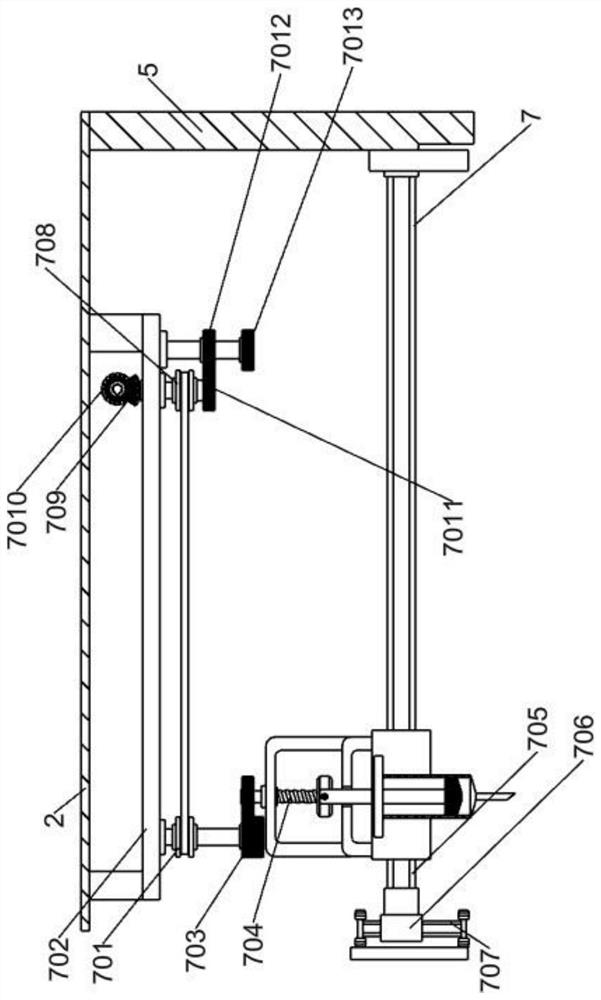

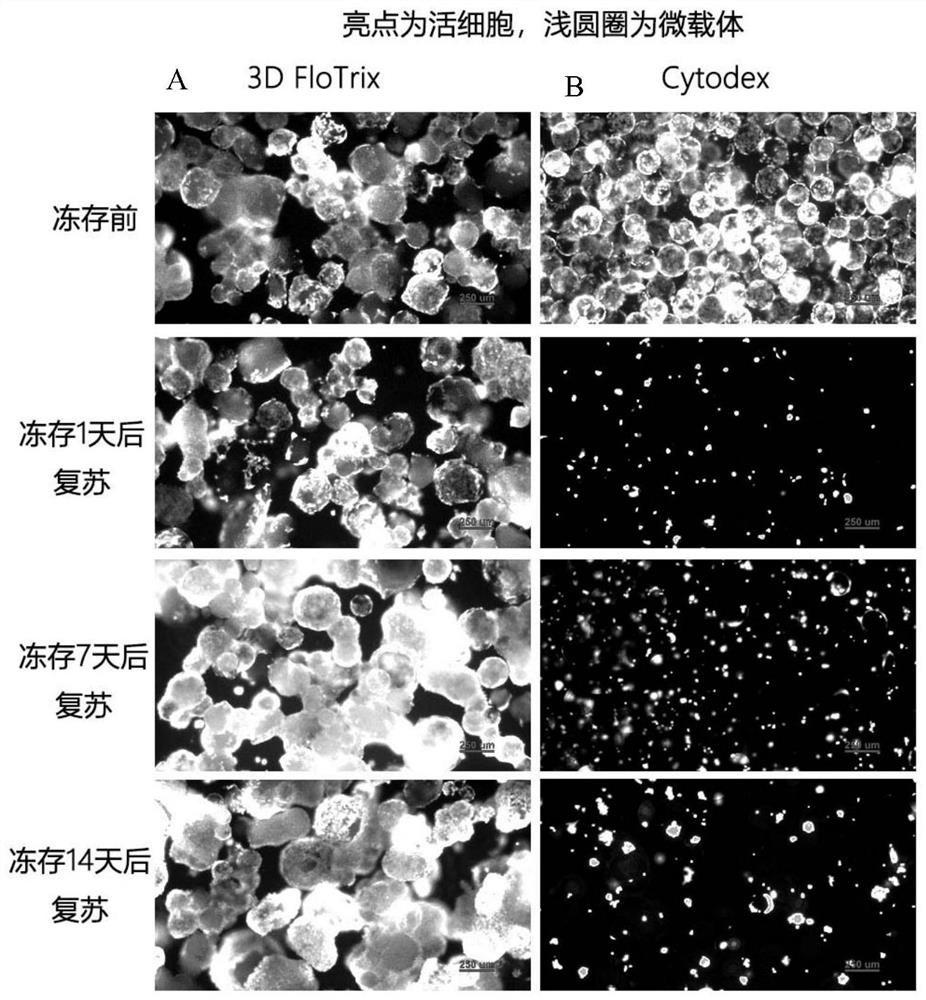

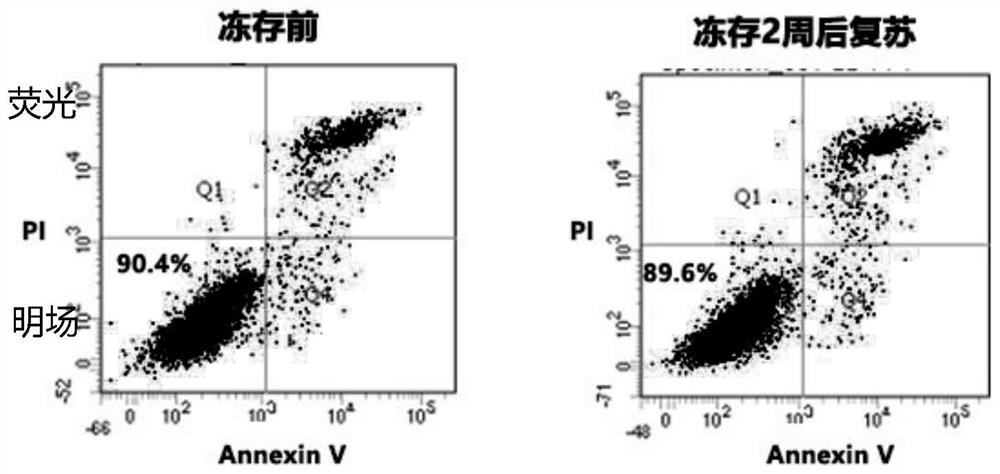

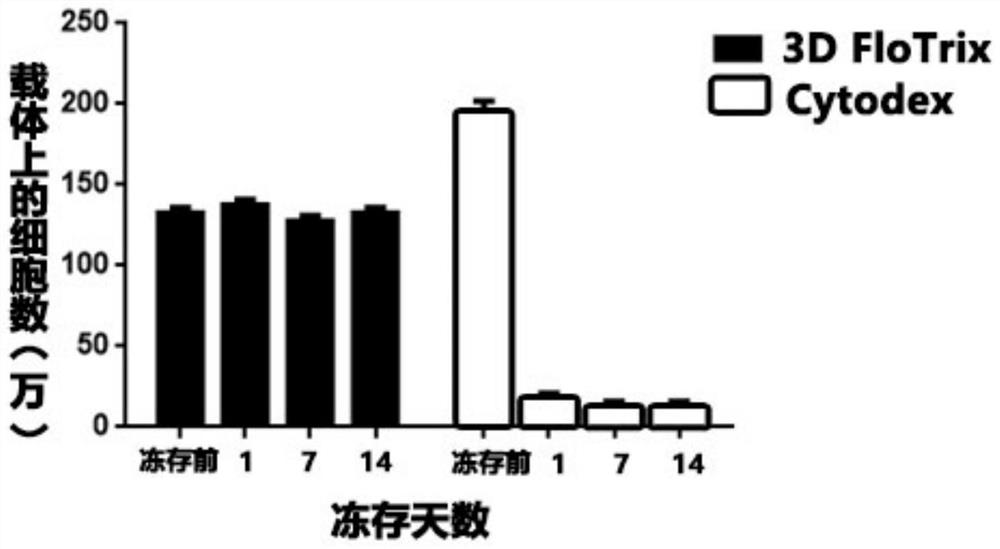

Method for in-situ cryopreservation of cells by three-dimensional micro-carrier

ActiveCN109566604AIncrease vitalityCharacteristics unchangedDead animal preservationCryopreservationLiquid nitrogen

Owner:BEIJING CYTONICHE BIOTECH CO LTD

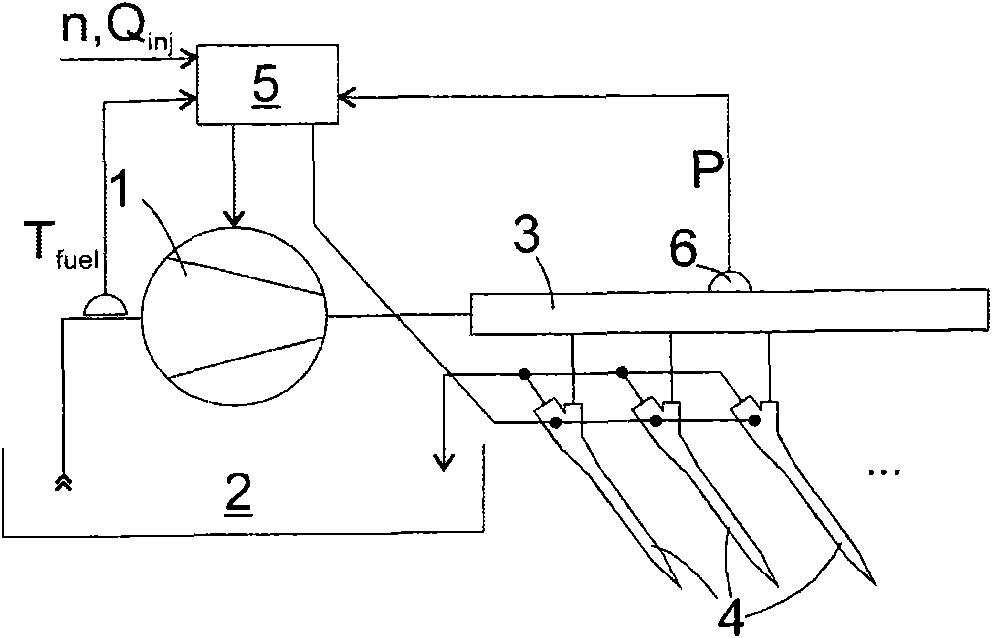

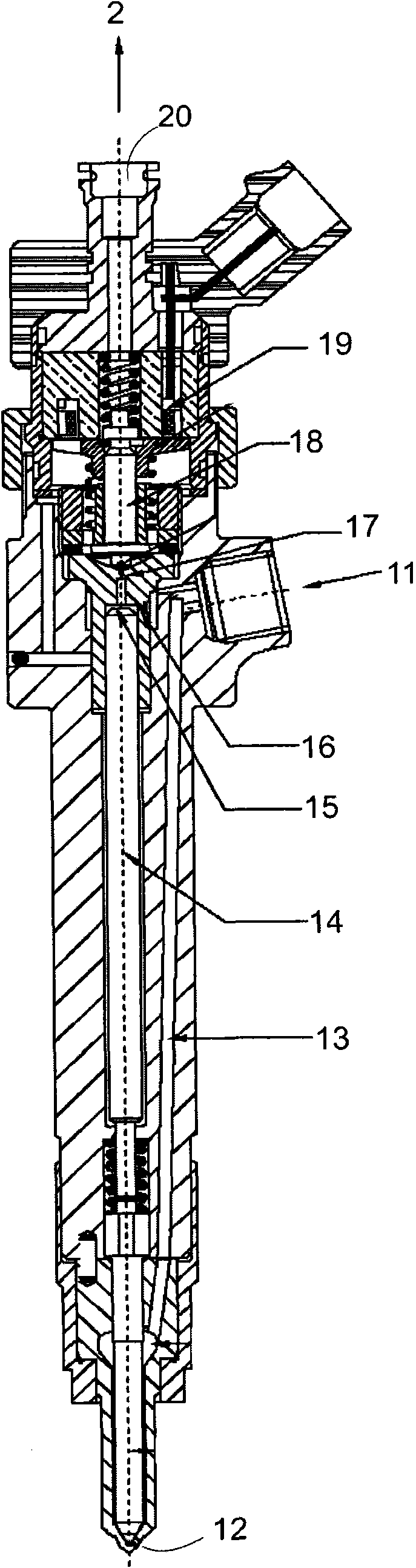

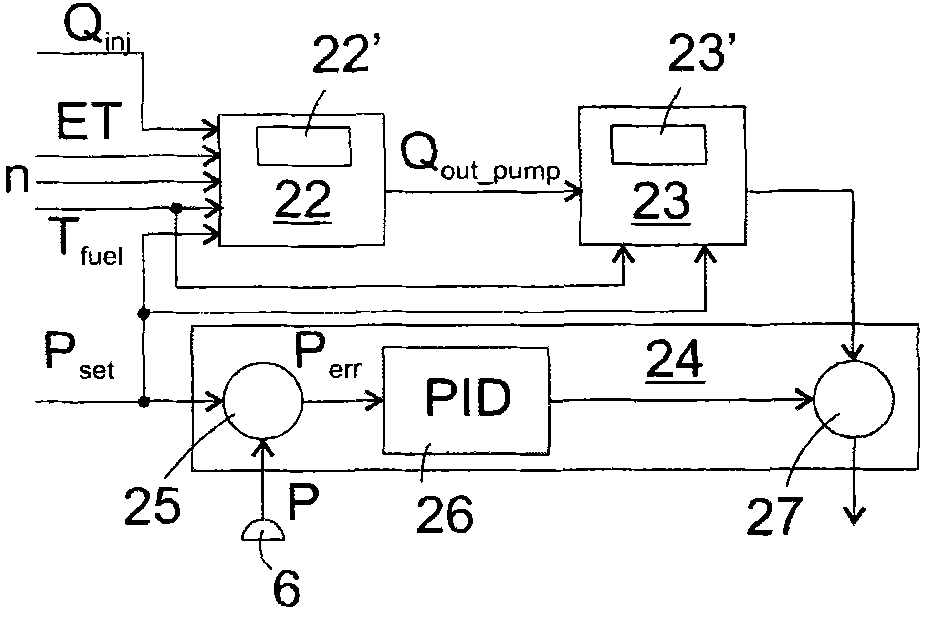

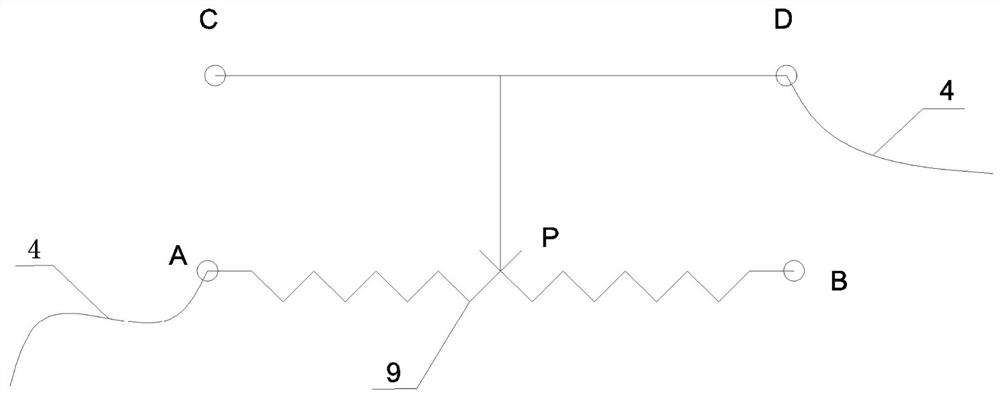

Method and system for controlling fuel pressure

InactiveCN102011656ACharacteristics unchangedElectrical controlFuel injection apparatusRail pressureFuel supply

A method for controlling rail pressure in a fuel supply system comprising a fuel pump 1, at least one injector 4 and a rail 3 connecting the injector (4) to the pump (1), comprises the steps of establishing a relationship between rail pressure (P) and a leak rate of the injector (4), estimating a fuel drain rate from the rail based on a fuel injection rate (Qinj), rail pressure (P) and rail pressure / leak rate relationship; estimating a desired intake flow rate of the pump based on fuel drain rate and controlling the pump (1) to operate at a desired intake flow rate.

Owner:GM GLOBAL TECH OPERATIONS LLC

Tissue culture and rapid propagation method for sspindus mukurossi

InactiveCN104663459AReduce dependencyCharacteristics unchangedPlant tissue cultureHorticulture methodsSoapbark TreePlantlet

The invention discloses a tissue culture and rapid propagation method for sspindus mukurossi. The sspindus mukurossi is also named as soapbark, is a deciduous tree, is mainly propagated by seed sowing, and is hard in seed coat, high in moth rate, irregular in seedling emergence and long in growth period. Defects of seed propagation can be made up by tissue culture, the excellent characteristics of a mother plant are kept unchanged, the propagation speed is high, the propagation coefficient is high, the production cost can be reduced, and the needs of large-scale planting of the sspindus mukurossi are met. A stem with nodes of the sspindus mukurossi is taken as an explant, a sspindus mukurossi in-vitro replanting plant is successfully obtained by adventive bud induction culture, multiplication culture, rooting culture, acclimatization and transplantation, and the like, a sspindus mukurossi tissue culture and rapid propagation system is established, an effective way is provided for the large-scale seedling growing of the sspindus mukurossi, and foundation is laid for the factorial production and application of sspindus mukurossi nursery-grown plants.

