Microcosmic checking device for glass panel

A microscopic inspection, glass panel technology, applied in the direction of measuring devices, optical devices, measurement/testing in the manufacturing process, etc., can solve problems such as impossible defect detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Now, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

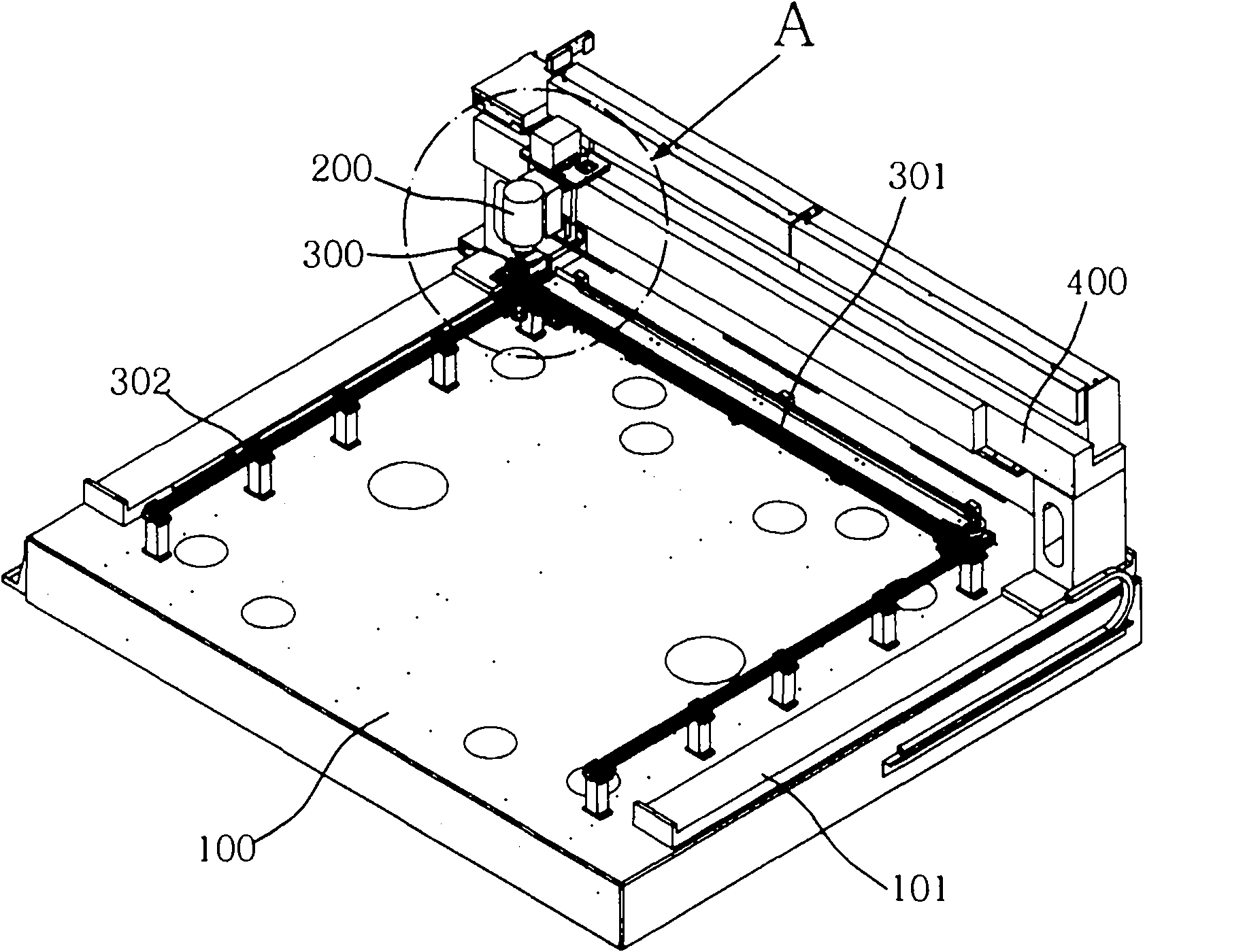

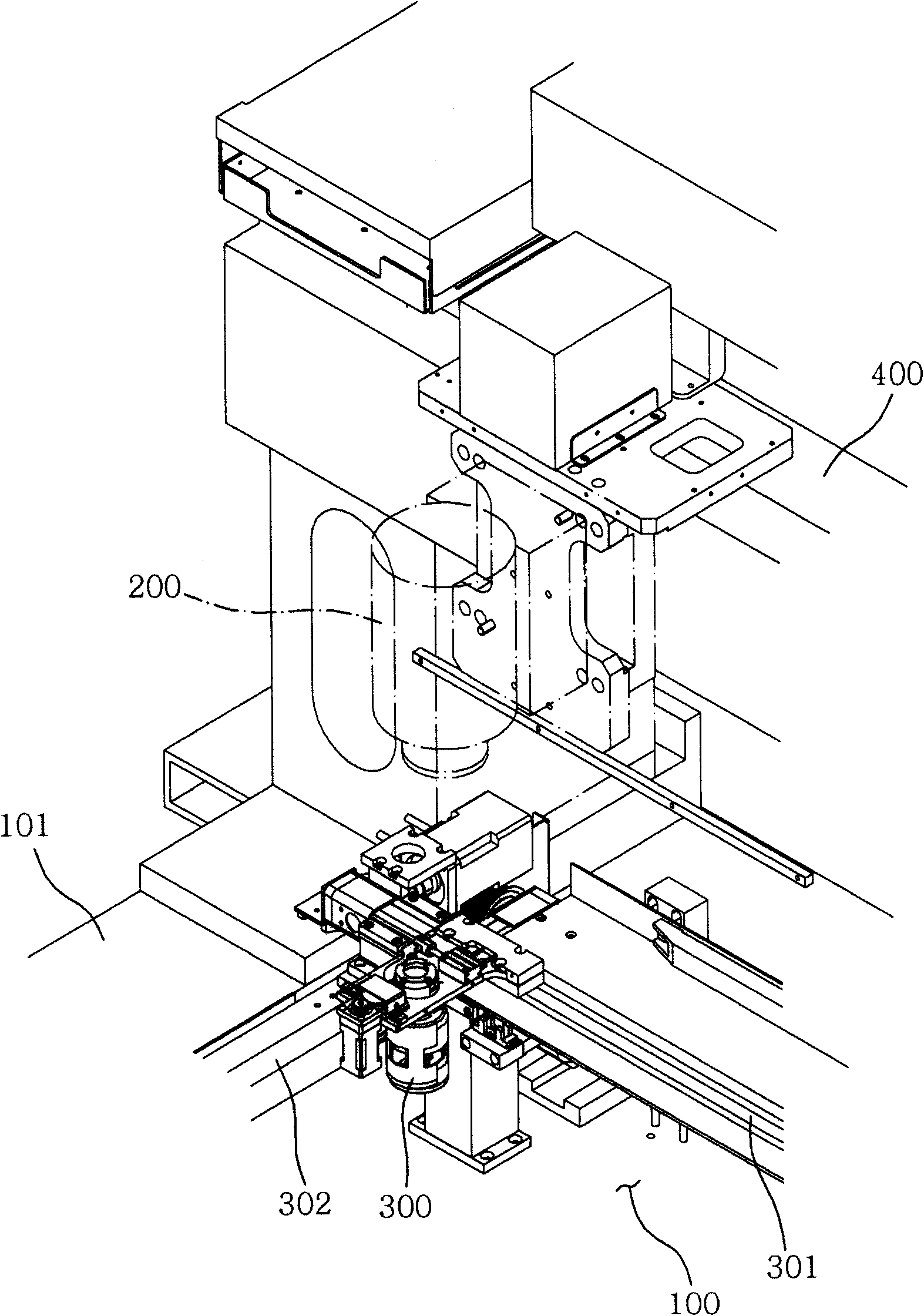

