Patents

Literature

49results about How to "Good cell shape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Improved mesenchyme stem cell protection solution and application thereof

ActiveCN101919380ACharacteristics unchangedMeet application needsDead animal preservationMesenchymeCell activity

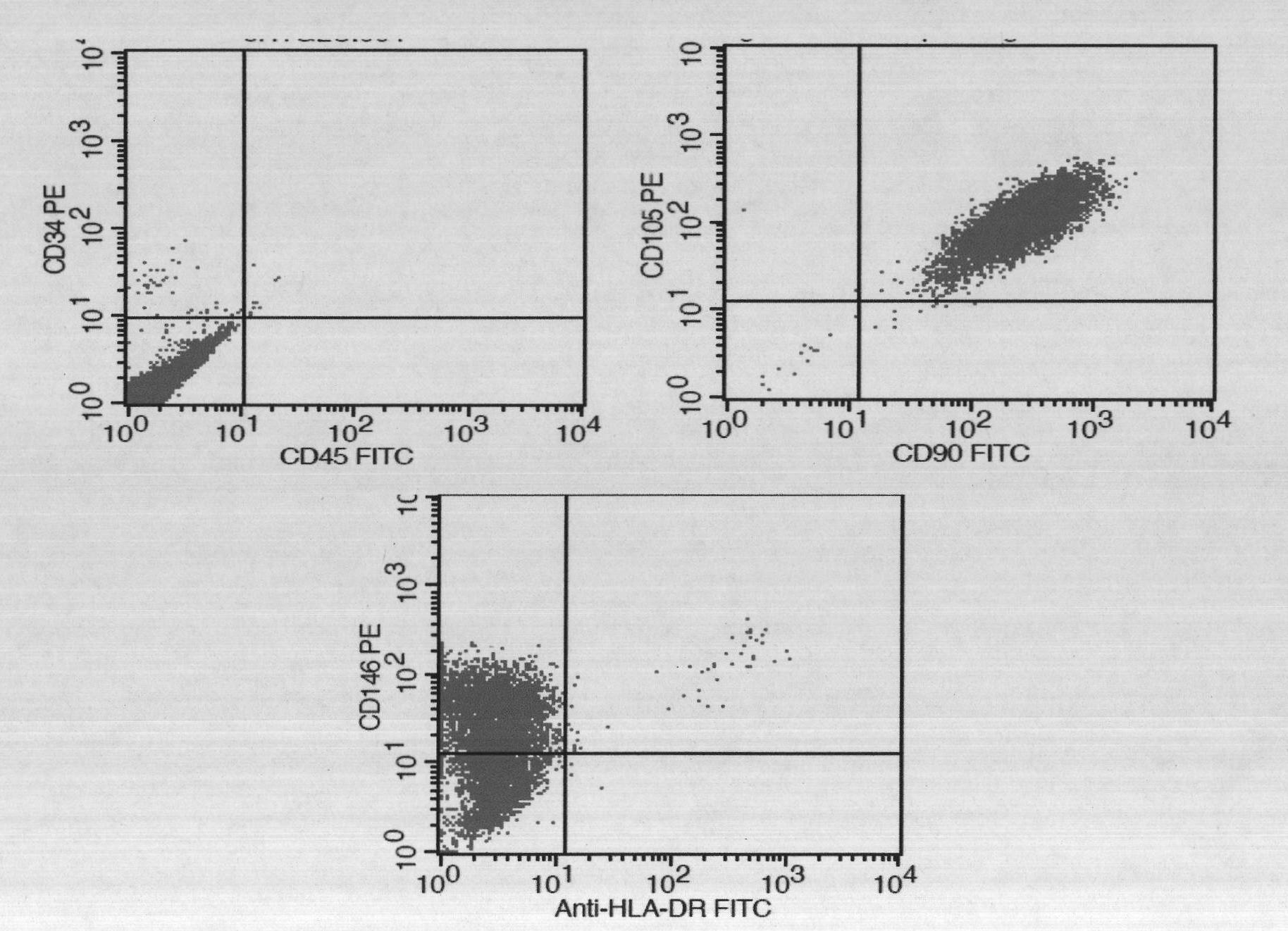

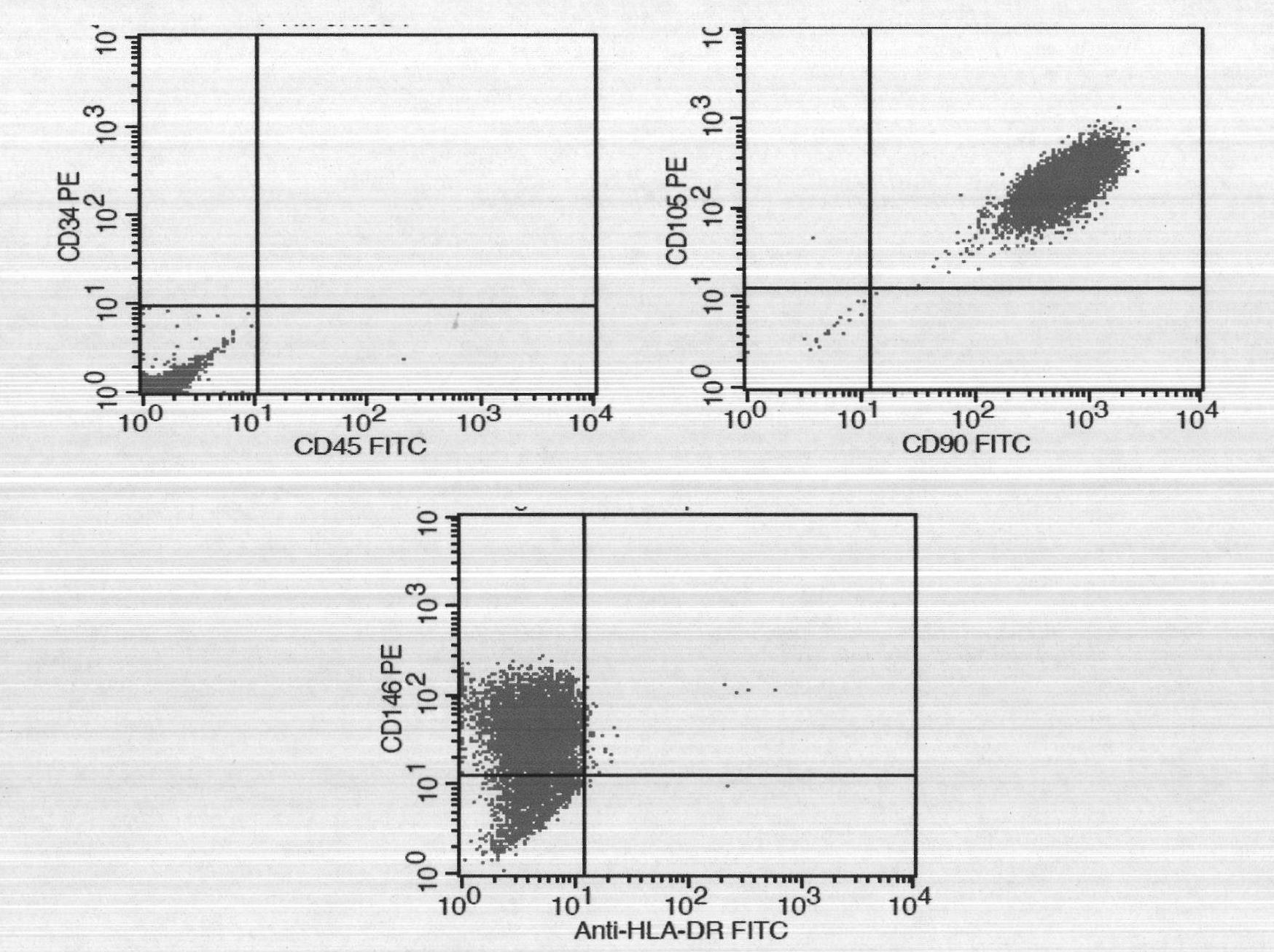

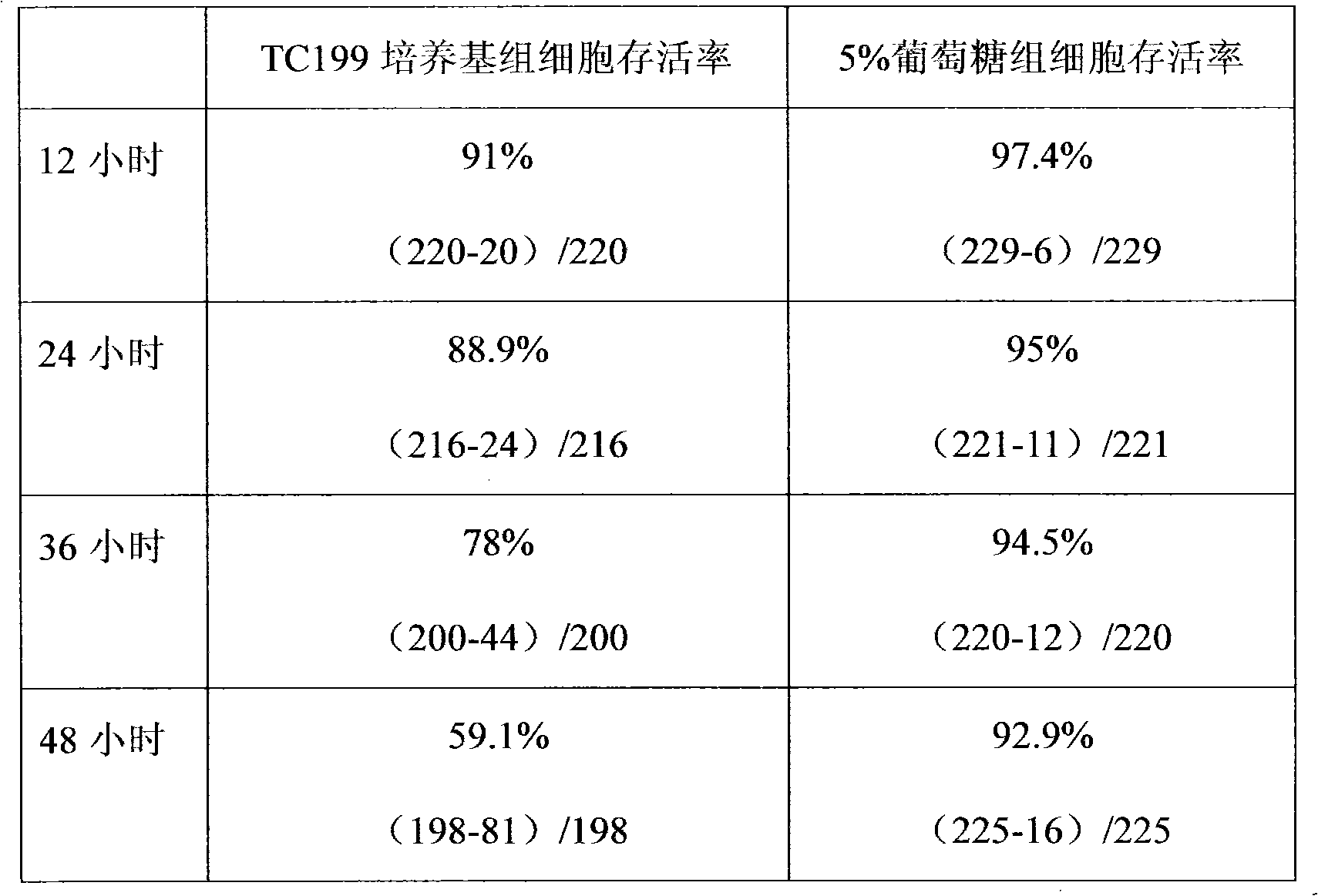

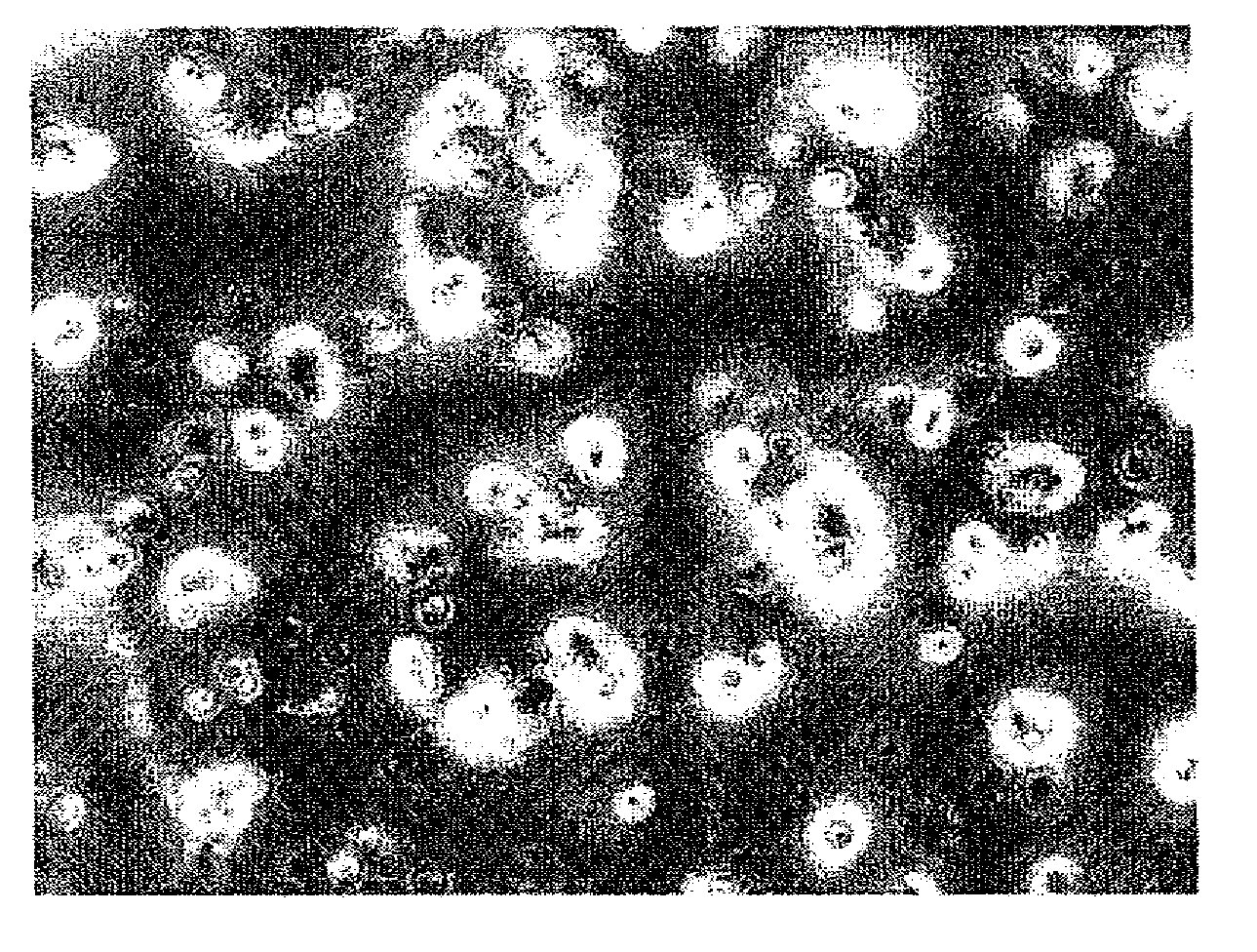

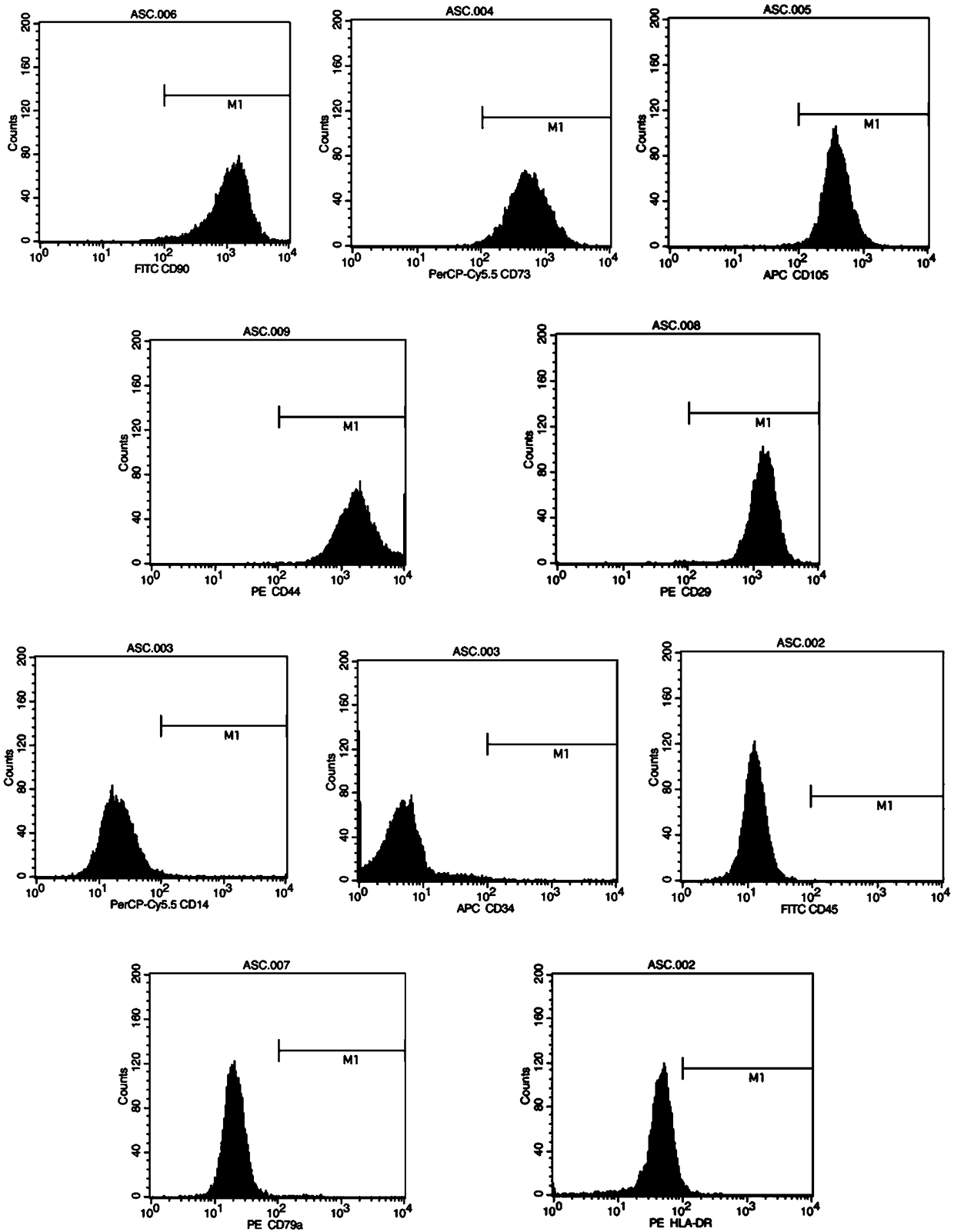

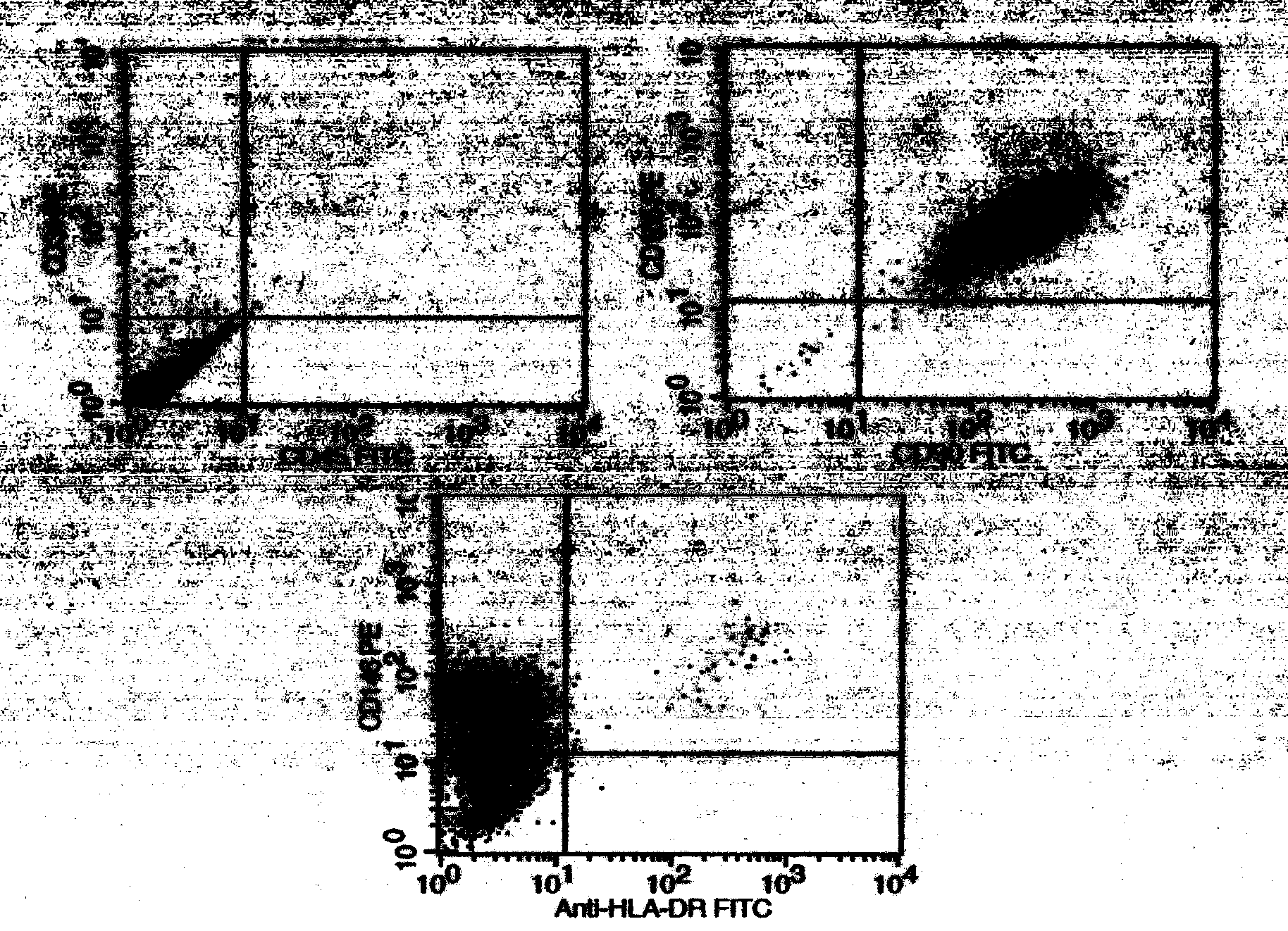

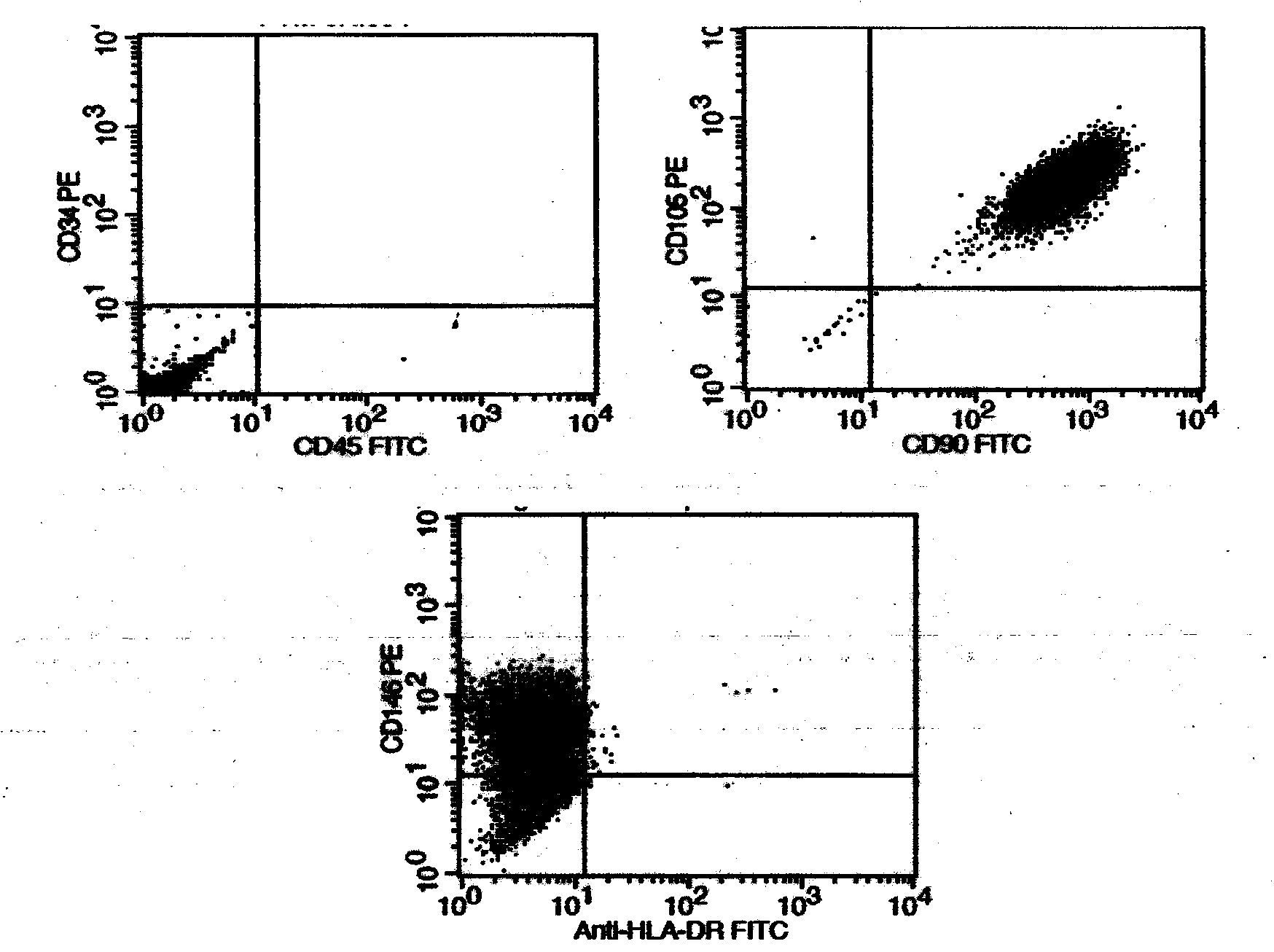

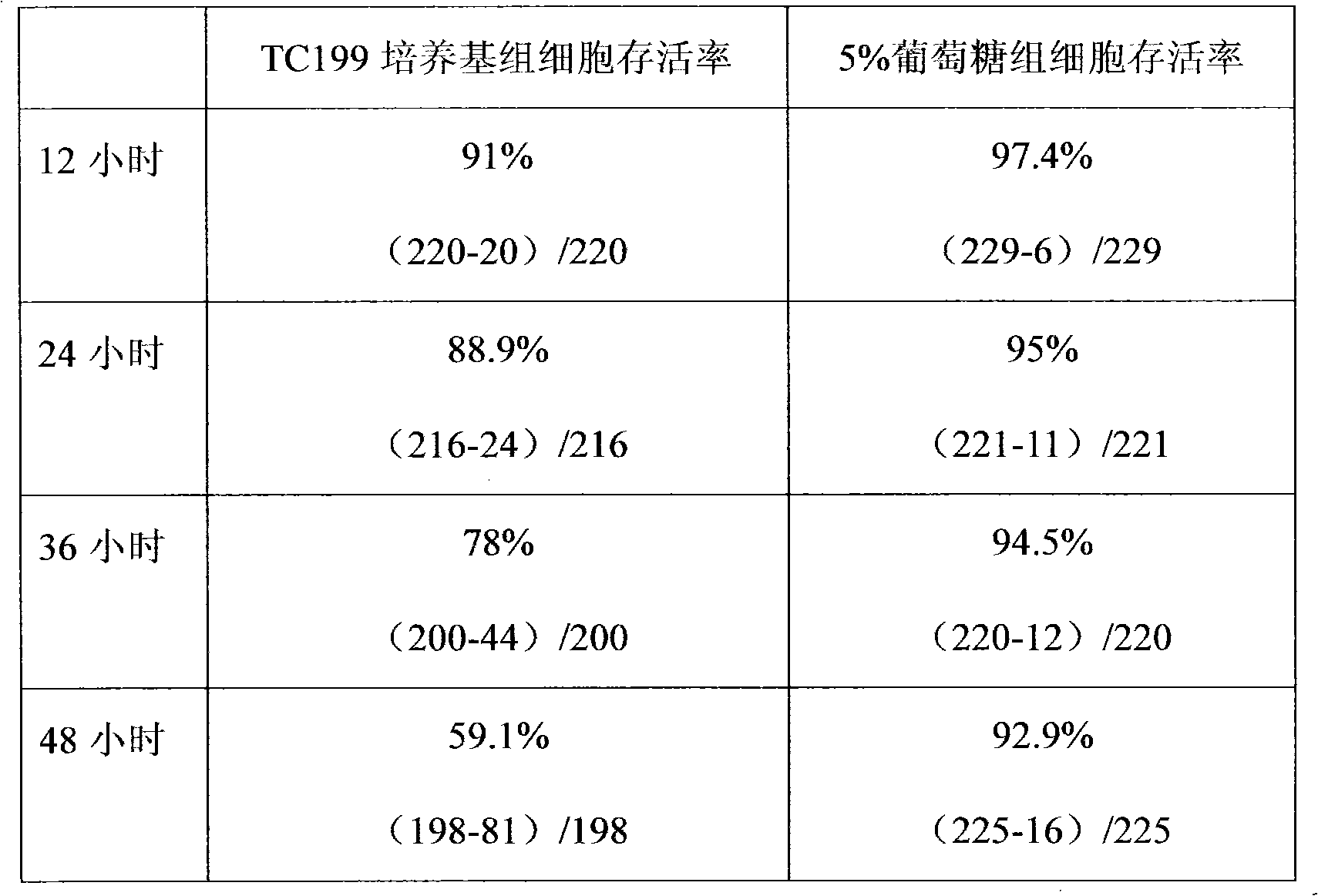

The invention relates to an improved mesenchyme stem cell protection solution as well as application and a preparation method thereof. The protection solution can effectively prolong the activity remaining time of mesenchyme stem cells, reduces preparation cost, and has the advantages of wide raw material source, simple preparation, safe and reliable direct