Steam generator of washing machine

A technology of a steam generating device and a steam generator, which is applied in steam generating, washing devices, other washing machines, etc., and can solve the problems of the steam generator 200 such as deformation of the shell, damage of connecting parts, failure to ensure airtightness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

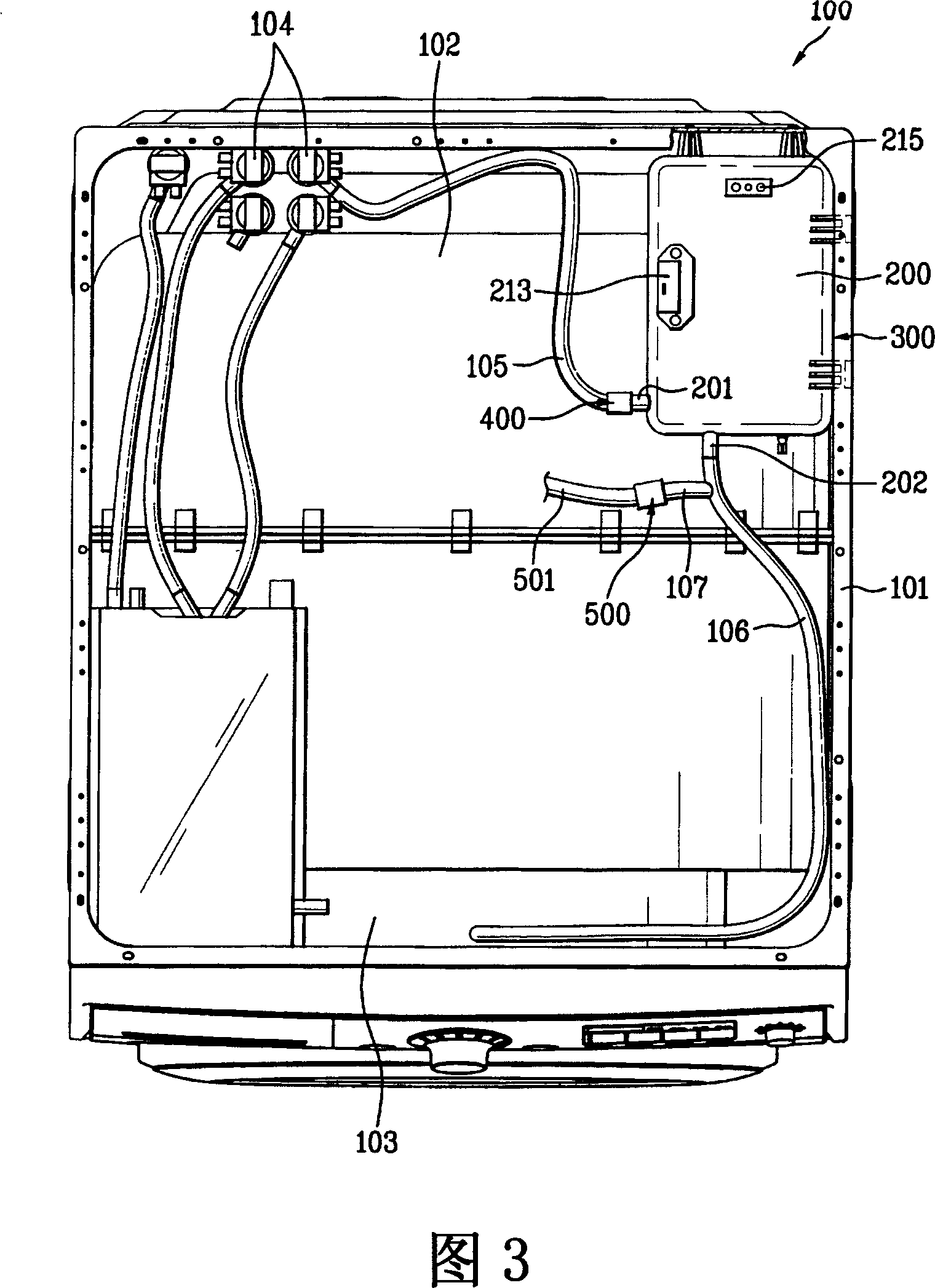

[0054] Here, the same components as those in the prior art will be given the same names and the same reference numerals, and detailed descriptions thereof will be omitted.

