Ink cartridge for ink jet recording device

An inkjet recording and ink cartridge technology, applied in printing and other directions, can solve the problems of impossible printing, increase the amount of remaining ink, and reduce printing quality, and achieve the effect of easy ink storage and easy change.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

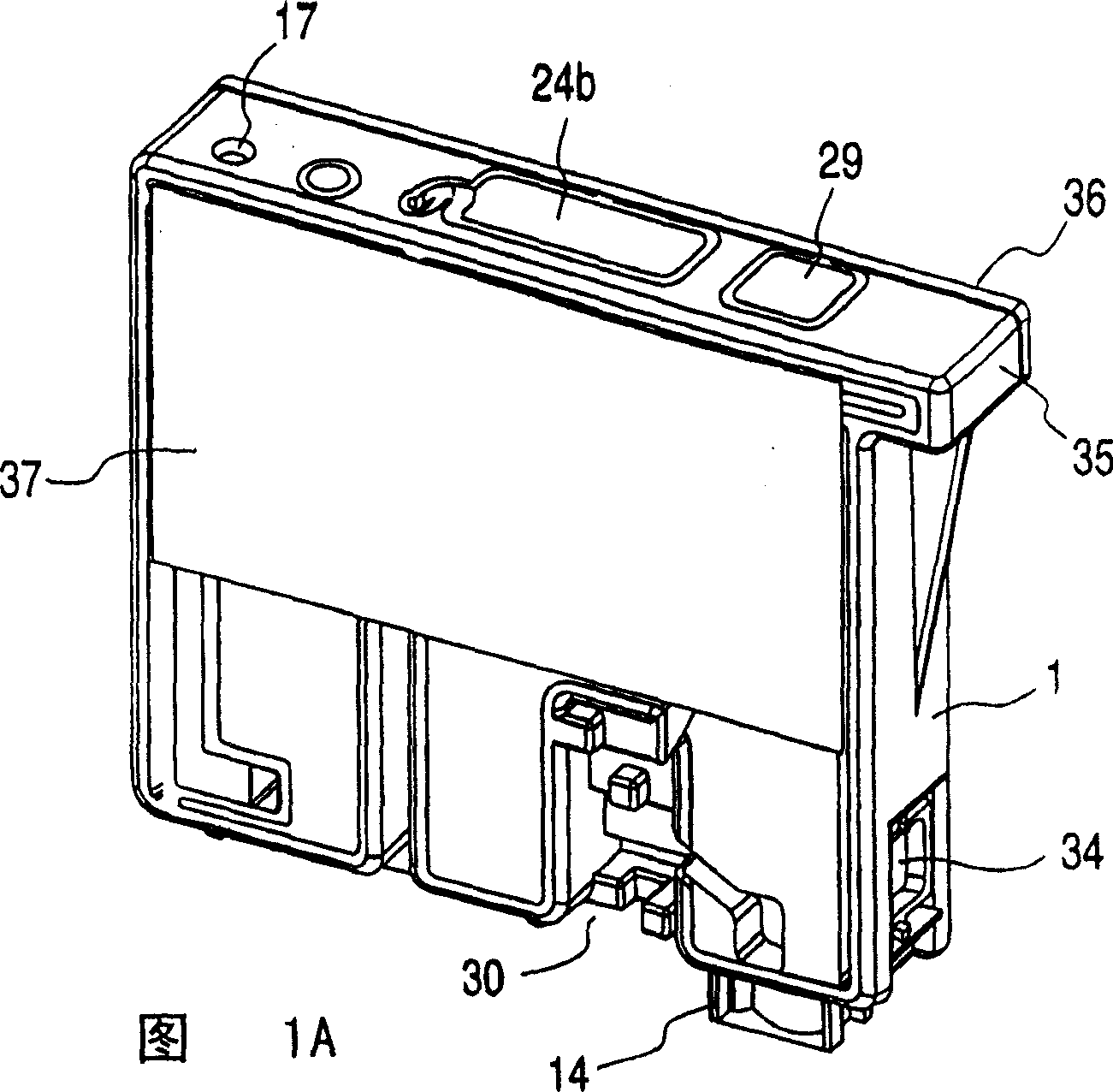

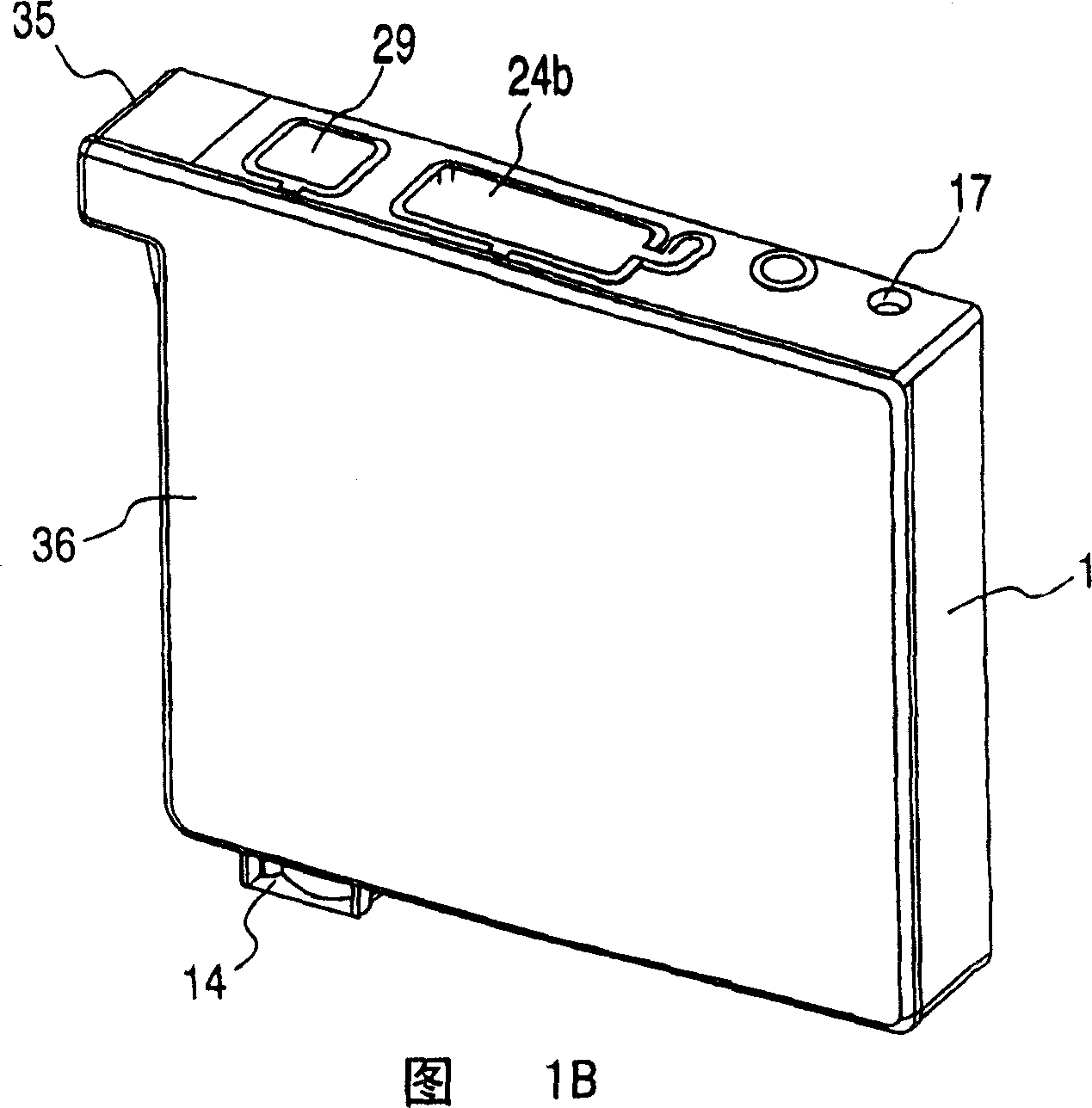

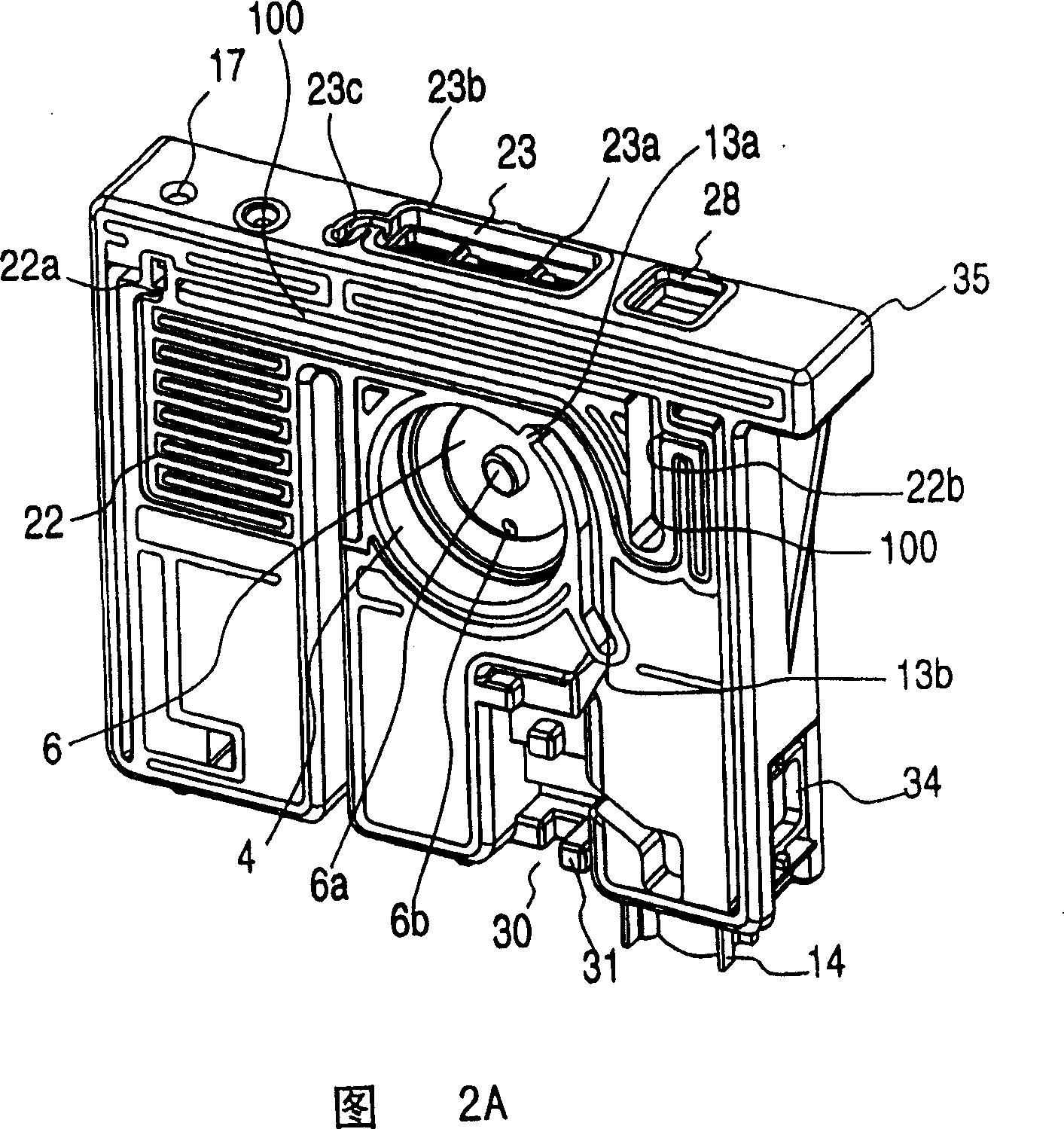

[0073] 1A, 1B, 2A and 2B show the front and rear structures of a container main body 1 forming an ink cartridge, which constitutes a first embodiment of the present invention. FIG. 3 shows the bottom structure of the container main body 1 . The interior of the container body 1 is vertically divided into a lower region and an upper region by a substantially horizontally extending wall 2 . In the lower area, the first ink chamber 3 serving as the lower ink chamber is formed in the lower area. Formed in the upper region are a differential pressure valve storage chamber 4 serving as a negative pressure generating mechanism to be described below; a filter chamber 5 for storing a filter; and a second ink chamber 8 serving as an upper ink chamber and also First and second ink storage portions 15 and 16 are included.