clinical application; and after the mesenchyme stem cells are preserved for 48 hours in the protection solution, the cell activity is still above 90 percent, the cell morphology is normal, and the multiplication capacity and mesenchyme stem cell phenotype characteristics are not influenced.

Owner:青岛奥克生物开发有限公司

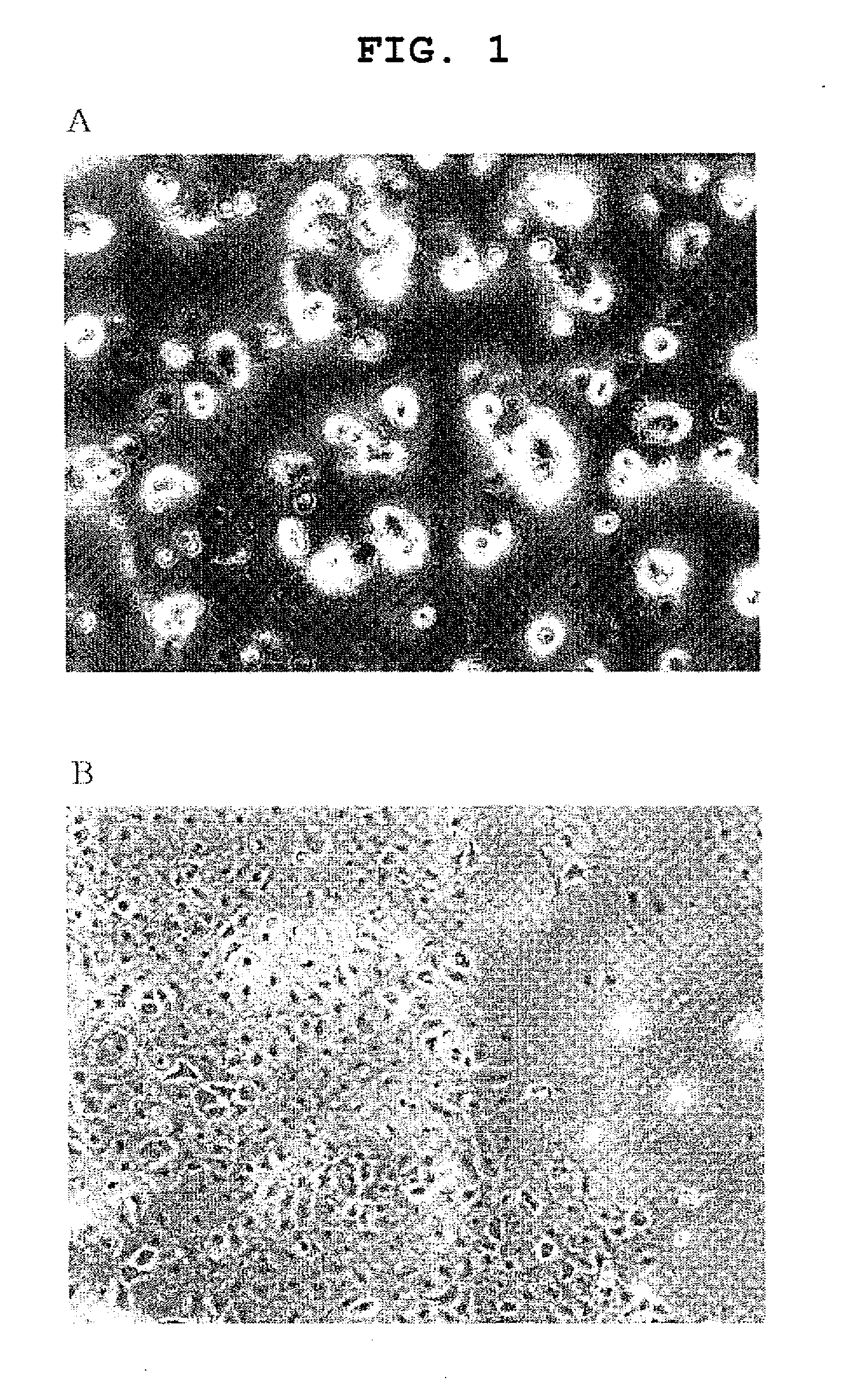

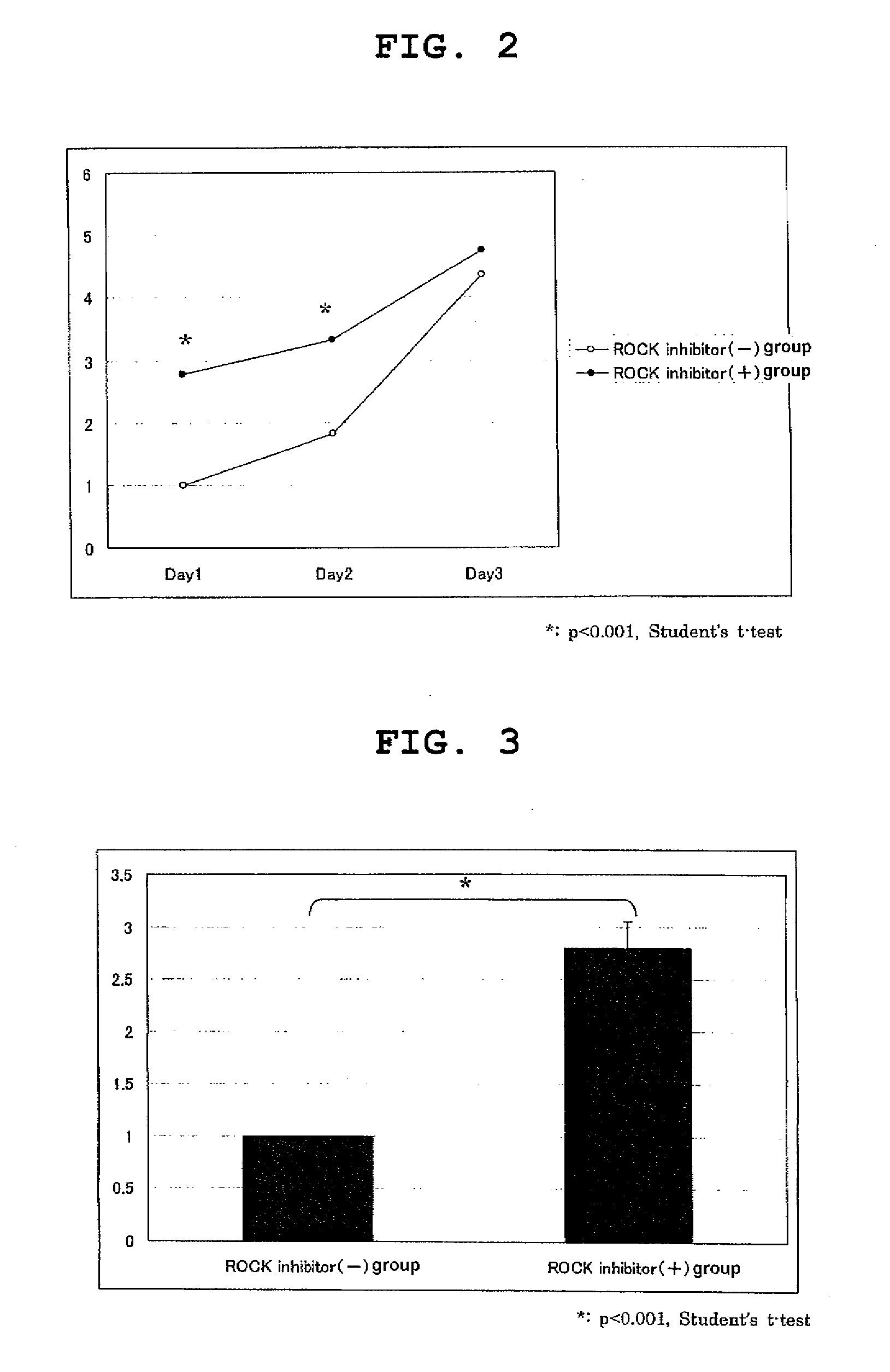

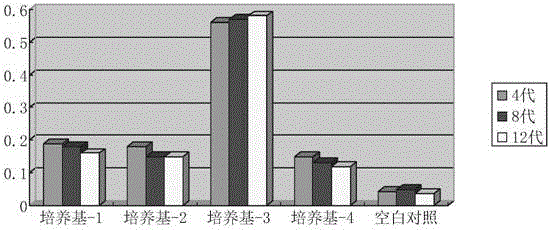

Agent for promoting corneal endothelial cell adhesion

ActiveUS20100209402A1Promote adhesionGood cell morphologyBiocideOrganic active ingredientsCorneal endothelial cellBiology

The invention provides an agent for promoting adhesion of a corneal endothelial cell, containing a Rho kinase inhibitor, as well as a culture medium for a corneal endothelial cell, a solution for preservation of cornea, and a method of producing a corneal endothelial preparation, which includes culturing the corneal endothelial cell using the aforementioned culture medium.