Owner:黎有辉

Anther culture method of primula forbesii

ActiveCN101766121AShorten the breeding processPromote growthHorticulture methodsPlant tissue cultureDiseaseSucrose

The invention provides an anther culture method of primula forbesii, comprising selection of the explant, disinfection and vaccination of the explant, induction and proliferation of the callus, differentiation of the callus, and rooting culture and transplantation of the tissue culture seedling, wherein, the medium of the induction and proliferation of the callus is as follows: MS +6- BA1.0mg / L +2,4-D 0.5mg / L, 30g / L sucrose, 6g / L agar, pH 5.9-6.0; the differentiation medium of the callus is as follows: MS +6- BA 0.2mg / L + NAA 0.01mg / L, 40g / L sucrose, 7g / L agar, pH 5.9-6.0; the rooting medium is as follows: MS, pH 5.9-6.0. The seedling obtained through the method provided by the invention has good growth, strong consistency and adaptability, less pests and diseases, easy management, and is easy for scale production.

Owner:BEIJING FORESTRY UNIVERSITY

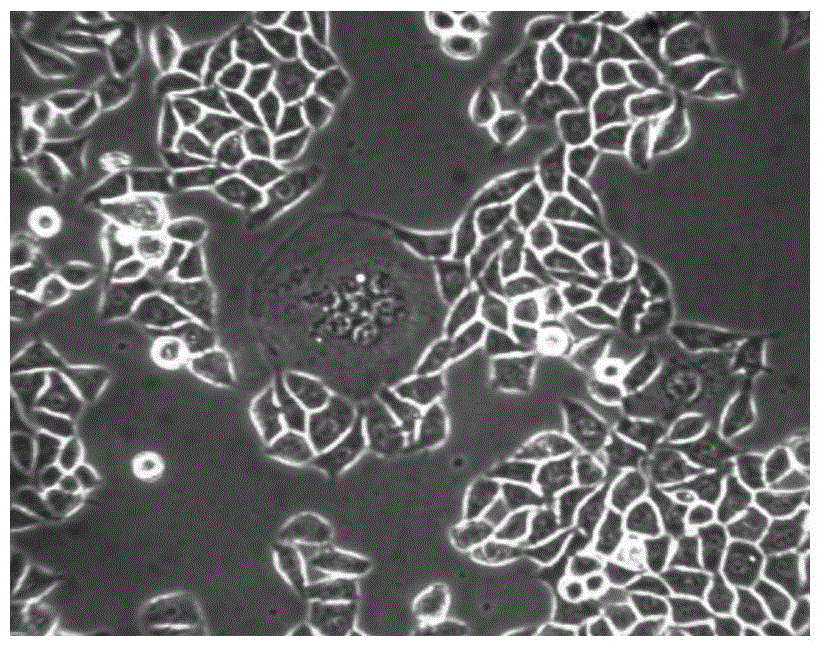

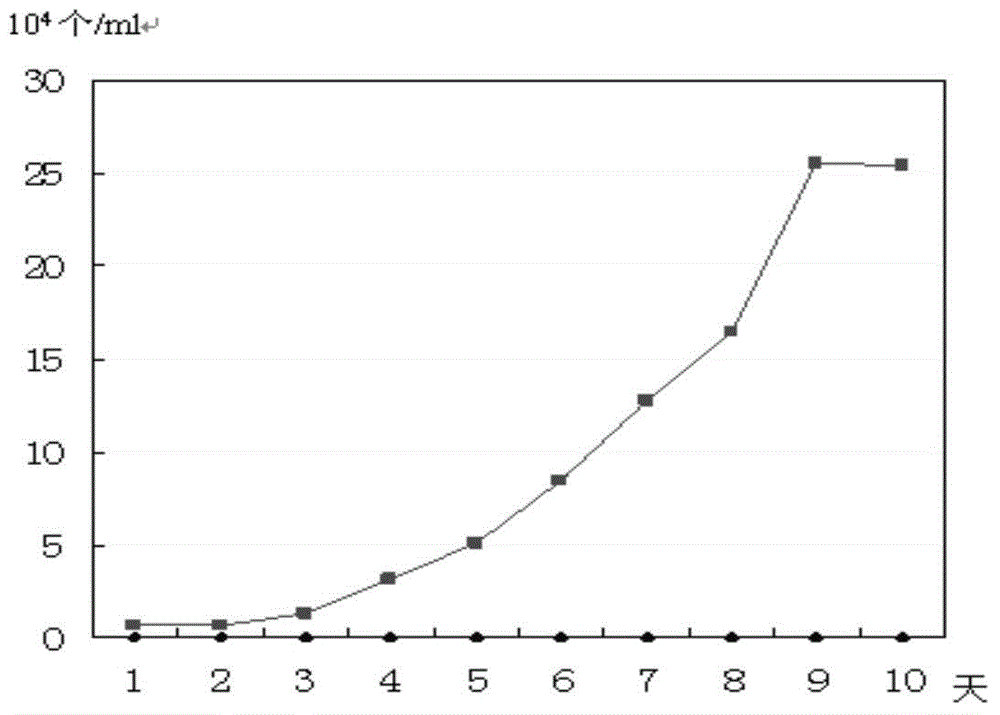

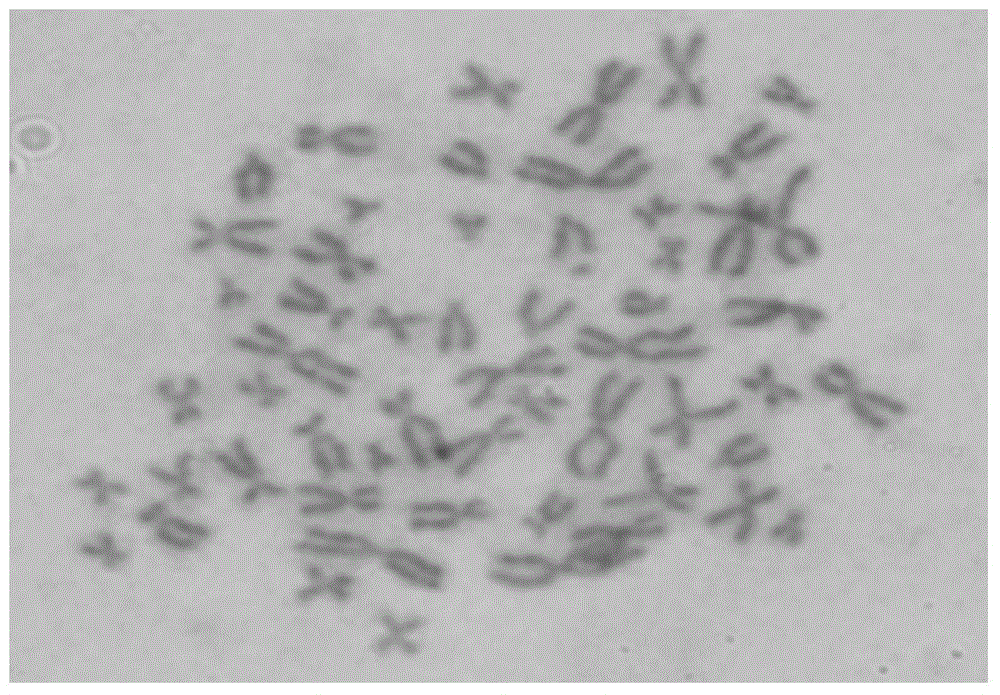

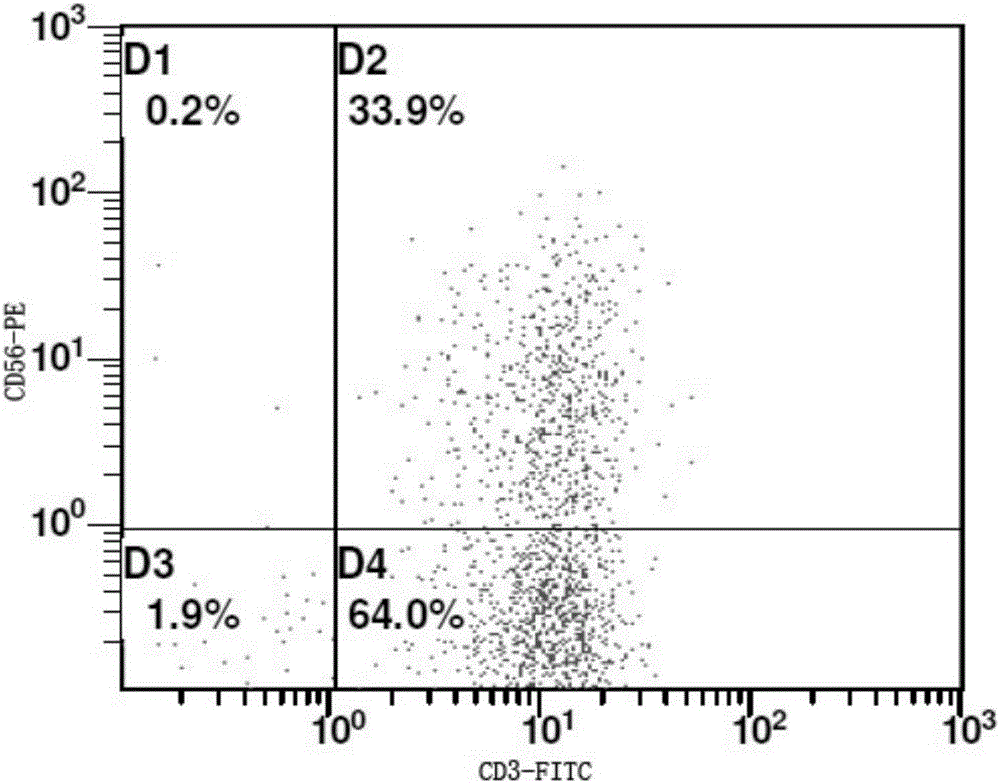

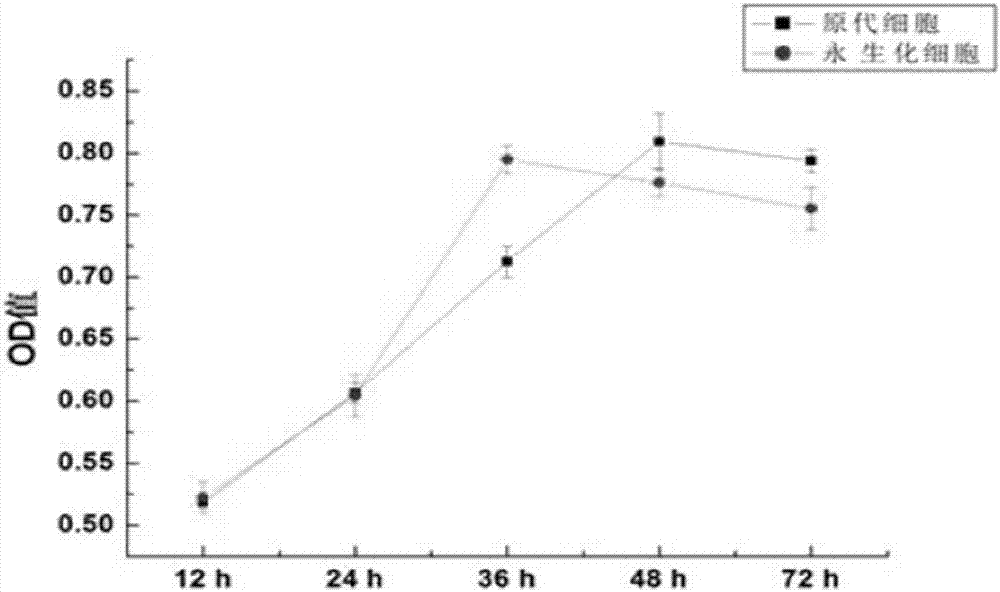

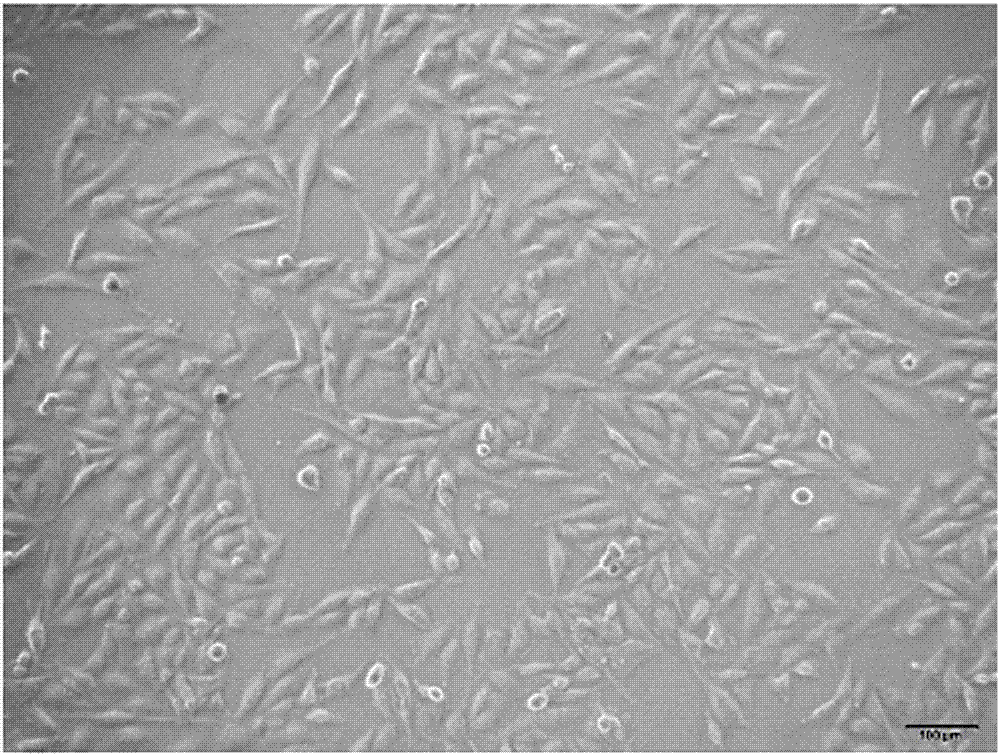

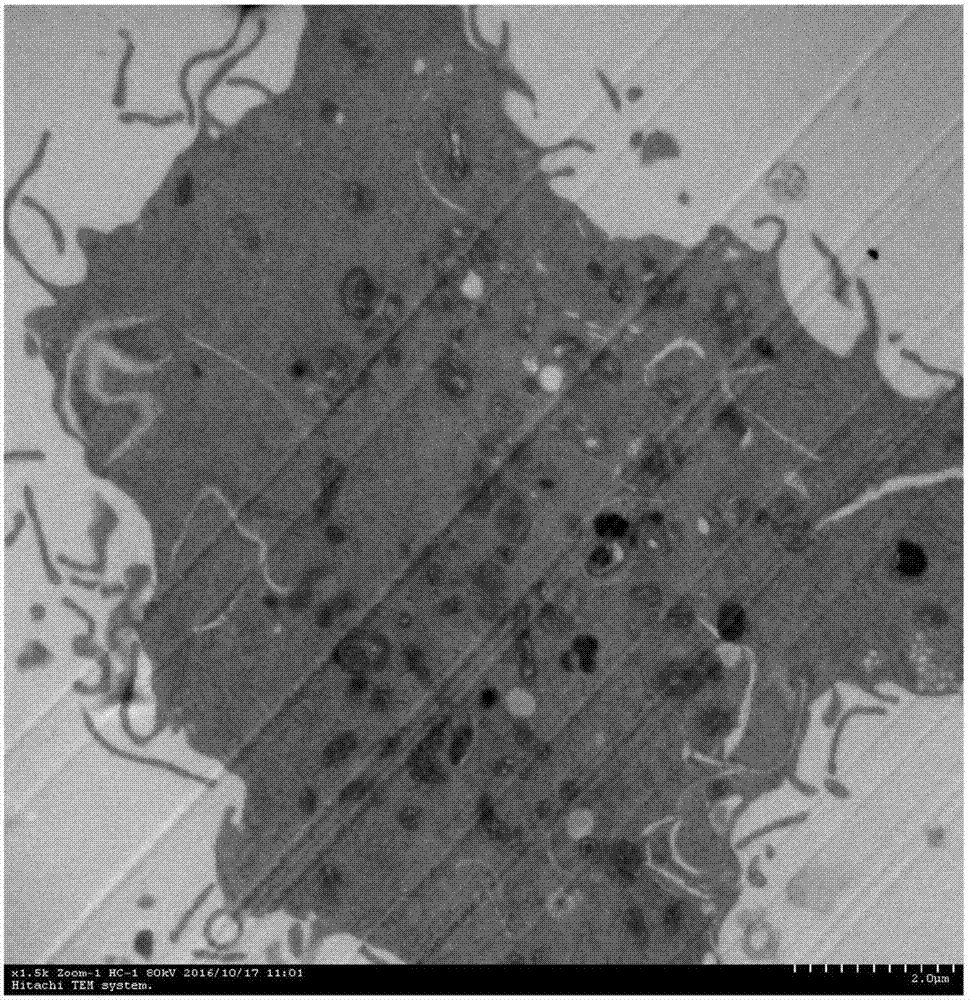

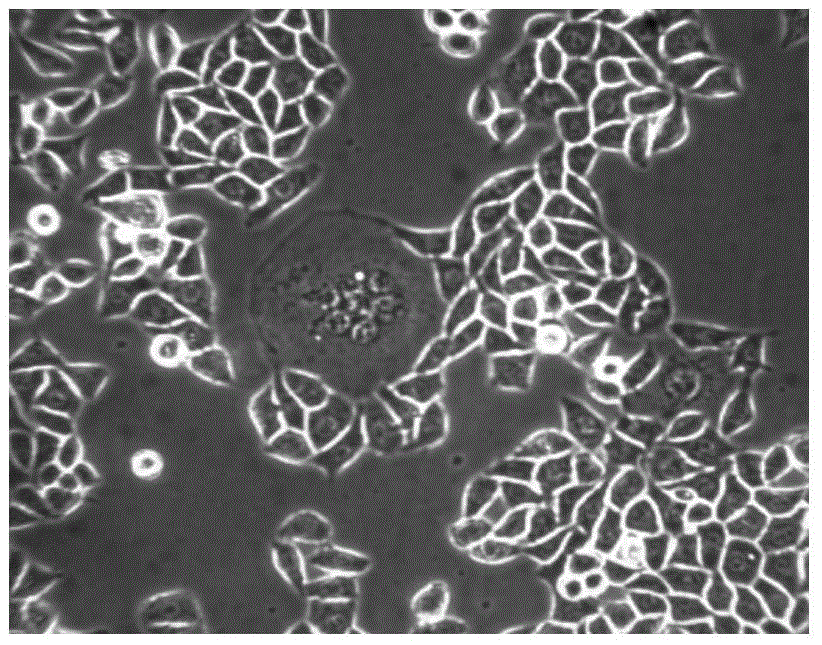

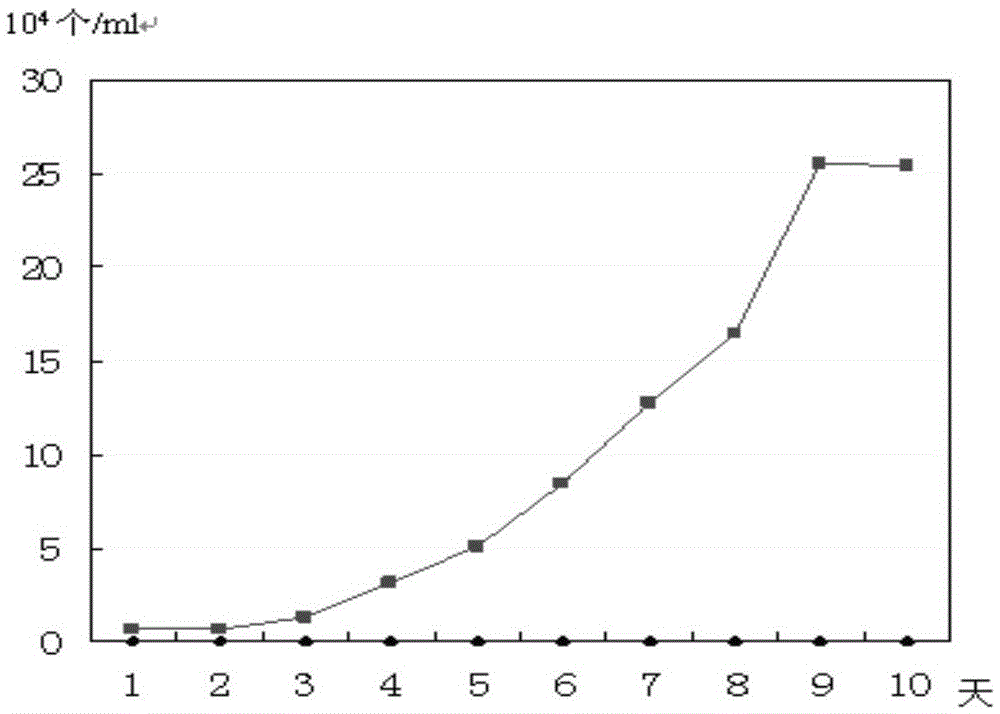

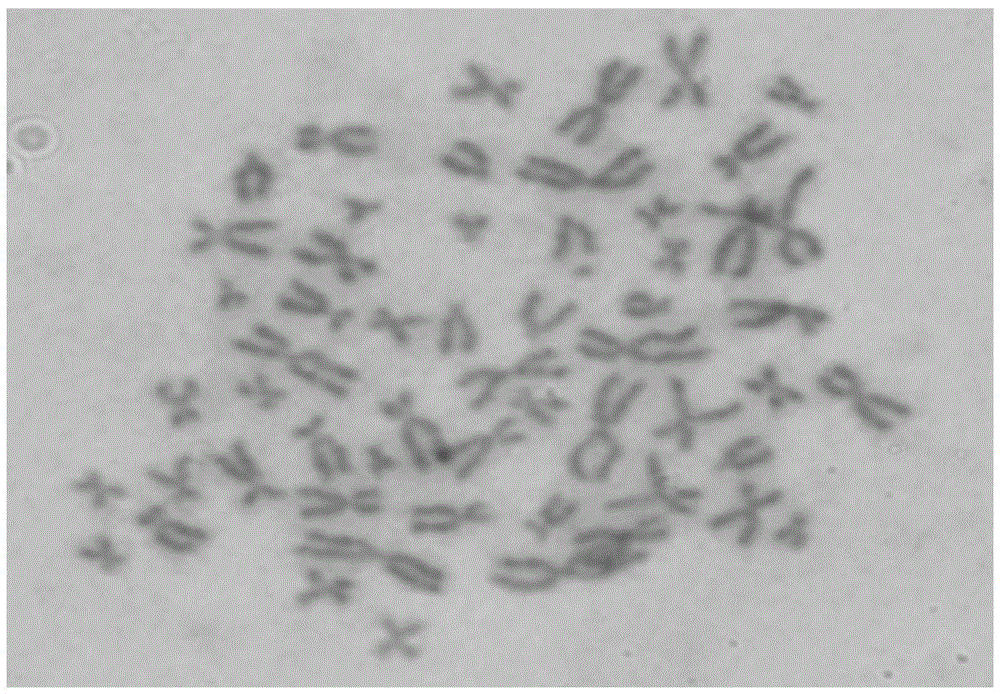

Human thymoma cell line and application thereof

InactiveCN104087554AIn vitro tumorigenic abilityCharacteristics unchangedMicrobiological testing/measurementMicroorganism based processesAbnormal tissue growthLymphatic Spread

