Metal plastic composite section bar and producing method thereof

A composite profile, metal-plastic technology, applied in the direction of metal layered products, chemical instruments and methods, layered products, etc., can solve problems such as deformation of plastic profiles, and achieve the effect of high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below, the present invention is described in further detail in conjunction with accompanying drawing and specific embodiment:

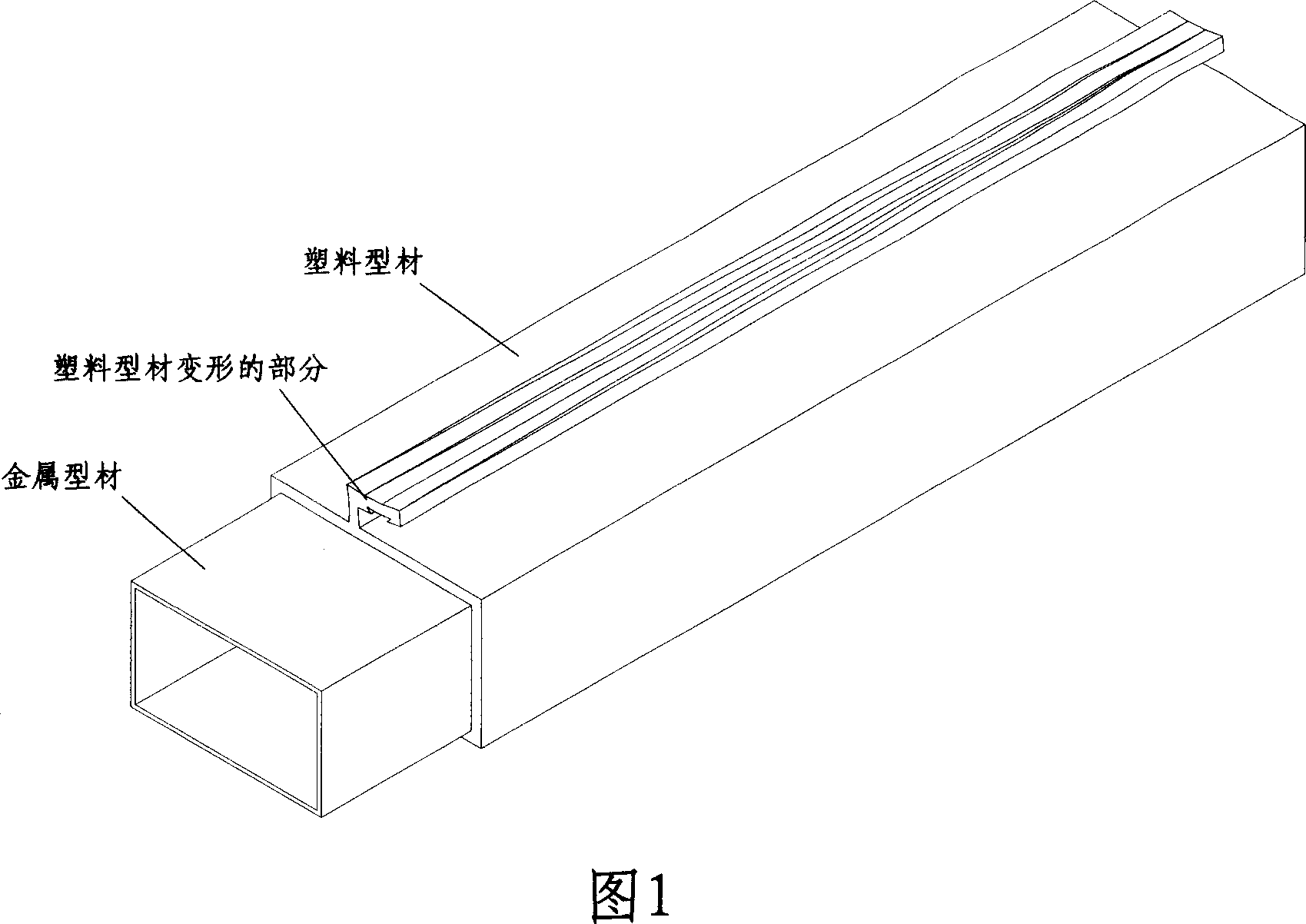

[0016] Figure 1 shows that the metal profile in the cavity of the plastic profile cannot constrain the deformation of the cavity-free part of the plastic profile.