Owner:SENJU PHARMA CO LTD +1

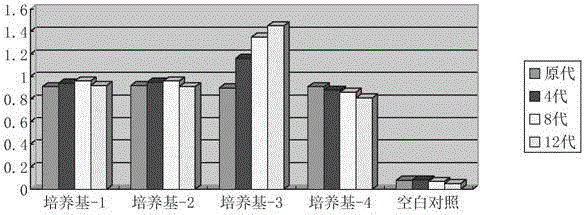

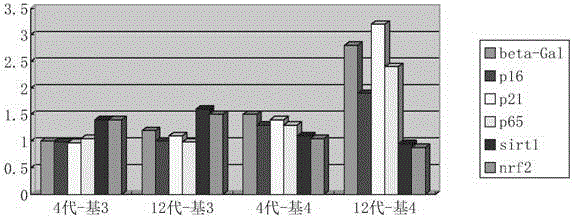

Undifferentiated anti-aging amplification culture medium for human umbilical cord/adipose tissue-derived stem cells

InactiveCN106754683APromotes growth and migrationPromote angiogenesisCulture processSkeletal/connective tissue cellsBiological macromoleculeBrown adipose tissue

The invention provides an undifferentiated anti-aging amplification culture medium for human umbilical cord / adipose tissue-derived stem cells. The problem in the prior art that a serum-free medium used for culturing mesenchymal stem cells is easy to differentiate and easily causes aging and apoptosis of adult stem cells is solved. The undifferentiated anti-aging amplification culture medium for human umbilical cord / adipose tissue-derived stem cells comprises cell factors, vitamins and chemical small molecules, and the culture system comprises multiple chemical small molecules and biomacromolecules and has the effects of improving physiological metabolism and proliferation and growth potential of cells, resisting oxidative stress response, scavenging free radicals, preventing DNA mutation, protecting mitochondria, reducing molecular wastes in the cells and activating longevity genes and telomerase.

Owner:北京殷氏细胞生物科技集团有限公司

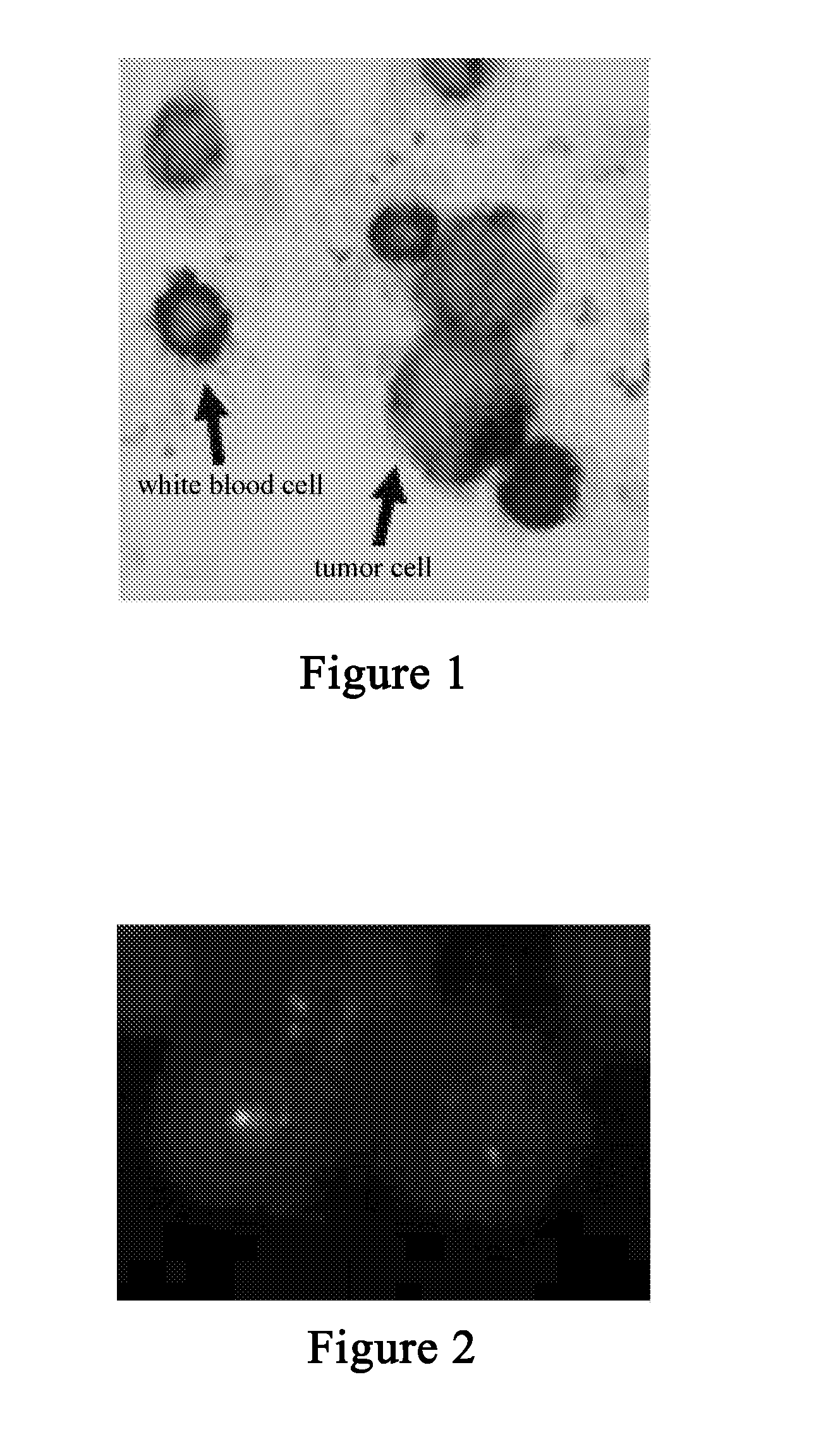

Integrated Method for Enriching and Detecting Rare Cells from Biological Body Fluid Sample

InactiveUS20110195413A1Good cell shapeHigh recovery rateBioreactor/fermenter combinationsBiological substance pretreatmentsStainingSorbent

The present invention relates to an integrated method for enriching and detecting rare cells in biological body fluid sample. The enriching method comprises: (a) removing plasma protein by centrifugation; (b) optionally adding a red cell lysis solution to carry out red cell lysis so as to remove the red blood cells; (c) adding immunomicrospheres or immunoadsorbent to incubate; and (d) carrying out density centrifugation based on a special cell separation medium for separating the circulating rare cells, residual red blood cells after removing red blood cells and the white blood cells combined on the immunomicrospheres. The method for detecting the enriched rare cells according to the present invention comprises combining immunohistochemistry based staining with immunofluorescence, or bicolor, tricolor or multicolor staining based on immunohistochemistry, and observing and identifying by fluorescence or ordinary optical microscope or a scanner based on microscope principle. The novel and unique method for enriching and staining has been proved to have low cost and can rapidly, effectively and high specifically enrich and quantitatively detect the rare cells in blood.

Owner:CYTTEL BIOSCI BEIJING

Method for freezing preservation nervous stem cells

InactiveCN101070534AAvoid damageAvoid mechanical damageDead animal preservationTissue cultureCell membraneVolumetric Mass Density

The invention provides a neural stem cell cryopreservation method, which belongs to cell biotechnology field. Its characteristic is fixes directly the cell embedding in certain density collagen culture medium, saves in the tube to become the rubber frozen; Through the experiment determined that freezing protecting agent DMSO inducts the time best in the collagen - cell compound;15%2XDMSO will induct in the collagen - cell compound, the room temperature is balanced 15 minutes ; frozen pipe will be diverted to control speed cooling frozen boxes, boxes and frozen at -85 degree C refrigerator placed to ensure that the rate of cooling -1 degree C / min, four hours after the turn -196 degree C liquid nitrogen preservation. The effect of this invention and the benefits of this method is to reduce the infiltration process of DMSO on both sides of the membrane pressure differential caused injury. After the recovery, the cell - collagen compound maintains the good integrity, the cellular form and activeness is good, may use in vivo transplant directly.

Owner:DALIAN UNIV OF TECH

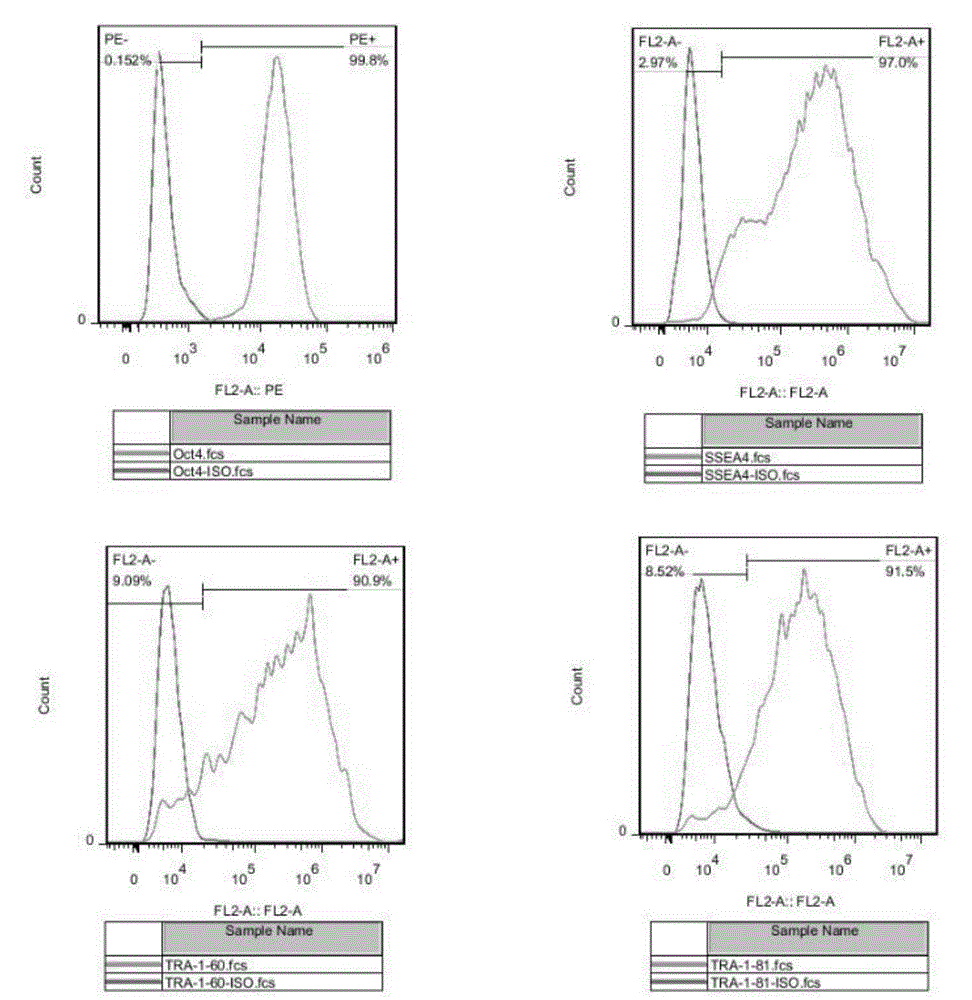

Low-density-tolerant feeder-layer-free human pluripotency stem cell culture medium

ActiveCN106032527AProliferate fastLow costArtificially induced pluripotent cellsNon-embryonic pluripotent stem cellsMagnesium phosphateReprogramming

The present invention discloses a feeder-layer-free human pluripotency stem cell culture medium, which contains L-ascorbate-2 magnesium phosphate, sodium selenite, recombinant human insulin, human apotransferrin, basic fibroblast growth factor, transforming growth factor beta 1, heparin lithium and / or heparin sodium, a DMEM / F-12 base culture medium and an osmotic pressure regulator. According to the present invention, with the culture medium, when the hiPSC culture is performed in low density and normal density, the proliferation rate is high, and the cell morphology and the pluripotency are well maintained; the use of the expensive heparitin sulfate is not required so as to substantially reduce the cost; and almost all of the hiPSCs maintaining cultures at the current stage can be met, and various small molecule compounds are added to perform induction reprogramming culture (removal of TGFB1 and DM), such the culture medium is suitable for extensive researches of various basic scientific researches and clinical scientific research experiments.

Owner:FUTURE HOMO SAPIENS INST OF REGENERATIVE MEDICINE CO LTD (FHSR)

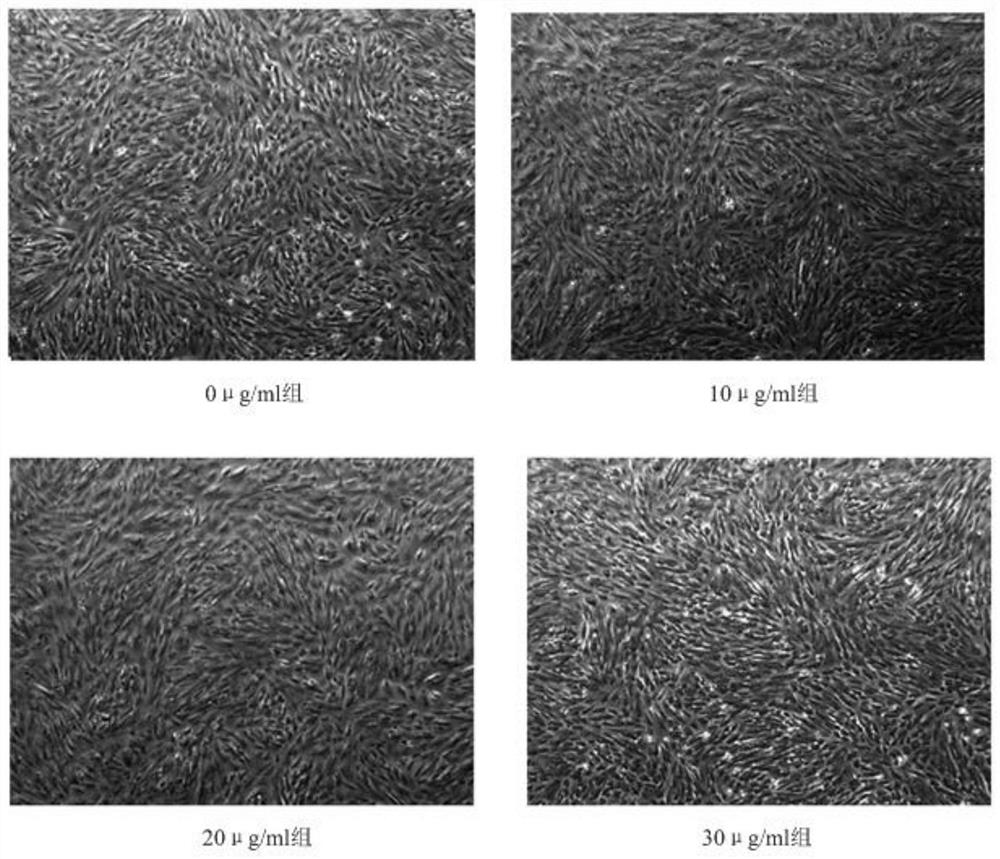

Adipose derived stem cell large-scale culture method

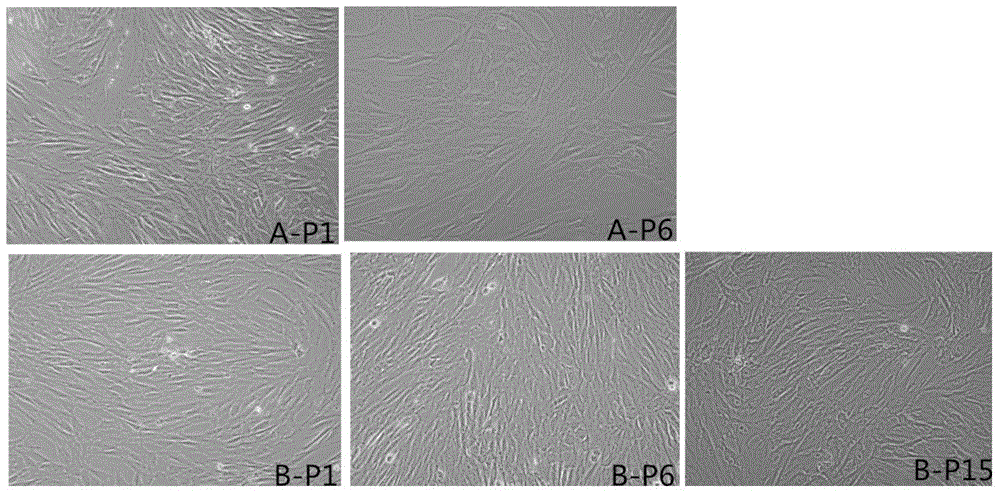

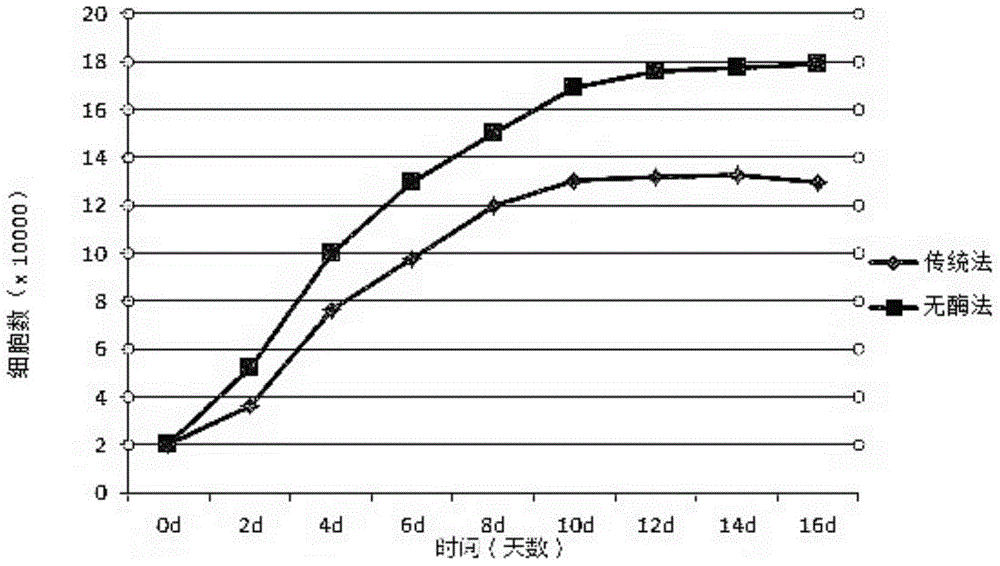

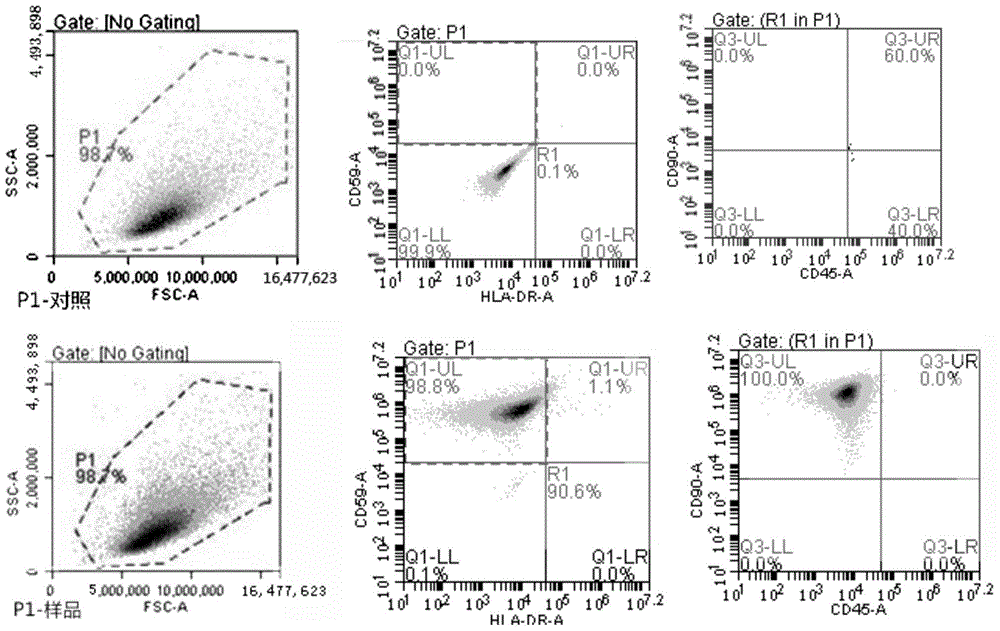

ActiveCN104611292AGood cell shapeImprove cell activitySkeletal/connective tissue cellsBlood serumSerum free media

The invention discloses an adipose derived stem cell (ADSC) large-scale culture method. The method selects a non-enzymatic digestion method (TrypLE) to collect adipose derived stem cells adhering to walls, adopts a minimum TrypLE dosage to maximumly reduce the damage of the cell digestion process to cells, and selects the optimum inoculation density of 1.3*10<4> / cm<2> to culture cells, uses a serum-free medium (UltraCULTURE MEDIUM), and adds appropriate concentration EGF into the medium so as to conduct large-scale culture in a phi 15cm culture dish. Thus, the passage number of ADSC is increased to over 15 and the original dryness can still be maintained, thereby greatly satisfying the requirement of mesenchymal stem cells for scientific research and application.

Owner:GUANGZHOU SALIAI STEMCELL SCI & TECH CO LTD

Serum-free cartilage cell culture solution

ActiveCN104630138AClear outlineGood refractive indexSkeletal/connective tissue cellsGlucanTransferrin

A serum-free cartilage cell culture solution is obtained by adding exogenous additives to a basic culture solution. The basic culture solution is a DMEM culture solution or an F12 culture solution or a DMEM culture solution-F12 culture solution mixed culture solution, and the exogenous additives are nonessential amino acids, glucan, vitamin C, glutamine, sodium pyruvate, insulin or insulin-like growth factor, transferrin, growth hormone, triiodothyronine, hydrocortisone, dexamethasone, sodium selenite, beta-mercaptoethanol, lipid concentrate, progesterone, succinimide, a basic fibroblast growth factor, an epidermal growth factor, a transforming growth factor, a bone morphogenetic protein and a platelet derived growth factor respectively. The serum-free cartilage cell solution can avoid potential risks due to the use of serum, improves the extracellular matrix secreting ability of cartilage cells, makes the growth propagation state approach the growth propagation state of the cells in a serum-containing culture solution, and allows the dedifferentiation rate and the matrix secreting ability of low density inoculation cartilage cells to be obviously better than those of the cells in the serum-containing culture solution respectively.

Owner:SHAANXI RUISHENG BIOTECH

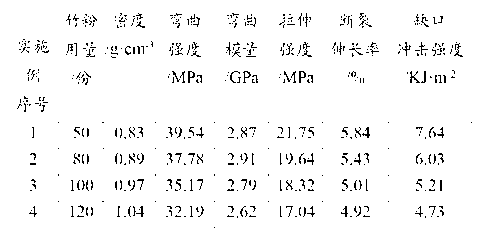

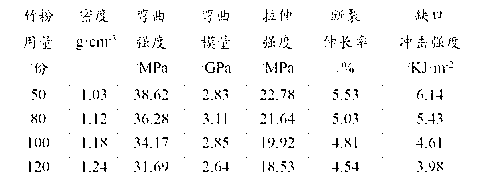

Preparation method of polypropylene-based bamboo-plastic foam composite material

ActiveCN103224668AOvercome the problem of difficult foamingHigh specific strengthCross-linkPolypropylene

The invention discloses a preparation method of a polypropylene-based bamboo-plastic foam composite material. The polypropylene-based bamboo-plastic foam composite material is prepared by the following steps: extruding polypropylene resin, a cross-linking agent, an auxiliary cross-linking agent, a foaming agent and a foaming promoter through a torque rheometer to prepare a foam master batch; heating and uniformly mixing polypropylene resin, a lubricant, an anti-oxidant, an anti-ultraviolet agent, a bamboo powder and an interfacial compatibilizer in a high-speed mixer to prepare a premix, banburying the premix in a torque rheometer, discharging and crushing to obtain bamboo-plastic particles; uniformly mixing the bamboo-plastic particles and the foam master batch and placing in a press vulcanizer, and carrying out pre-compaction, hot briquetting and cold compression for shaping. The content of the bamboo powder reaches up to 60%. The raw materials are cheap and can be recovered. The production process is convenient and environmentally friendly. The polypropylene-based bamboo-plastic foam composite material has advantages of good Foam cell form, low density, high specific strength and good water resistance and heat resistance, and has good market space and application prospect.

Owner:FUJIAN AGRI & FORESTRY UNIV

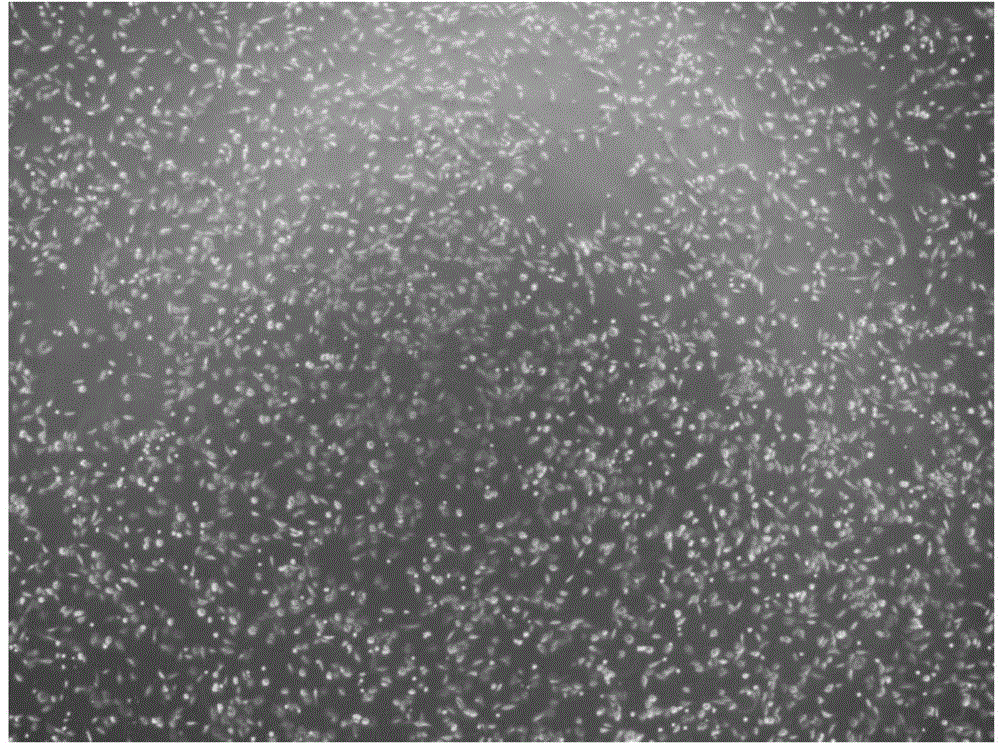

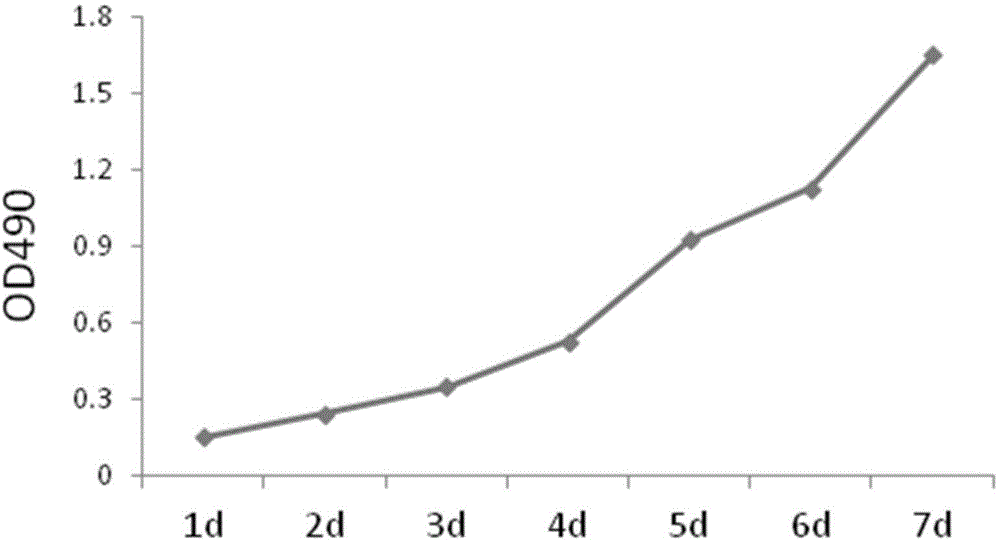

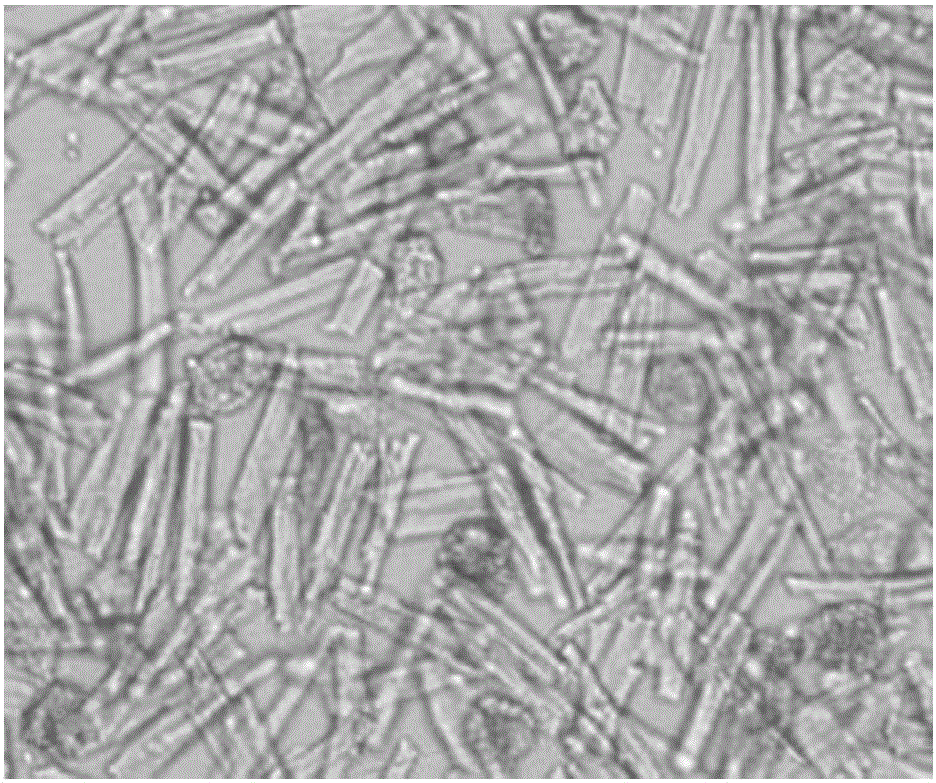

High-activity primary cartilage cell preparing method

ActiveCN104911145APromote digestionAvoid damageSkeletal/connective tissue cellsCartilage cellsMedicine

The invention discloses a high-activity primary cartilage cell preparing method. The high-activity primary cartilage cell preparing method includes the following steps that 1, cartilage tissues of joints in limbs of an immature rat are extracted; 2, a blade special for operations is adopted to cut up the cartilage tissues; 3, the cut-up cartilage tissues are placed in a constant temperature shaking table to be shaken and placed in a horizontal centrifuge for centrifugation by 1500-2000 rpm, cell sediments are left, the cartilage tissues continue to be placed in the shaking table to be digested, are separated from cartilage matrixes after being repeatedly blown and beaten by a gun head of 1 ml, and are placed in the horizontal centrifuge for centrifugation by 1500-2000 rpm, and cartilage cell sediments are left; and 4, the cartilage cell sediments are planted in a culture dish and cultured in a DMEM high-glucose culture medium containing 10% of FBS to obtain high-activity primary cartilage cells. Compared with a traditional cartilage cell extracting method, the high-activity primary cartilage cell preparing method shortens the time by a half and improves the yield of cartilage cells by at least ten times; experiments verify that the obtained cartilage cells have a good rate of increase and good cellular morphology.

Owner:SHUGUANG HOSPITAL AFFILIATED WITH SHANGHAI UNIV OF T C M

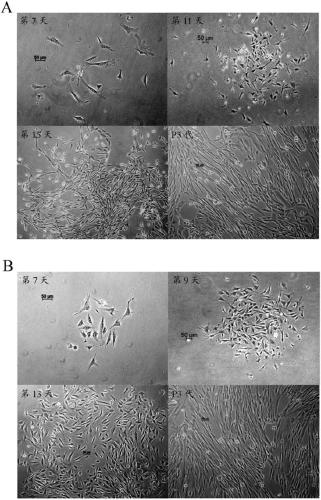

In-vitro separation and purification method for tree-shrew corneal endothelial cells

ActiveCN106244549AEnhance cell viabilityTypical endothelial cell morphologyCell dissociation methodsMicrobiological testing/measurementHigh cellPurification methods

The invention discloses an in-vitro separation and purification method for tree-shrew corneal endothelial cells. The in-vitro separation and purification method includes the steps that tree-shrew corneal endothelial cells are separated, purified and subjected to passage cultivation through CECs, and corneal endothelial cells are obtained. The separated corneal endothelial cells have high cell activities, purification of the corneal endothelial cells can be achieved in the passed P3 generation is passed, the purified cells have typical endothelial cell morphology, and are identified through NSE immunofluorescence, and the dyeing rate is high. The purification efficiency of the method is greatly improved, the cost is low, using is convenient, and the large quantity of tree-shrew corneal endothelial cells can be obtained. In-vitro cultivation of the tree-shrew corneal endothelial cells is achieved, and the void that a specific corneal-endothelial-primary-cell in-vitro cultivation technology for a tree-shrew species does not exist ate present is filled; the material taking and purification methods of primary cells are easy to operate, the cost is low, and in-vitro cultivation tree-shrew corneal endothelial cells can be kept the good cell states in the long-term passage cultivation process.

Owner:INST OF MEDICAL BIOLOGY CHINESE ACAD OF MEDICAL SCI

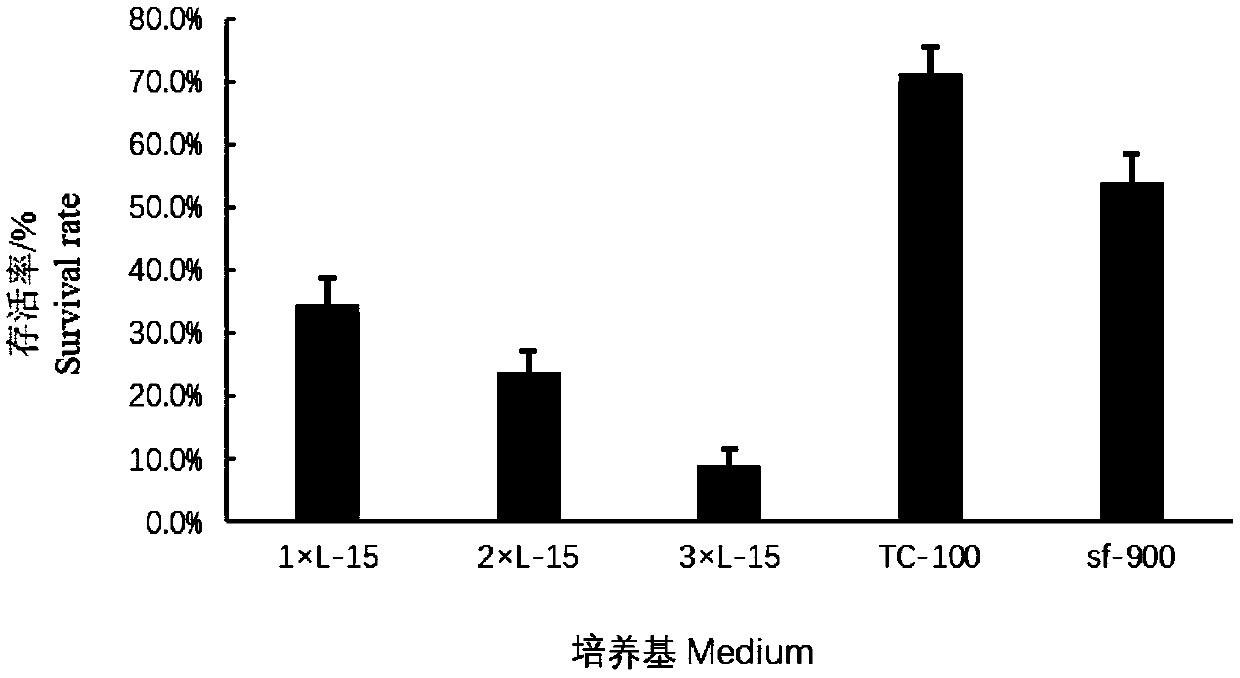

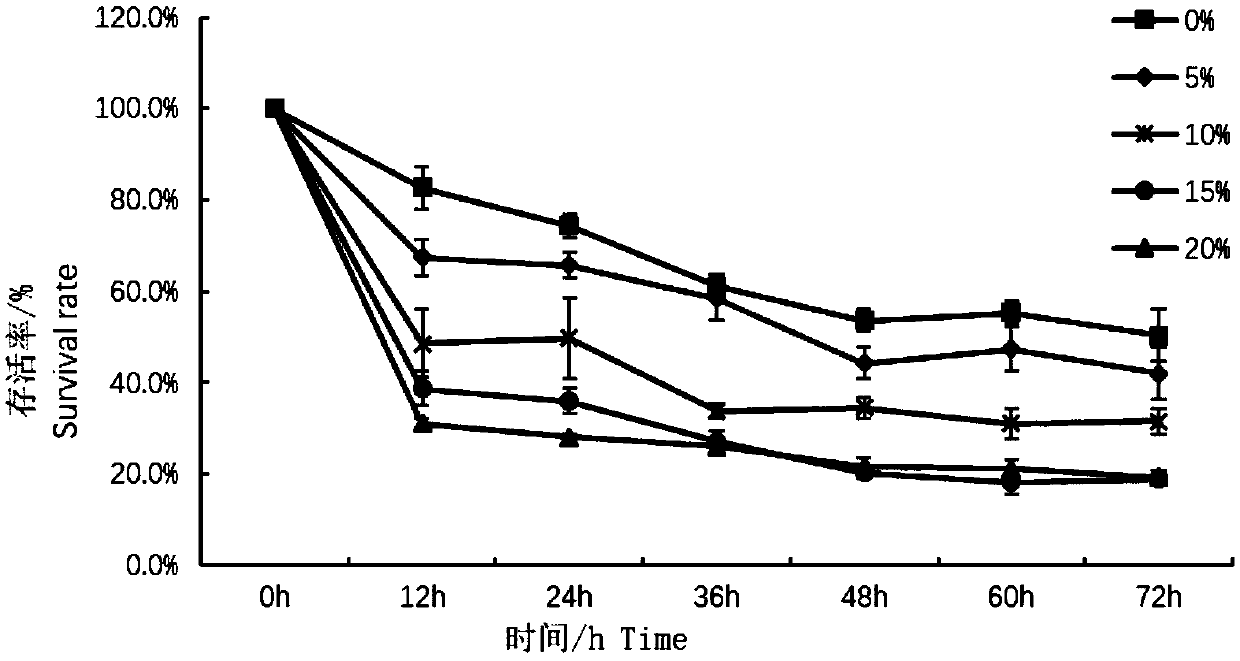

Chinese mitten crab blood cell culture medium and culturing method

ActiveCN109609435AImprove survival rateImprove the cultivation effectInvertebrate cellsClimate change adaptationBiologyCulture mediums

The present invention belongs to the technical field of cell culture and particularly relates to a Chinese mitten crab blood cell culture medium and a culturing method. The Chinese mitten crab blood cell culture medium comprises a basic culture medium and added components, wherein the basic culture medium is selected from a TC-100 basic culture medium; and the added components and concentrations thereof are as follows: 1%-10% of a buffer solution, 1g / L-2g / L of calcium chloride, 1g / L-2g / L of alkali metal chloride, 1.5g / L-2.5g / L of glucose and 1%-1.5% of antibiotic. The culture medium significantly improves survival rate of Chinese mitten crab blood cells in in-vitro culture and prolongs duration of the blood cell culture in vitro, and the blood cells cultured in vitro can maintain good cellmorphology.

Owner:SHANGHAI OCEAN UNIV

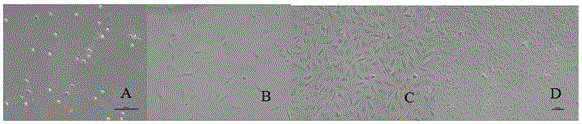

Preparation method of human primary cartilage cells with high yield rate

InactiveCN106011055APromote digestionHigh yieldCell dissociation methodsSkeletal/connective tissue cellsCartilage cellsTrypsinization

The invention belongs to the field of cell in-vitro culture, and particularly discloses a preparation method of human primary cartilage cells with high yield rate. The preparation method comprises the following steps of obtaining a cartilage tissue, and shearing the cartilage tissue by a pair of ophthalmology scissors; adding trypsinization, adsorbing supernatant, and discarding; adding II-type collagen digestion, staying overnight, filtering, adding into a culture medium, terminating digestion, centrifuging for 5min at the speed of 1000-1500rpm, obtaining precipitate of cartilage tissue, planting into a culture dish, and culturing, so as to obtain the human primary cartilage cells with high yield rate. The preparation method is mainly used for improving the shearing and centrifuging speeds of cartilage tissue blocks. The preparation method has the advantages that the centrifuging rotation speed is increased to 1000-1500rpm, the damage to the cartilage cells is avoided, and the yield rate of the cartilage cells is greatly improved; compared with the traditional cartilage cell preparation method, the yield rate of the cartilage cells is increased by about 3.55 times; after proofing by experiments, the cartilage cell has good cellular morphology.

Owner:GUANGDONG SECOND PROVINCIAL TRADITIONAL CHINESE MEDICINE HOSPITAL

High-strength polylactic acid foamed plastic and preparation method thereof

PendingCN110483962AImprove mechanical propertiesNo pollution in the processSodium bicarbonatePolymer science

The invention relates to the technical field of foamed plastic, particularly to high-strength polylactic acid foamed plastic including, by mass, 38-46% of polylactic acid, 1.2-3% of a chain extender,6-8% of a plasticizer, 2-3% of azodicarbonamide, 1.6-2.2% of sodium bicarbonate, 0.1-3.2% of zinc oxide, 6-8% of talcum powder, 8-12% of nano aluminum dioxide, and 9-14% of atactic polypropylene, withthe balance being deionized water. The invention further discloses a preparation method of the high-strength polylactic acid foamed plastic. The preparation method comprises the following preparationsteps: S1, weighing and proportioning; S2, dehydrating the polylactic acid; S3, modifying and mixing; S4, extruding and granulating; S5, cooling and shaping. The plastic has the beneficial effects that the formula is more scientific and reasonable, the polylactic acid is filled with the nanometer aluminum dioxide, and the chemical bond effect between the nanometer aluminum dioxide and the polylactic acid is utilized, so that the plastic has good mechanical performance, can be completely biodegraded, does not pollute the environment, is higher in functionality and is beneficial to popularization.

Owner:HUBEI UNIV OF ARTS & SCI

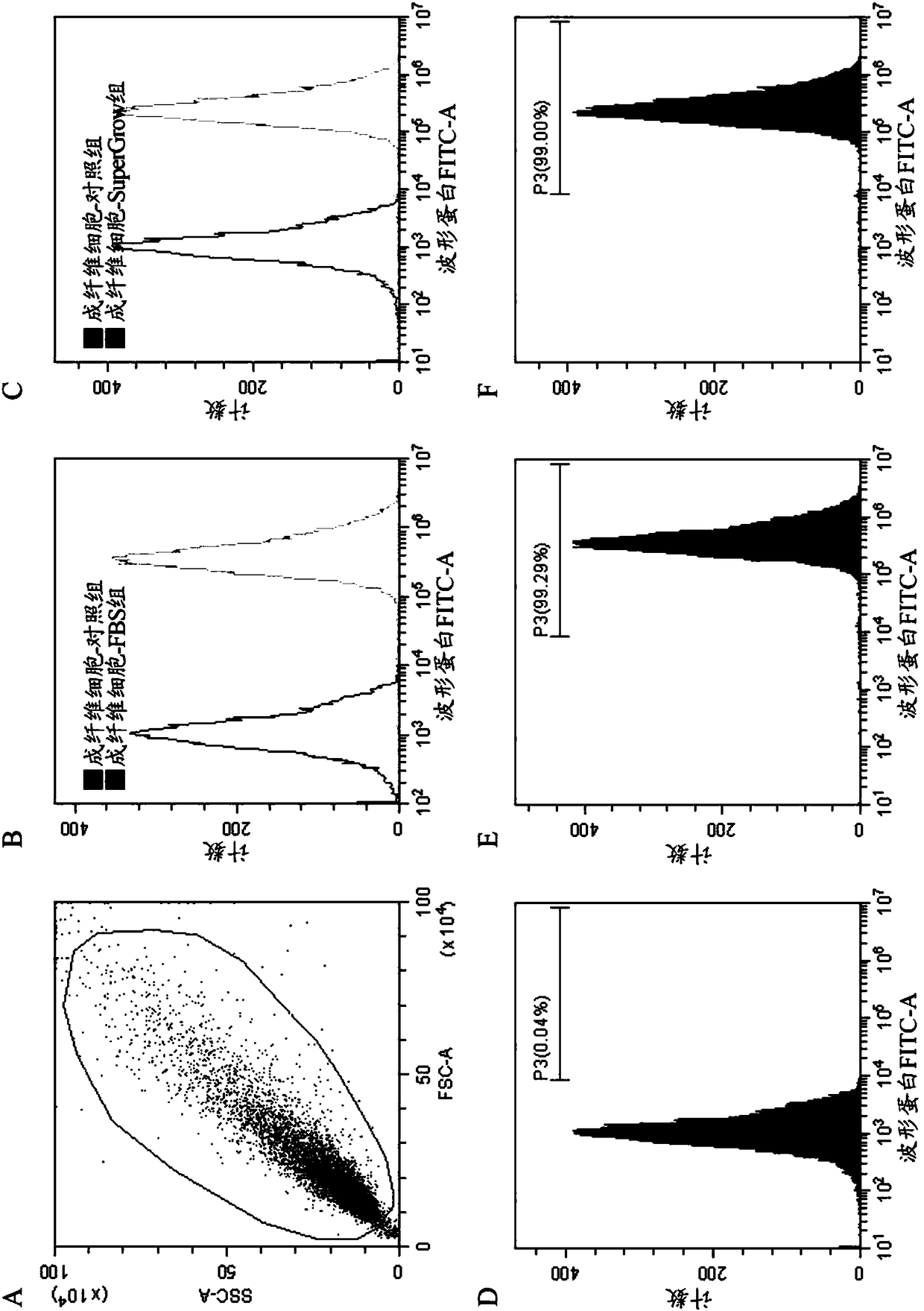

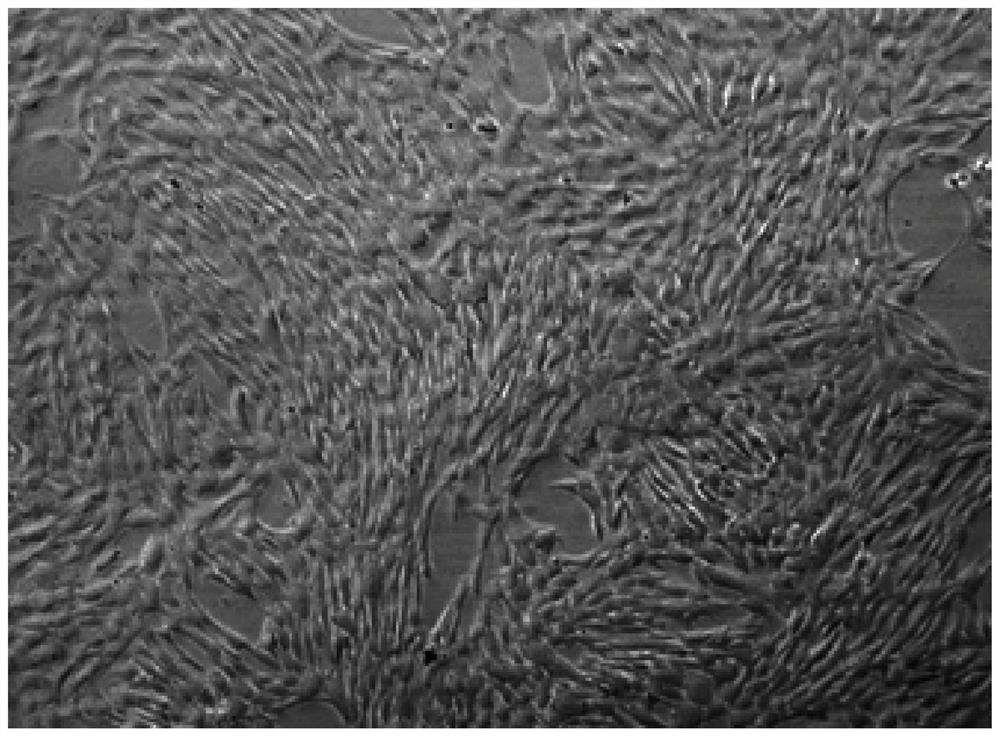

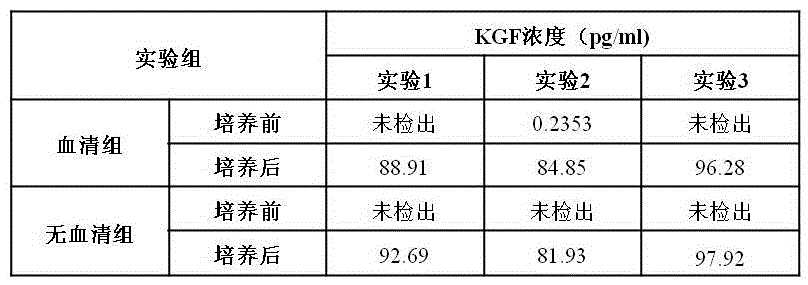

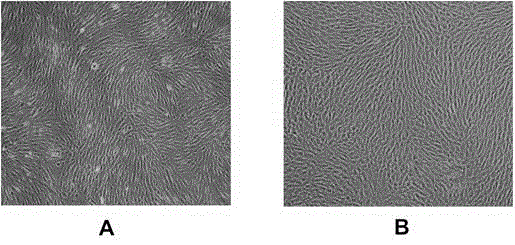

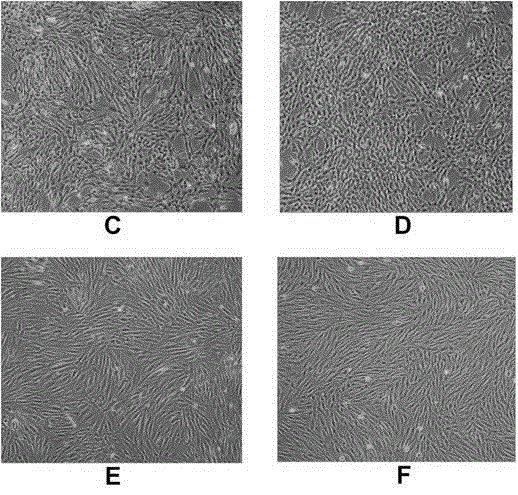

Fibroblast culture medium and application thereof

ActiveCN109112101AAvoid safety hazardsAvoid variance between different batchesCell dissociation methodsCulture processTissue repairCell culture media

The invention provides a culture medium. The culture medium comprises a basal medium and a platelet lysate, preferably, comprises gutamic acid and / or proline. The invention also provides a method of culturing the fibroblasts using the above cell culture medium, and an application of the cultured fibroblasts as a raw material for cosmetic or tissue repair.

