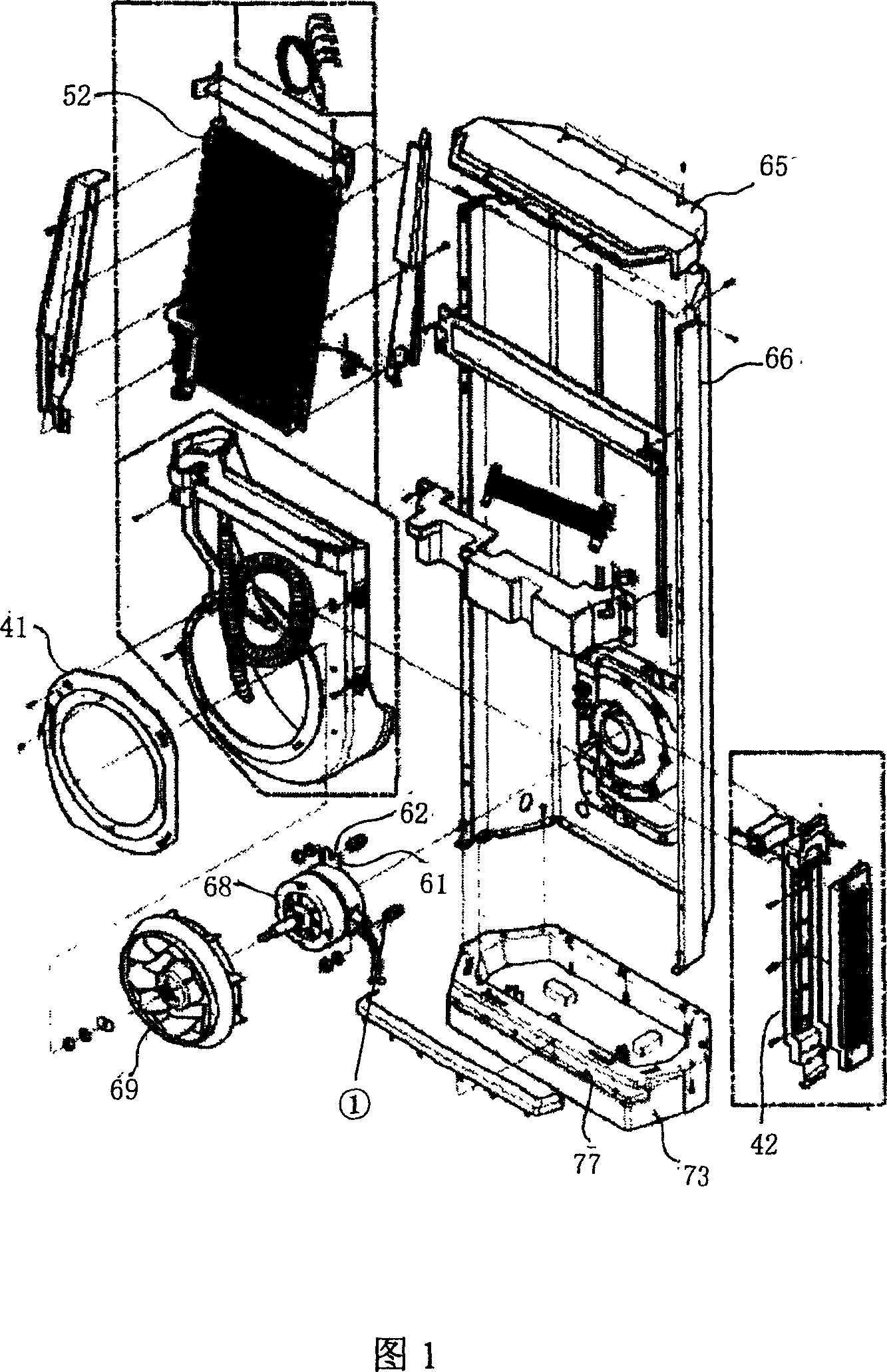

Motor pad structure of air-conditioner

A pad structure and air conditioner technology, applied in the direction of shock absorbers, shock absorbers, mechanical equipment, etc., can solve the problems of poor shock absorption and noise reduction effects, large installation contact surface, etc., and achieve good shock absorption and noise elimination effects, The effect of simple mold, convenient production and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

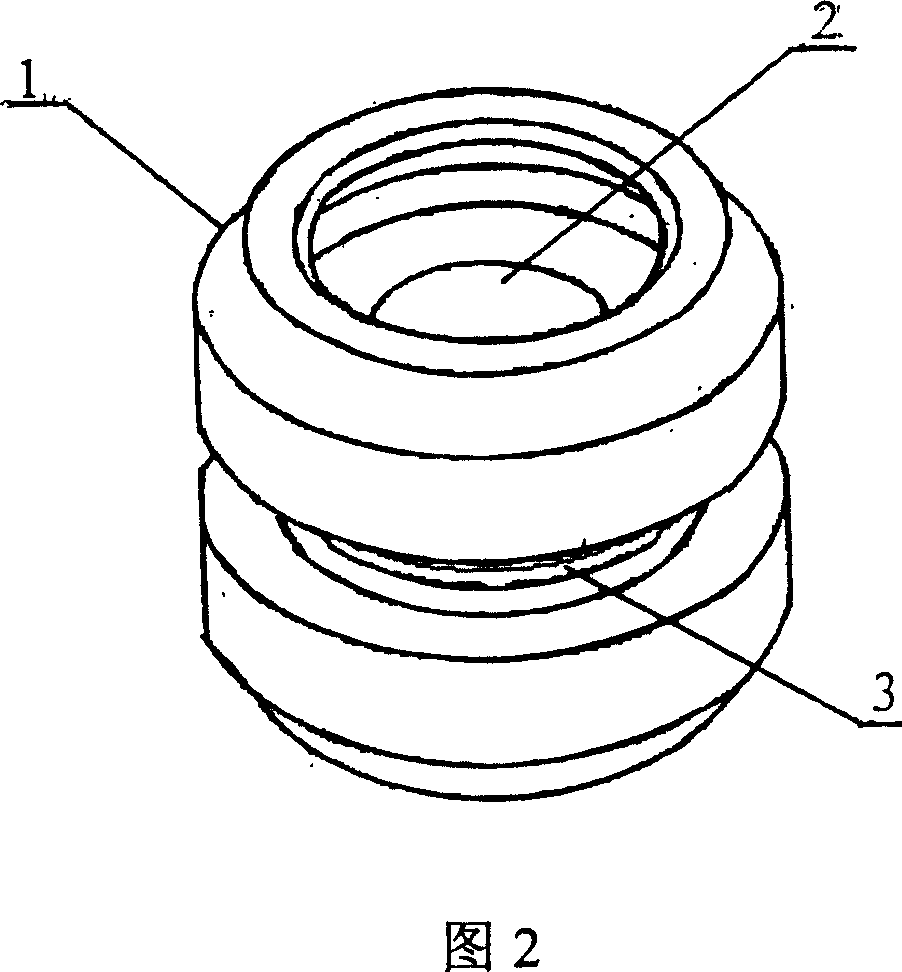

[0024] In order to further understand the motor pad structure of the air conditioner of the present invention, the description is as follows in conjunction with the accompanying drawings of examples:

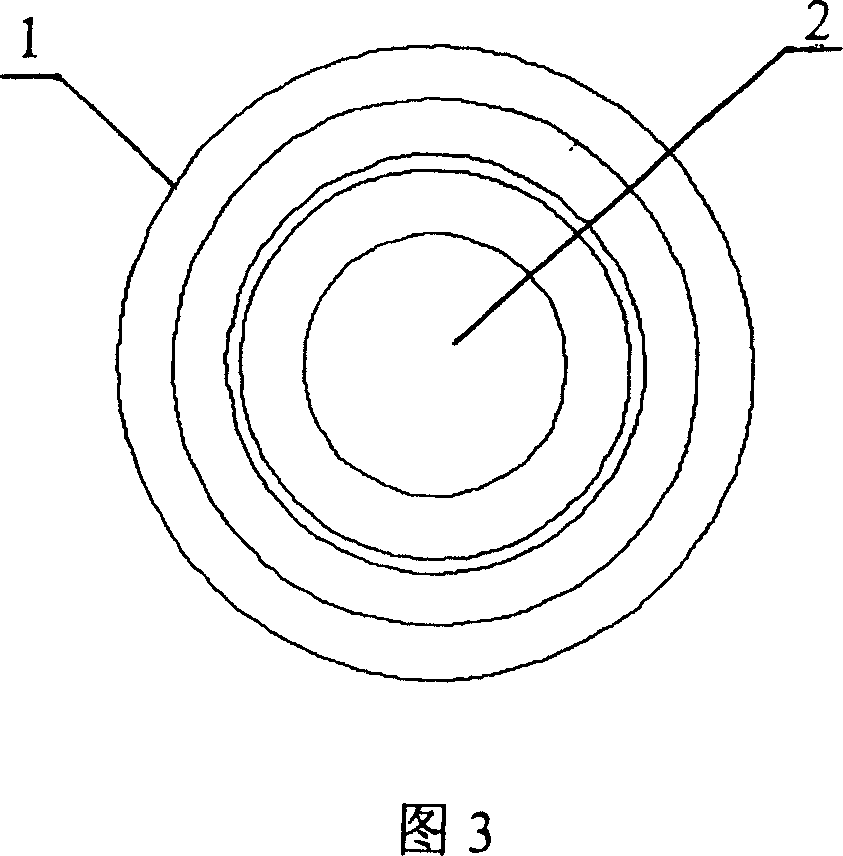

[0025] As shown in Figures 4 and 5, the structure of the motor pad 1 of the air conditioner of the present invention is made of rubber with a through hole 2 in the axial center and an 8-shaped longitudinal section, and is characterized in that the axial central through hole is polygonal star shape.

[0026] Motor pad axial center through hole 2 is preferably hexagonal star shape, and star-shaped convex end forms through hole diameter equal to bolt diameter, and star-shaped radial convex end forms circumscribed circle diameter and is smaller than motor pad slender waist 3 diameters.

[0027] The diameter of the thin waist part 3 in the middle of the motor pad is smaller than the diameter of the motor foot piece gap 62, and the width of the thin waist part 3 is greater than the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com