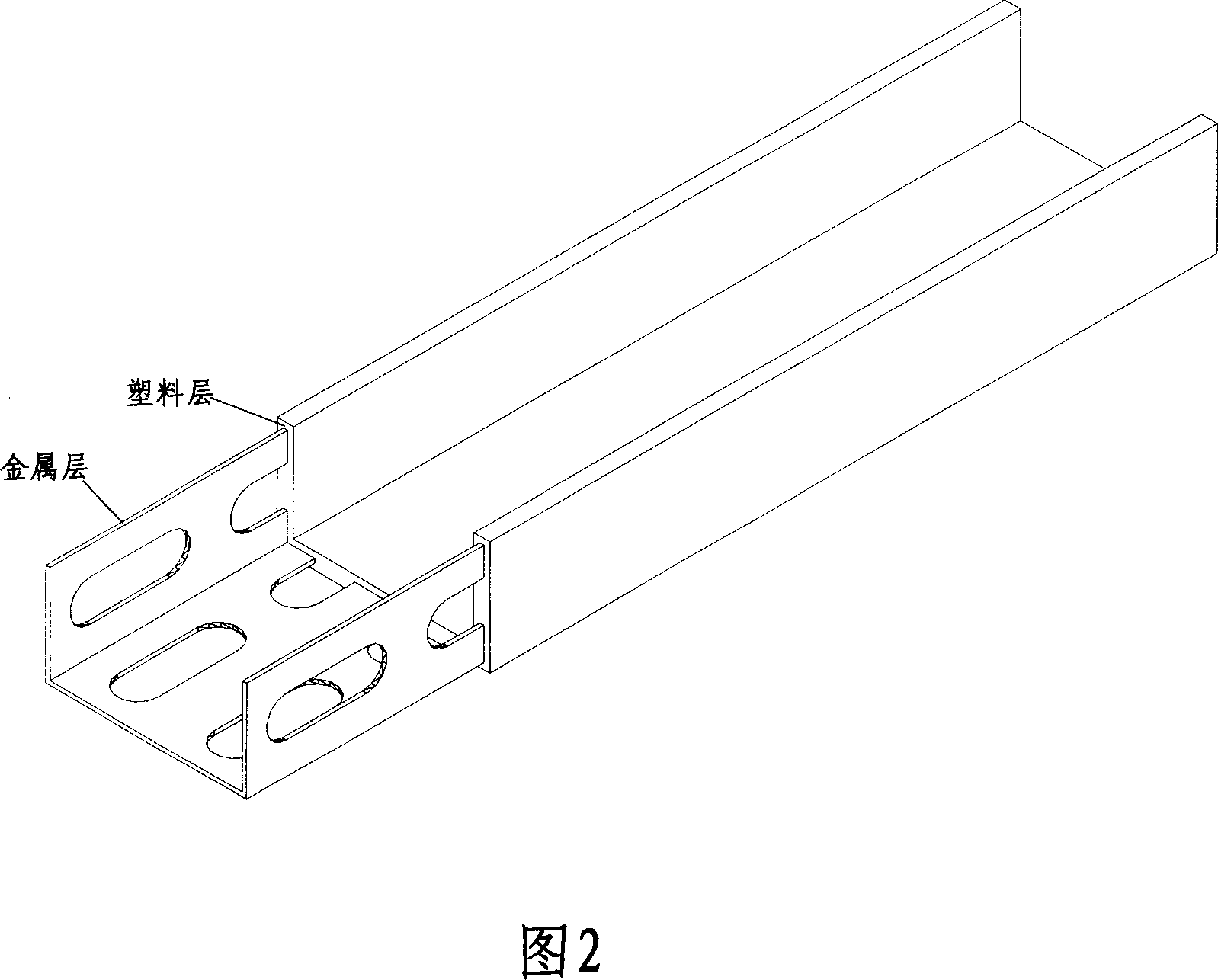

[0017] Fig. 2 shows: the feature of the cavity-free composite profile wall structure is: the plastic on both sides of the wall passes through the metal layer with holes in the middle layer, and is connected with the metal layer as a whole.