Owner:BIOCELLS BEIJING BIOTECH CO LTD

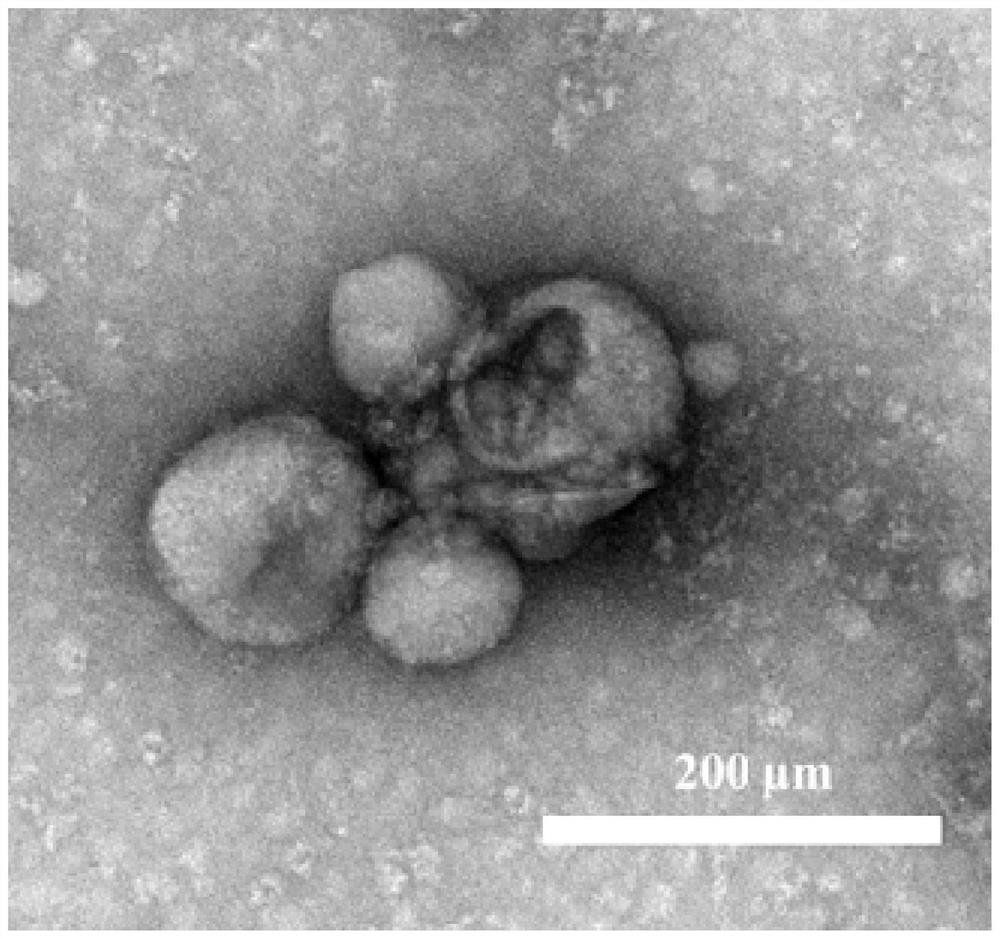

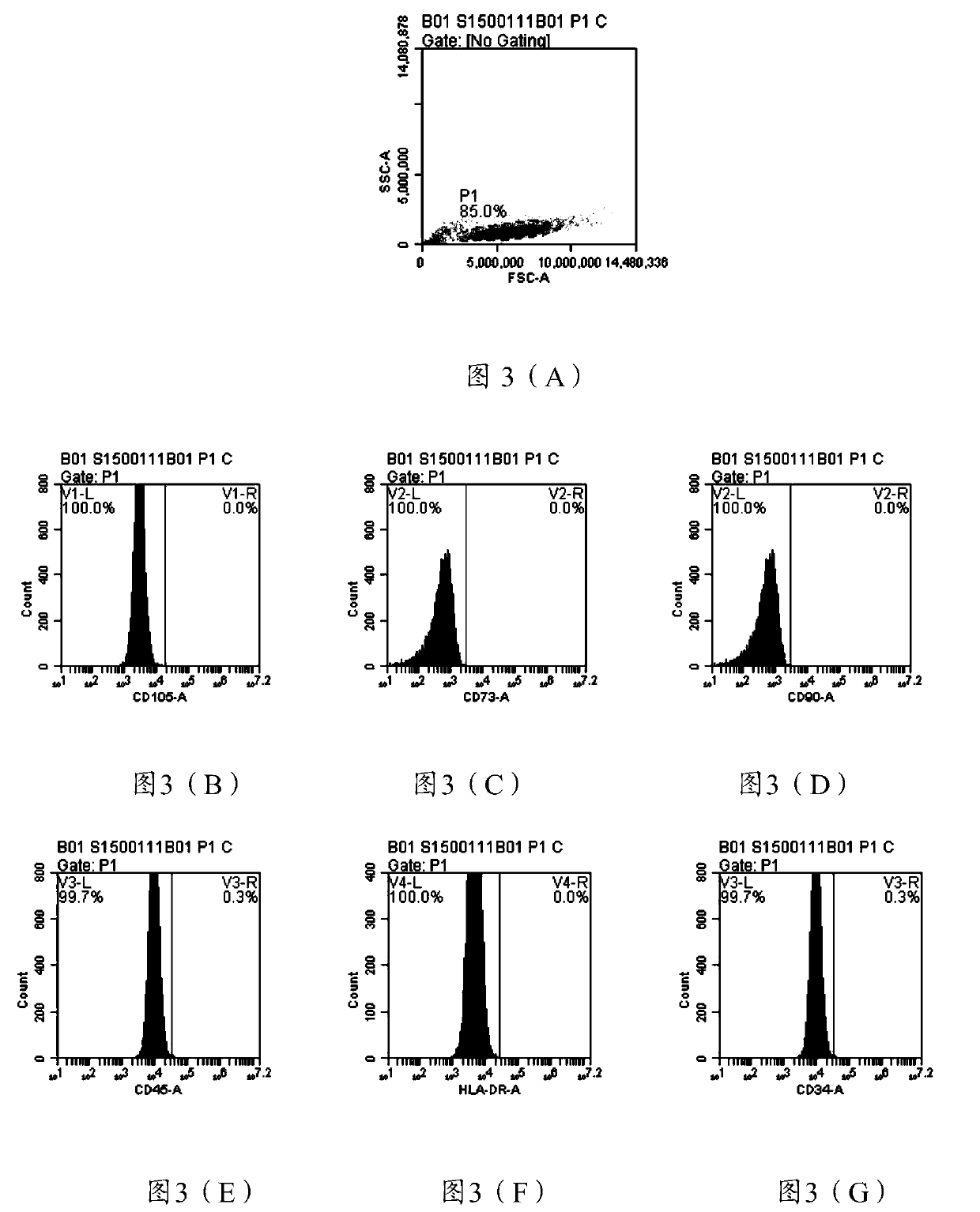

Application of exosome in promotion of growth of mesenchymal stem cells of decidua parietalis

PendingCN113151162ABroaden the extraction conditionsImprove extraction efficiencyCell dissociation methodsCulture processCell activityMesenchymal stem cell

The invention discloses application of a human umbilical mesenchymal stem cell exosome in promotion of growth of mesenchymal stem cells of decidua parietalis and a method for promoting the growth of the mesenchymal stem cells of the decidua parietalis. According to the application and the method, after the human umbilical mesenchymal stem cell exosome and PDB-MSCs are cultured jointly, the PDB-MSCs is high in cell proliferation capability, good in cellular form and high in cellular activity, thus, the human umbilical mesenchymal stem cell exosome disclosed by the invention can be used for improving the quality of the PDB-MSCs, the cell factor VEGF and SCF secreting capability of the PDB-MSCs is improved effectively, thus, the problems of the PDB-MSCs that repeated transfer of generation is lowered in proliferation capability and poor in cell activity can be solved, and then, the large-scale culture and clinical application of the PDB-MSCs is facilitated effectively.

Owner:GUANGDONG VITALIFE BIOTECHNOLOGY CO LTD

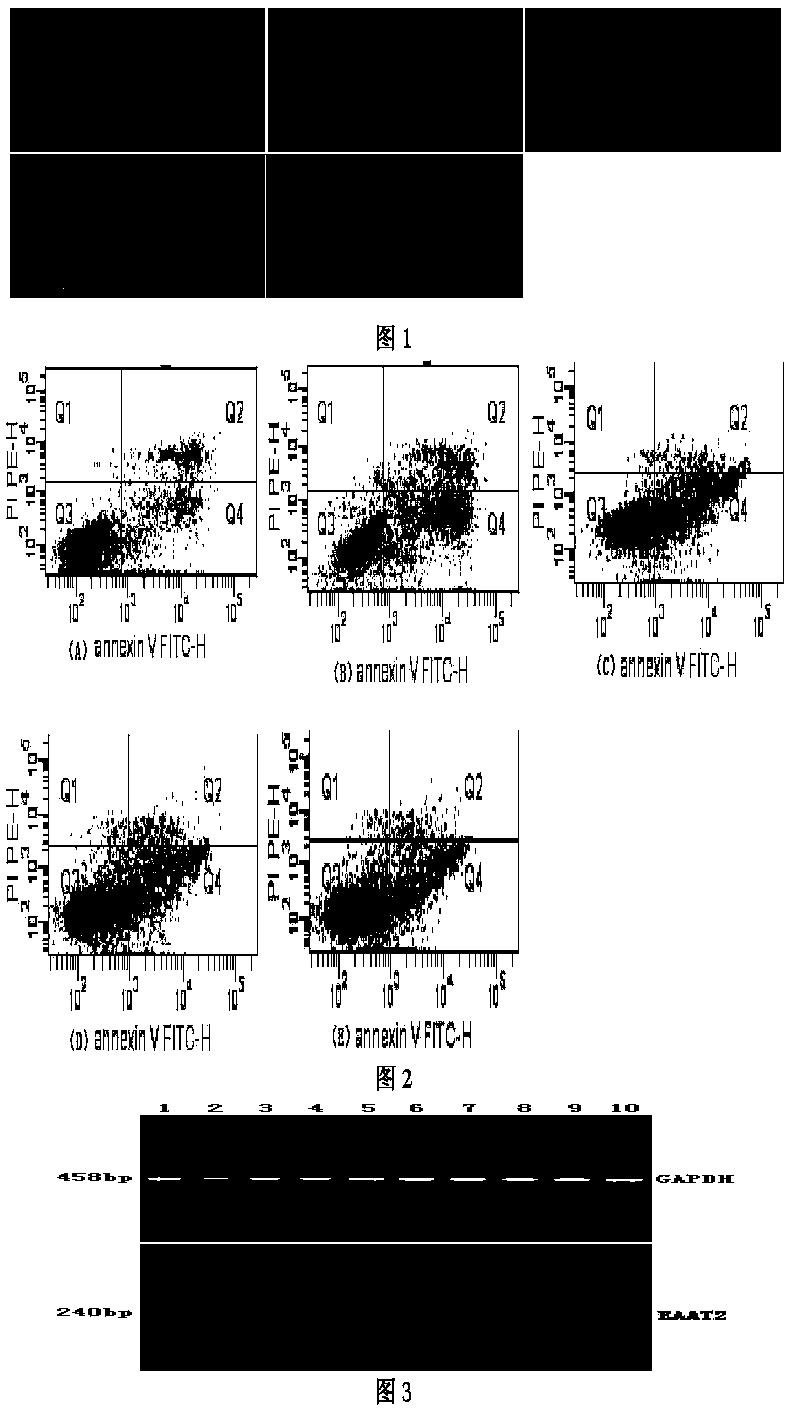

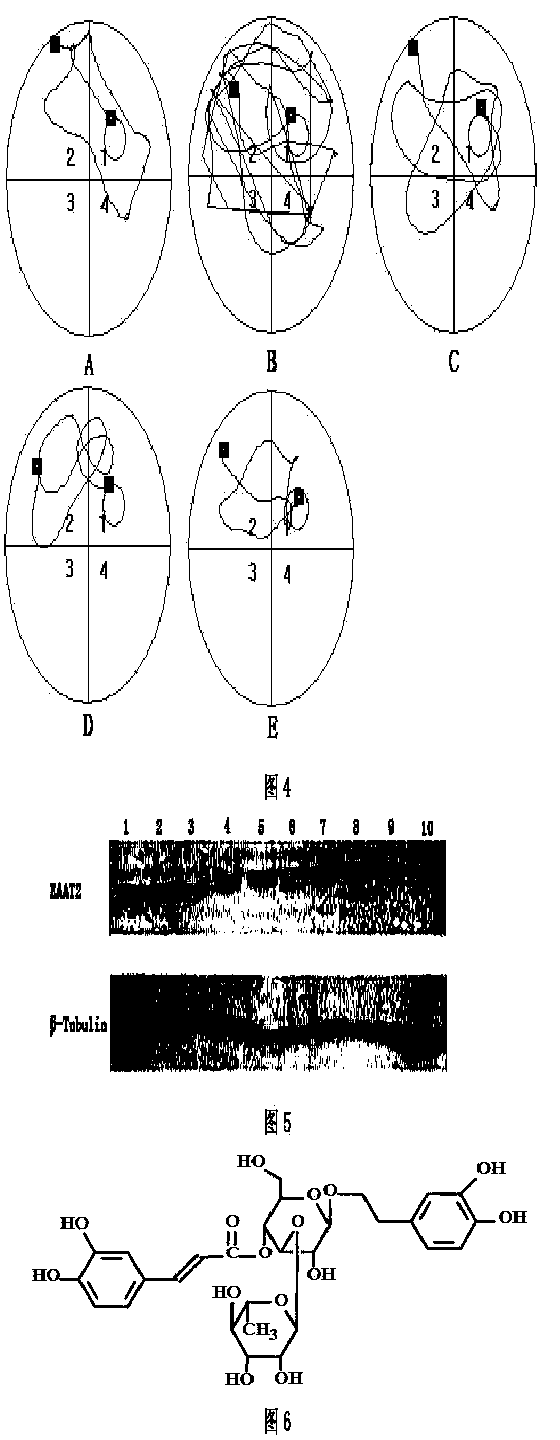

Application of acteoside in preparing medicine protecting cranial nerve cells damaged by ingestion and restraint of glutamate transporter

InactiveCN103816168AGood cell shapeImprove survival rateOrganic active ingredientsNervous disorderExcitatory amino-acid transporterL-glutamate transport

The invention relates to the technical field of application of acteoside in preparing medicines protecting cranial nerves, in particular to application of acteoside in preparing a medicine protecting cranial nerve cells damaged by ingestion and restraint of glutamate transporter. The application of the acteoside provides that the acteoside acts on the glutamate transporter to play function of protecting the cranial nerve cells for the first time; the acteoside can improve learning ability and memory remarkably, and improve SOD activity, EAAT2mRNA transcription level of nerve cells and expressing level of the EAAT2 gene of cranial nerve cells, so that the acteoside has a remarkable protective effect on the cranial nerve cells damaged by ingestion and restraint of the glutamate transporter; the protective mechanism relates to up regulation of expressing level of the EAAT2 gene; the application of acteoside has an important significance in seeking for a novel and effective medicine curing chronic neurodegenerative diseases.

Owner:新疆维吾尔自治区维吾尔医药研究所

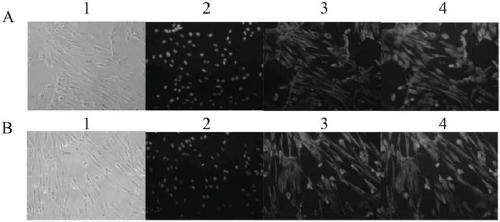

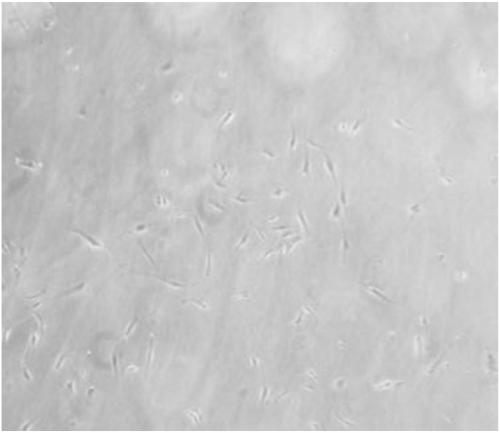

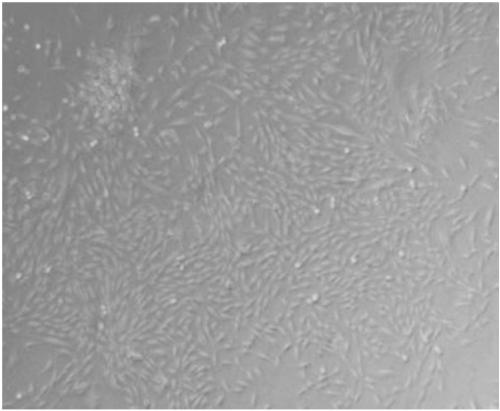

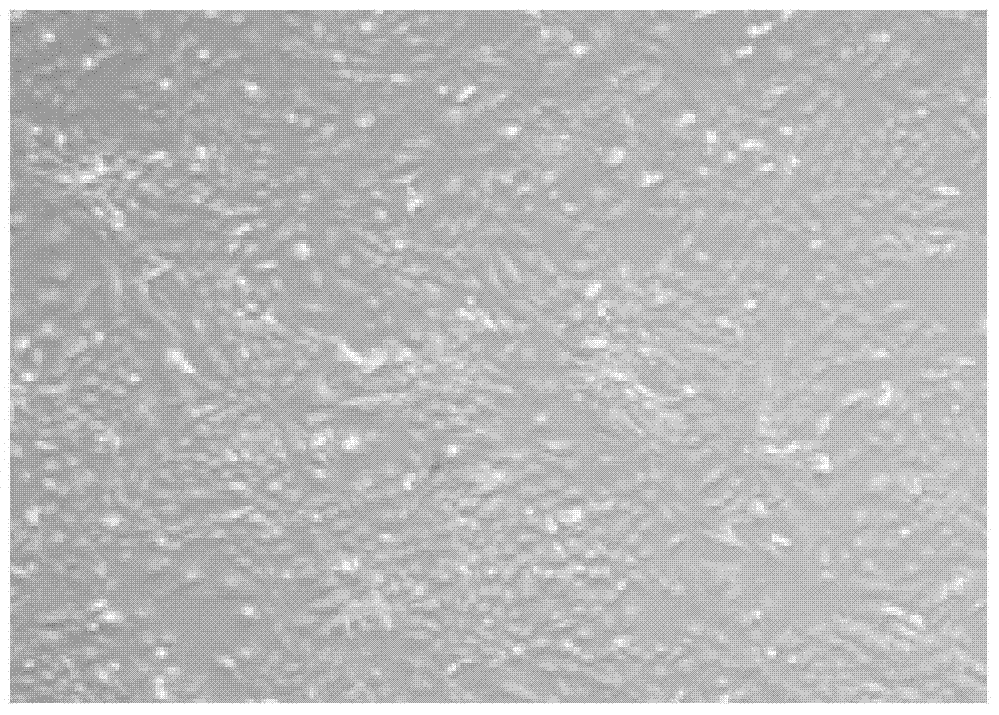

Method for isolating and culturing eyebag adipose-derived stem cell in vitro

InactiveCN109266605AReduce harmGood conditionCell dissociation methodsCulture processCell separationCell state

A method for isolating and culturing eyebag adipose-derived stem cell in vitro is characterized by comprising that following step: obtaining adipose tissue, isolating adipose-derived stem cells and culturing adipose-derived stem cells in vitro. The invention has the advantages that compared with the prior art, the method for isolating and culturing the adipose stem cells in vitro has the followingadvantages: 1, the cells are cultured in the serum-free culture medium without the addition of the heterologous serum components, thereby reducing the injury to the cells and the risk of the later clinical use; 2, that cell state is good, the viability is good, the cell shape, the proliferation ability, the surface mark expression and the differentiation ability are good.

Owner:希瑞干细胞科技有限公司

An improved mesenchymal stem cell protection solution and its application

ActiveCN101919380BCharacteristics unchangedMeet application needsDead animal preservationSkeletal/connective tissue cellsMesenchymeCell activity

The invention relates to an improved mesenchyme stem cell protection solution as well as application and a preparation method thereof. The protection solution can effectively prolong the activity remaining time of mesenchyme stem cells, reduces preparation cost, and has the advantages of wide raw material source, simple preparation, safe and reliable direct clinical application; and after the mesenchyme stem cells are preserved for 48 hours in the protection solution, the cell activity is still above 90 percent, the cell morphology is normal, and the multiplication capacity and mesenchyme stem cell phenotype characteristics are not influenced.

Owner:青岛奥克生物开发有限公司

A kind of serum-free fibroblast culture medium and preparation method thereof

ActiveCN103911339BLow costEasy to stretchVertebrate cellsArtificial cell constructsAntioxidantPurine

A serum-free fibroblast culture medium and a preparation method thereof, the basal medium of the present invention is DMEM medium or its mixing with F12 medium; exogenous additives include hormones, metalloproteins, glutamine, lipids Concentrates, antioxidants, purines, sugars and cell growth factors. Compared with the prior art, the present invention has the following advantages: no animal-derived or recombinant albumin is added, which avoids possible safety hazards and reduces the cost of the medium; it is suitable for the primary and subculture of fibroblasts, and maintains a good The cell morphology is similar to that of the cells in the serum group; it does not need to be coated with adhesion factors, the adhesion rate of the primary 24h is > 60%, and the adhesion rate of the subcultured 24h is > 80%, which is no different from that of the cells in the serum group; It meets the needs of multiple passages, and the growth status remains similar to that of serum group cells after 15 passages; the fibroblasts are directly transferred from the serum-containing culture to the culture of the present invention, and the cells can adhere to the wall and extend smoothly without gradually adapting to the process .