The invention discloses a human thymoma cell line and application thereof, belonging to the field of tumor biology. The human thymoma cell line is named Thy0517 and has a collection number of CGMCC (China General Microbiological Culture Collection Center) No.9328. The human thymoma cell line Thy0517 has main advantages of having protein expression similar to primary tumor tissues, abnormal karyotype and characteristics of tumor cells with in-vitro tumor forming capability. After in-vitro continuous passage culture, the characteristics of thymoma cells keep unchanged, and therefore the human thymoma cell line can be used as a cell material for researching and developing thymoma-related drugs. EGFR (Epidermal Growth Factor Receptor) expression of the human thymoma cell line is positive, so that proliferation, angiogenesis, adhesion, invasion and metastasis of the tumor cells can be promoted; the cell line can be used as a powerful cell tool for researching EGFR-targeted drugs.

Owner:张鹏

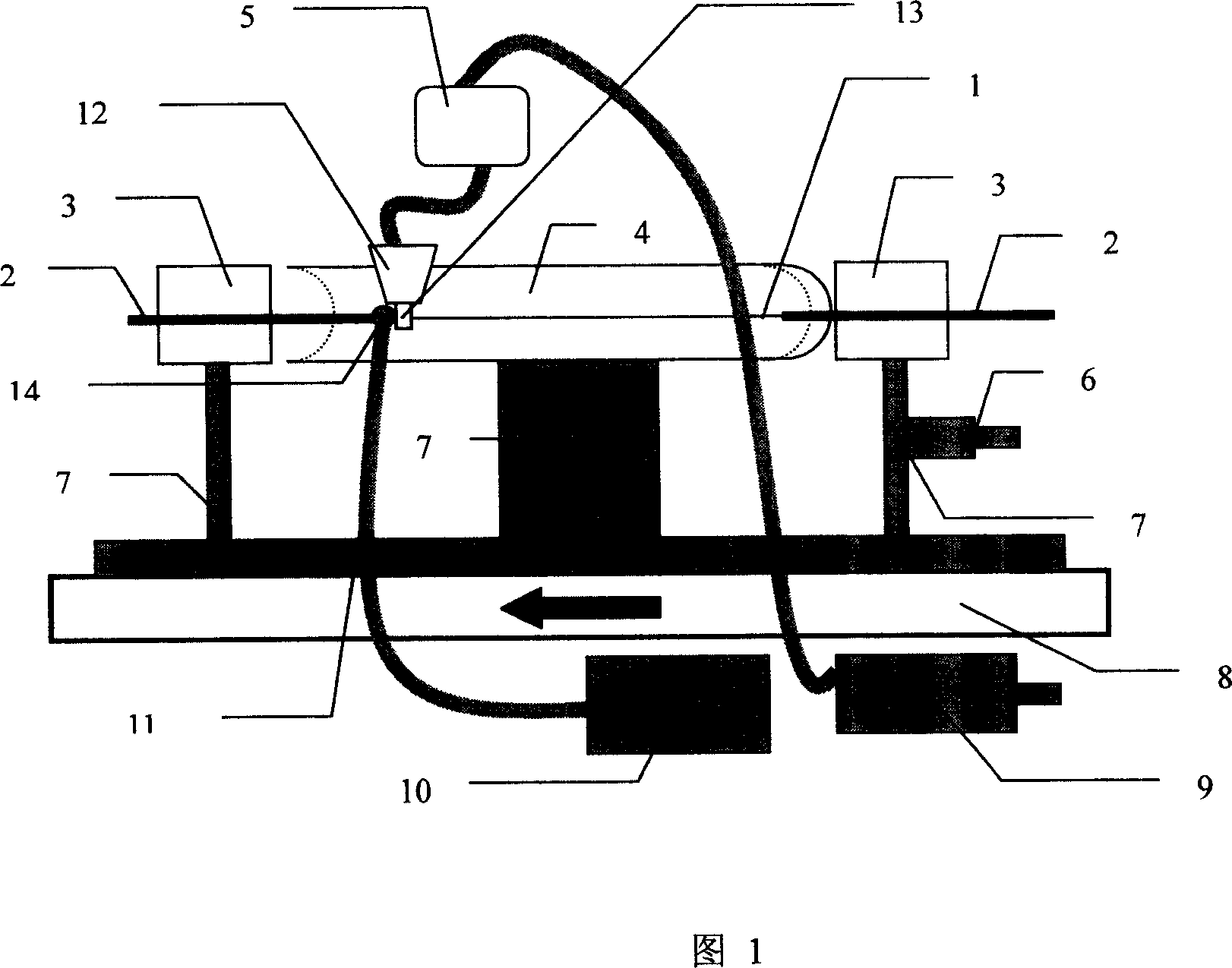

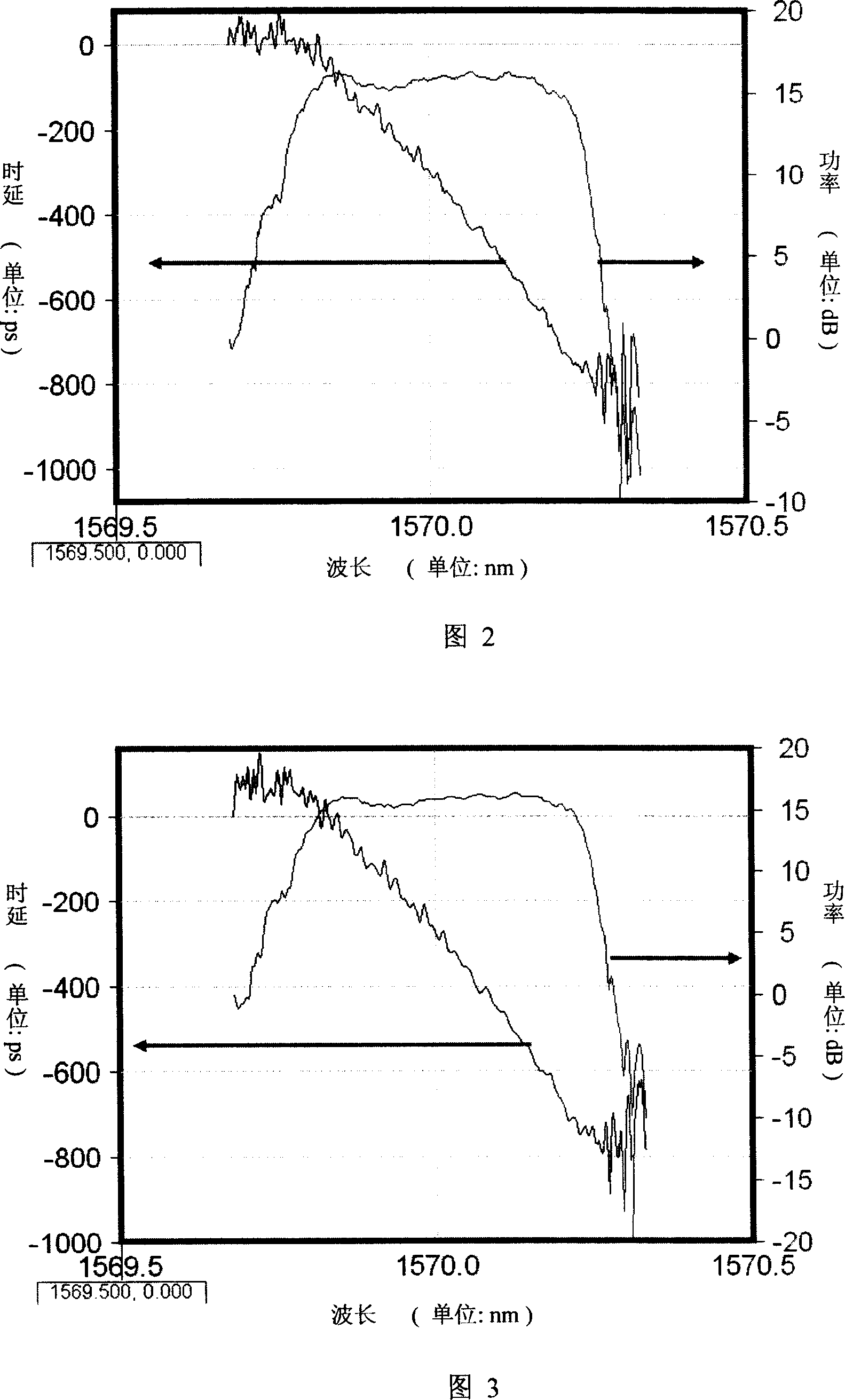

Coating apparatus and process for longoptic fiber grating

InactiveCN1986081AMeet coating requirementsCoating length adjustablePretreated surfacesCoatingsGratingFiber gratings

The present invention discloses coating apparatus and process for long fiber grating. The coating apparatus consists of high precision mobile platform, stress adjustable optical regulator, controllable coating material container, coating pliers, ultrasonic light source, reflector, etc. and has relatively low cost. The coating process includes shifting the high precision mobile platform, regulating the optical regulator, regulating the stress, controlled coating the fiber grating, and curing the coated layer with the precisely controlled ultrasonic light source. The present invention has adjustable coating length up to 200 mm, unchanged characteristic of the coated fiber grating and raised mechanical stress performance.

