Air knife for controlling zinc coat thickness

A technology of galvanized layer and air knife, applied in coating, hot-dip plating process, metal material coating process, etc., can solve the problems of limited edge thickness suppression and difficulty in overcoming the edge thickness of the coating, and achieve the suppression of edge thickness defects , easy to adjust the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

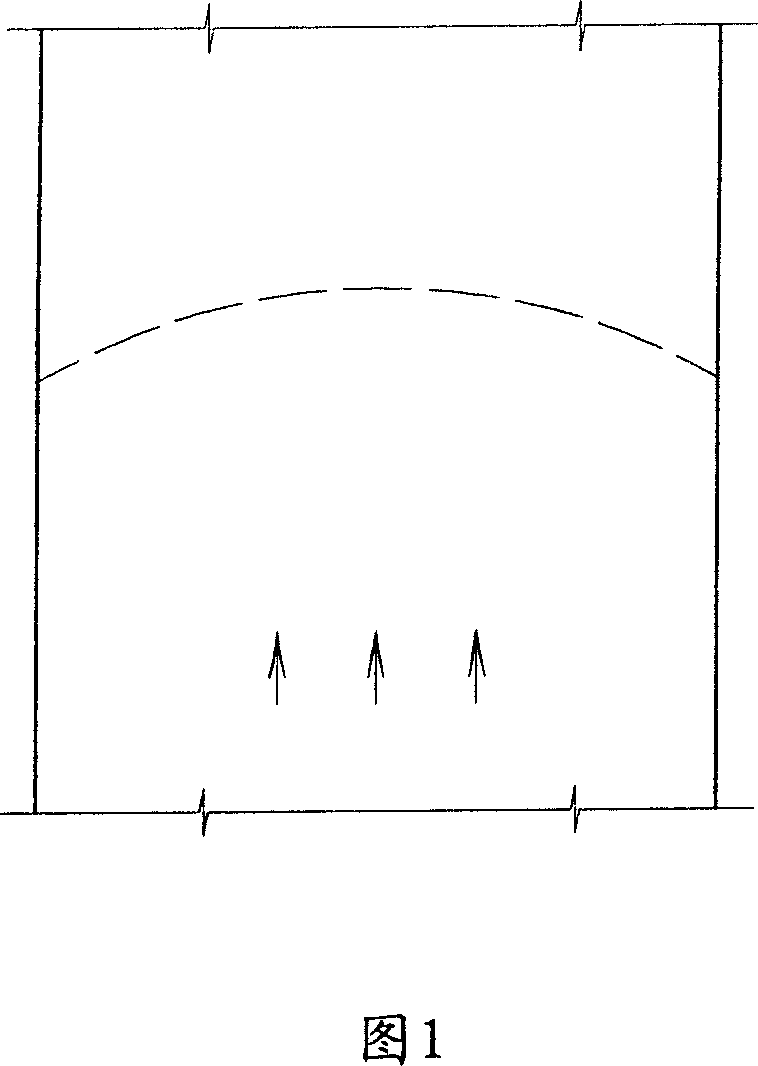

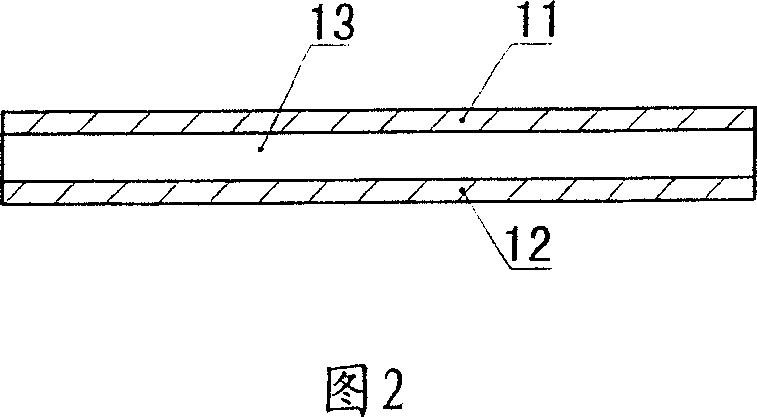

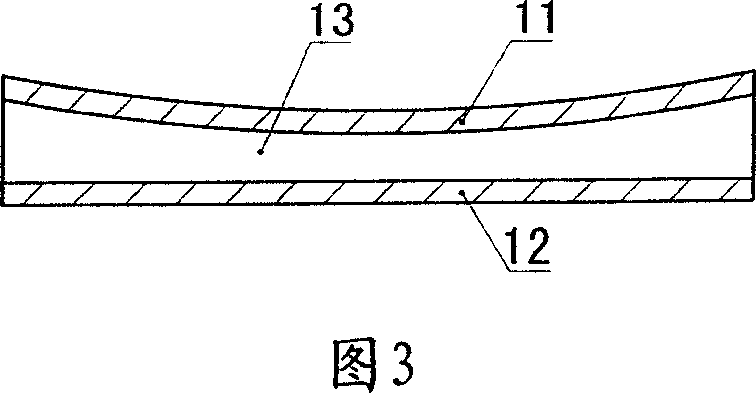

[0021] With reference to Fig. 6, the air knife used for controlling the thickness of the galvanized layer in the present invention includes an air knife body 20 and an upper knife lip 11 and a lower knife lip 12 installed and fixed thereon, and the front ends of the upper knife lip 11 and the lower knife lip 12 Air knife slits 13 are formed at longitudinal intervals. Referring to FIG. 5 , the orthographic projection of the air knife slit 13 is in the shape of a parabola. Since the orthographic projection of the air knife slit 13 is parabolic, the air flow ejected through the air knife slit 13 can evenly act on the surface of the strip along the entire length of the zinc liquid solidification line, so it can effectively suppress the hot-dip galvanized sheet edge. Generation of thick defects.

[0022] In order to adjust the shape of the air knife gap to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com