Bridge type lifting composite device for car body transportation

A compound device and bridge-type technology, which is applied in the field of bridge-type lifting compound devices, can solve problems such as low efficiency and difficulty in turning over, and achieve the effects of improving efficiency and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

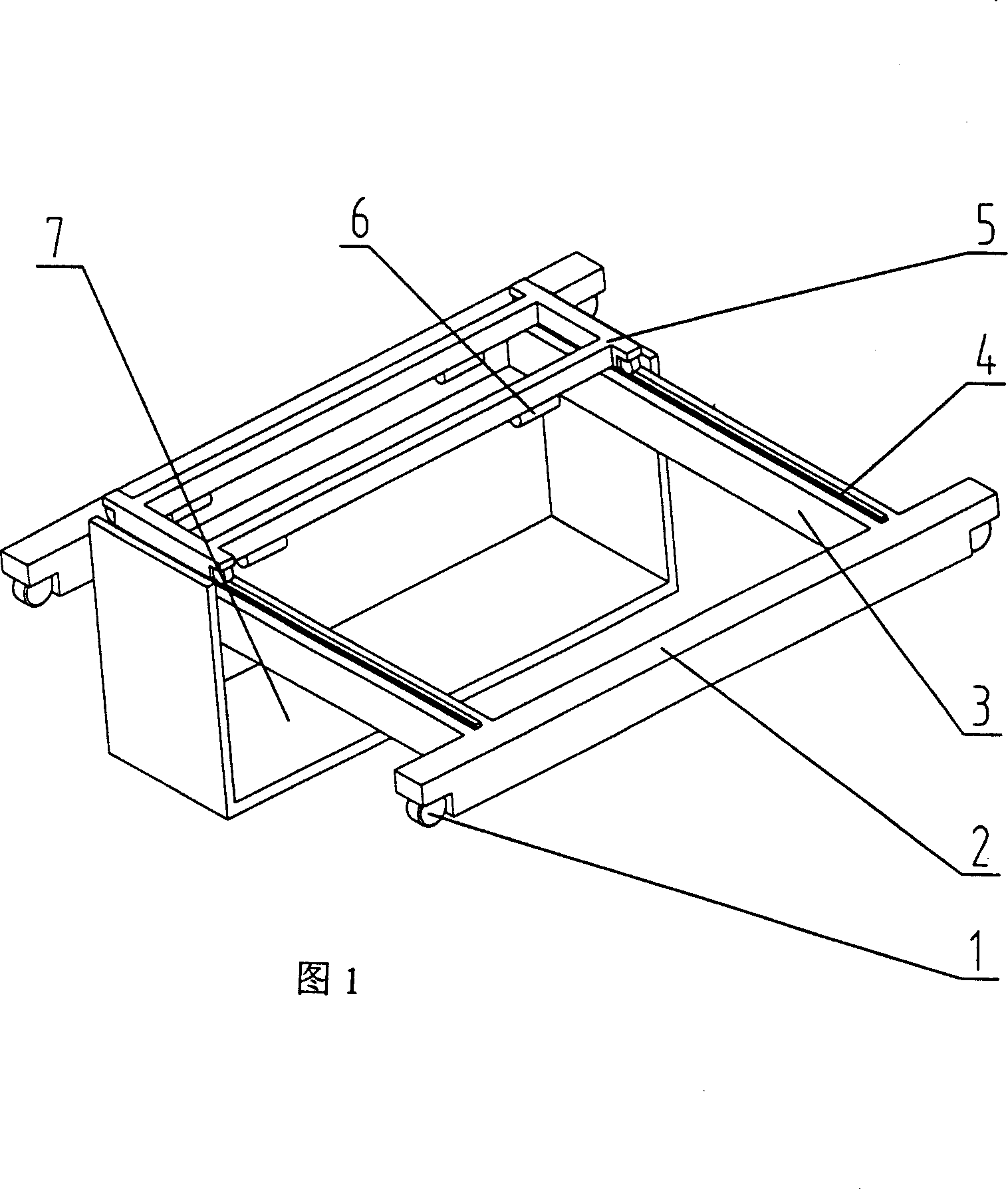

[0010] With reference to accompanying drawing 1, its structure is that the rail 4 on the crane frame is welded and connected to the main girder 3 in the crane frame, and the bridge-type hoisting crane 5 is installed on the rail 4 of the crane frame through the traveling wheel 1, It can move freely, the electric hoist 6 on the hoisting crane is installed on the main beam of the bridge crane 5, the sliding suspension plate 7 is connected by rolling and installed on the main beam 3 in the crane frame, the whole suspension plate can be Cover the hoisting range of overhead crane 5.

[0011] The structure of the crown block frame is that the beam 2 and the main beam 3 are welded together, and the running wheel 1 is installed with a bearing box,

[0012] The structure of the bridge crane 5 is composed of two main girders 3 and two crossbeams 2 welded, the two ends of the crossbeam 2 are respectively equipped with a bearing box and a running wheel 1, the bearing box is connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com