Sartorius with thread-cutting device

A sewing machine and thread-cutting technology, applied in the field of sewing machines, can solve the problems of inefficient sewing operation, requiring a lot of effort for assembly, and difficult to handle sewing fabrics, etc. The effect of reducing assembly work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

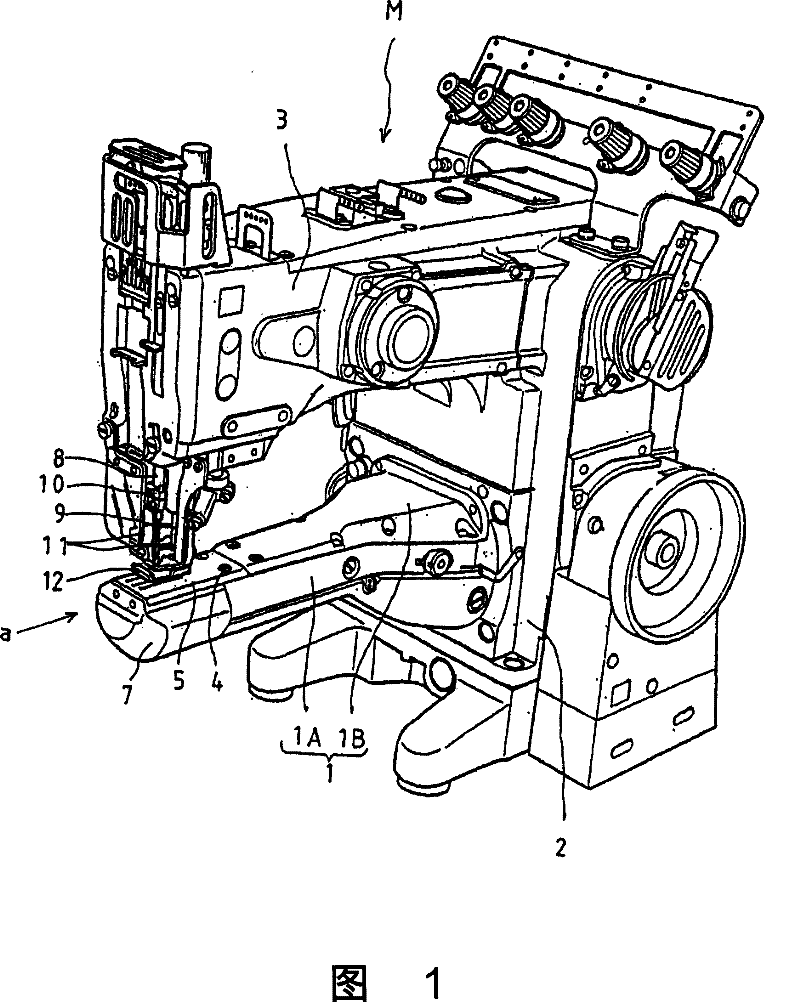

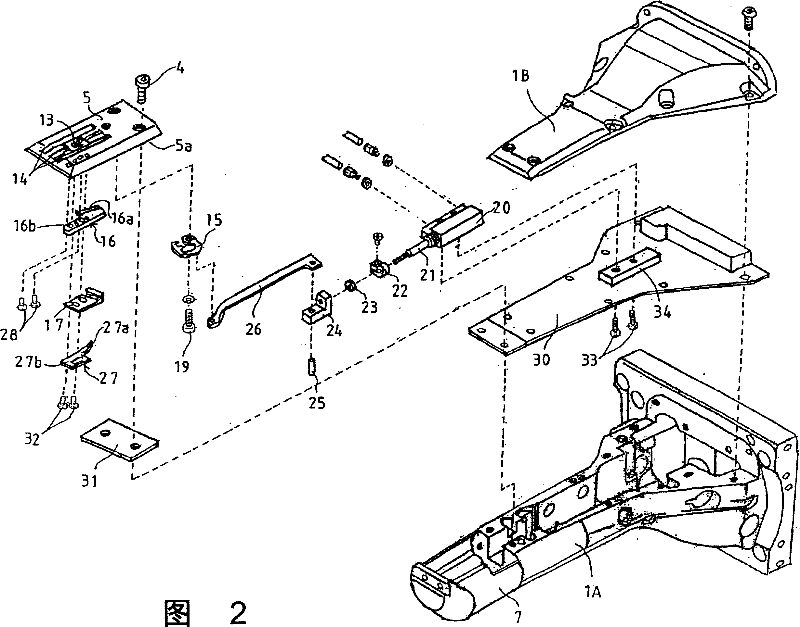

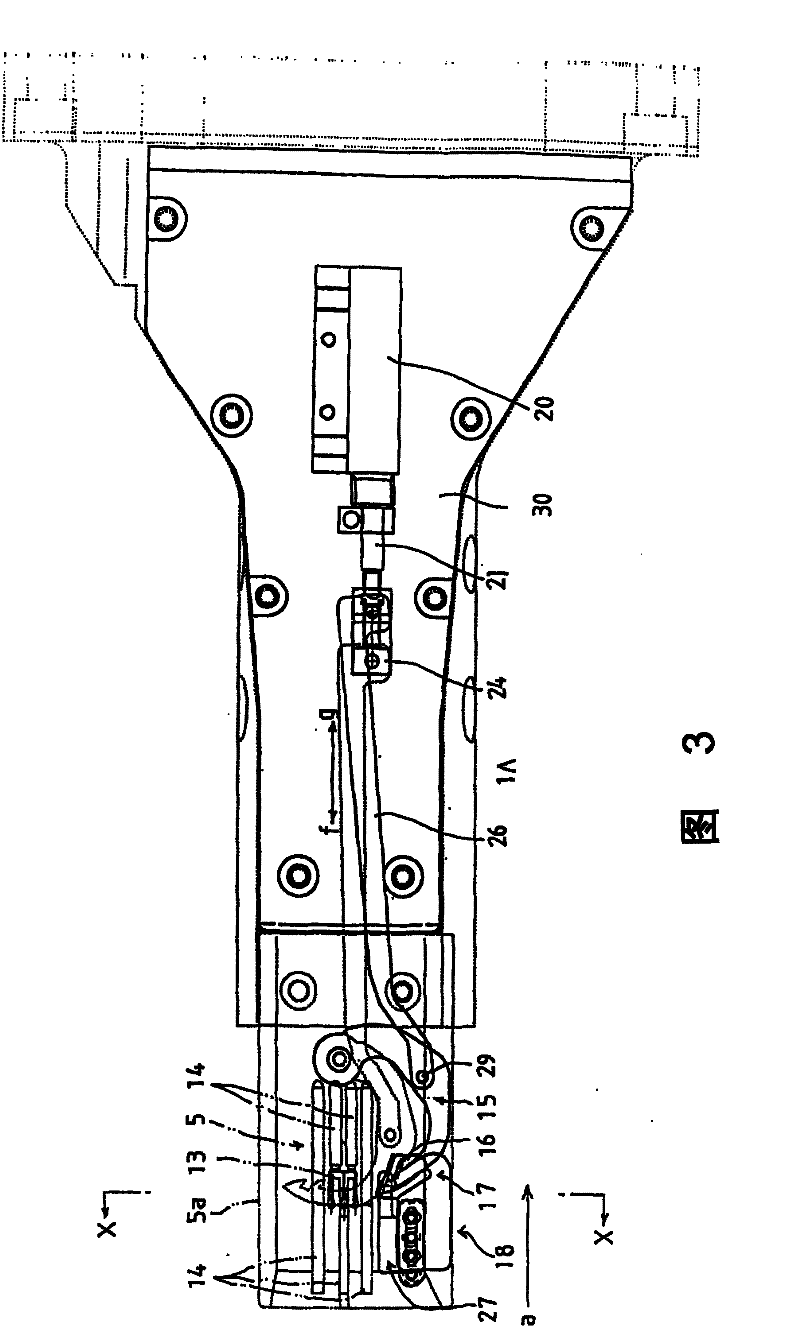

[0018] figure 1 It is a schematic perspective view of the whole of the three-needle cylinder sewing machine with the thread cutting device of the present invention, figure 2 It is an exploded perspective view of the components of the thread cutting device, image 3 It is a plan view in which part of the sewing machine is cross-cut, centering on the vicinity of the thread cutting device as the main part, Figure 4 (A) is along image 3 The enlarged longitudinal sectional view of the X-X line, Figure 4 (B) is Figure 4 Enlarged view of part B of (A). In this three-needle cylinder sewing machine M, a sewing machine main shaft, a needle drive mechanism, and a presser foot drive mechanism are provided extending forward from the lower portion of the sewing machine base (sewing machine body) 2 (since these components are known, so The detailed structure and description thereof are omitted) of the sewing machine arm 3 and the cylindrical seat 1.

[0019] Such as figure 2 As ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com