Composite cold stamping mold

A technology of cold stamping and mold, which is applied in the field of composite mold structure of various cold stamping processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

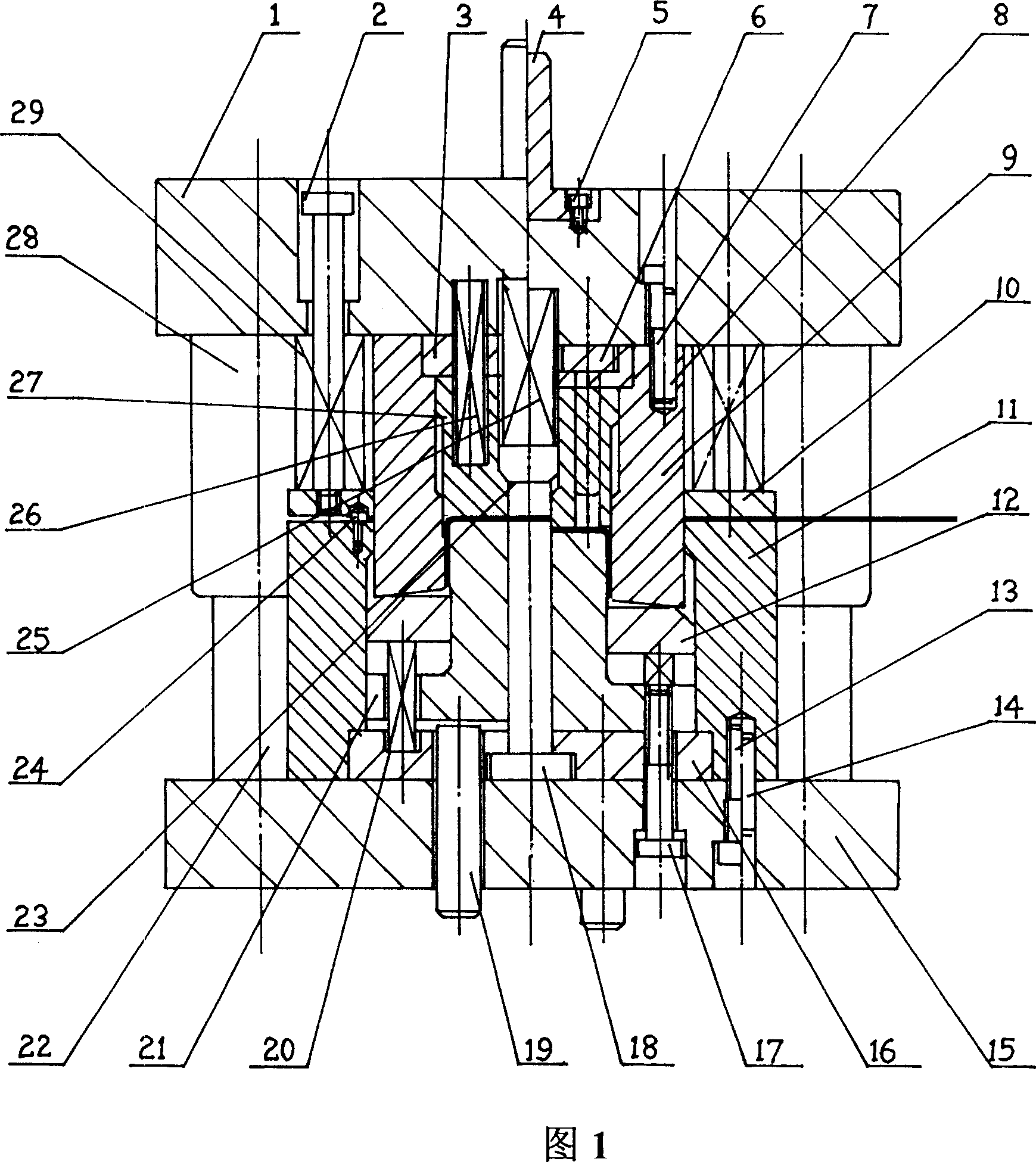

[0013] As shown in Figure 1, the composite cold stamping die of the present invention includes two parts, an upper die and a lower die. The upper mold is composed of the upper mold base 1, the mold handle 4 directly installed on the upper center of the upper mold base 1 through the positioning hole and the screw 5, and respectively installed under the upper mold base 1 through the positioning hole, the backing plate 25, the screw 7 and the pin 8 Guide sleeve 28, guide post 6, punch and die 9, spring 25, spring 26, ejector 27 and ejector block 23 installed in punch and die 9, are installed on the upper die through unloading screw 2 and unloading spring 29 The unloading plate 10 around the convex and concave die 9 under the seat 1 is composed of; The lower mold is composed of the lower mold base 15, the guide post 22 directly installed on the lower mold base 15 through the positioning hole, the die 11 installed in the center of the lower mold base 15 through the screw 13 and the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap