Array imaging system

An imaging system and array technology, applied in antenna arrays, electrical components, circuits, etc., can solve the problems of high cost, small waveguide size, increased waveguide loss, etc., and achieve the effect of quick and convenient coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

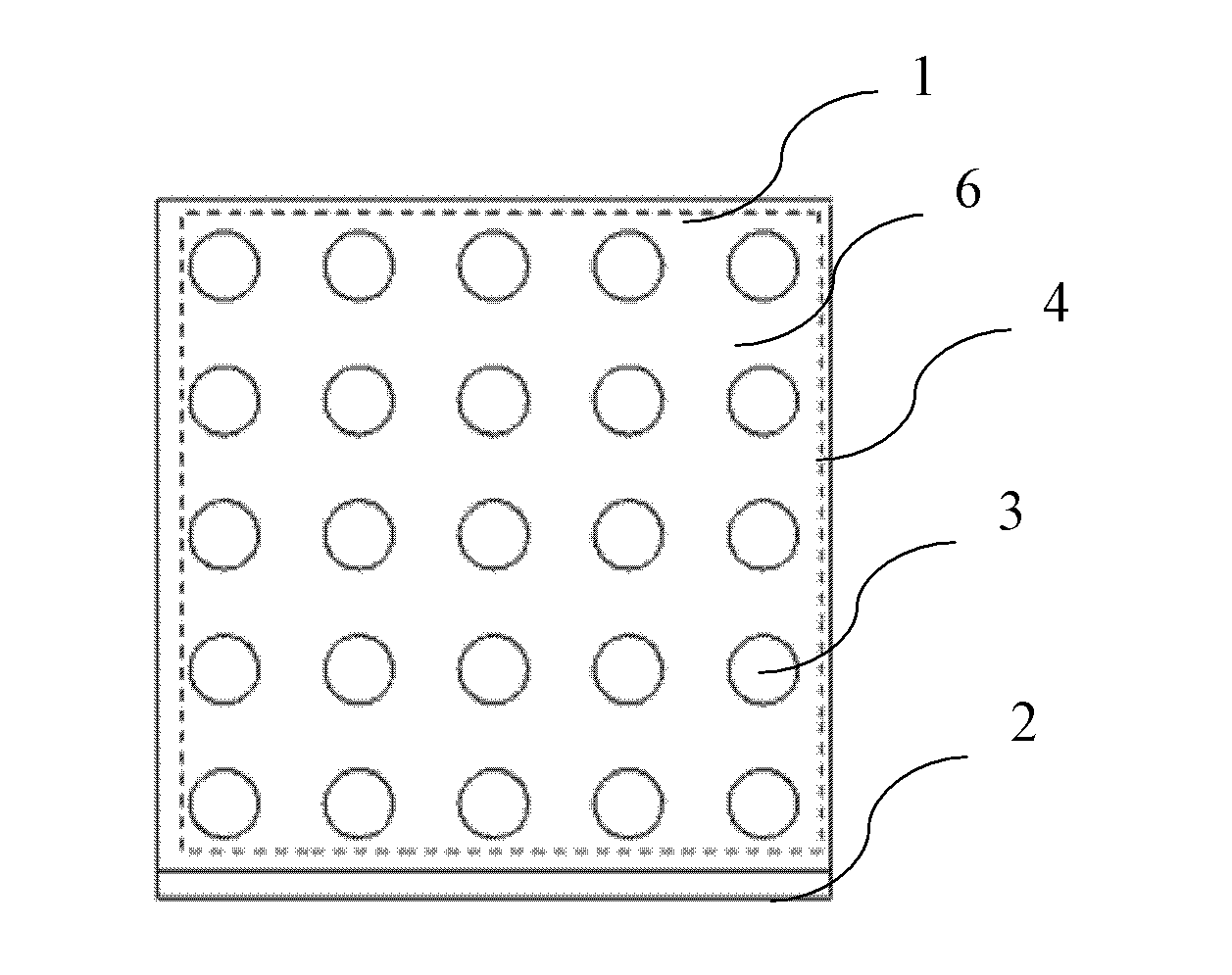

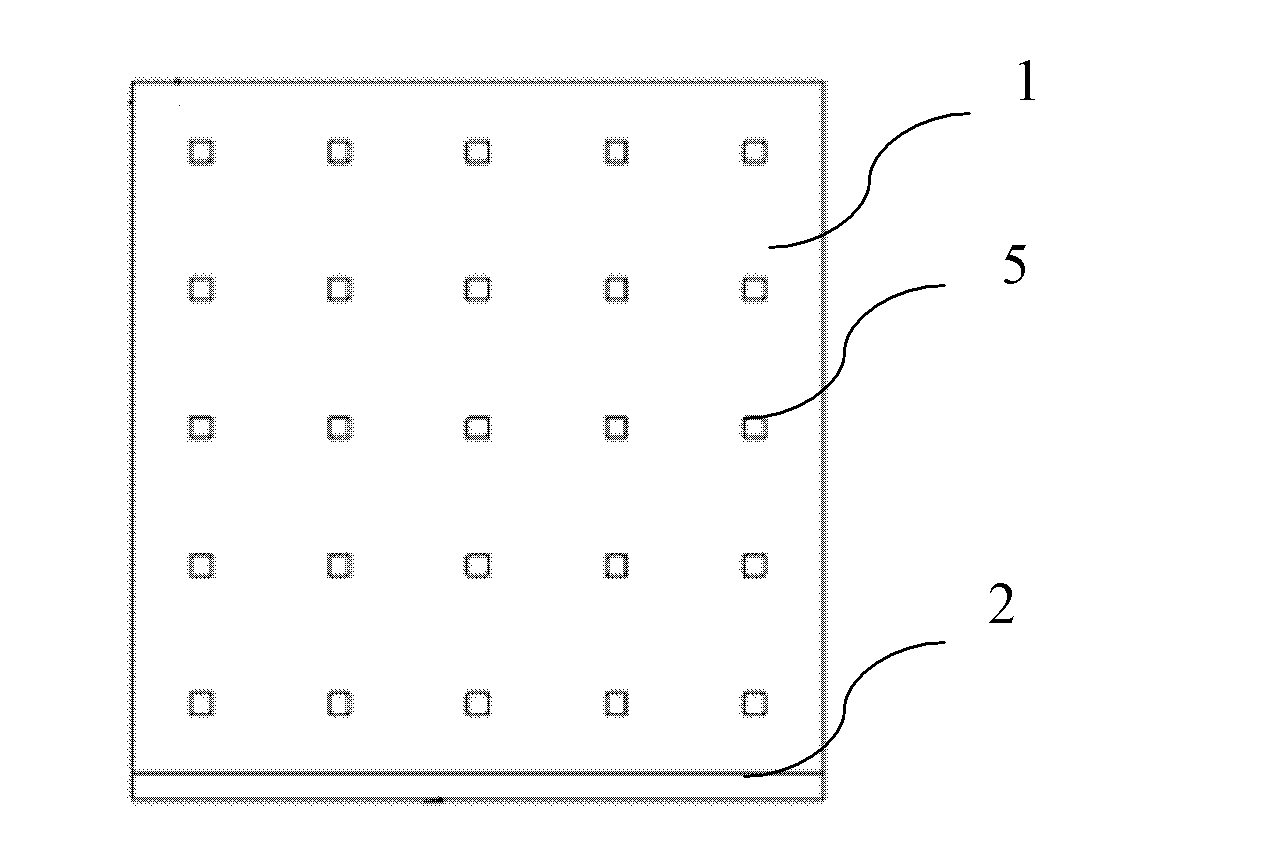

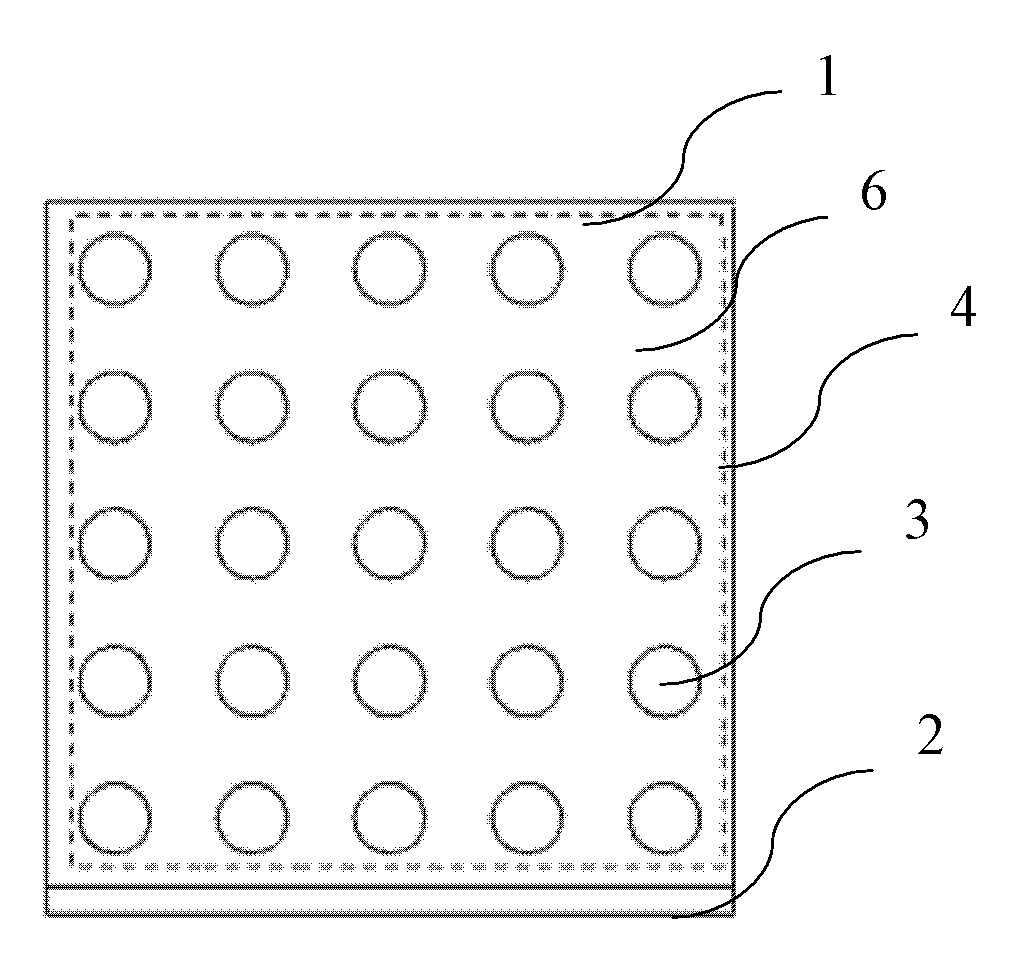

[0018] Embodiment 1, with reference to figure 1 and figure 2 , an array imaging system 1, including a base 2 and a 5×5 silicon lens array 4 composed of 25 silicon lenses 3 arranged on the base 2 ( figure 1 In the dotted line box of ), the front surface of the silicon lens 3 is coated with an anti-reflection layer with a thickness of 1 / 4 wavelength, and a terahertz detector 5 is