Owner:BEIJING JIAOTONG UNIV

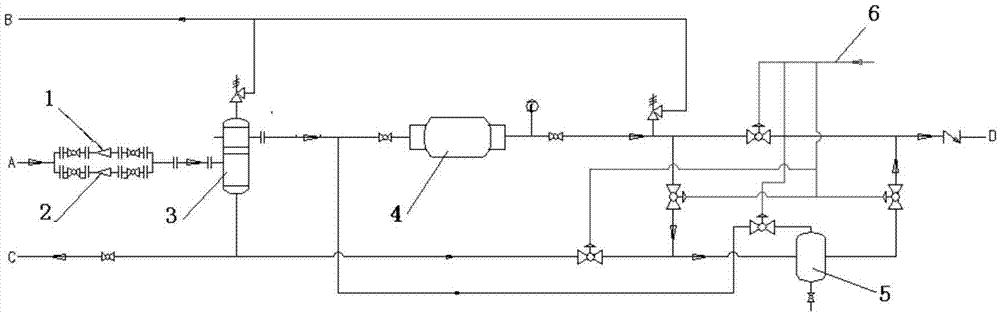

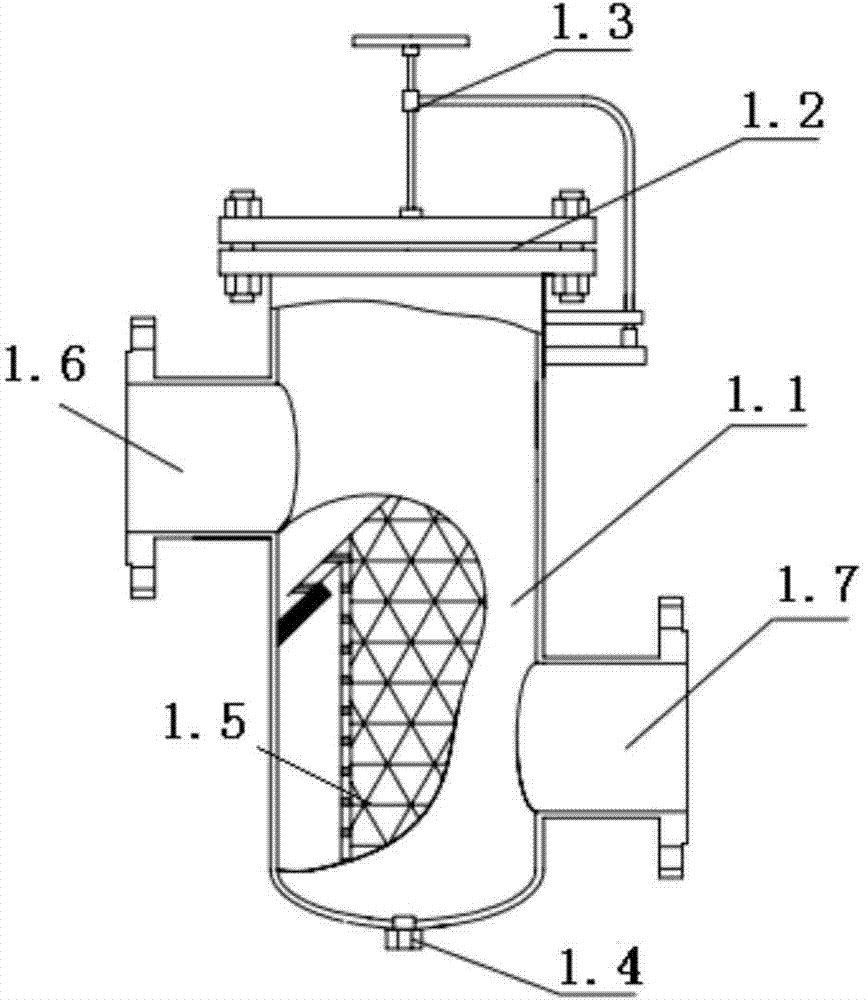

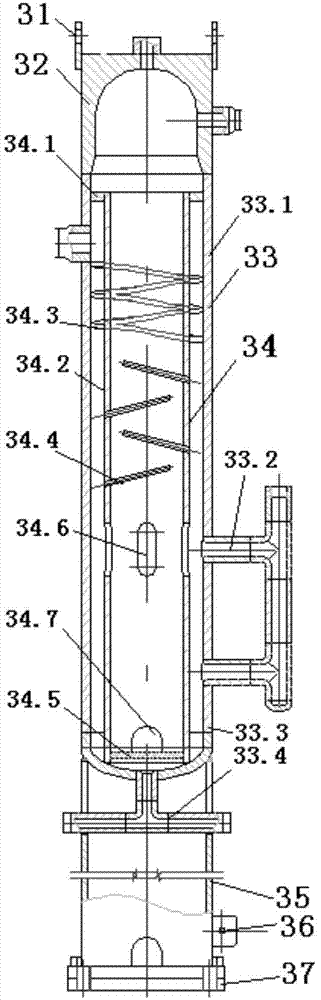

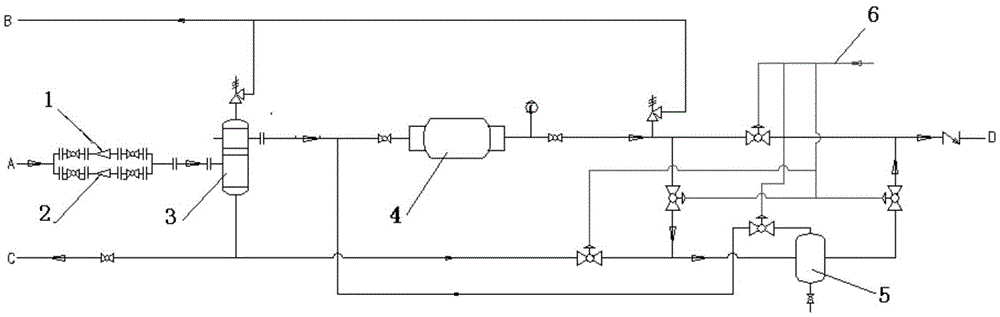

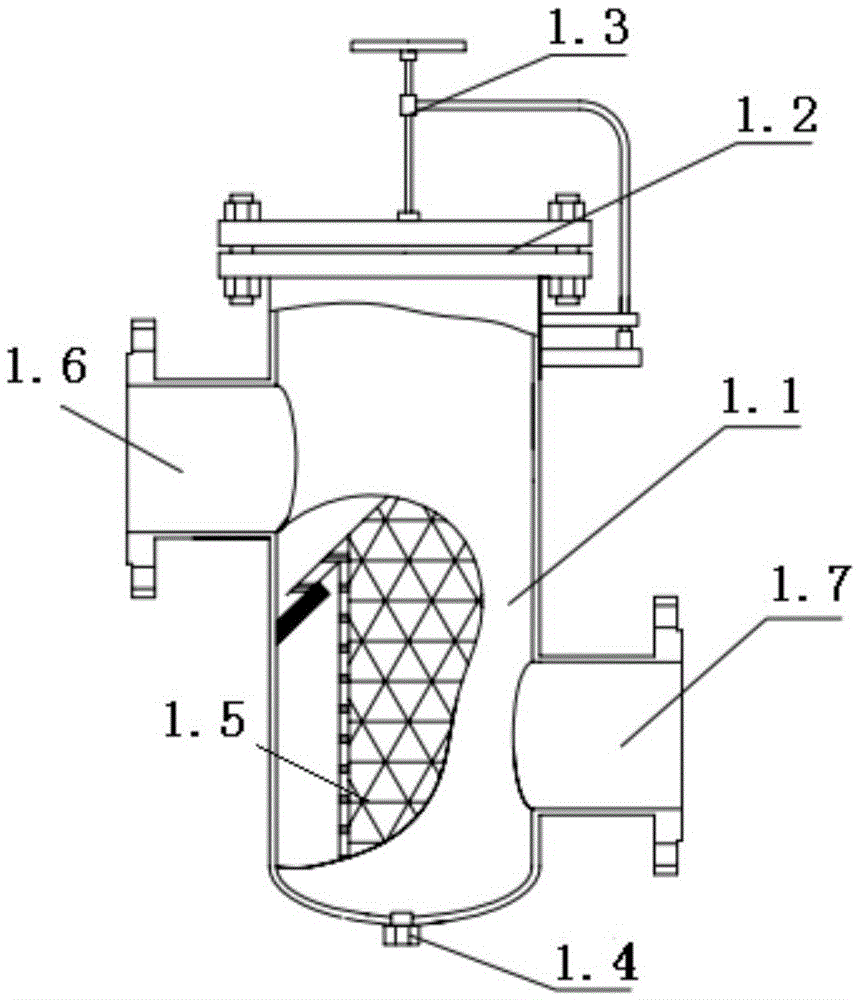

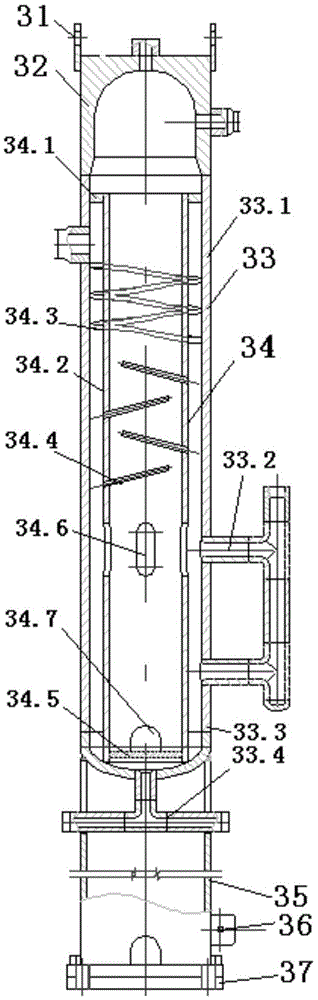

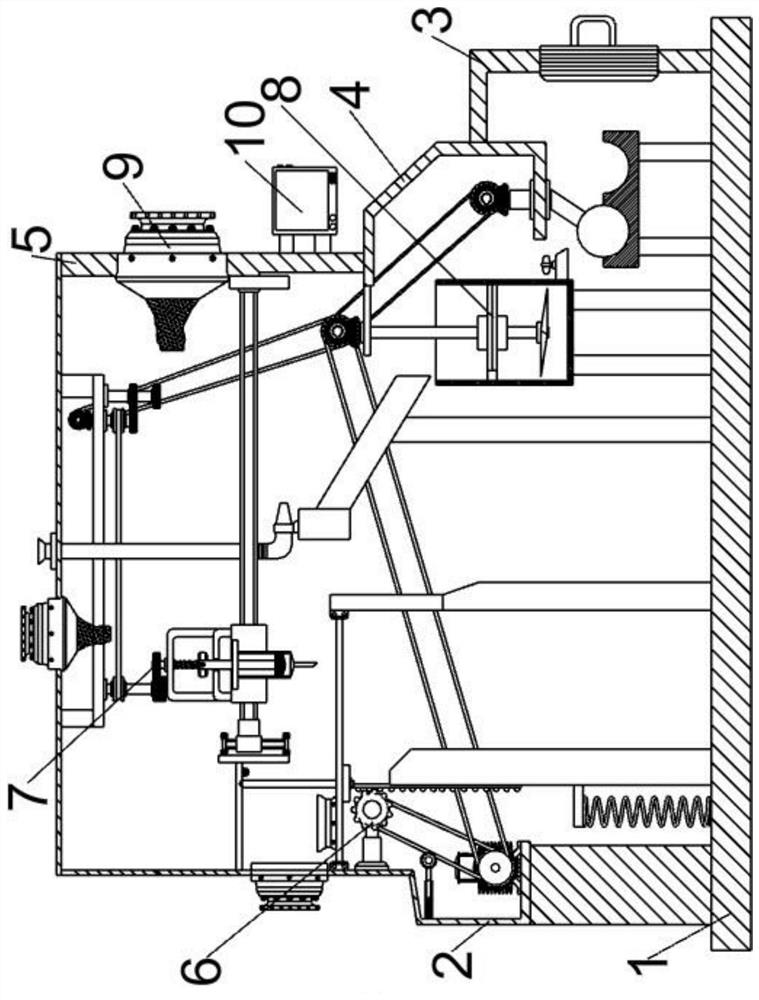

Gas-liquid mixed transportation supercharging system

ActiveCN104771938AGuaranteed continuityGuaranteed reliabilityLiquid degasificationDispersed particle separationProduct gasShale gas

The invention relates to a gas-liquid mixed transportation supercharging system. The gas-liquid mixed transportation supercharging system comprises a solid filtering part, a gas liquid separation part and a compression storage part, wherein the solid filtering part is arranged at the front end of the gas-liquid separation part and communicated with a mixed transportation inlet, and is used for filtering gas-liquid mixed transportation components entering from the mixed transportation inlet; the gas-liquid separation part is arranged behind the solid filtering part, an inlet of the gas-liquid separation part is communicated with an outlet of the solid filtering part to receive the filtered gas-liquid mixed transportation components; and the compression storage part is arranged behind the gas-liquid separation part and then s used for compressing gas and storing liquid. As a result, the gas-liquid mixed transportation supercharging system guarantees high-pressure gas-liquid mixed transportation components at the outlet of a pipeline through filtering, separation and supercharging of low-pressure gas-liquid mixed transportation components at the inlet of the device, ensures the continuity of gas-liquid mixed transportation, is suitable for long-distance transportation of shale gas, coal bed gas, wellhead gas and the like currently exploited in China, and is environment-friendly and convenient to maintain.