Owner:西安博鸿生物技术有限公司

Myocardial cell separation method

InactiveCN106676061AAvoid form changesInhibitory activityCell dissociation methodsSkeletal/connective tissue cellsHigh concentrationDigestion

The invention discloses a myocardial cell separation method, comprising the following steps: putting a fresh excised heart into 4DEG C precooled protection fluid, scissoring ventricular tissues, washing the ventricular tissues with flushing fluid, and then scissoring the ventricular tissues into bits; then sequentially carrying out trypsin digestion, high concentration buffer immersion, digestive juice digestion and low concentration buffer immersion; uniformly mixing a mixture of the high concentration buffer immersion fluid, postdigestive supernatant fluid and low concentration buffer immersion fluid, beating with a suction tube, then filtering off myocardial tissue precipitate, collecting the filtrate and centrifuging to obtain the separated myocardial cell precipitate. The method disclosed by the invention uses concentration decrease of potassium ions to generate stimulation on the myocardial cells, thereby improving the activity of the myocardial cells, and avoiding the problems of change of form of the myocardial cells and reduction of survival rate of the cells.

Owner:HENAN MEDICAL COLLEGE

Method for preparing edible mushroom packaging material from laccase modified water lettuce fiber

ActiveCN106674610AInhibition of breedingExtend fresh storage timeFlexible coversWrappersFiberMonoglyceride

The invention relates to a method for preparing an edible mushroom packaging material from laccase modified water lettuce fiber, and belongs to the technical field of packaging materials. The method comprises the following steps: firstly, preparing water lettuce fiber from water lettuce leaves by using processes such as boiling, acid extraction, alkali extraction and the like, dissolving carboxymethyl chitosan and xanthan gum into water, mixing with methanol so as to obtain a mixed liquid, modifying the water lettuce fiber with laccase, performing a reaction with the mixed liquid, concentrating after the reaction so as to obtain a concentrated liquid, mixing with montmorillonite, sorbitol and succinylated monoglycerides so as to obtain a viscous fluid, defoaming, performing membrane blowing, and cutting, thereby obtaining the edible mushroom packaging material. The edible mushroom packaging material prepared by using the method not only is capable of inhibiting propagation and reproduction of malignant bacteria, enabling the decomposition function of edible mushroom to be in a lowest state and prolonging the freshness preservation time, but also is of a micropore structure, effectively retards moisture loss, keeps a relatively good cell morphology, and is convenient and safe to use.

Owner:上海盘点食品科技有限公司

A kind of micro-foamed polyethylene-based wood-plastic composite material and preparation method thereof

The invention discloses a micro-foaming polyethylene-matrix wood-plastic composite material and a preparation method thereof. The micro-foaming polyethylene-matrix wood-plastic composite material is prepared by the following steps of stirring a matrix polyethylene resin, modified wollastonite powder and talcum powder, a crosslinking agent, a lubricant, a heat balance type foaming agent, an antioxidant, an anti-ultraviolet agent, pigment and modified plant fiber, heating and uniformly mixing, then cooling and discharging to obtain a premix, wherein the modified plant fiber is one of wood powder, bamboo powder and rice hull powder or a mixture of two or more at any proportion; putting the premix into an extruder, and performing granulation, extrusion foaming and cooling formation. The micro-foaming polyethylene-matrix wood-plastic composite material disclosed by the invention is convenient to produce and manufacture, the raw materials are cheap and environment-friendly, the average diameter of the pores of the micro-foaming polyethylene-matrix wood-plastic composite material is reduced to 10 microns, and the content of the plant fiber is increased to 45%; moreover, the composite material has low density and high bending strength and impact toughness, is widely applicable and can be applied to the fields such as decoration, building, municipal administration, packaging, automotive upholsteries and the like.

Owner:FUJIAN AGRI & FORESTRY UNIV

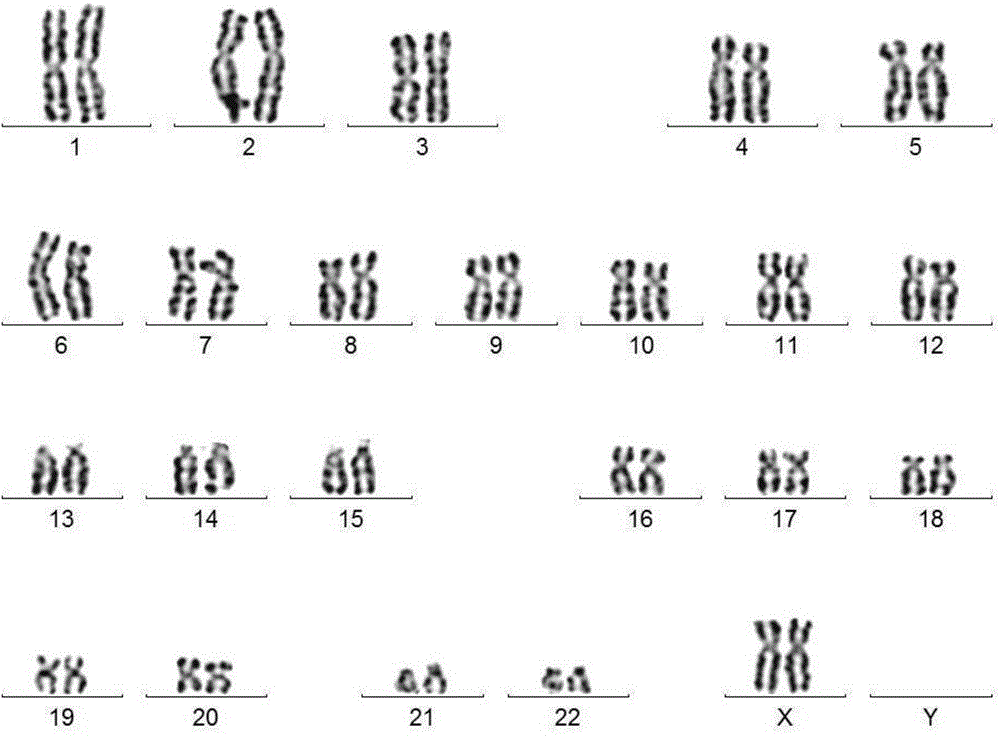

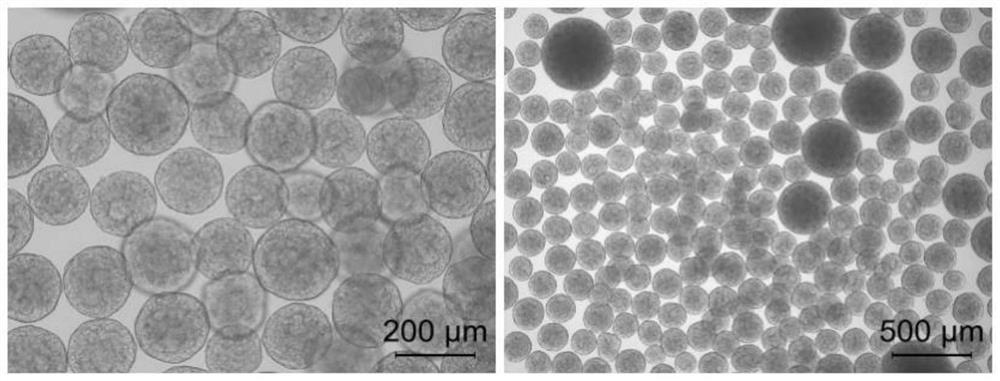

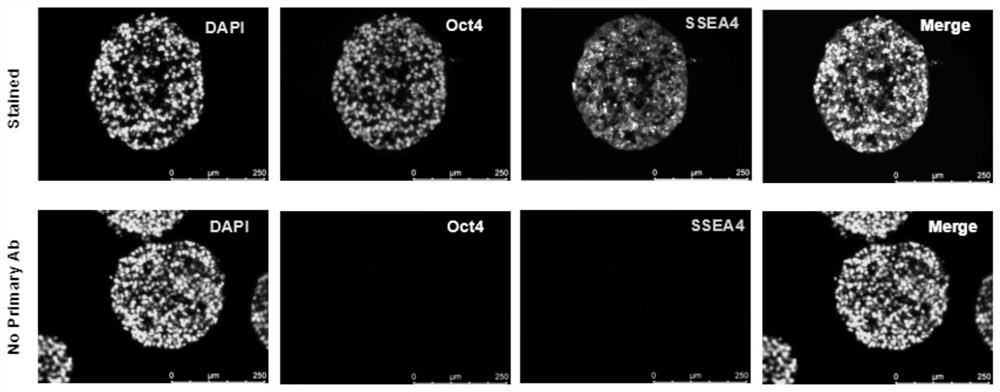

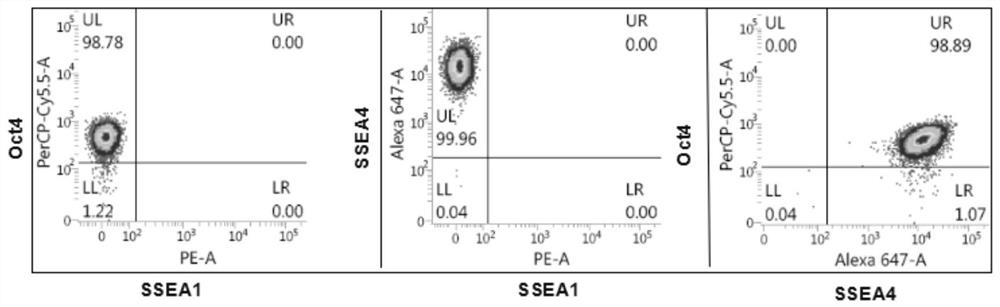

Method for culturing pluripotent stem cells

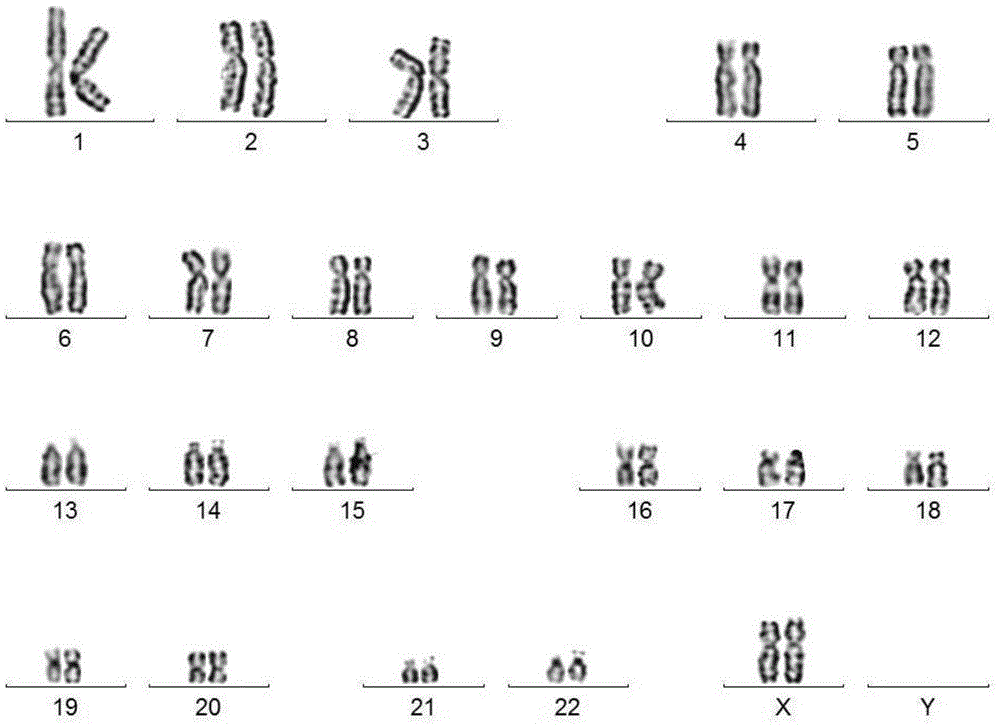

ActiveCN113046306ASignificant progressEfficient screeningMicrobiological testing/measurementDrug screeningBiotechnologyKaryotype

The invention relates to a method for culturing pluripotent stem cells. The method adopts a 48-pore plate as a culture container, the cell inoculation density is 4.5-6.5 * 10 < 5 > cells / mL, the culture volume is 0.4-0.6 mL, and the rotating speed of a shaking table is 170-190 rpm. According to the method, a 48-pore plate suspension culture system suitable for growth and differentiation of the pluripotent stem cells is established from nothing to thing, and the culture system can be used for efficiently screening a differentiation inducer of the pluripotent stem cells. The culture method provided by the invention has the advantages of low cost, high efficiency, capability of maintaining better cellular morphology, stable proliferation multiple, capability of maintaining better karyotype and phenotype, smaller difference between experiments in the differentiation process and the like.

Owner:SUNSHINE LAKE PHARM CO LTD

Anti-aging foaming material and preparation method thereof

The invention discloses an anti-aging foaming material and a preparation method thereof. The anti-aging foaming material is prepared from the following components in parts by weight: 90-100 parts of high-melt-strength polypropylene, 8-10 parts of dried lacquer, 12-18 parts of vermiculite schist seu, 6-8 parts of manganese borate, 5-7 parts of ethyltrichlorosilane, 2-4 parts of diallyl phthalate, 3-8 parts of azodicarbonamide, 1-3 parts of N-phenyl-alpha-aniline and 0.5-0.7 part of ethylene thiourea. The foaming material has excellent mechanical performance, excellent aging resistance, excellent thermal and sound insulation performance, relatively good cell shape and uniform cell distribution, and the material quality is greatly improved.