respectively arranged in the center of the back of each silicon lens 3 to form a terahertz detector For the array, on the front surface of the base 2 , the metal surface between several silicon lenses 3 is covered with a layer 6 of terahertz wave-absorbing material.

[0019] The manufacturing method of the terahertz absorbing material layer 6 is as follows:

[0020] 1) Clean the front surface of the base 2 of the detector array;

[0021] 2) Use a knife or scissors to cut the terahertz absorbing material into the shape of the metal surface of the detector array;

[0022] 3) Use a pressure-sensitive ...

Embodiment 2

[0026] This example is basically the same as Example 1, but the material used for the terahertz wave-absorbing material layer 6 is a terahertz radiation-absorbing surface layer made of Stycast and SiC, and the surface layer includes a black first Stycast epoxy resin layer. A SiC particle layer is provided on the first Stycast epoxy resin layer, and a second Stycast epoxy resin layer is provided on the SiC particle layer. That is, the first and second Stycast epoxy layers stick the SiC particle layer to the metal surface.

[0027] The manufacturing method of the terahertz absorbing material layer 6 is as follows:

[0028] 1) Clean the metal surface of the base and roughen the surface with sandpaper;

[0029] 2) First layer of Stycast epoxy on the surface painted black;

[0030] 3) Sprinkle a layer of SiC particles on the surface, with a diameter of about 0.1 mm;

[0031] 4) Finally, apply a second layer of black Stycast epoxy resin to fix the SiC particles;

[0032] 5) Wait...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com