Owner:武汉齐达康能源装备有限公司

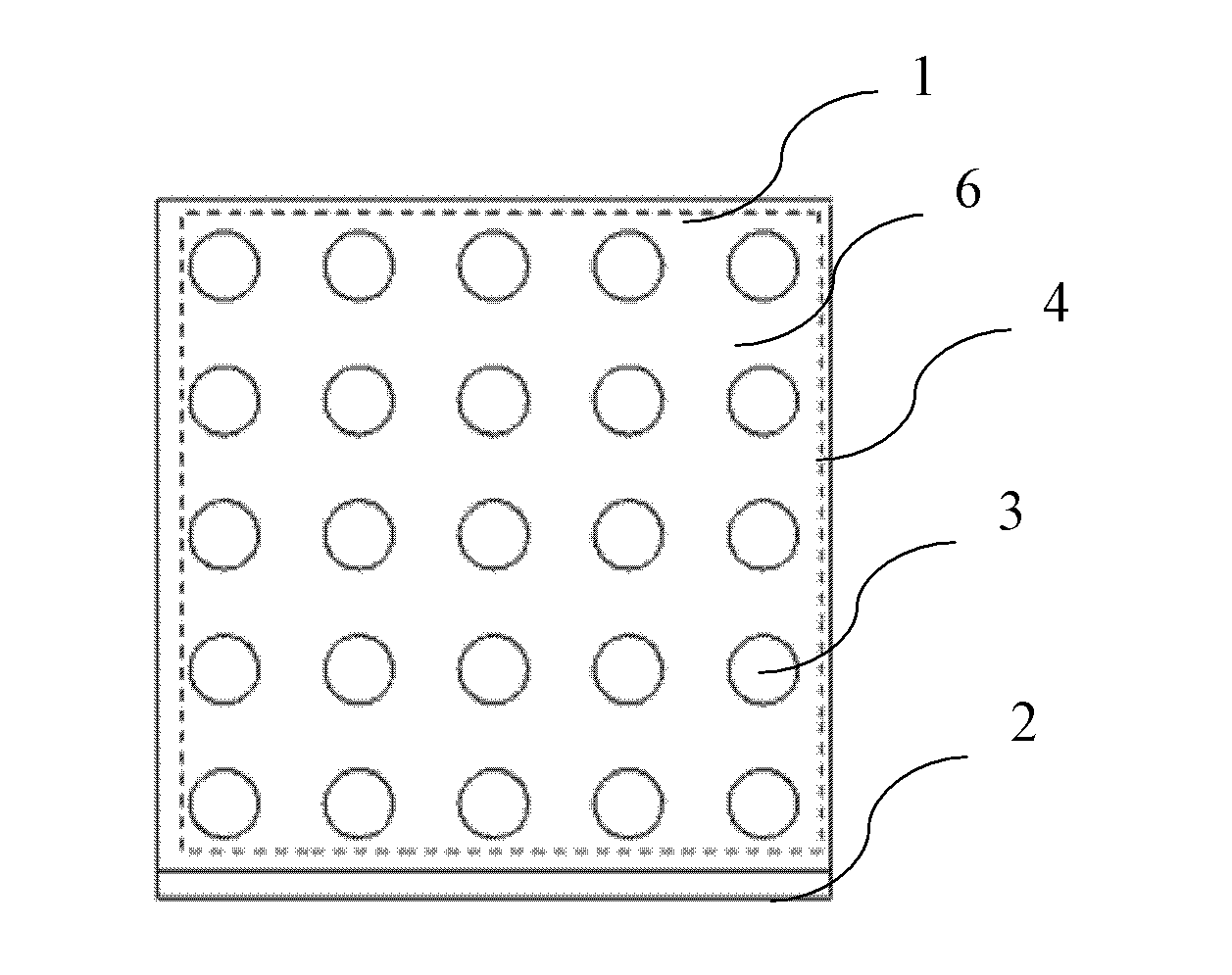

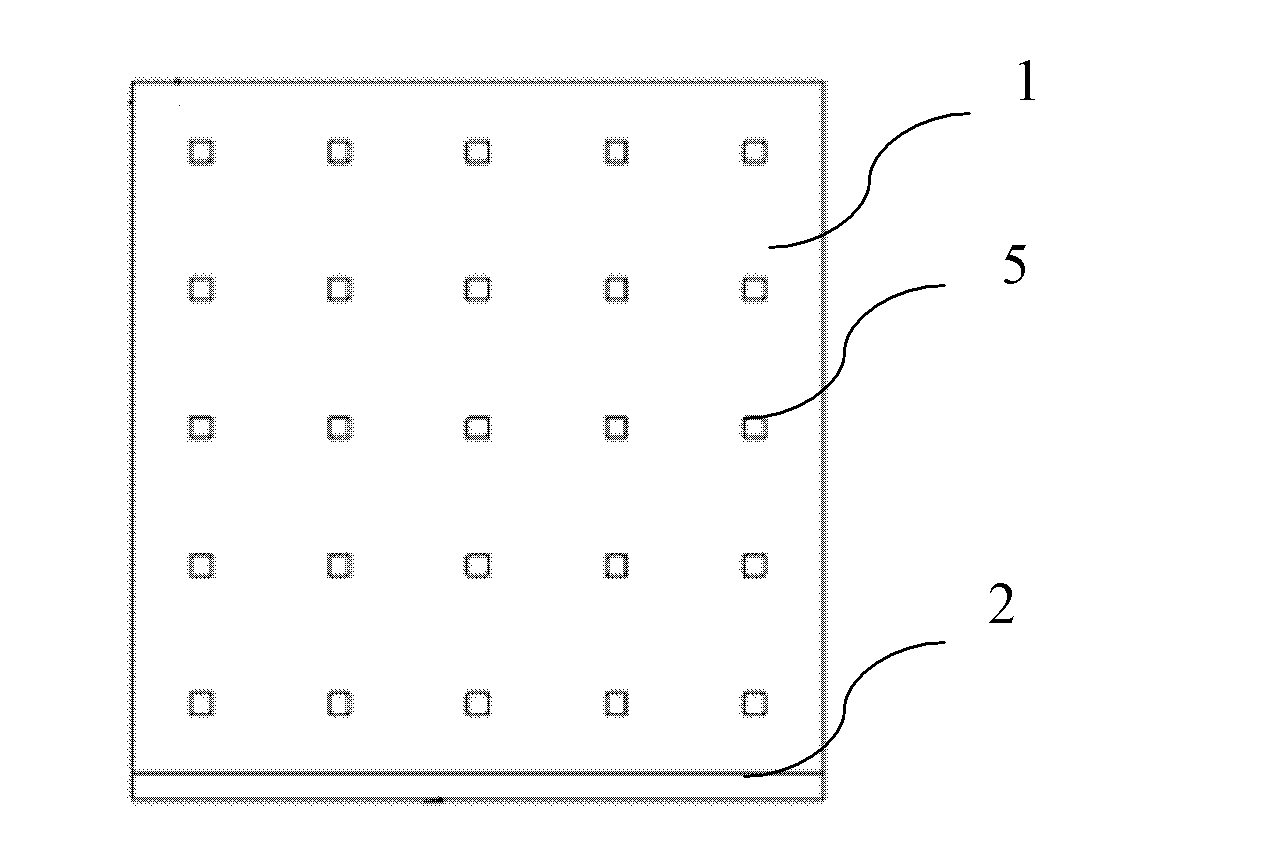

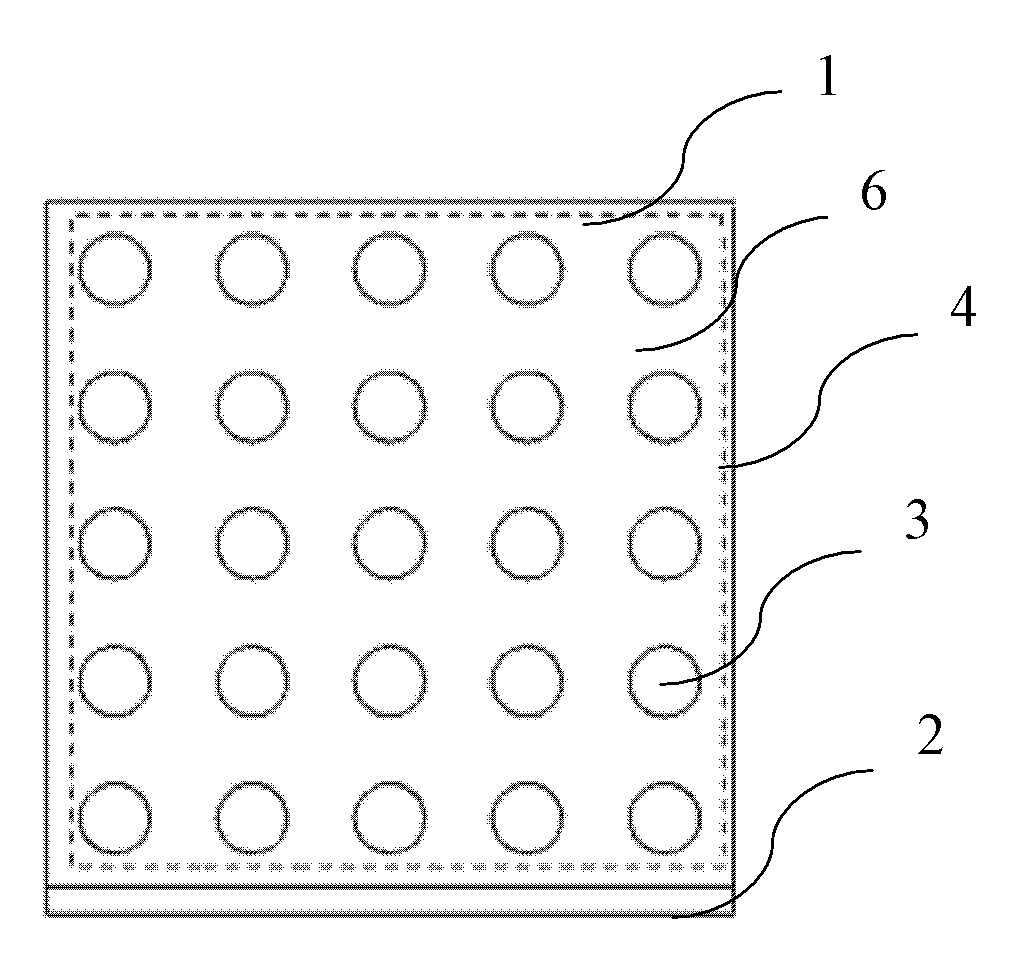

Array imaging system

InactiveCN102593609AEasy to applyEliminates effects of far-field beam characteristicsAntenna arraysLength waveSilicon

The invention relates to an array imaging system. The system comprises a base and a silicon lens array which is arranged on the base and formed by a plurality of silicon lenses, an anti-reflect layer with thickness of a quarter of a wavelength is plated on the surface of the frontal side of each of the silicon lens, a terahertz probe is installed in the center of the back of each of the silicon lens to form a terahertz probe array, and a terahertz wave-absorbing material layer is covered on a metal surface among the plurality of the silicon lenses on the frontal side of the base.

Owner:ZIJINSHAN ASTRONOMICAL OBSERVATORY CHINESE ACAD OF SCI

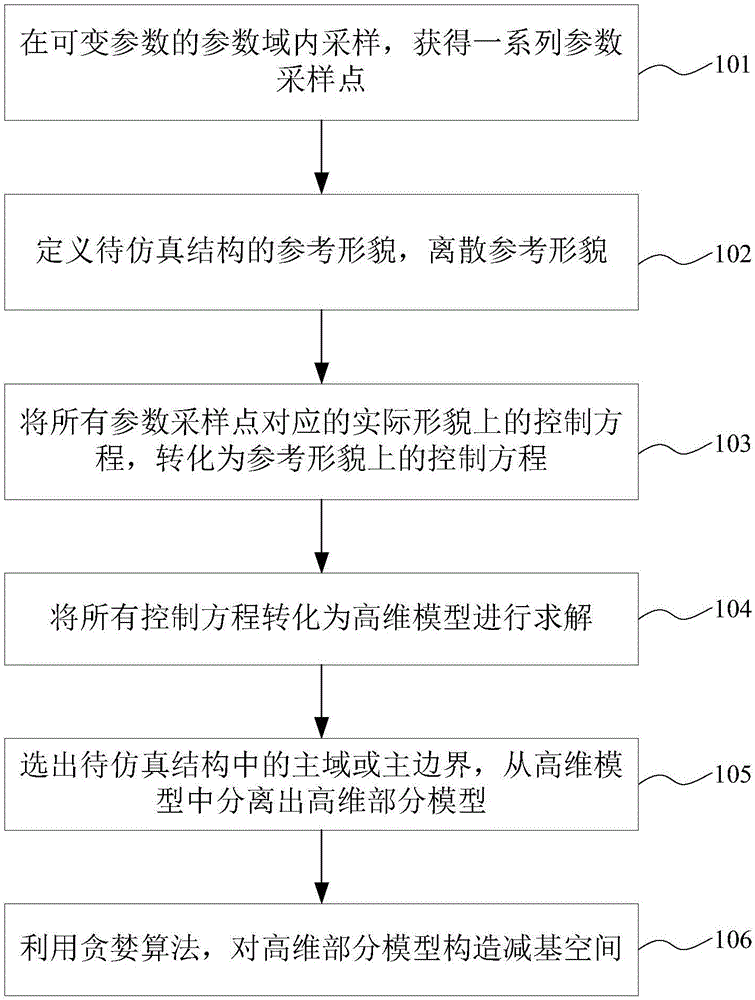

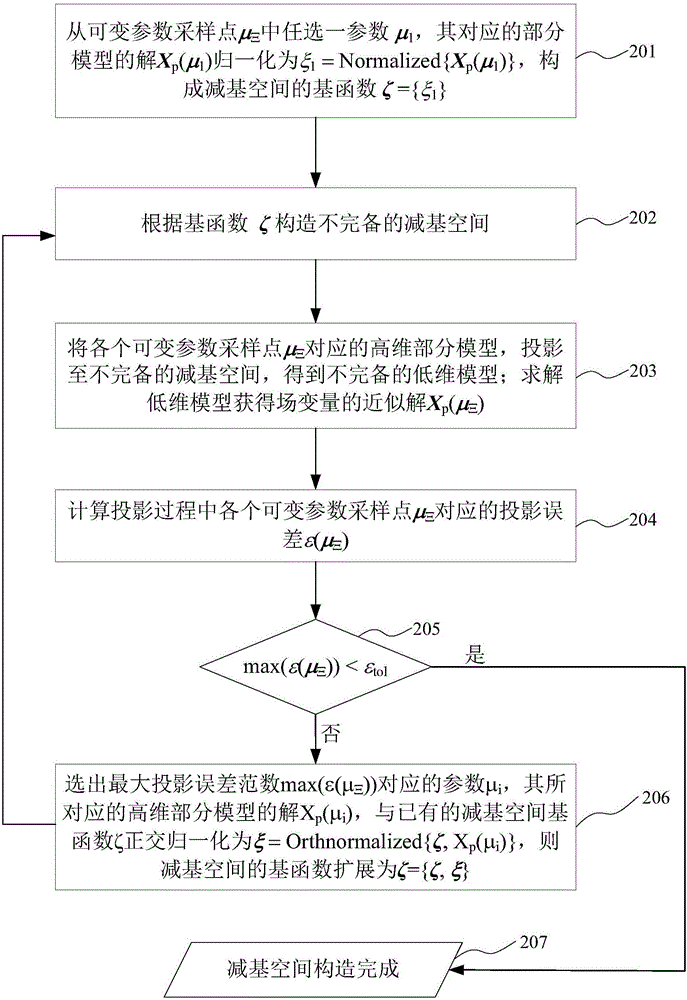

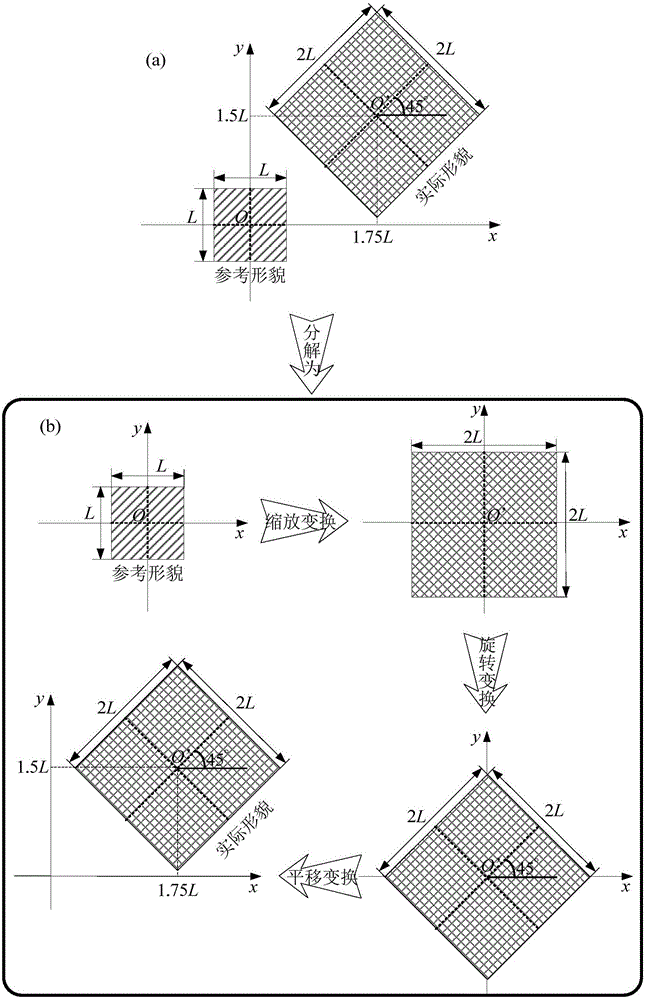

Method for quickly constructing low-dimensional reduced-basis space in electromagnetic scattering modeling

InactiveCN106709152AImprove construction efficiencyReduce dimensionalityDesign optimisation/simulationSpecial data processing applicationsAlgorithmPartial solution

The invention discloses a method for quickly constructing a low-dimensional reduced-basis space in electromagnetic scattering modeling. The method comprises the steps of firstly, selecting out a domain or a boundary which determines a final output variable from geometric domains or geometric boundaries of a to-be-simulated structure, wherein the selected domain or boundary is called as a main domain or a main boundary; secondly, based on an original high-dimensional model, constructing a high-dimensional partial model about a variable in the main domain or on the main boundary, and constructing a reduced-basis space for the high-dimensional partial model in a parameterization environment, wherein the obtained reduced-basis space is called as a partial reduced-basis space; and finally, projecting the high-dimensional partial model to the partial reduced-basis space to obtain an approximate low-dimensional model, and replacing solving of the original high-dimensional model with solving of the low-dimensional model, thereby improving the solving efficiency of a simulation model is improved. The method is especially suitable for the situation that the final output variable is determined only by a partial solution in the high-dimensional model. Compared with a conventional reduced-basis method, the method has the advantages that the dimensions of the reduced-basis space are further reduced (correspondingly, the dimensions of the low-dimensional model are further reduced) and the construction speed of the reduced-basis space is greatly increased.

Owner:HUAZHONG UNIV OF SCI & TECH

Method for culturing and cryopreservation of CIK cells by applying serum-free lymphocyte culture medium and obtained CIK cells

InactiveCN106635983AImprove cell activityGuaranteed amplification efficiencyDead animal preservationBlood/immune system cellsCell culture mediaBlood serum

The invention discloses a method for culturing and cryopreservation of CIK cells by applying a serum-free lymphocyte culture medium and obtained CIK cells. The cell culture method can develop 3*10<9> lymphocytes in a short time without introducing animal derived serum; the cell cryopreservation method can maximally improve the ratio of cryopreserved target cells and the survival rate after cell recovery. The method provides convenience for culturing, storing and related clinical research of the CIK cells.

