Semi-horniness flame-proof PVC sheath material for high-voltage cable

A high-voltage cable, semi-rigid technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of outer sheath damage, breakage, large difference, etc., to improve the situation of easy cracking, improve the shear deformation ability, The effect of improved scratch resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with embodiment:

[0032] Composition of each component

Dosage (parts by weight)

Example 1

Example 2

Example 3

Example 4

PVC resin

100

100

100

100

35.0

36.0

37.0

39.0

Low temperature impact modifier

5.0

5.5

6.5

7.0

stabilizer

5.0

5.5

6.5

7.0

flame retardant

6.0

7.0

8.0

9.0

filler

20.0

22.0

23.5

25.0

0.5

0.65

0.85

1.0

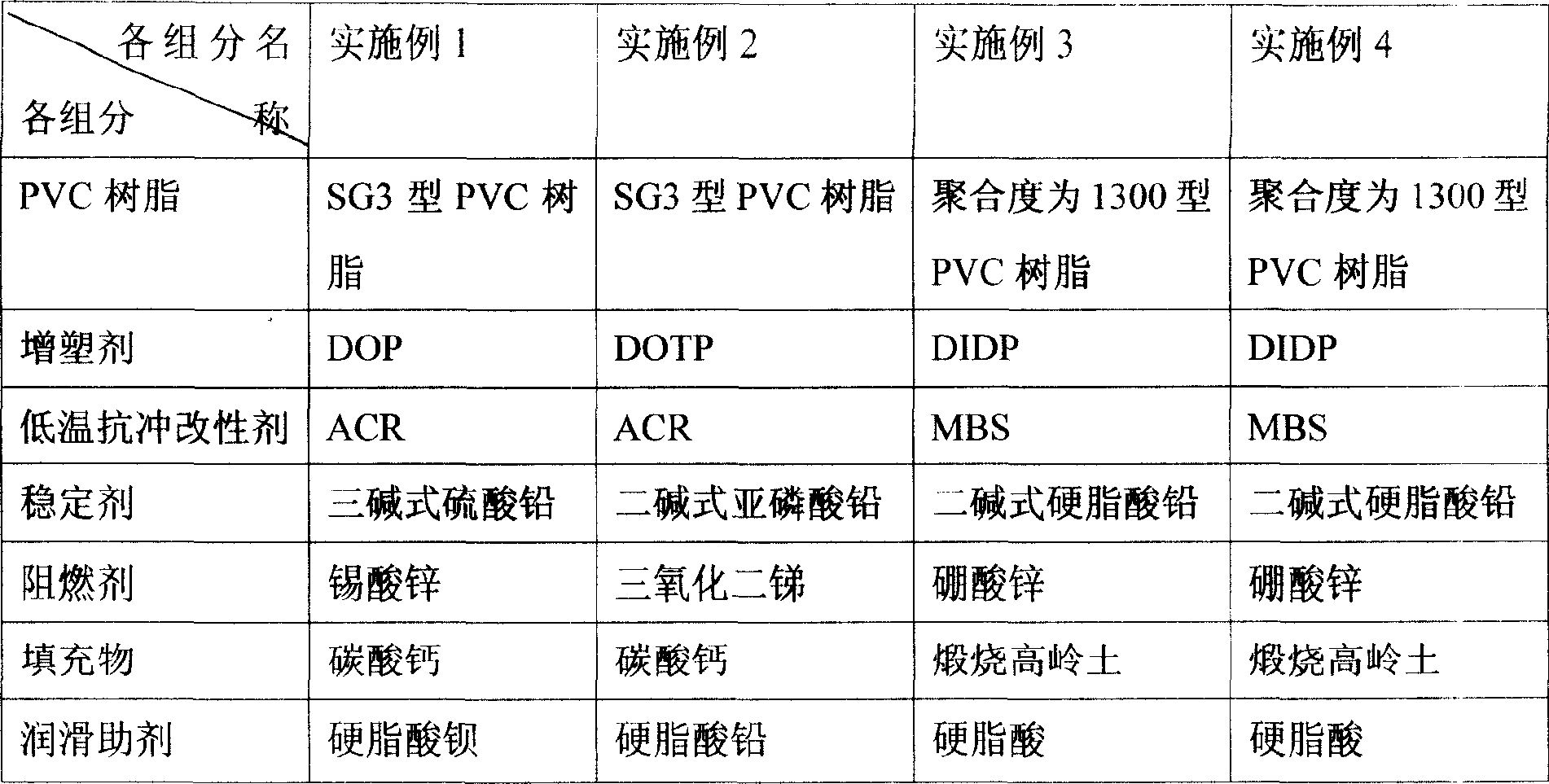

[0033] The following table is the specific name of each component used in each embodiment.

[0034]

[0035] The production process is carried out in sequence according to the following steps: preparation of raw and auxiliary materials → weighing according to the corresponding proportion → high-speed kneading → ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com