[0074] The differential pressure valve storage chamber 4 and the filter chamber 5 are separated from each other by a wall 6 located substantially at the central porti...

no. 2 example

[0100] 12A and 12B are schematic external appearances of an ink cartridge constituting a second embodiment of the present invention. The ink cartridge 61 is mainly composed of a flat, rectangular container main body 62 with its side open, and a cap member 63 for hermetically closing the opening. The container body 62 is integrally formed with the ink supply port at the front end of the ink cartridge, locking members 65 and 66 at the upper corners as viewed from the cartridge insertion direction (lower part in this embodiment). A storage device 67 is arranged below the locking element 65 . A valve reservoir 68 is arranged below the other locking element 66 . A valve member (not shown) is stored in the ink supply port 64 so that when the ink supply needle is inserted into the ink supply port 64, the valve member is opened.

[0101] 13 and 14 are schematic views showing the flow path formed in the container body 62 of the ink cartridge. The inner space of the container main bo...

no. 3 example

[0150] 22A, 22B and 23A to 23D are schematic external views of another ink cartridge according to an embodiment of the present invention, which constitute a third embodiment. The ink cartridge 61 is mainly composed of a flat, rectangular, box-shaped container main body 162, one surface of which is open and the other opposite surface is closed, and a cover member 163 for closing the open face of the container main body 162 is constituted. An ink supply port 164 is formed at a longitudinally offset position on the leading end side in the insertion direction, that is, on the bottom surface of this embodiment. Locking elements 165 and 166 are integrally formed with container body 162 at an upper lateral portion.

[0151] The locking element 165 near the ink supply port has a pivot point 165a which is slightly above the leading end side of the locking element 165 as viewed from the insertion direction, i.e. at the lower end of the locking element 165 of this embodiment. , Therefor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com