Viscous fluid-sealed damper and disk device

A viscous fluid and damper technology, applied in liquid shock absorbers, shock absorbers, shock absorbers, etc., can solve the problems of sound skipping and the deterioration of the vibration attenuation effect of viscous fluid enclosed in the damper 1, so as to improve durability, Efficient vibration damping effect, avoiding the effect of local stretching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

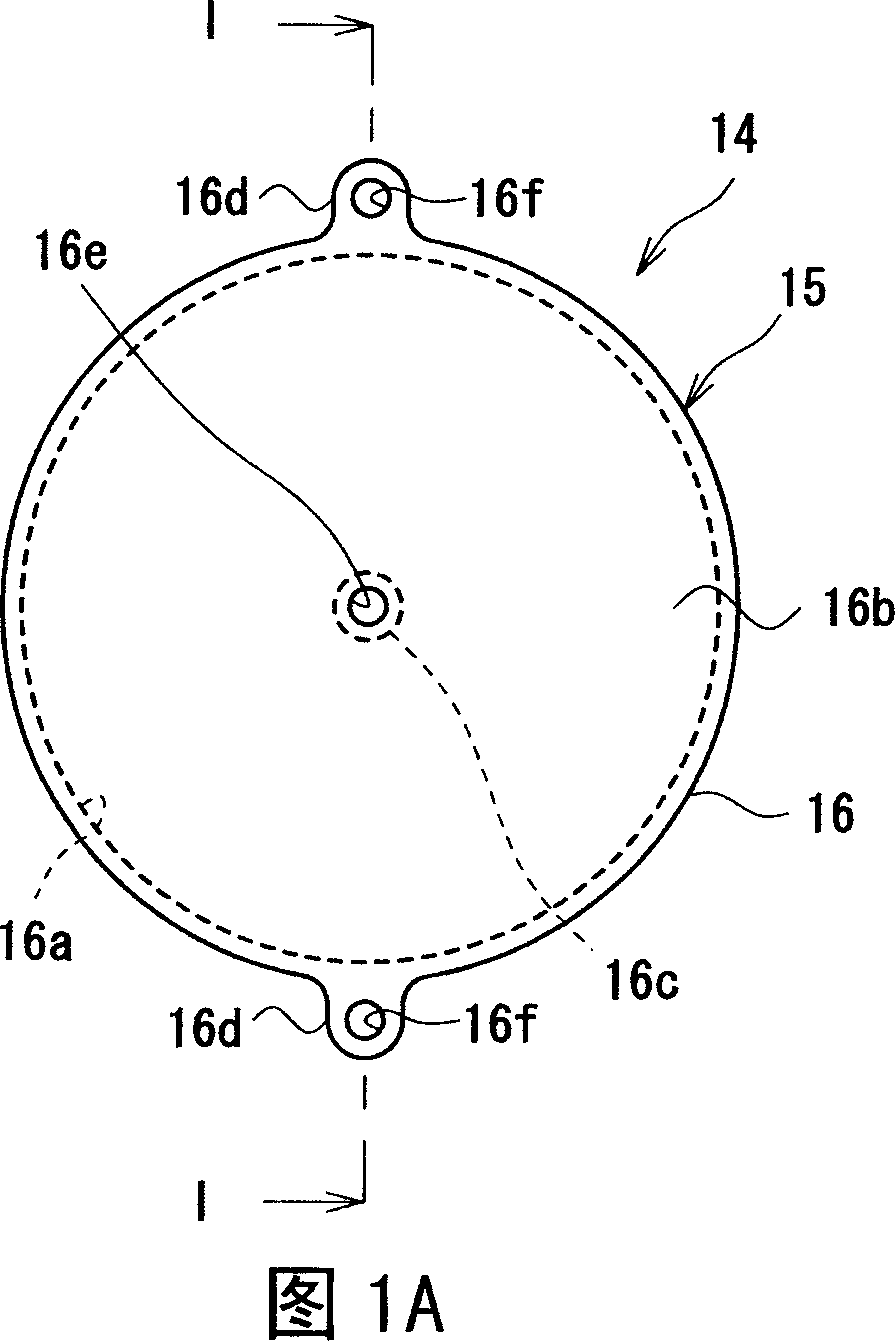

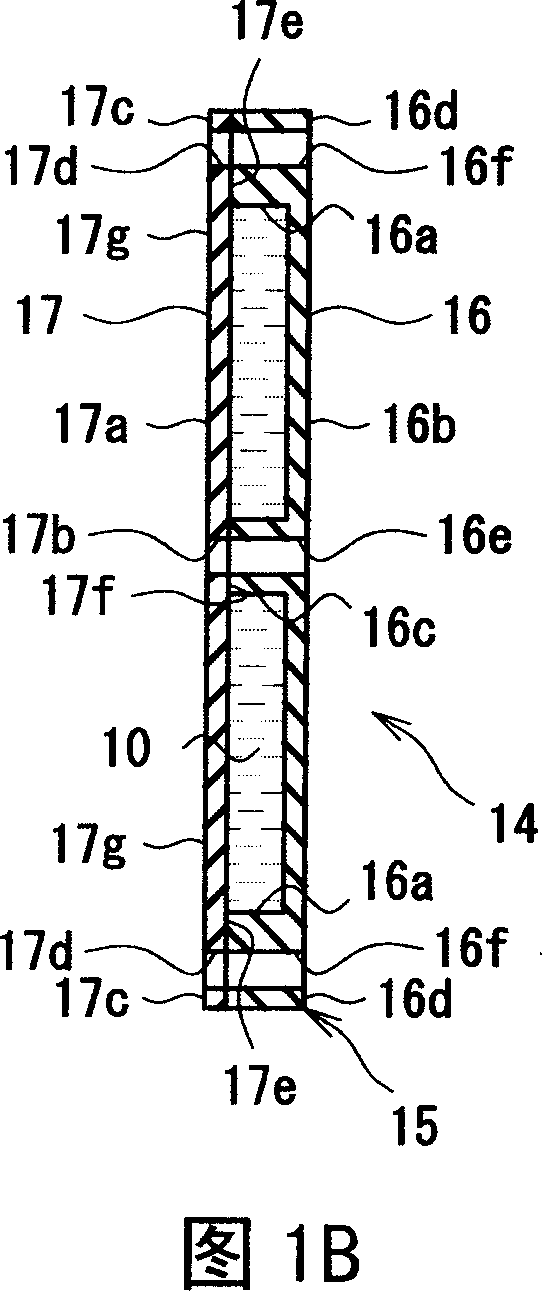

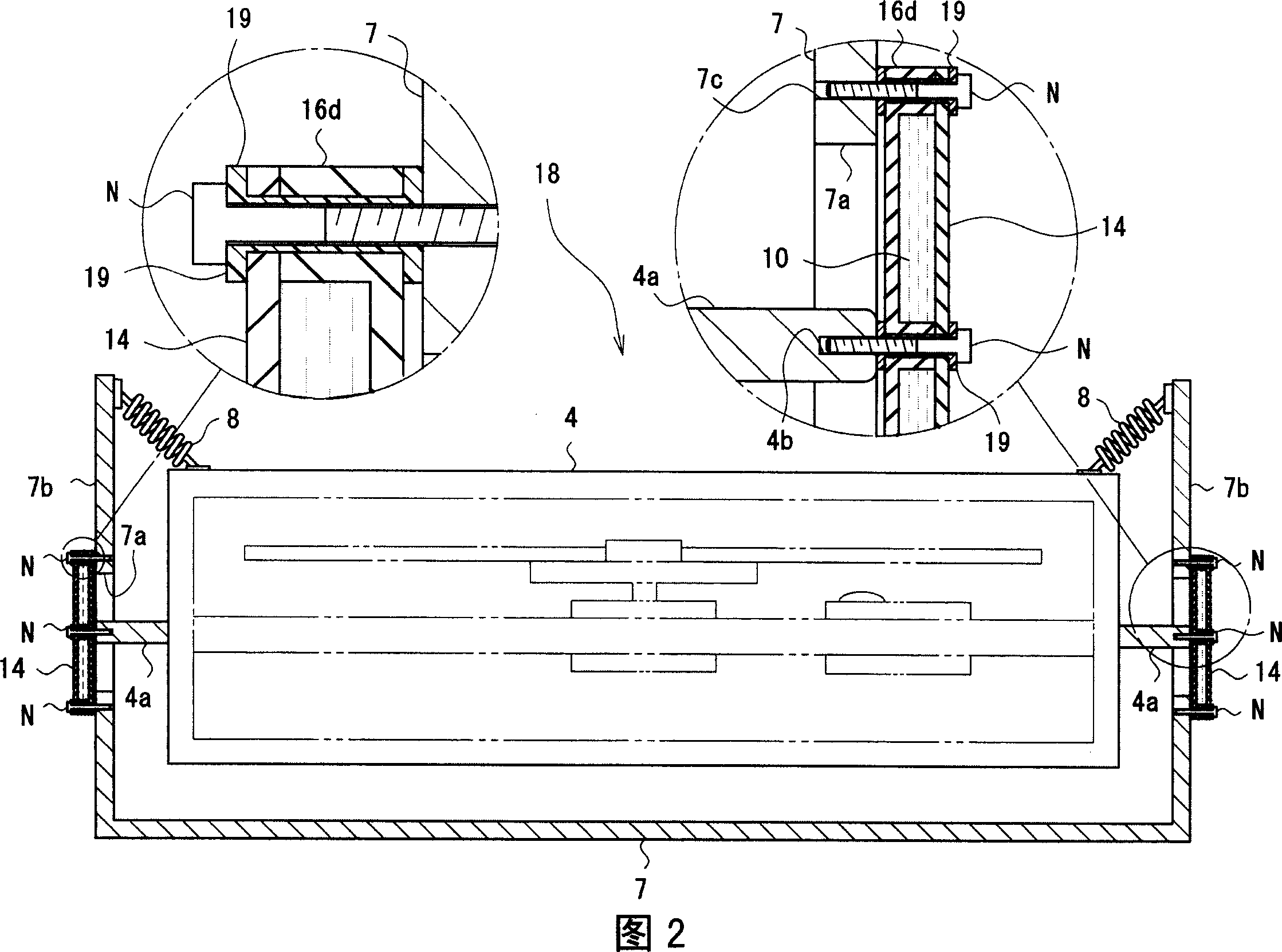

[0057] First Embodiment (FIGS. 1A to 4)

[0058] A. Embodiment of Viscous Fluid Encapsulation Damper: The viscous fluid encapsulation damper 14 of the first embodiment employs a structure in which viscous fluid 10 is enclosed in an airtight container 15 . The airtight container 15 is formed in the shape of a hollow disc made of a rubber-like elastic body, and is bonded with an adhesive to a lid body 17 formed separately from the container body 16 .