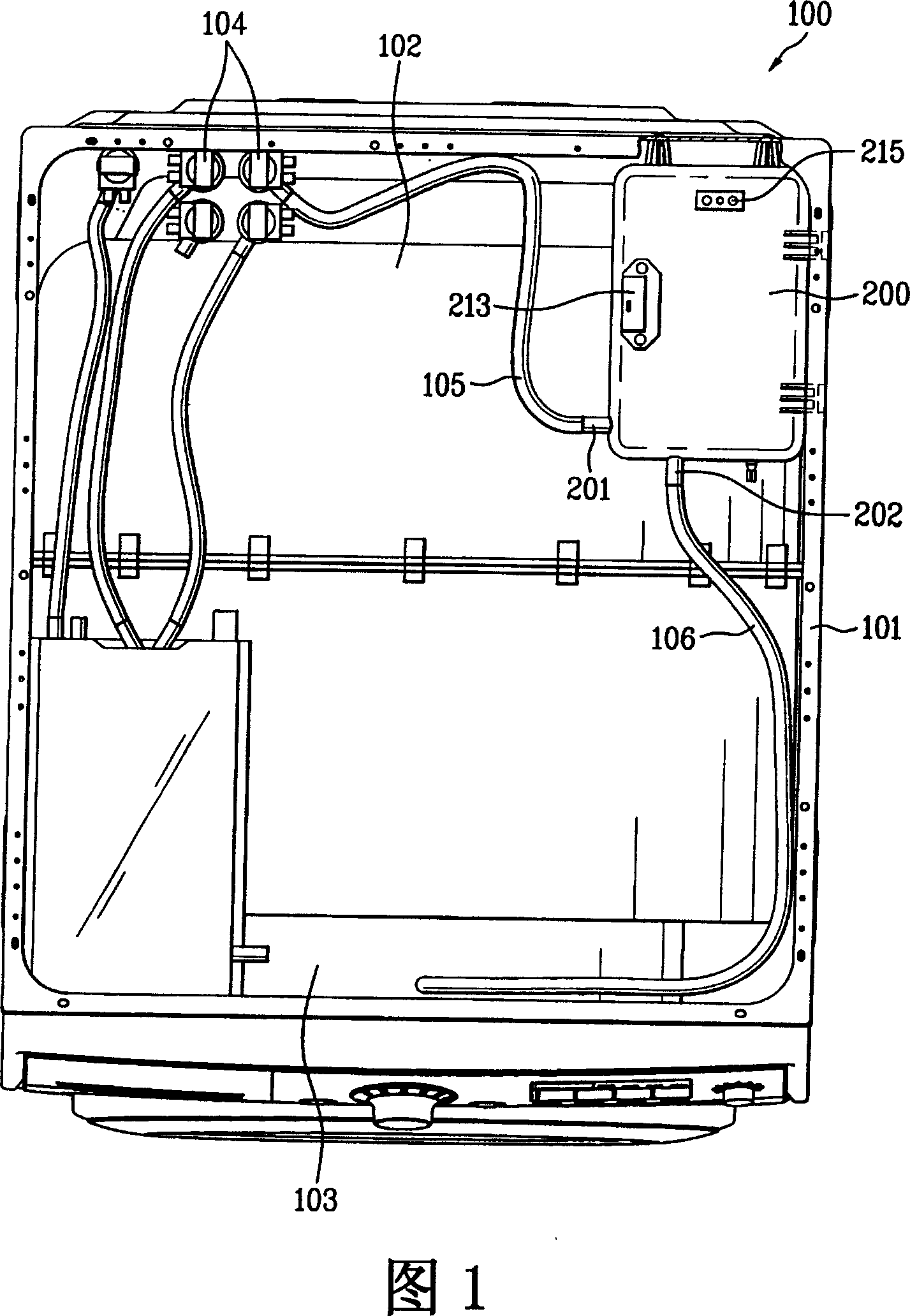

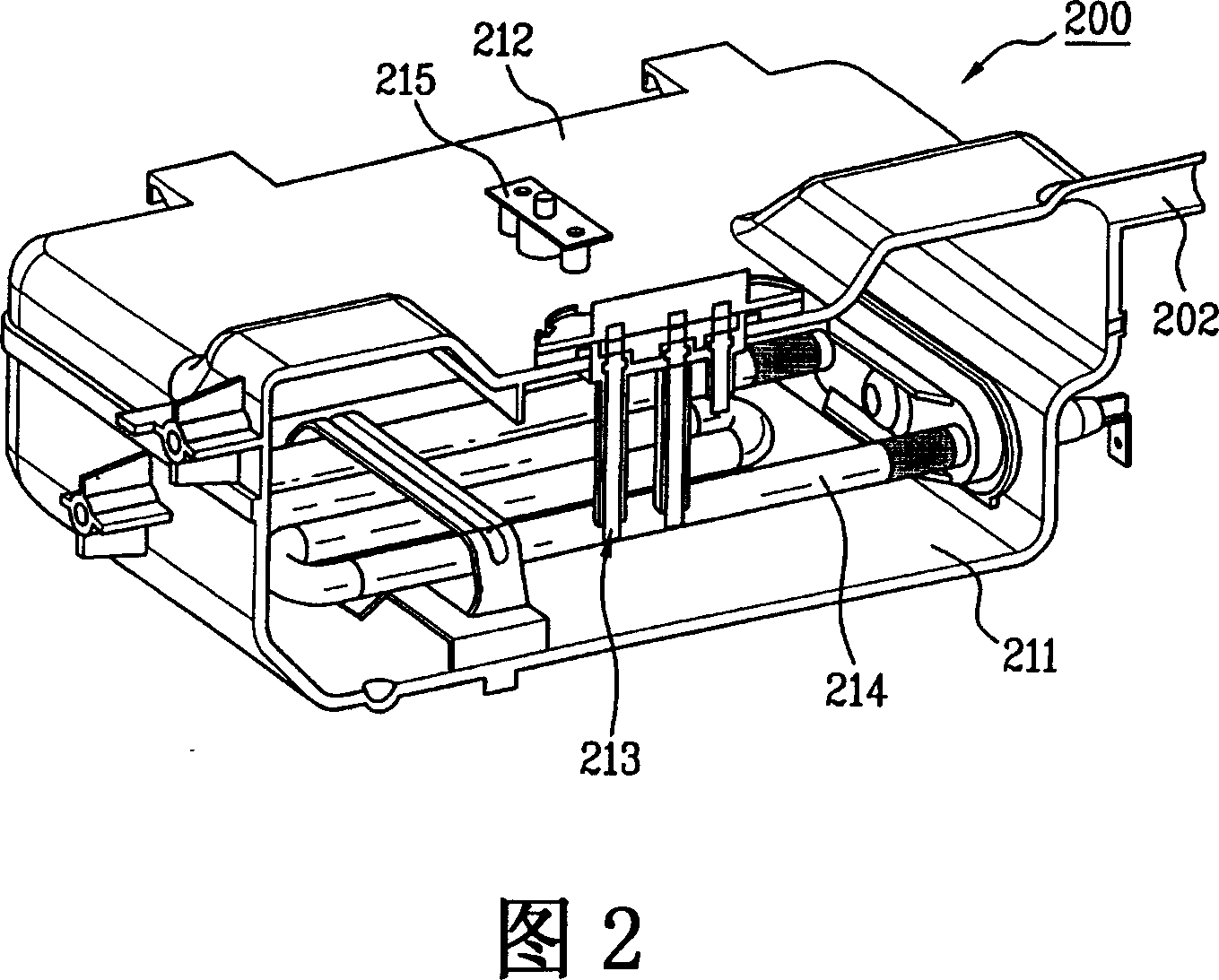

[0055] First, as shown in FIG. 3 , the steam generator 300 of the washing machine according to the embodiment of the present invention includes: a steam generator 200 for generating steam; a heater 214 for heating the water supplied in the steam generator 200; The water supply port 201 installed on one side of the above-mentioned steam generator 200; the steam discharge port 202 installed on the other side of the above-mentioned steam generator 200; the water supply pipe 105 connected with the above-mentioned water supply 201; The reverse flow device 400 ; the branch pipe 107 branched from the steam outlet 202 ; and the exhaust device 500 attached to the branch pipe 107 .

[0056] Wherein, the water supply port 201 of the steam generator 200 is connected to the water supply pipe 105 connected to the water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com