Owner:ANHUI SOYA DECORATIVE MATERIALS

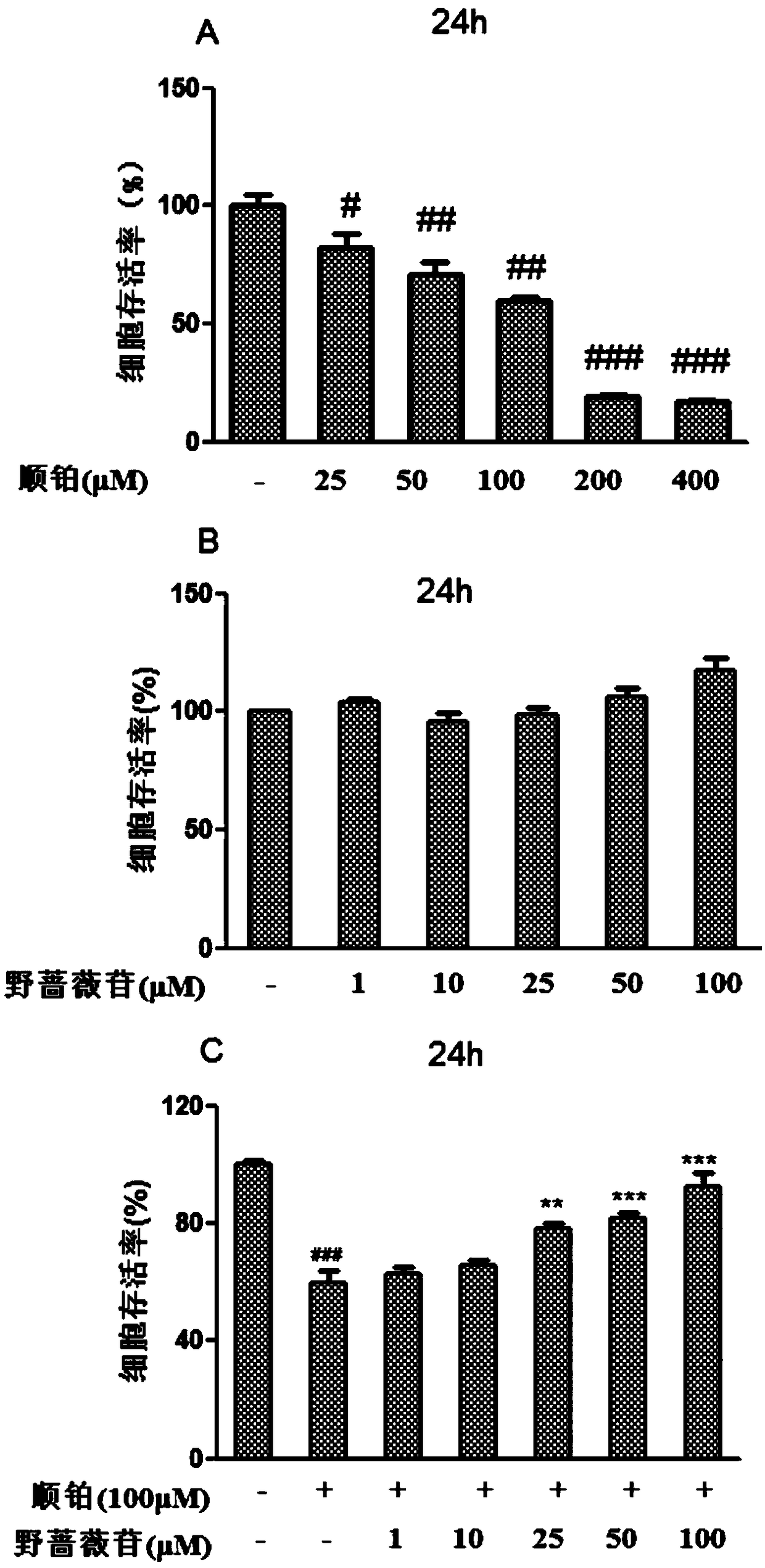

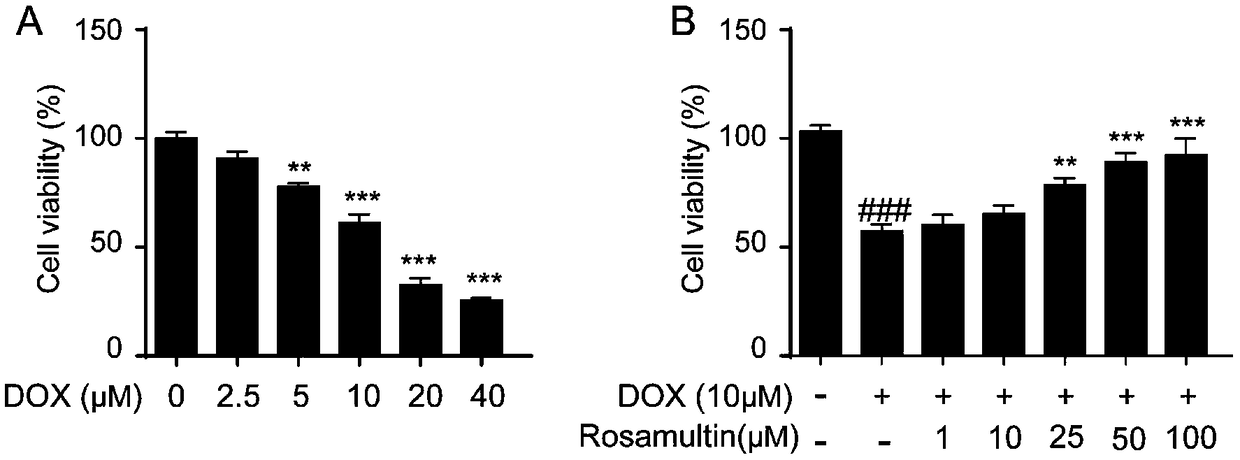

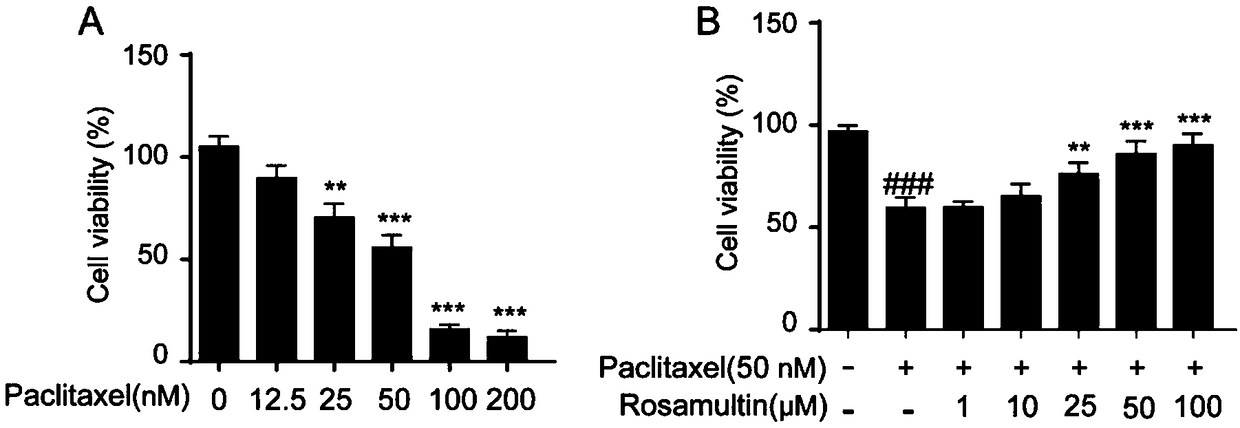

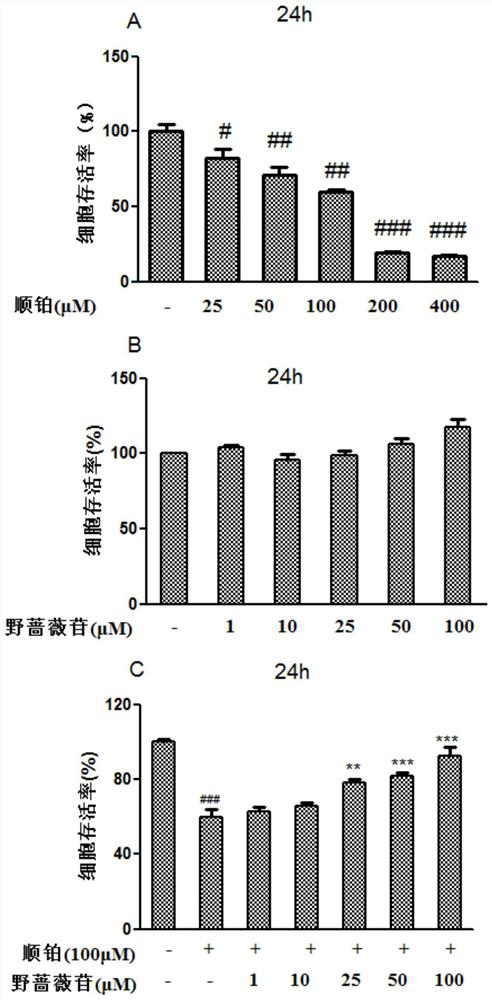

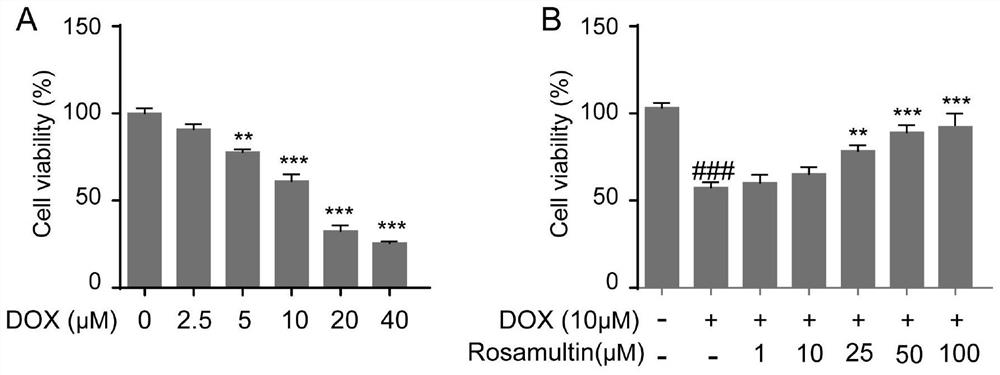

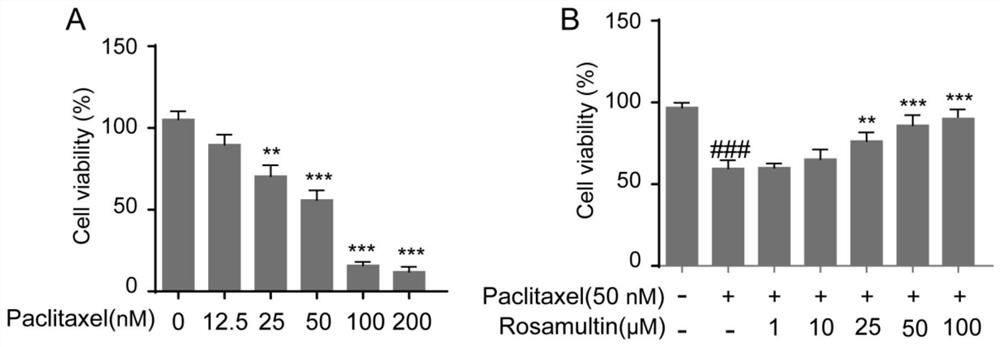

Novel application of wild rose glycoside

ActiveCN108836975ASmall toxicityDoes not weaken antitumor efficacyHeavy metal active ingredientsOrganic active ingredientsTolerabilitySide effect

The invention belongs to the technical field of medicines. The invention provides novel application of wild rose glycoside, in particularly application of the wild rose glycoside to preparation of medicines for reducing toxic and side effects of cytotoxic chemotherapeutic medicines. Experiments show that the wild rose glycoside can improve the cell viability of cytotoxic chemotherapeutic medicine-damaged cells, improve the cell morphology of the cytotoxic chemotherapeutic medicine-damaged cells, and improve organ damage caused by the cytotoxic chemotherapeutic medicines; meanwhile, after combined use of the wild rose glycoside and the cytotoxic chemotherapeutic medicines, the antitumor medicinal effects of the cytotoxic chemotherapeutic medicines are not weakened. Experiments indicate thatthe wild rose glycoside can reduce the toxic and side effects of the cytotoxic chemotherapeutic medicines, improve tolerance of tumor patients to chemotherapy, improve the life quality of the tumor patients, enhance the physique and prolong the lifetime.

Owner:广西英路维特药物有限公司

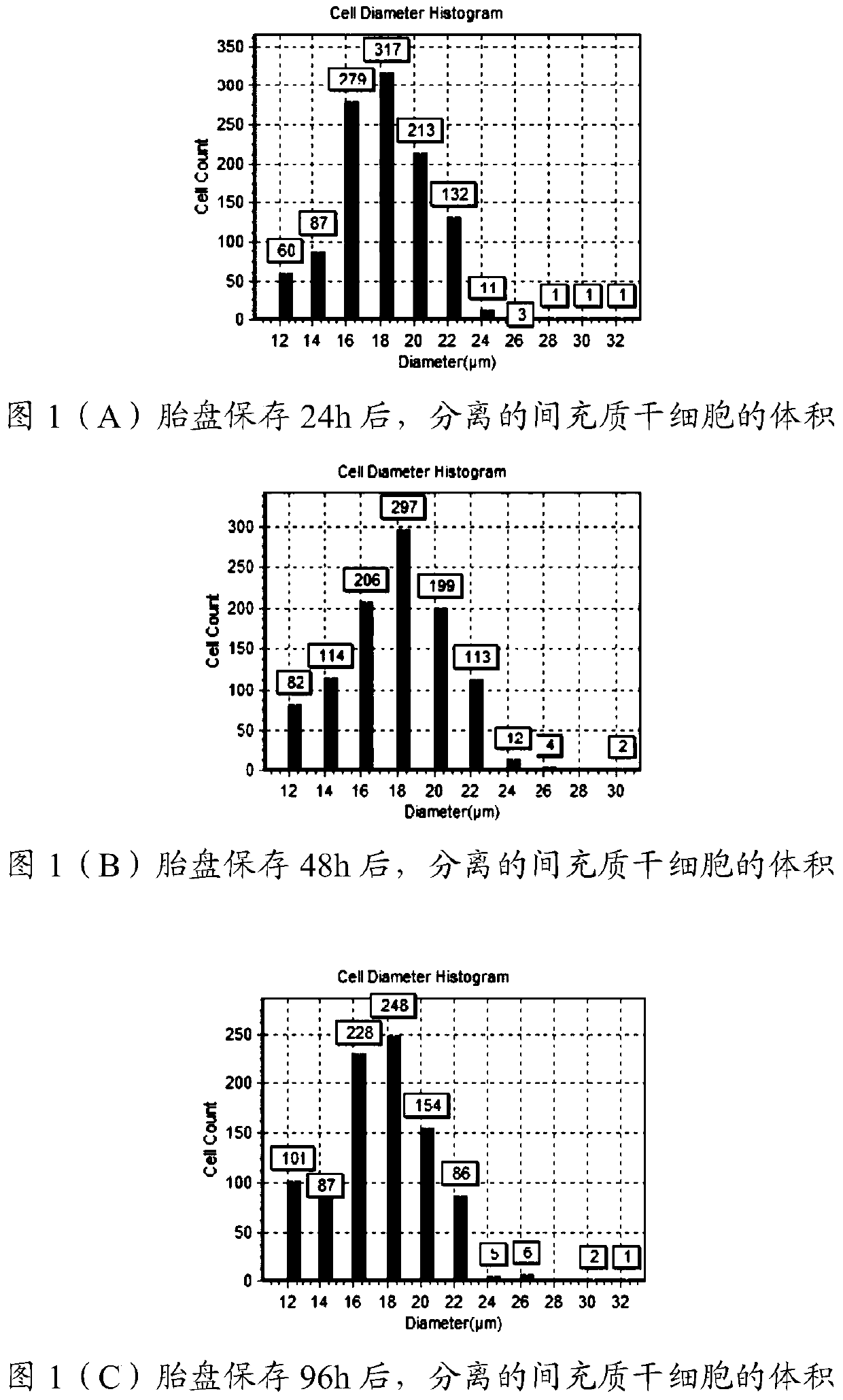

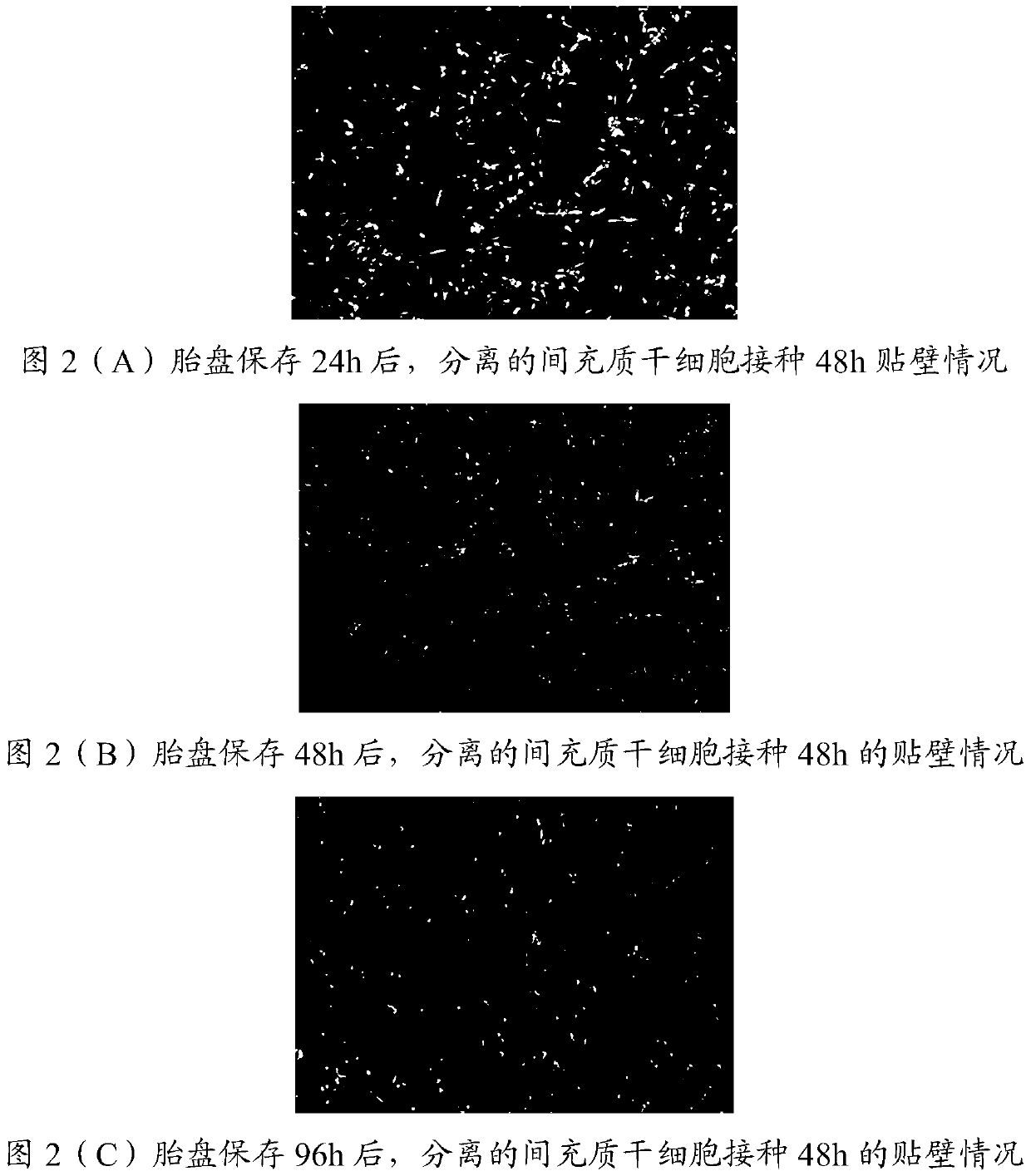

Composition and use thereof, placenta preservation preparation and preparation method thereof

ActiveCN104839146BGuaranteed survival rateImprove survival rateDead animal preservationVitamin CAntioxidant

The invention relates to the field of medicines, in particular to a composition and an application thereof, a placenta preservative and a preparation method of the placenta preservative. Umbilical cord plasma is adopted as a nutrient of a placenta-derived mesenchymal stem cell preservation solution for the first time, so that multi-element nutrient substances are provided for seed cells; the cell viability is maintained; and the original cell morphology and biological characteristics of placenta-derived mesenchymal stem cells can be well kept. Due to the addition of reducing agents such as N-acetylcysteine and vitamin C, and an antioxidant, the resistivity of the placenta-derived mesenchymal stem cells is greatly improved; and the vitality of the placenta-derived mesenchymal stem cells can still be well kept within 24 hours.

Owner:GUANGZHOU SALIAI STEMCELL SCI & TECH CO LTD

New Application of Rosaside

ActiveCN108836975BSmall toxicityDoes not weaken antitumor efficacyOrganic active ingredientsHeavy metal active ingredientsSide effectTolerability

The invention belongs to the technical field of medicine, and the invention provides a new application of rosin, especially the application of rosin in the preparation of drugs for reducing the toxic and side effects of cytotoxic chemotherapeutic drugs. Experiments show that rosin can improve the cell survival rate of cells damaged by cytotoxic chemotherapy drugs, improve the cell morphology of cells damaged by cytotoxic chemotherapy drugs, and improve the organ damage caused by cytotoxic chemotherapy drugs. At the same time, the combined use of rosin and cytotoxic chemotherapeutic drugs will not weaken the antitumor efficacy of cytotoxic chemotherapeutic drugs. It shows that rosin can reduce the toxic and side effects of cytotoxic chemotherapy drugs, improve the tolerance of cancer patients to chemotherapy, improve the quality of life of cancer patients, enhance their physical fitness, and prolong their survival.

Owner:广西英路维特药物有限公司

Method for separating and purifying oligodendrocyte precursor cells of cerebral cortex of tupaia belangeri in vitro

ActiveCN109666642AEnhance cell viabilityHigh purityCell dissociation methodsNervous system cellsHigh cellCell separation

The invention relates to a method for separating and purifying oligodendrocyte precursor cells of the cerebral cortex of tupaia belangeri in vitro, and belongs to the technical field of cell separation and purification. According to the method, trypsin and DNase I are combined to digest the cerebral cortex, and the OPCs of tupaia belangeri are well separated and purified by conducting differentialadherence purification twice. The method is simple in operation step, has the advantages of being quick in cell adherence, high in survival rate and the like, has the extremely high cell purity in asubsequent identification experiment and the high reliability of an identification result, can meet the requirements for relevant experimental research on tupaia belangeri in various research fields of medicine, biology, pharmacy and life science, and is suitable for application and popularization in general laboratories.

Owner:INST OF MEDICAL BIOLOGY CHINESE ACAD OF MEDICAL SCI

A kind of placenta preservation method, placenta preservation solution and preparation method thereof

The invention discloses a placenta preservation method, placenta preservation fluid and a placenta preservation fluid preparing method. The placenta preservation fluid contains cord plasma and / or glucose, penicillin-streptomycin and low molecular dextran-40. The placenta preservation fluid preparing method comprises the step of adding 3-5 v / v% of cord plasma, 5 m / v% of glucose solution, 1X-3X of penicillin-streptomycin and low molecular dextran glucose injection to PBS, wherein the final concentration of low molecular dextran-40 is 1 m / v%. According to the placenta preservation method, placentas are soaked in the placenta preservation fluid to be preserved in a dark place at 2-4 DEG C. An ion buffer system and a nutrition system of the preservation fluid are improved, constituents and content of constituents in the preparation are optimized, long-time preservation of in vitro placentas can be achieved, the vigor of placental mesenchymal stem cells can be well maintained, and functional variation of cells is avoided.

Owner:GUANGZHOU SALIAI STEMCELL SCI & TECH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com