Method for manufacturing land leveler blade

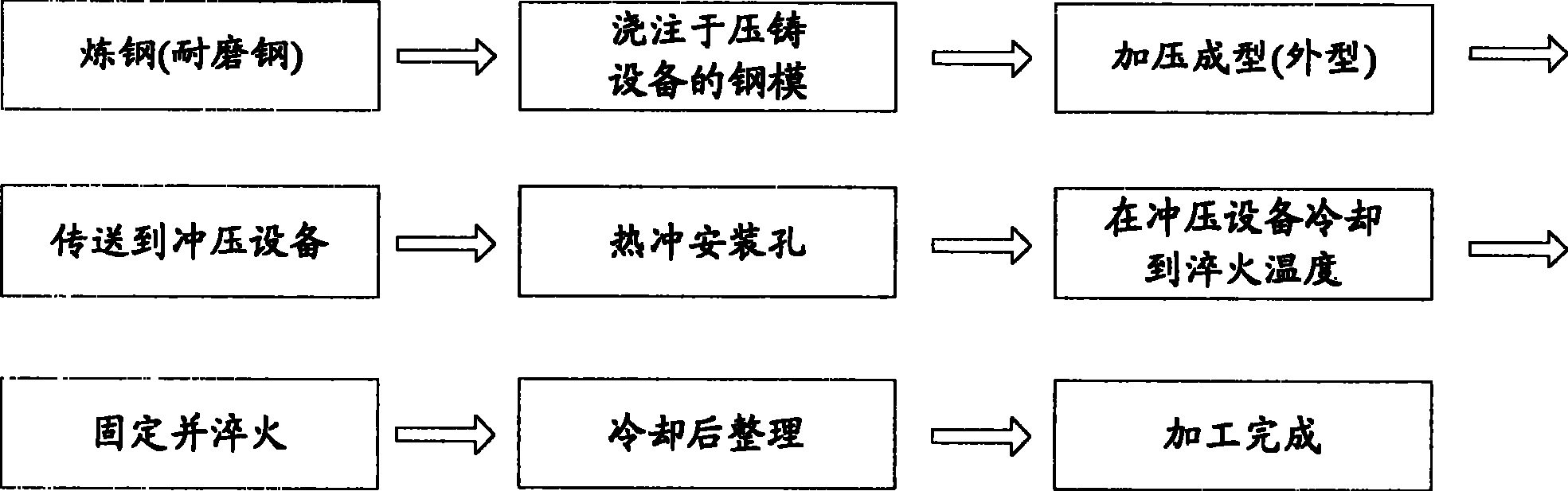

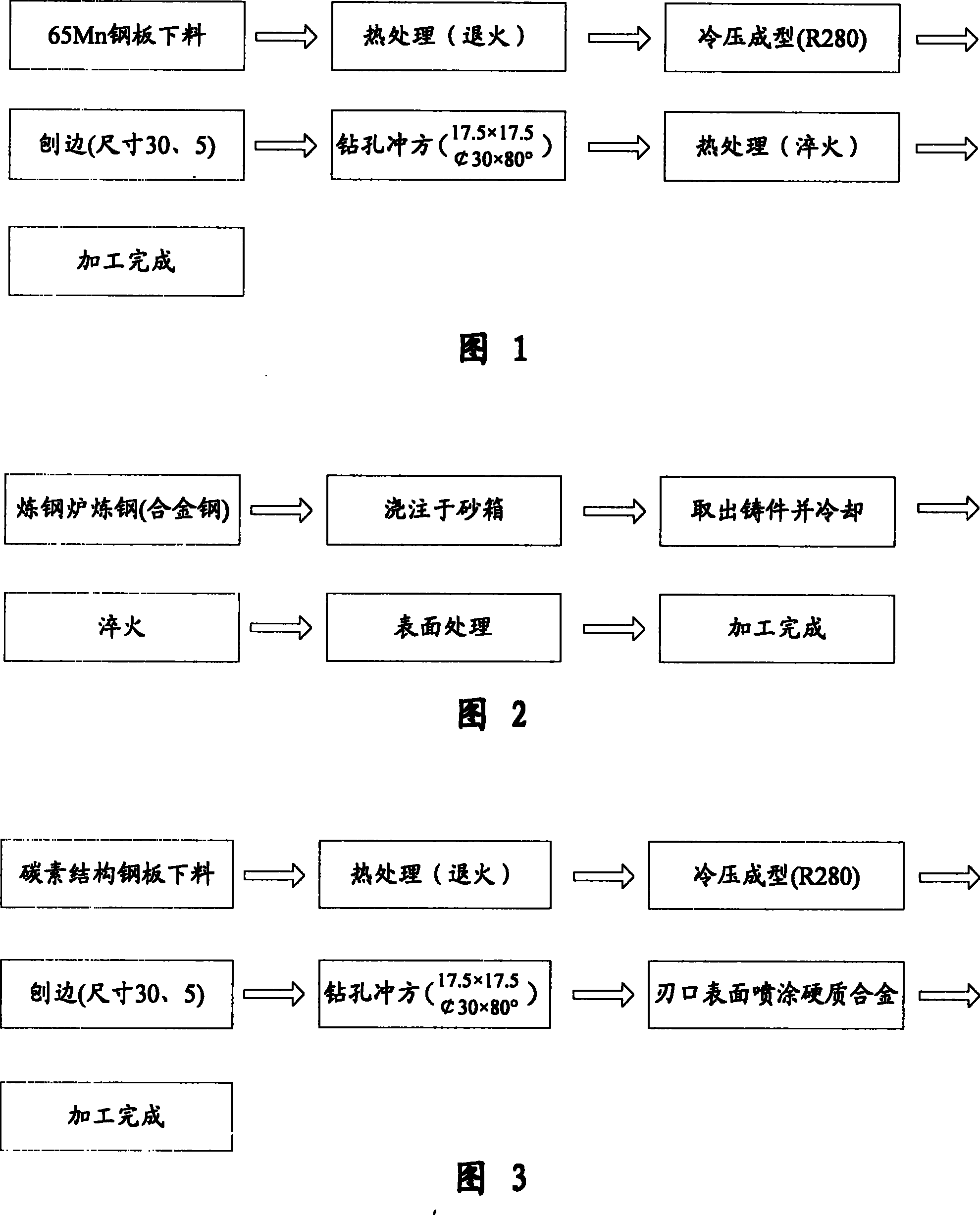

A manufacturing method and technology for graders, which are applied in the direction of earthmoving machines/shovels, construction, etc., can solve the problems of high production cost, affecting market share, scraper dimensional tolerance and flatness cannot be reliably guaranteed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

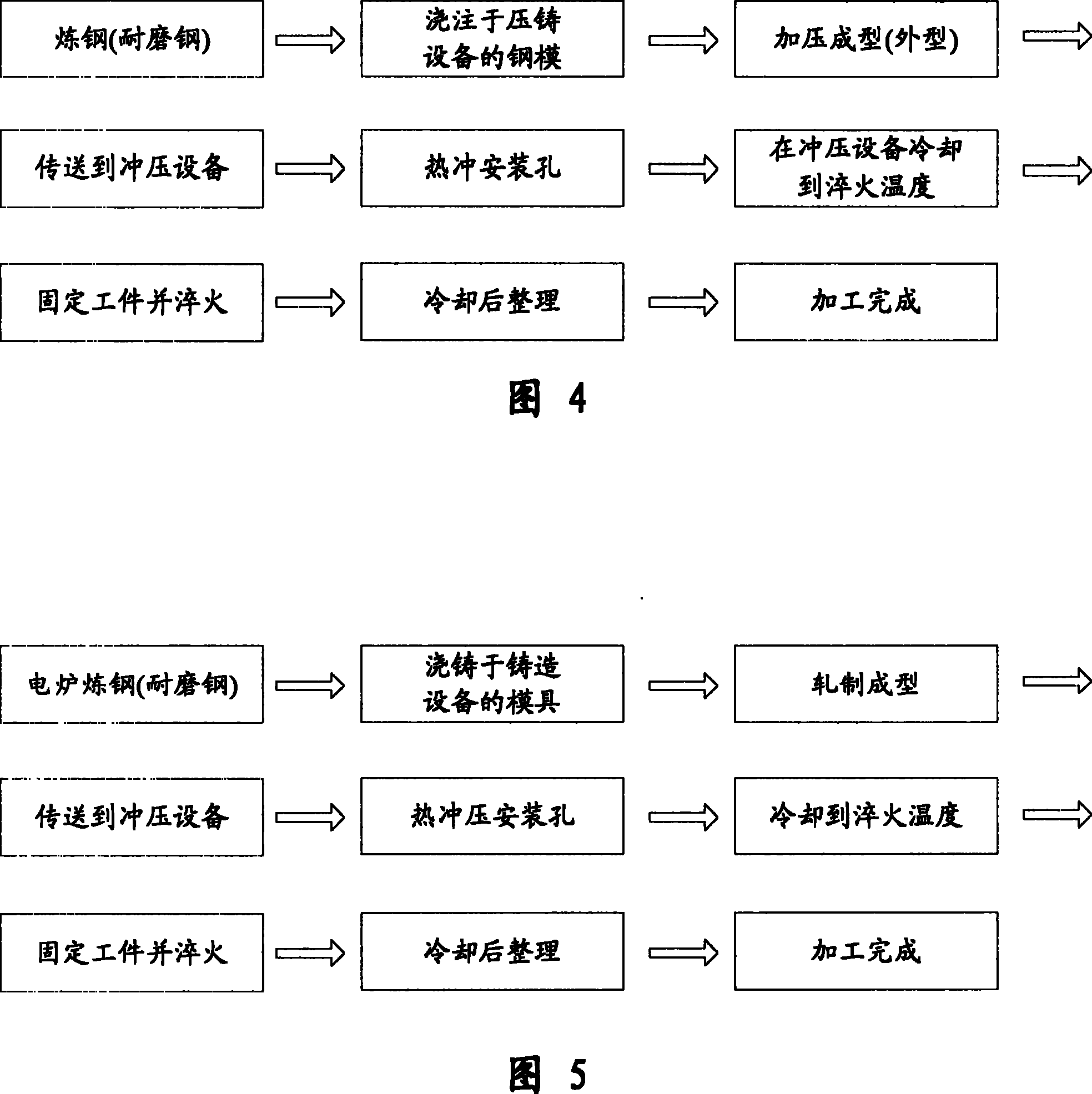

[0034] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0035] Referring to Fig. 4, introduce the processing method that the present invention manufactures grader scraper, comprise following operation:

[0036] (1) The wear-resistant steel is smelted in the steelmaking furnace, and the molten steel is poured into the steel mold of the die-casting equipment.

[0037] (2) The die-casting equipment pressurizes the steel mold for pressure casting, so that the molten steel is slowly cooled and formed in the steel mold to reach the outer contour of the finished scraper, and the material is dense to avoid looseness and air bubbles.

[0038] (3) The workpiece is transported to another device via the transfer device, and after the workpiece is fixed, each mounting hole is hot-stamped and cooled naturally in the device at the same...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com