Constant velocity universal joint

A constant velocity universal joint and track technology, applied in the field of universal joints, can solve problems such as cost increase, unpredictable enhancement of the torsional stiffness of the connecting shaft, etc., and achieve the effects of reducing swing, improving NVH characteristics, and increasing design flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

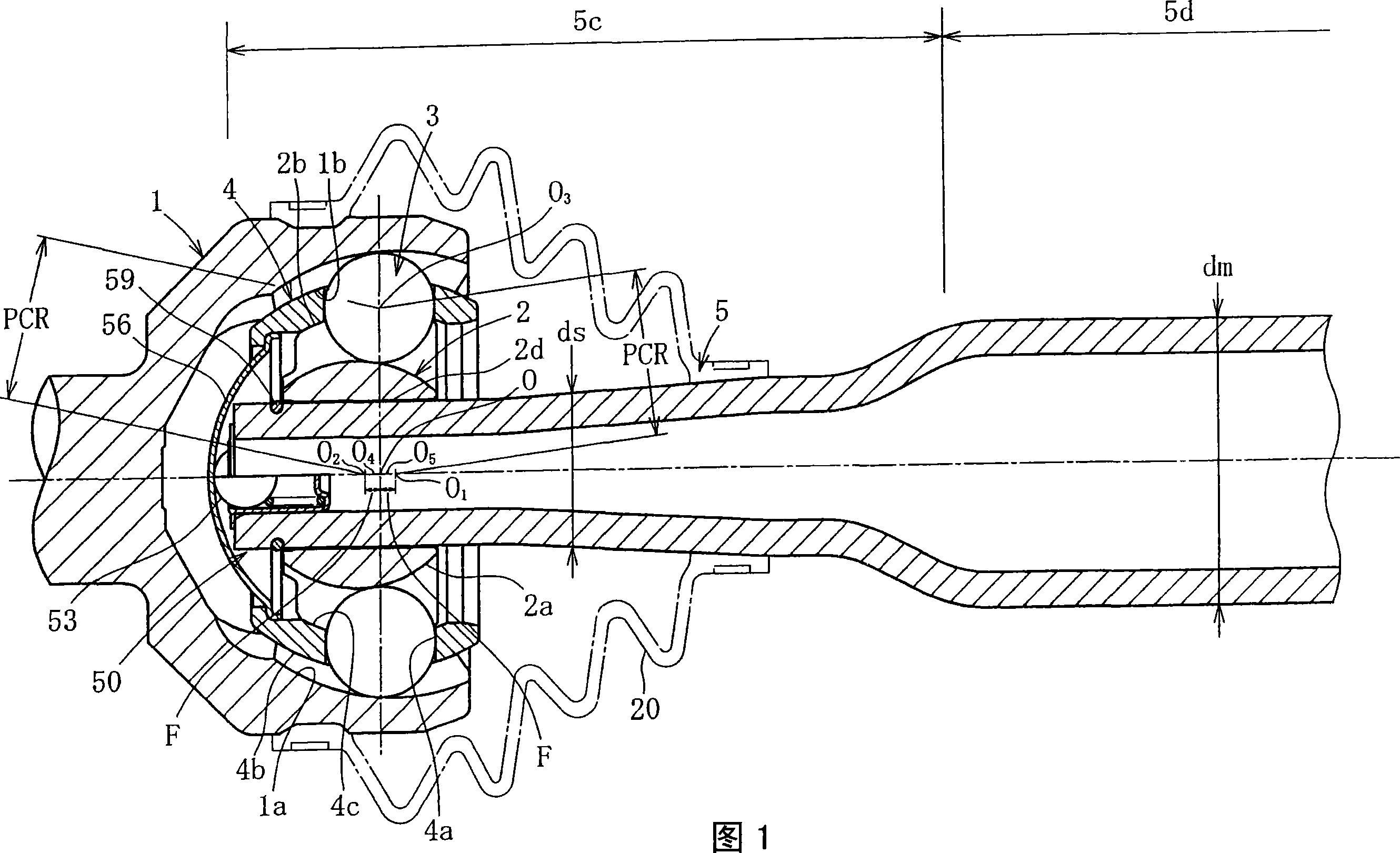

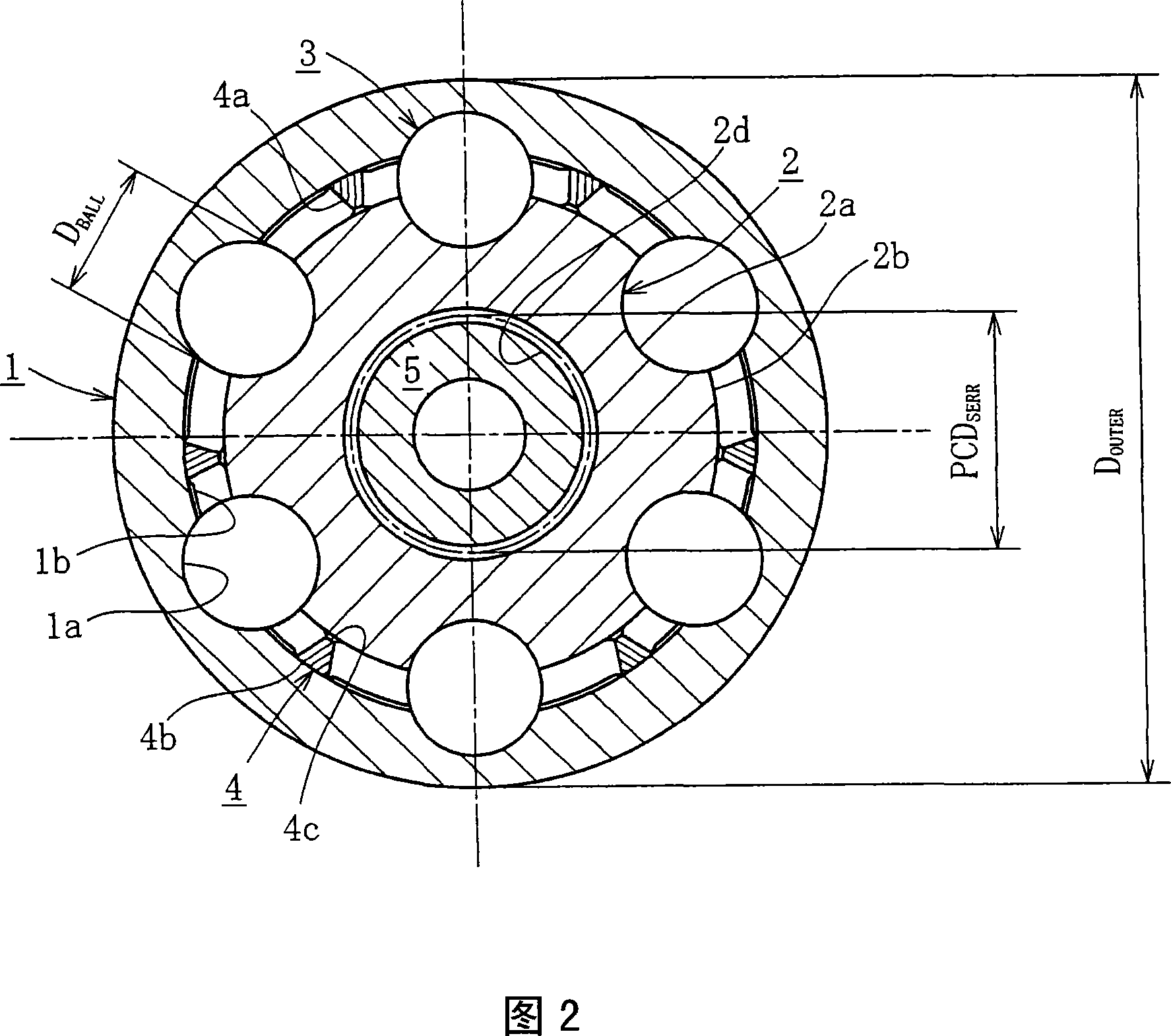

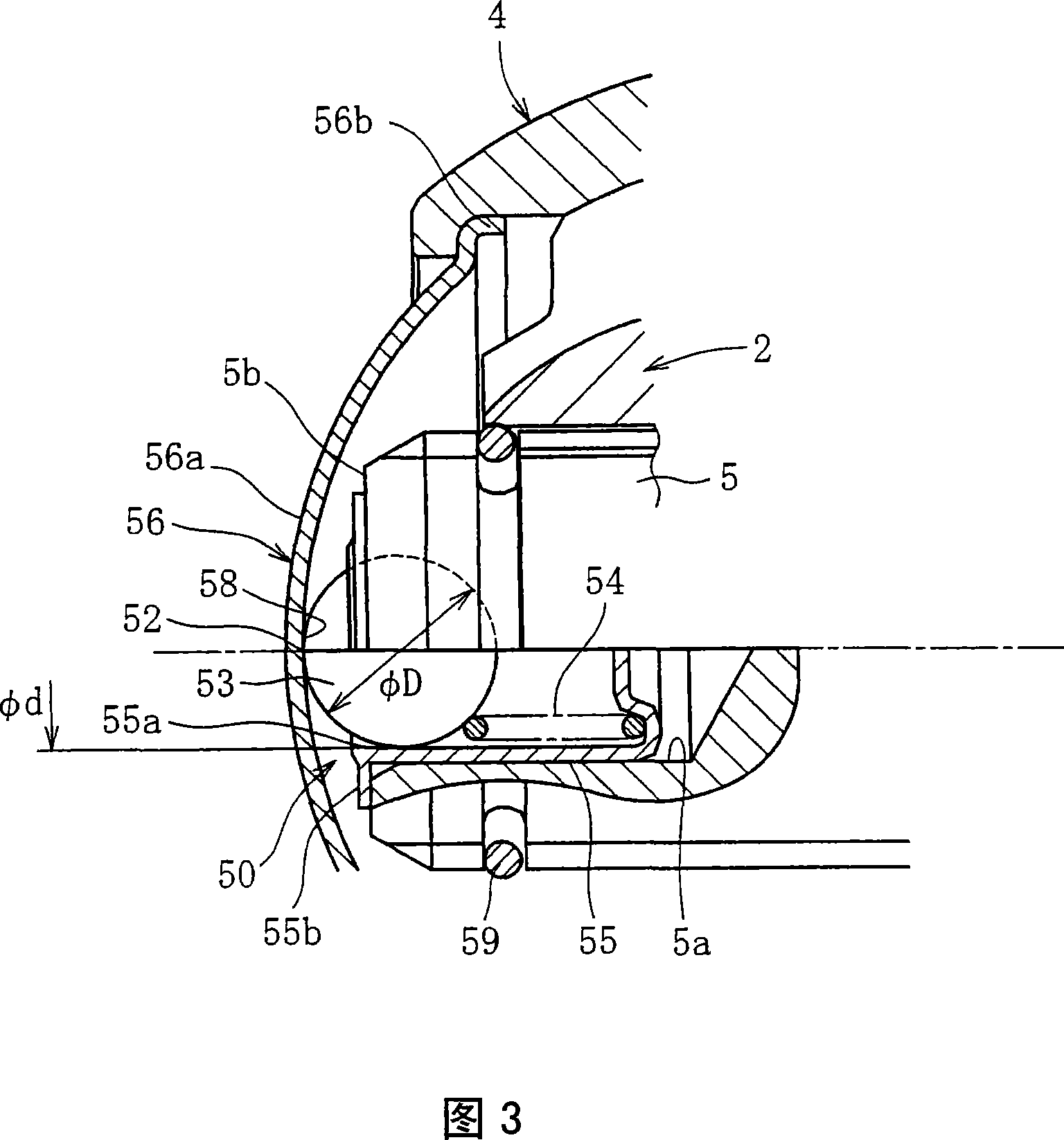

[0023] The embodiments of the constant velocity joint according to the present invention will be explained in detail below. The embodiments described below take as an example the application of the present invention to a ball and cage type constant velocity joint (BJ) which is one of the fixed type constant velocity joints. However, the present invention is not limited to this, and can also be applied to undercut free-type (UJ). The constant velocity universal joint according to the present invention can be used not only for steering but also for drive shafts or transmission shafts.

[0024] First, the steering device in which the fixed type constant velocity joint is installed will be briefly explained. As shown in Figures 5(a) to 5(c), in order to convert the rotational movement of the steering wheel (steering wheel) into the reciprocating movement of the tie rod 69, the steering device is passed by one or more steering The steering column constituted by the shaft 62 transmits t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com