Owner:TIANJIN PURUI SAIER BIOLOGICAL TECH CO LTD

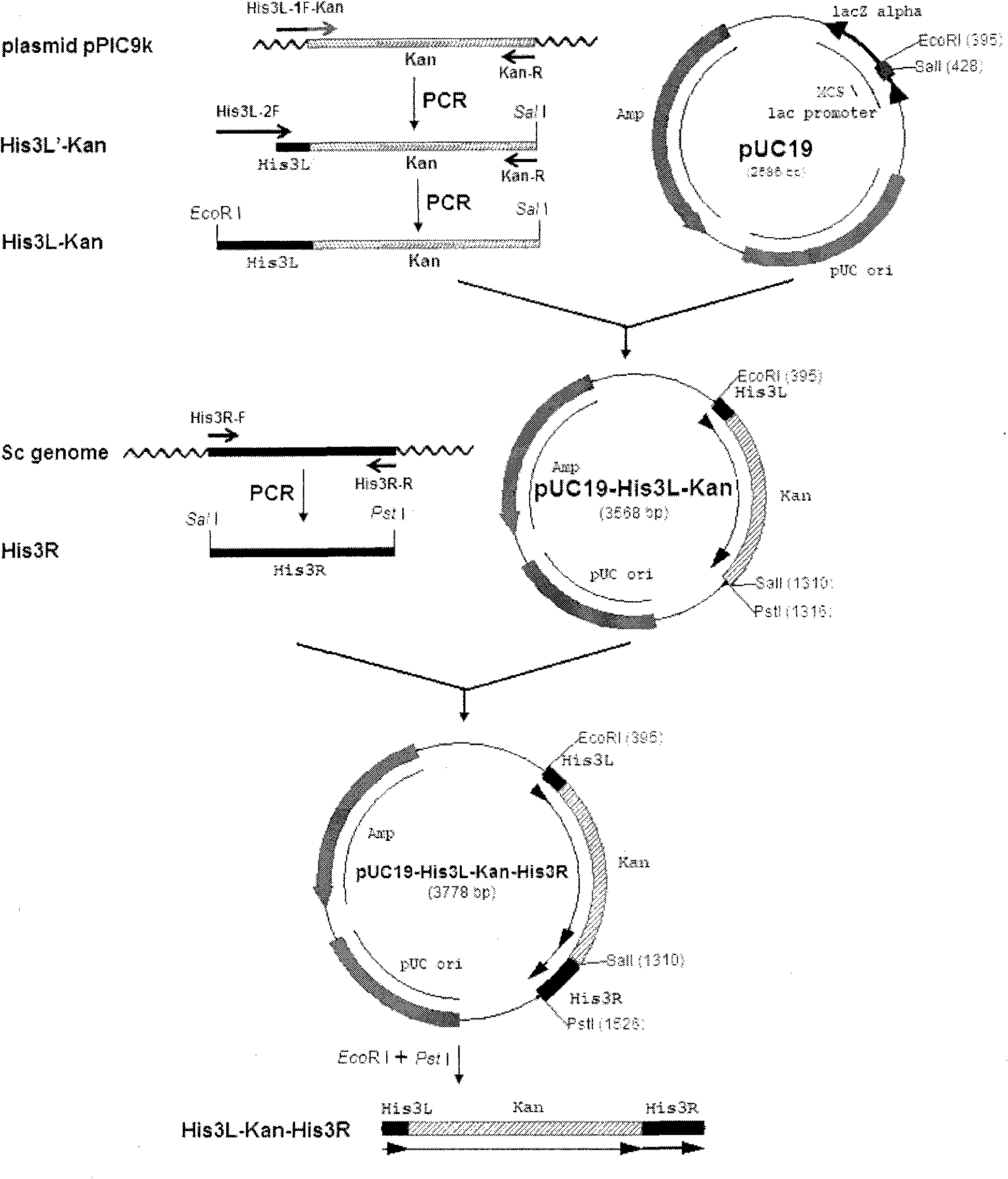

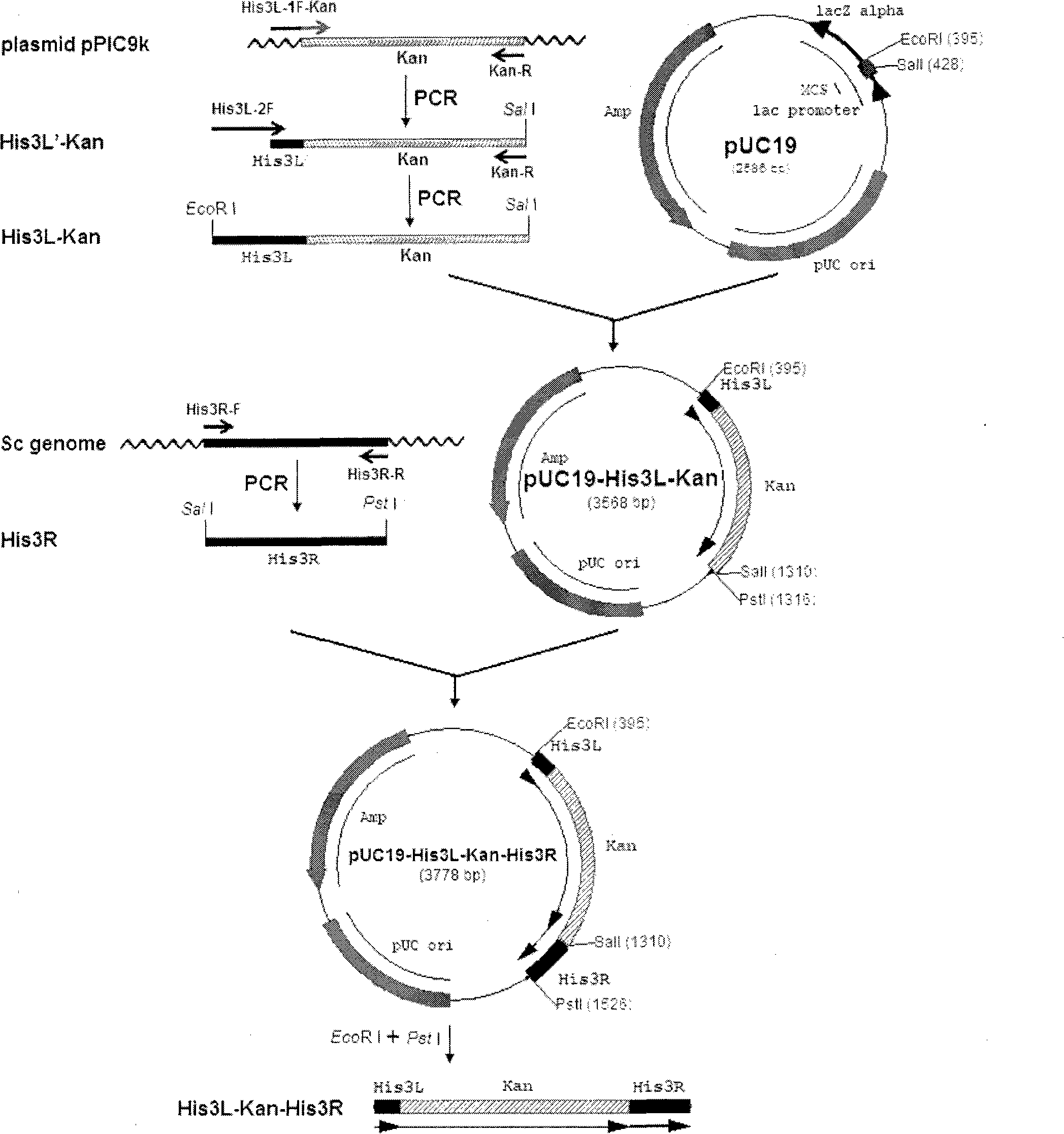

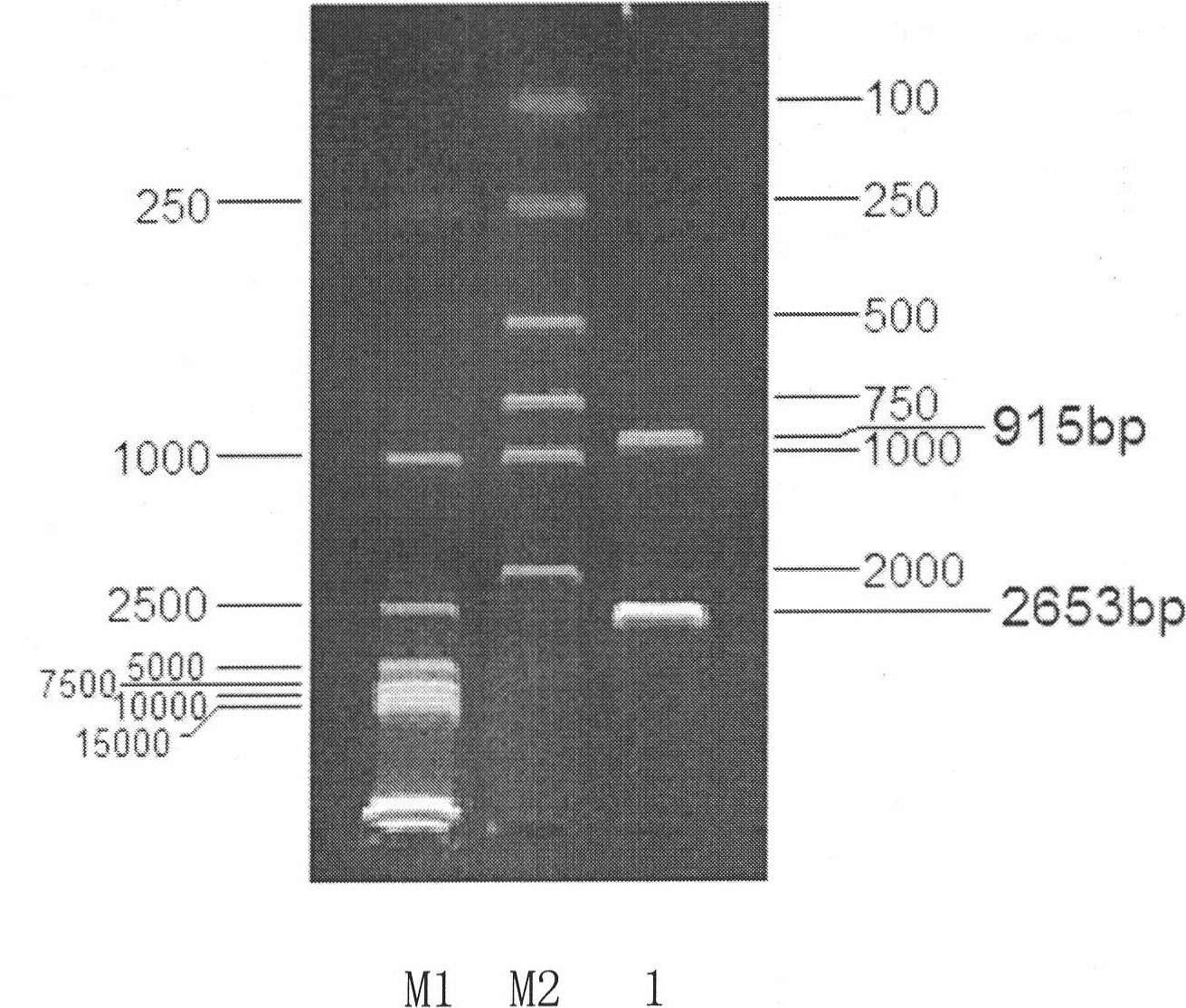

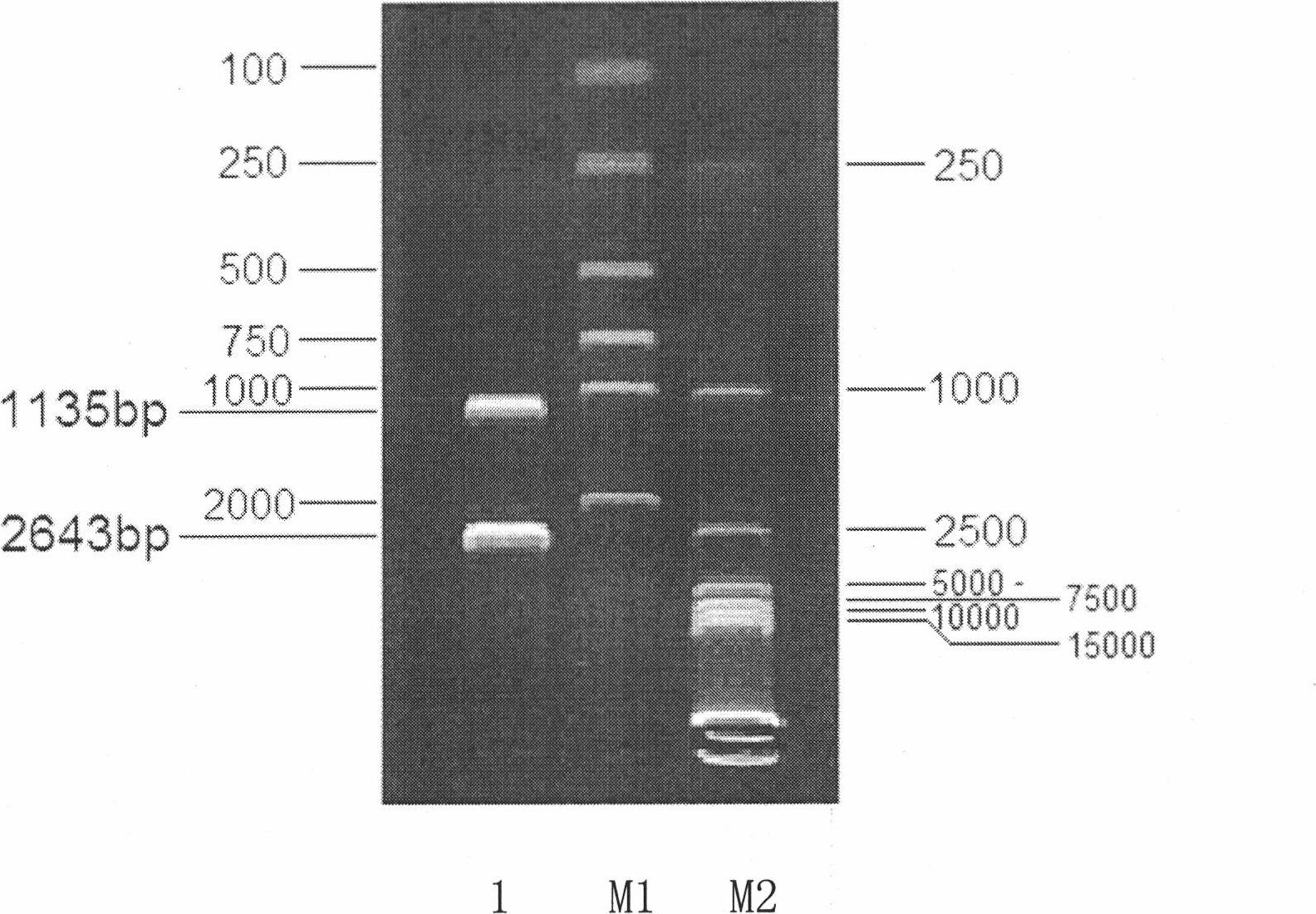

Amphiploid histidine auxotroph saccharomyces cerevisiae and constructing method thereof

InactiveCN101525580ACharacteristics unchangedEasy to identifyFungiMicroorganism based processesBiotechnologyBio engineering

The invention discloses amphiploid histidine auxotroph saccharomyces cerevisiae and a constructing method thereof, belonging to the field of microorganism biological engineering. The saccharomyces cerevisiae is made from an amphiploid saccharomyces cerevisiae bacterial strain which is TSH-Sc-001(His3- / -) and contains a histidine auxotrophic mark and a g418 resistance mark. The constructing method of the amphiploid histidine auxotroph saccharomyces cerevisiae comprises the following steps: the amphiploid saccharomyces cerevisiae bacterial strain is adopted as a start bacterial strain, the start bacterial strain is transformed twice by a segment with target genes, and the amphiploid histidine auxotroph saccharomyces cerevisiae bacterial strain with two chromosomes being subjected to homologous recombination is obtained by two-time homologous recombination. The saccharomyces cerevisiae is easily identified and protected; in addition, the constructing method of the amphiploid histidine auxotroph saccharomyces cerevisiae provides a novel way and a method for the reconstruction of gene engineering of amphiploid or multiploid saccharomyces, is simple and highly efficient, and keeps the primary characteristic of the saccharomyces unchanged.

Owner:TSINGHUA UNIV

An improved mesenchymal stem cell protection solution and its application

ActiveCN101919380BCharacteristics unchangedMeet application needsDead animal preservationSkeletal/connective tissue cellsMesenchymeCell activity

The invention relates to an improved mesenchyme stem cell protection solution as well as application and a preparation method thereof. The protection solution can effectively prolong the activity remaining time of mesenchyme stem cells, reduces preparation cost, and has the advantages of wide raw material source, simple preparation, safe and reliable direct clinical application; and after the mesenchyme stem cells are preserved for 48 hours in the protection solution, the cell activity is still above 90 percent, the cell morphology is normal, and the multiplication capacity and mesenchyme stem cell phenotype characteristics are not influenced.

Owner:青岛奥克生物开发有限公司

Cell cryopreservation method

ActiveCN103518702ARapid coolingIncrease vitalityDead animal preservationCell membraneCryopreservation

The invention relates to the field of a cell biotechnology, relates to a cell cryopreservation method and particularly relates to an improved rapid freezing method. The cell cryopreservation method can be used for improving the activity of cells under the condition of ensuring that the cell characteristics are unchanged. The cell cryopreservation method has the characteristics that a gauze bag with a hole is adopted, a freezing tube is suspended in a liquid nitrogen steam layer so as to ensure that the cells in the freezing tube are rapidly cooled, and the activity of the resuscitated cells reaches up to 95%-99%; 10% of DMSO (dimethylsulfoxide) and 90% of serum are used as cryopreservation liquid, so that the permeability of a cell membrane to water can be improved, crystals outside the cells are frozen within short time, and the permeation of moisture is prevented from causing the damage to the cells. The cell cryopreservation method is suitable for the long-term storage of all cell lines. Compared with the prior art, the cell cryopreservation method has the advantages that steps are omitted, the technology is simplified, the resuscitated cells have high activity and unchanged cell characteristics, and the long-term storage purpose can be realized.