[0059] The container main body 16 has a shallow-bottomed circular shape and is composed of an outer cylindrical portion 16a, a bottom portion 16b, an inner cylindrical portion 16c, and two main body protrusions 16d. The outer cylinder portion 16a has a cylindrical shape, and one end thereof is closed by a disk-shaped bottom portion 16b. In the center of the bottom portion 16b, a cylindrical inner tube portion 16c protruding from the inner surface of the bottom portion 16b is formed along the cylinder axis direction of the outer t...

no. 2 approach

[0082] Second Embodiment (FIG. 7A to FIG. 8)

[0083] A. Embodiment of viscous fluid-filled damper: The viscous fluid-filled damper 20 of the second embodiment differs from the viscous fluid-filled damper 14 of the first embodiment in the structure of the main body protrusion 16g of the container main body 16 . The rest of the structure is the same as that of the first embodiment.

[0084] The body protruding portion 16g of the viscous fluid-filled damper 20 is formed to have the same thickness as the bottom portion 16b, and is formed to pass through the circular body outer hole 16f.

[0085] In the viscous fluid sealing damper 20 of the second embodiment, the main body projecting portion 16g and the cover body projecting portion 17c constitute “outer mounting portions 16g, 17c”. That is, the "outer attachment parts 16g, 17c" are parts that protrude in parallel and are bisected, and the main body outer hole 16f and the cover outer hole 17d constitute the "outer attachment hol...

no. 3 approach

[0091] Third Embodiment (FIG. 9A to FIG. 10)

[0092] A. Embodiment of viscous fluid-filled damper: The viscous-fluid-filled damper 22 of the third embodiment differs from the viscous-fluid-filled damper 14 of the first embodiment in that the use of mounting screws N is completely eliminated. Specifically, firstly, for the container main body 16, a solid central shaft portion 16h and a main body protrusion portion 16d are formed; secondly, for the lid body 17, the lid inner hole 17b and the lid outer hole of the first embodiment are deleted. 17d. In other words, the difference lies in that the inner wall portions 16c, 17f of the viscous fluid-enclosed damper 14 of the first embodiment have a structure having inner mounting holes 16e, 17b, whereas the viscous-fluid-enclosed damper 22 of the present embodiment has The inner wall portion 16h is constituted by a solid central shaft portion 16h, and has an inner mounting protrusion 16i protruding outward. In addition, the differe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com