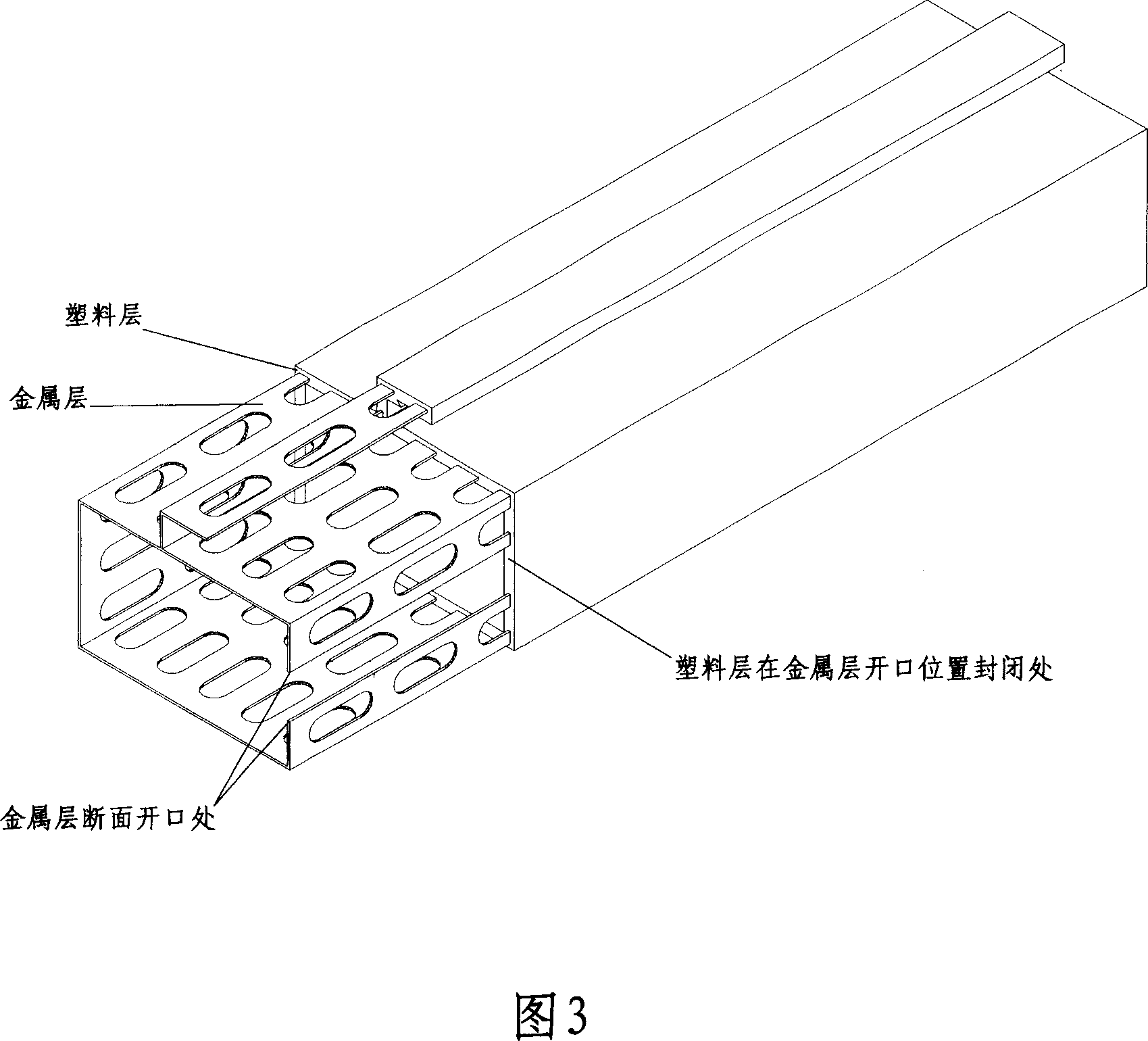

[0018] Fig. 3 shows: the characteristic of the composite profile wall structure with cavity is: the plastic layer on both sides of the wall passes through the metal layer with holes in the middle layer, and is connected with the metal layer as a whole. And make the original unsealed section of the metal with holes in the middle layer become a closed section (the metal layer with holes in the middle layer is made into an unsealed section, on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com