Owner:SHANGHAI JUNWEI BIOTECH CO LTD

Paddy rice seeds production method and application thereof

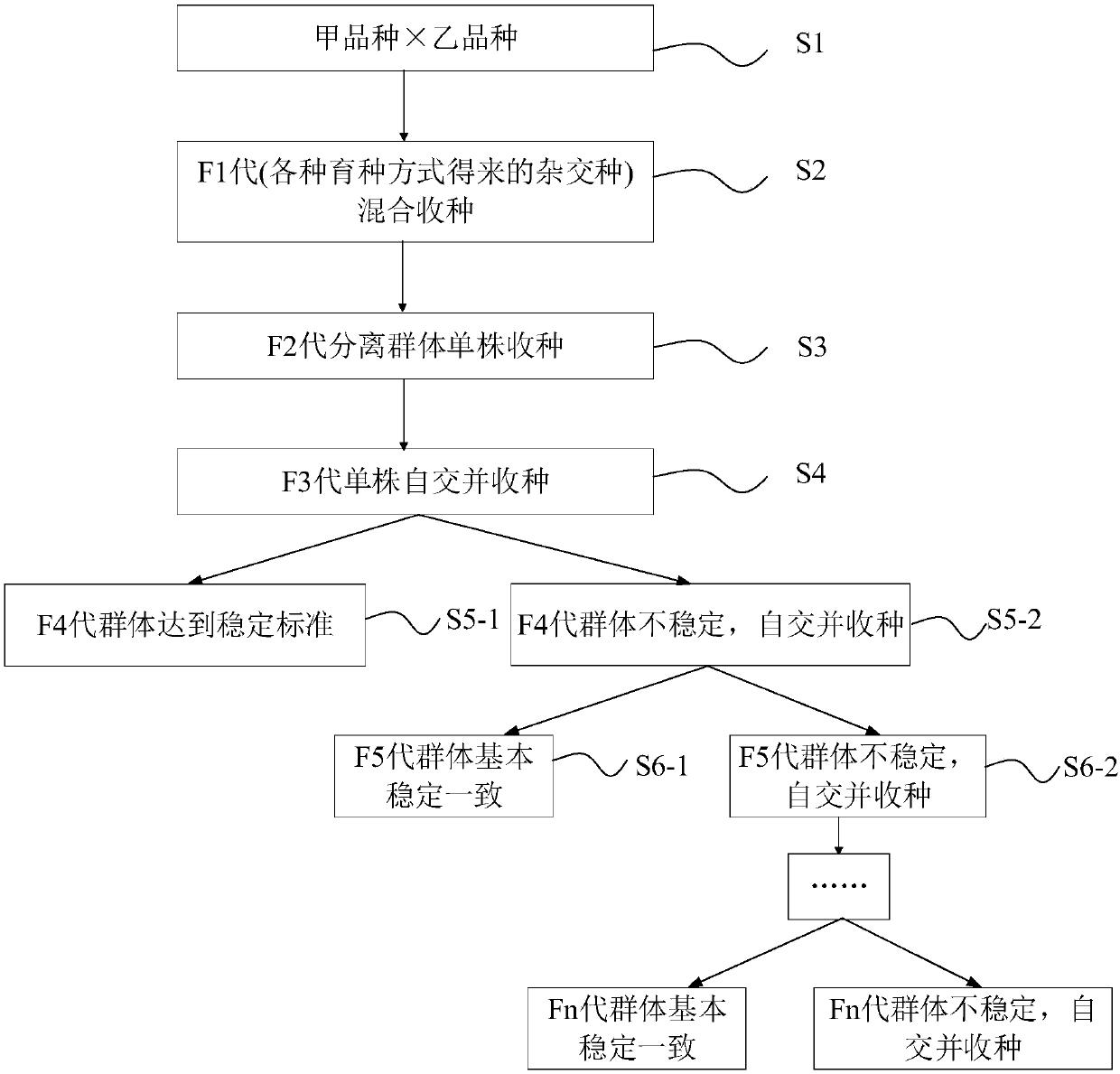

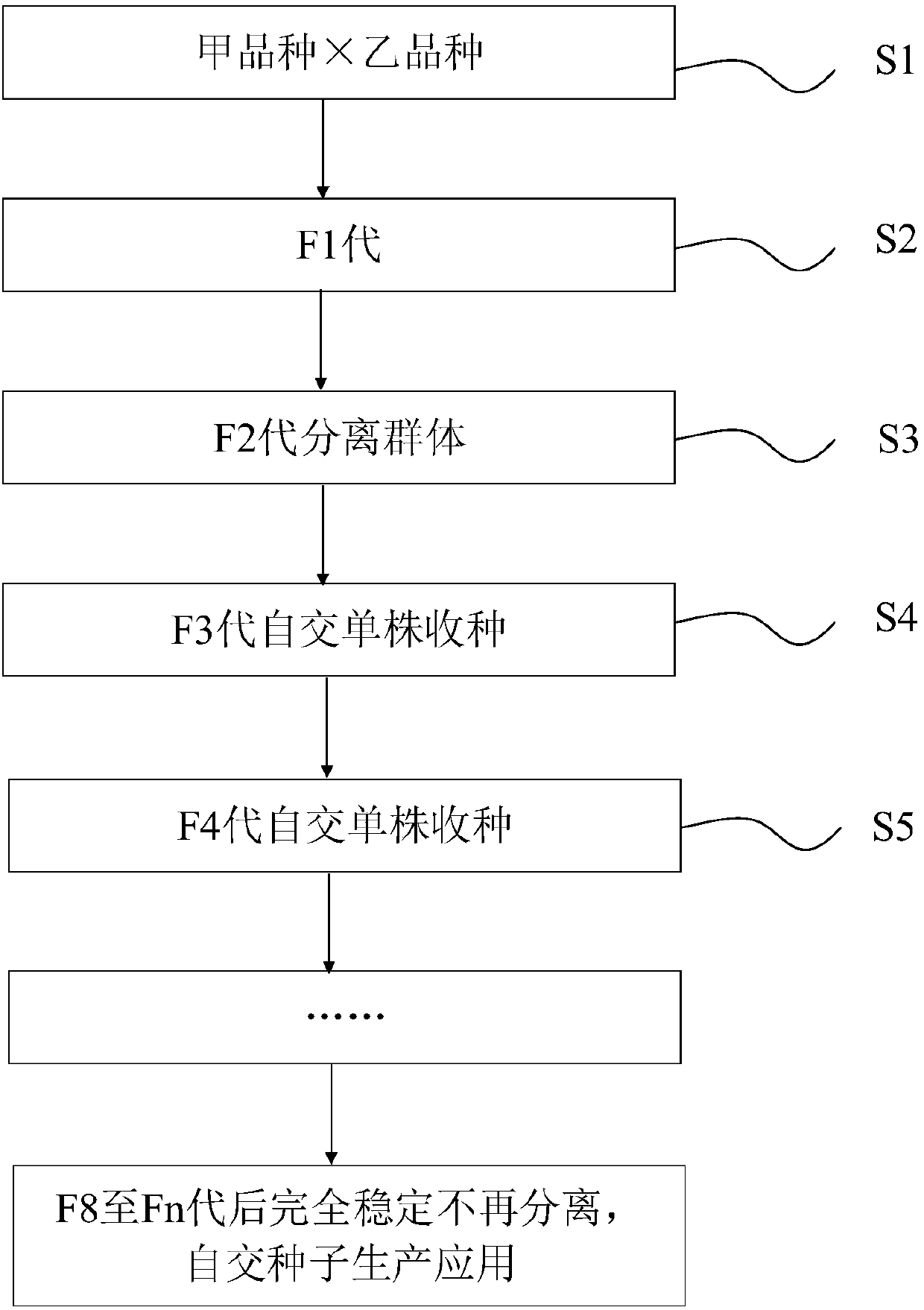

ActiveCN107667852AHigh heterozygosityCharacteristics unchangedPlant genotype modificationHybrid seedF1 generation

The invention relates to a paddy rice seed production method and an application thereof. The production method comprises the following steps: S1: rice variety A and rice variety B are subjected to hybridization or multi-variety composite hybridization, or biological, physical, and chemical methods to generate a property heterozygote, and F1-generation paddy rice hybrid seeds are collected; S2: theF1-generation paddy rice hybrid seeds are sown and cultured, and the F2-generation paddy rice seeds are collected; S3: the F2-generation paddy rice seeds are sown and cultured, and the F3-generationpaddy rice seeds are collected; S4: the F3-generation paddy rice seeds are sown and cultured, and then are subjected to self-hybridization, and the F4-generation paddy rice seeds are collected; and S5-1: the F4-generation paddy rice seeds are sown and cultured, colony stability identification is carried out, the F3-generation rice stubble corresponding to the stable and standard F4-generation colony is subjected to regeneration breeding; a material after regeneration breeding is continuously cultivated, and after self-hybridization, the seeds are collected to obtain the required seeds.

Owner:雅安雨禾农业科技有限责任公司

Gas-liquid mixed booster system

ActiveCN104771938BGuaranteed continuityGuaranteed reliabilityLiquid degasificationDispersed particle separationShale gasTransport engineering

The invention relates to a gas-liquid mixed transportation supercharging system. The gas-liquid mixed transportation supercharging system comprises a solid filtering part, a gas liquid separation part and a compression storage part, wherein the solid filtering part is arranged at the front end of the gas-liquid separation part and communicated with a mixed transportation inlet, and is used for filtering gas-liquid mixed transportation components entering from the mixed transportation inlet; the gas-liquid separation part is arranged behind the solid filtering part, an inlet of the gas-liquid separation part is communicated with an outlet of the solid filtering part to receive the filtered gas-liquid mixed transportation components; and the compression storage part is arranged behind the gas-liquid separation part and then s used for compressing gas and storing liquid. As a result, the gas-liquid mixed transportation supercharging system guarantees high-pressure gas-liquid mixed transportation components at the outlet of a pipeline through filtering, separation and supercharging of low-pressure gas-liquid mixed transportation components at the inlet of the device, ensures the continuity of gas-liquid mixed transportation, is suitable for long-distance transportation of shale gas, coal bed gas, wellhead gas and the like currently exploited in China, and is environment-friendly and convenient to maintain.

Owner:武汉齐达康能源装备有限公司

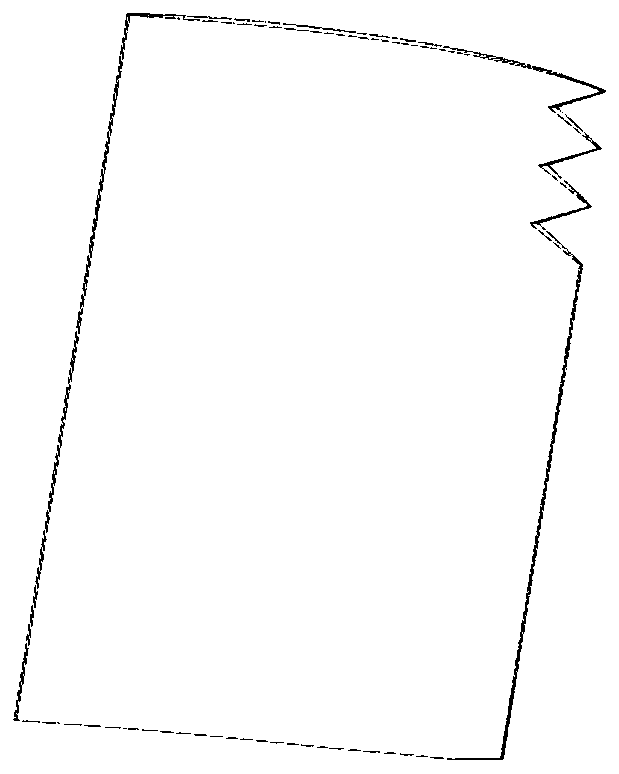

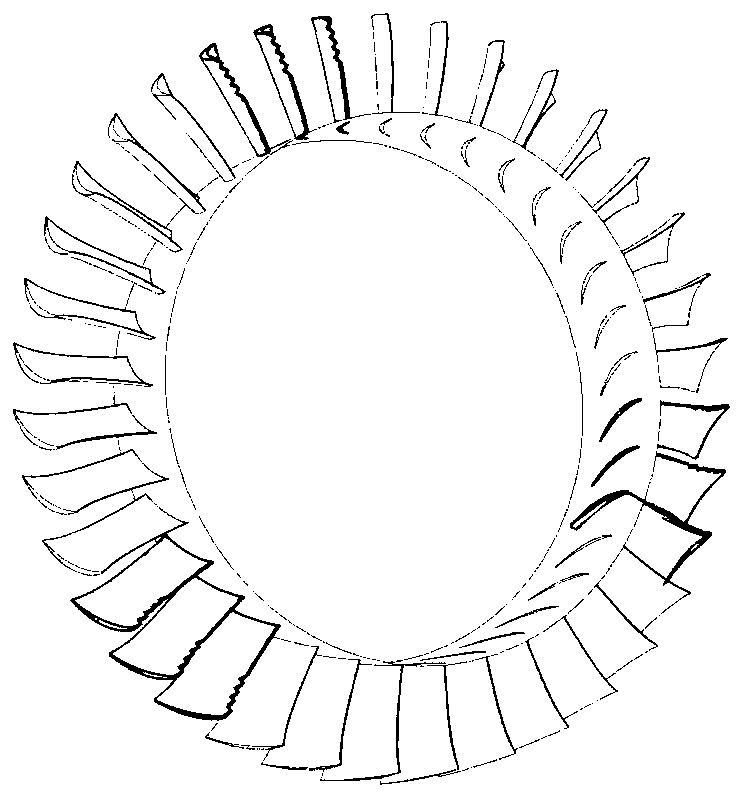

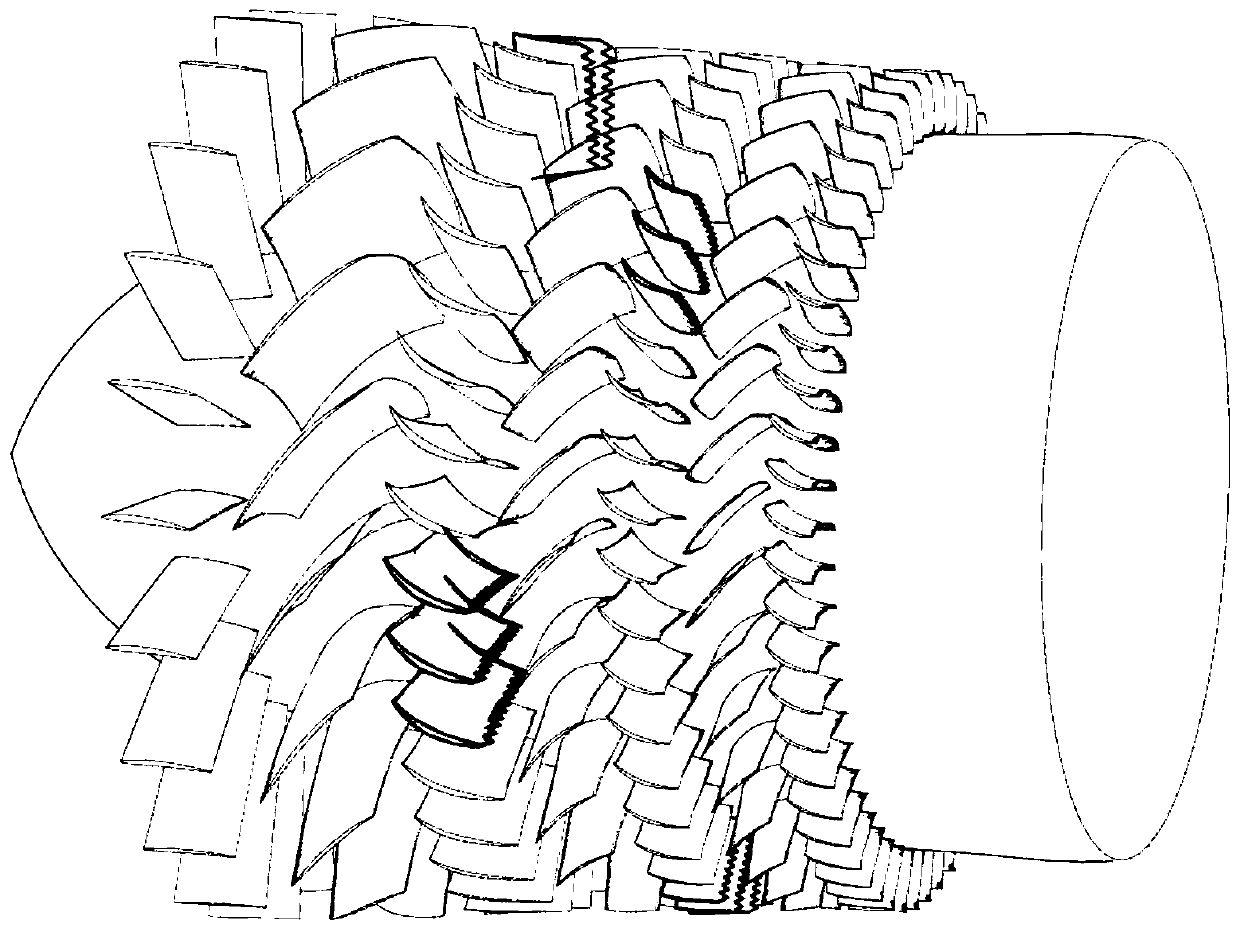

Multistage axial flow compressor stability improvement structure based on sawtooth tailing edge blade

ActiveCN110821851AImprove stable working rangeThe overall structure is light in weightPump componentsAxial flow pumpsMechanical engineeringMechanics

The invention discloses a multistage axial flow compressor stability improvement structure based on a sawtooth tailing edge blade. The sawtooth tailing edge is arranged on a blade of a multistage axial flow compressor to form a sawtooth tailing edge blade, and the sawtooth tailing edge blades are arranged on one or more blade rows of the multistage axial flow compressor; the tooth height H of onesawtooth tailing edge blade is 8%-16% of the blade chord length, the tooth apex angle theta is 20 degrees-60 degrees, and the tooth number is 1-20; the sawtooth trailing edge blades are provided withsawtooth structures near the blade tips or the blade roots; and the sawtooth tailing edge blades are arranged symmetrically in the circumferential direction of the blade row, or the whole blade row isprovided with the sawtooth tailing edge blades. According to the structure, the sawtooth configuration and the pressure difference on the two sides of the blades are utilized to generate the streamwise vortex, the streamwise vortex sucks the main flow into the vortex and interacts with a tailing trace shearing layer, a large-scale vortex structure in the tailing trace is broken away, the shape ofthe blade tailing trace and the characteristic of the flow field concerned with the downstream blades are improved, the stall of the compressor is delayed, and the stability margin of the compressoris widened. The sawtooth tailing edge blade structure has the advantages of no other equipment, light structure weight and the like.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Human pituitary adenoma cell strain and purpose thereof

ActiveCN107541497ACharacteristics unchangedCompound screeningApoptosis detectionBio engineeringDrug target

The invention discloses a human pituitary adenoma cell strain and purpose thereof and belongs to the field of oncobiology. The preservation number of the human pituitary adenoma cell strain HPA1446 isCGMCC No. 12672. The invention has the following advantages: the cell strain can be cultured in vitro for a long time and keep cell characteristics unchanged, is a powerful tool for researches related to hypophysoma, and is a powerful tool for the research on tumor incidence and related molecular mechanism, preparation of tumor-associated animal experimental models, research and development and screening and evaluation of cancer therapeutic drugs / methods / diagnostic reagents, development of tumor drug target and tumor biotherapy new techniques and detection of bio-engineering product research.

Owner:BEIJING NEUROSURGICAL INST

Amphiploid histidine auxotroph saccharomyces cerevisiae and constructing method thereof

InactiveCN101525580BCharacteristics unchangedEasy to identifyFungiMicroorganism based processesMicroorganismMicrobiology

The invention discloses amphiploid histidine auxotroph saccharomyces cerevisiae and a constructing method thereof, belonging to the field of microorganism biological engineering. The saccharomyces cerevisiae is made from an amphiploid saccharomyces cerevisiae bacterial strain which is TSH-Sc-001(His3- / -) and contains a histidine auxotrophic mark and a g418 resistance mark. The constructing methodof the amphiploid histidine auxotroph saccharomyces cerevisiae comprises the following steps: the amphiploid saccharomyces cerevisiae bacterial strain is adopted as a start bacterial strain, the start bacterial strain is transformed twice by a segment with target genes, and the amphiploid histidine auxotroph saccharomyces cerevisiae bacterial strain with two chromosomes being subjected to homologous recombination is obtained by two-time homologous recombination. The saccharomyces cerevisiae is easily identified and protected; in addition, the constructing method of the amphiploid histidine auxotroph saccharomyces cerevisiae provides a novel way and a method for the reconstruction of gene engineering of amphiploid or multiploid saccharomyces, is simple and highly efficient, and keeps the primary characteristic of the saccharomyces unchanged.

Owner:TSINGHUA UNIV

Tissue culture method for fast propagation of primula poissonii

InactiveCN101015279BHigh reproductive coefficientStrong growthCultivating equipmentsHorticulture methodsAxillary budBud

The invention provides a method for tissue culturing and fast propagating Primula poisonii, comprising explant selection, surface disinfection, adventitious bud induction, subculture, rooting culture and test-tube seedling transplanting. The method is characterized in that one axillary bud can induce about 40-50 sprouts, the multiplication coefficient is about 3- 4 after 30- 40 days subculture, the rooting rate reaches above 95%, and the replanting survival rate is nearly 100%. The invention realizes preservation for single Primula poisonii, meanwhile, greatly increases seedling capacity for the Primula poisonii, reduces seedling time and cost, and provides technique support for Primula poisonii application in large areas.

Owner:BEIJING FORESTRY UNIVERSITY

A kind of production and processing technology of optical module shell

ActiveCN106078101BLow costReduce production and processing costsSoldering apparatusSurface cleaningContact center

A producing and processing technology for an optical module shell includes the steps that die-cast formation is conducted on the optical module shell through a zinc alloy, and surface nickel plating is conducted, wherein the thickness of a cover plate ranges from 0.4 mm to 0.55 mm, and the thickness of a base ranges from 0.6 mm to 0.8 mm; oxide and impurities on the surface of the cover plate and the surface of the base are removed; the base is placed in a clamp, and the space between the base and the cover plate is coated with soldering flux, wherein the thickness is 0.02 mm; the cover plate is placed on the base without dislocation; the cover plate is pressed downwards with force so that the cover plate, the soldering flux and the base can make close contact; the residual soldering flux is wiped off, and cleanness is kept; it is ensured that the surface of a seam welding electrode is clean and dry; the inner hole wall of the seam welding electrode is coated with conductive grease with the thickness being 0.02 mm, the seam welding electrode is installed on a parallel seam welding machine in the manner that the seam welding electrode can slightly rotate, and the whole seam welding electrode is kept clean; one point is formed at the position of the contact center of cover plate and the base through seam welding, the seam welding electrode is moved to the rightmost end or the leftmost end, and seam welding is started; and a qualified product is obtained. The producing and processing technology solves the problems that the production cost of the optical module shell is high and during packaging, the gas tightness and firmness are poor and a clad layer is damaged.