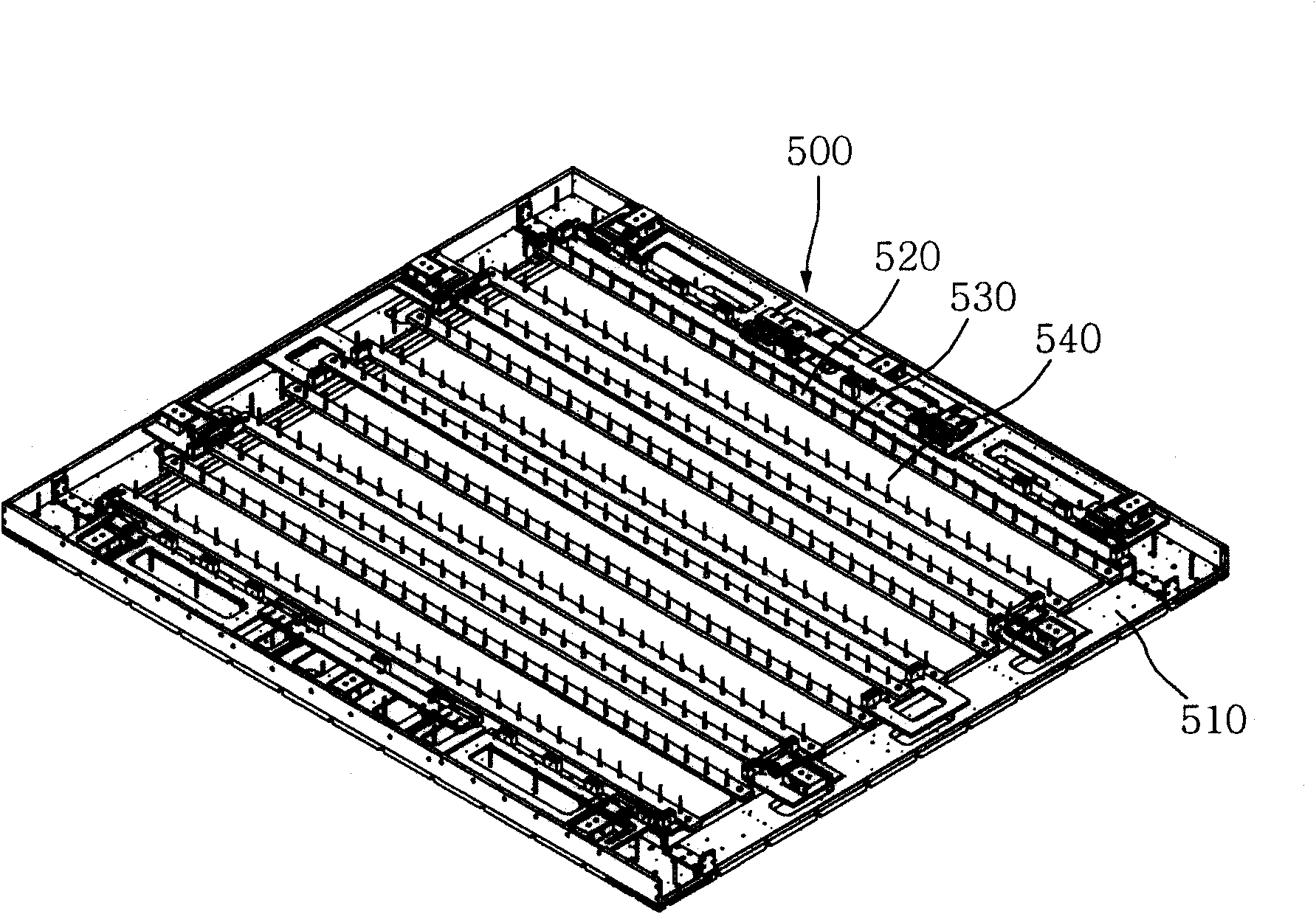

[0048] Figure 7 is a perspective view showing a microscopic detection device according to a preferred embodiment of the present invention, Figure 8 is shown Figure 7 An enlarged perspective view of part C in, Figure 9 yes Figure 8 Schematic front view of , while Figure 10 yes Figure 8 schematic side view of .

[0049] As shown in the figure, the present invention provides a micro inspection apparatus using a microscope 20 to accurately inspect defects of glass panels used in flat panel display devices such as liquid crystal displays (LCD) and plasma display panels (PHP). Bridges 40 are movably connected to opposite ends of the scoring table 10 . A microscope 20 and a light source lamp 30 emitting light toward a glass panel (not shown) are mounted on the bridge 40 . The microscope 20 and the light source lamp 30 are simultaneously ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com