Owner:8TH RES INST OF CETC

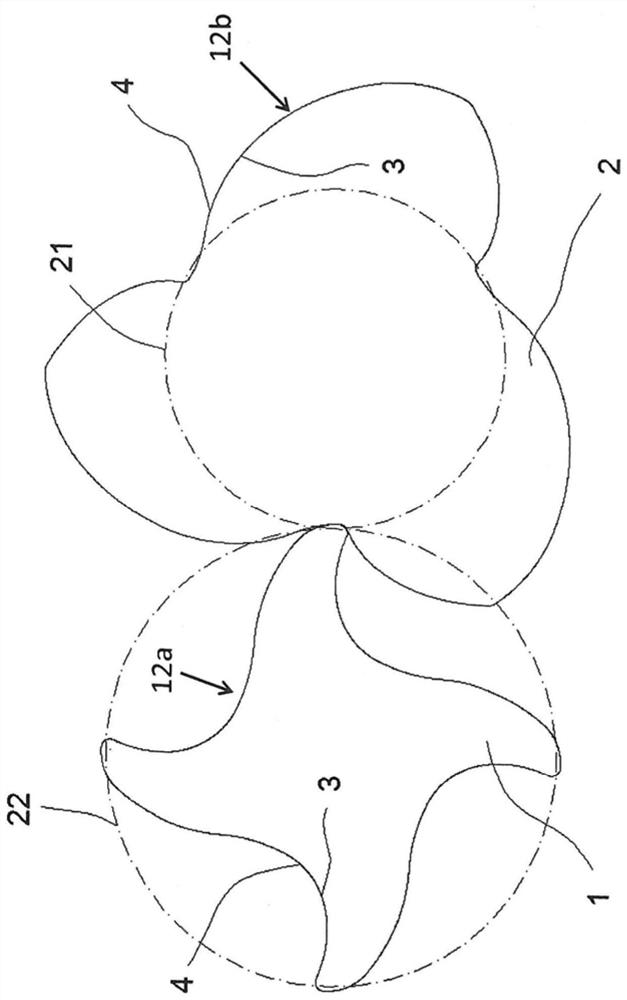

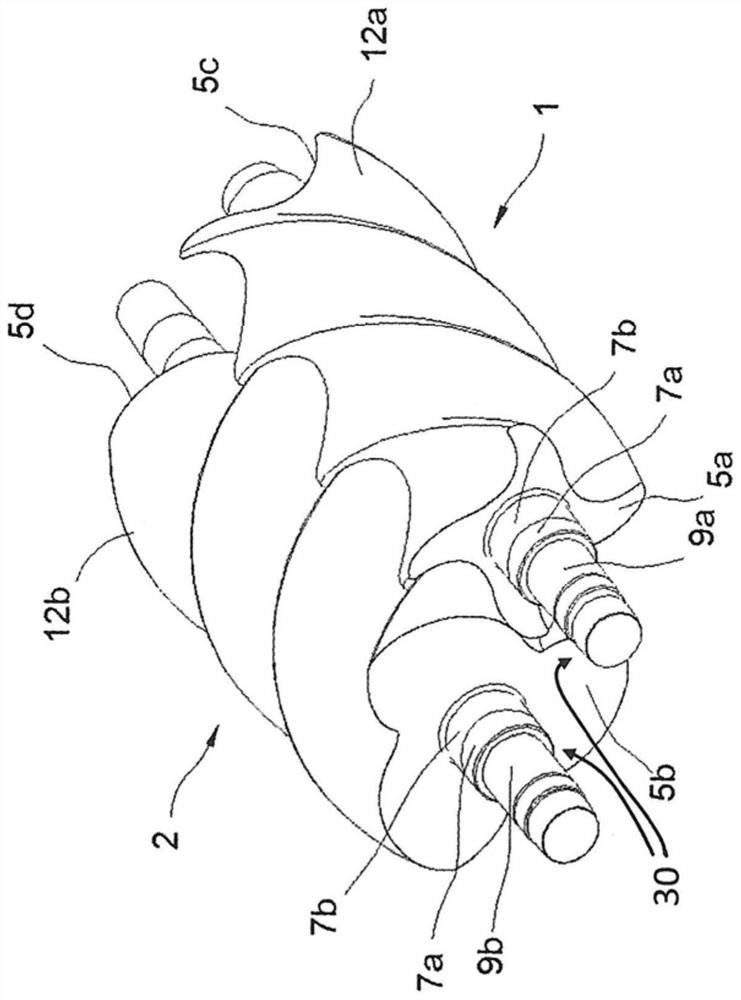

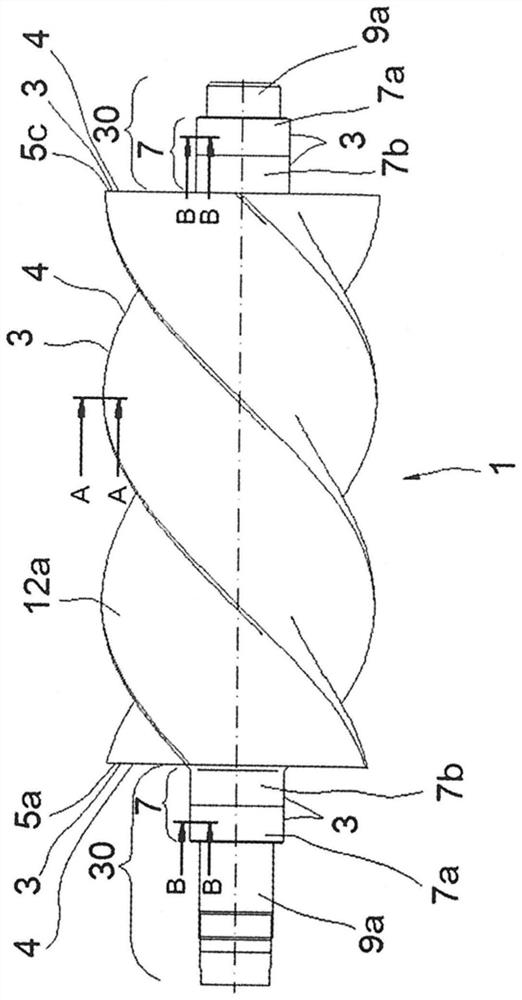

Screw compressor with multi-layer coated rotor screw

ActiveCN110621880BGood chemical resistanceCharacteristics unchangedSealing arrangement for pumpsRotary piston pumpsSynthetic materialsEngineering

A screw compressor comprising a compressor housing (11) having two rotor screws (1, 2) supported axially parallel therein, while the rotor screws are in a compression chamber (18) Mesh with each other, can be driven by a drive and synchronized with each other in their rotational movement, wherein the rotor screws (1, 2) each have a one-piece or multi-piece base body (24) and protrude from the end face (5a, 5b, 5c, 5d) shaft end (30), wherein the base body has two end surfaces (5a, 5b, 5c, 5d) and a profiled curved surface (12a, 12b) elongated therebetween, wherein at least the profiled curved surface (12a, 12b) is designed as multilayer, comprising a first inner layer (3) and a second outer layer (4), wherein both the first inner layer (3) and the second outer layer (4) comprise or are formed of a thermoplastic synthetic material, Particles ( 25 ) or pores ( 32 ) supporting the running-in process are embedded in the second outer layer ( 4 ), and the thermoplastic synthetic material defines a matrix for receiving the particles ( 25 ) or forming pores ( 32 ).

Owner:凯撒空压机有限公司

Organic fertilizer produced by cornflower herbs and production method of organic fertilizer

InactiveCN106966820AThe quality remains the sameAbundant resourcesCalcareous fertilisersBioloigcal waste fertilisersEthanolChemistry

The invention discloses an organic fertilizer produced by cornflower herbs and a production method of the organic fertilizer. The organic fertilizer comprises, by weight, 70-90 parts of cornflower herbs, 3-7 parts of pine needles, 3-7 parts of eucalyptus leaves, 1-3 parts of moxa sticks, 1-3 parts of industrial hydrochloric acid, 1-3 parts of absolute ethyl alcohol, 0.8-1.2 parts of oil cakes, 0.01-0.03 part of industrial paclitaxel and 1-3 parts of quicklime. The cornflower herbs can be produced into the organic fertilizer with good effects by the method, and the organic fertilizer can be popularized and used in vast rural areas and has good economic benefits.

Owner:贵州义龙万丰生态肥业有限公司

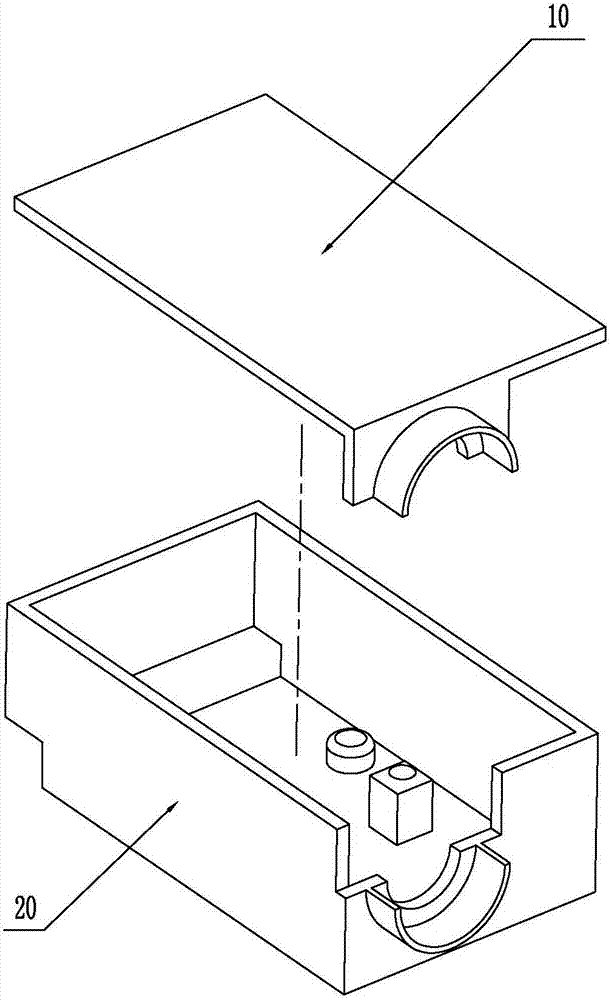

Tissue treatment device for protein purification

PendingCN111811863ACharacteristics unchangedAvoid interferenceWithdrawing sample devicesPreparing sample for investigationBiotechnologyAfter treatment

The invention relates to the field of protein purification and particularly relates to a tissue treatment device for protein purification. The technical problem to be solved by the invention is to provide the tissue treatment device for protein purification. The tissue treatment device for protein purification comprises a machine body bottom plate, an isolation sampling mechanism, an internal tissue sampling mechanism, a tissue cell breaking mechanism, an external sealing communication mechanism, an operation control screen and the like, wherein the top left side of the body bottom plate is welded to the top deck. The tissue treatment device is advantaged in that the sterile sample input is realized, sealing, isolating and sampling after disinfection of the sample are completed, the deviceextends into original sample tissues to extract internal fresh tissues, cell characteristics are unchanged, protein is invariant, interference of original impurities and bacteria on an outer surfaceof a sample is prevented, fine grinding after mincing is achieved, the device is always in a sealed and isolated state before and after treatment, and sterile cell mixed liquid is obtained.

Owner:李庆华

A method for in situ cryopreservation of cells by three-dimensional microcarriers

ActiveCN109566604BIncrease vitalityCharacteristics unchangedDead animal preservationCryopreservationMicrocarrier

The invention discloses a method for in-situ cryopreservation of cells by a three-dimensional micro-carrier. The method includes the following steps: (1) centrifuging a three-dimensional micro-carriersuspension of cells, and discarding a supernatant to obtain a carrier containing cells; (2) mixing the carrier containing the cells with a cryopreservation solution, and then adding the mixture intoa cryopreservation tube; (3) cooling the cryopreservation tube added with the carrier containing the cells in the step (2), and then transferring to liquid nitrogen to realize in-situ cryopreservationof the cells by the three-dimensional micro-carrier. The method can realize in-situ cryopreservation of cell culture on the three-dimensional micro-carrier without separating the cells from the micro-carrier and preforming cryopreservation, realizes that cell cryopreservation does not interrupt the three-dimensional culture process, is convenient for users to store, transport and resuscitate thecultured three-dimensional cell products, and is further convenient for long-term preservation of the cells.

Owner:BEIJING CYTONICHE BIOTECH CO LTD

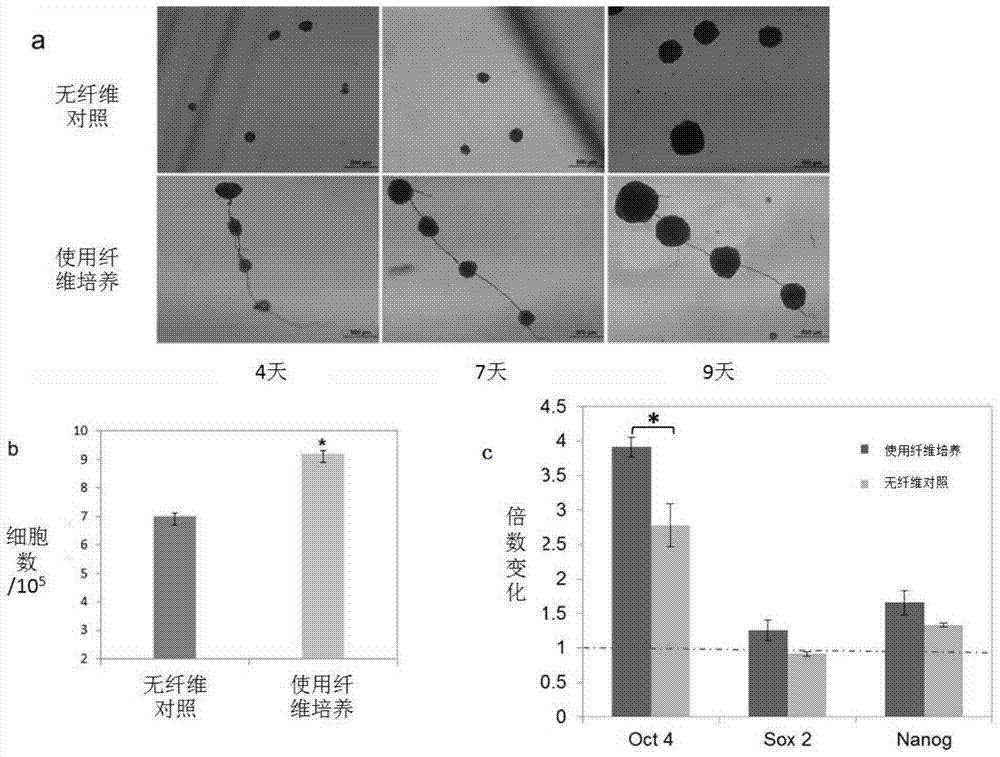

A method for selectively purifying and expanding stem cells in large quantities

ActiveCN105039249BEffective value-addedCharacteristics unchangedArtificial cell constructsSkeletal/connective tissue cellsFiberAgricultural science

The invention discloses a method for selectively purifying and expanding stem cells in large quantities. The method includes selectively expanding stem cells using absorbent cotton fibers or modified absorbent cotton fibers. The use of absorbent cotton fiber-based polymer materials can effectively increase the value of purified stem cells and maintain the same characteristics of stem cells, which is conducive to the realization of large-scale expansion of stem cells.

Owner:SOUTHEAST UNIV

A device and method for repairing broken water pipes using magnetic fluid

Owner:合肥九州龙腾科技成果转化有限公司

A kind of human thymoma cell line and its application

InactiveCN104087554BIn vitro tumorigenic abilityCharacteristics unchangedMicrobiological testing/measurementMicroorganism based processesLymphatic SpreadWilms' tumor

The invention discloses a human thymoma cell line and application thereof, belonging to the field of tumor biology. The human thymoma cell line is named Thy0517 and has a collection number of CGMCC (China General Microbiological Culture Collection Center) No.9328. The human thymoma cell line Thy0517 has main advantages of having protein expression similar to primary tumor tissues, abnormal karyotype and characteristics of tumor cells with in-vitro tumor forming capability. After in-vitro continuous passage culture, the characteristics of thymoma cells keep unchanged, and therefore the human thymoma cell line can be used as a cell material for researching and developing thymoma-related drugs. EGFR (Epidermal Growth Factor Receptor) expression of the human thymoma cell line is positive, so that proliferation, angiogenesis, adhesion, invasion and metastasis of the tumor cells can be promoted; the cell line can be used as a powerful cell tool for researching EGFR-targeted drugs.

Owner:张鹏

Tissue culture method for fast propagation of primula denticulata ssp.sino-denticulata

InactiveCN101015280BHigh reproductive coefficientStrong growthHorticulture methodsPlant tissue cultureAxillary budPrimula denticulata

The invention provides a method for tissue culturing and fast propagating Primula denticulata ssp.sino-denticulata, comprising explant selection, surface disinfection, adventitious bud induction, subculture, rooting culture and test-tube seedling transplanting. The method is characterized in that one axillary bud can induce about 40-50 sprouts, the multiplication coefficient is about 3- 4 after 30- 40 days subculture, the rooting rate reaches above 95%, and the replanting survival rate is nearly 100%. The invention realizes preservation for single Primula denticulata ssp.sino-denticulata, meanwhile greatly increases seedling capacity for Primula denticulata ssp.sino-denticulata i, reduces seedling time and cost, and provides technique support for Primula denticulata ssp.sino-denticulata application in large areas.

Owner:BEIJING FORESTRY UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com